Transcription

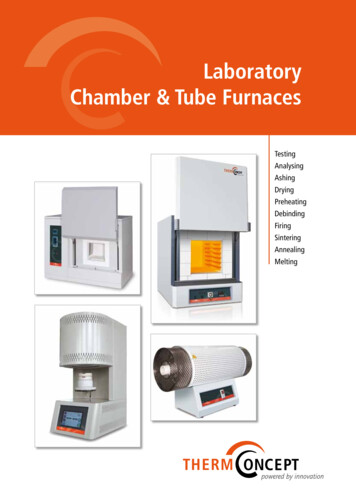

FurnacesLaboratory and IndustrialPrecise, Efficient, and ReliableFurnaces and Process SystemsMade to Your Specifications

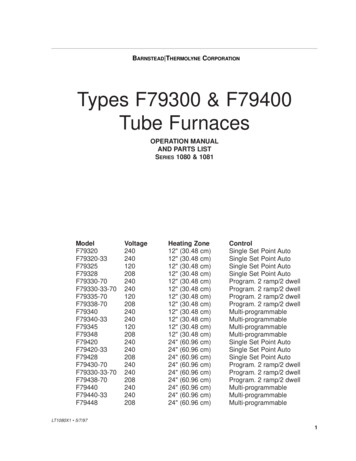

Introduction . 3Furnaces . 4-19Series 3110 Tube Furnaces . 4-5Series 3210 Split Tube Furnaces . 4-5Series 3150 Box Furnaces . 6-7Series 3160 Split Box Furnaces . 6-7Series 3310 High-Temperature Tube Furnaces . 8-9Series 3320 High-Temperature Split Tube Furnaces . 8-9Series 3330 Low-Profile High-Temperature Furnaces . 10-11Series 3330S Low-Profile High-Temperature Furnaces . 10-11Series 3350 High-Temperature Box Furnaces . 12-13Series 3350A High-Temperature Box Furnaces . 12-13Series 3410 Silicon Carbide Tube Furnaces . 14-15Series 3420 Silicon Carbide Split Tube Furnaces . 14-15Series 3410B Silicon Carbide Tube Furnaces . 16-17Series 3420B Silicon Carbide Split Tube Furnaces . 16-17Series 3450 Silicon Carbide Box Furnaces . 18-19Furnace Accessories . 20-25Quartz Viewports . 20End Caps, Port Plugs, Temperature Sensors . 21Extensometer Flats, Zone Dividers, Sample Supports . 22Element Shields, Heat Shields, Sealed Terminal Covers . 23Heat Equalizing Blocks, Controlled-Atmosphere Furnaces, Access Ports . 24Sealed Retort Assemblies . 25Furnace Mounting Components . 26-27Support Brackets, Support Plates, Mounting Brackets . 26Laboratory Baseplates, Vertical Support Stands . 27Test Frame Mounting Assemblies . 28-29Structural Frames . 28Vertical Support Columns, UTM Baseplates . 29Custom Equipment . 30-34Custom Furnaces . 30-31High-Temperature Process Systems . 32Mounting Arrangements . 33Industrial Furnaces . 34Temperature Control Systems . 35-36Applied Test Systems2www.atspa.com

Laboratory and Industrial Furnaces from ATSSince 1965, Applied Test Systems (ATS) has been working to create an unmatchedline of precise and affordable materials testing equipment. A large part of this effort has been in the field of high-temperature testing and production. As a result ofnearly four decades of research, development, design, testing, and re-testing, ATShas created a complete line of furnaces and high-temperature accessory items thatis unmatched in quality, versatility, and reliability.The standard line of ATS furnaces has been designed for general laboratory use andalso for testing to ASTM standards and other specifications. All ATS furnaces areconstructed to customer requirements in a wide variety of diameters, lengths, sizes,and configurations, and are shipped complete with mounting brackets and accessoryequipment. Heating elements are provided in various materials and configurationsdepending upon temperature requirements and the specific application. Furnaceshave been designed for easy replacement of failed elements in the laboratory, saving you time and money.Outstanding design features such as the use of low K-factor vacuum-cast ceramicfiber insulation and low watt-density heating elements provides significant advantagesand benefits to the user, including reduced power consumption, faster heatup, longerelement life, and lower shell temperatures.Several different types of furnaces are available, including tube, split tube, box,split box, high-temperature, low-profile, silicon carbide, controlled-atmosphere, andindustrial furnaces. All are described separately in this bulletin along with furnaceaccessories, mounting arrangements, components, and retorts. This bulletin alsodemonstrates the custom design capabilities for which ATS has become known worldwide. With over 30 years of design experience in custom testing equipment, ATSis sure to provide you with an ideal solution for all of your high-temperature testingand manufacturing needs.In addition to furnace systems, ATS manufactures a complete line of laboratory testing machines and accessories, including universal testing machines, creep/stressrupture test frames, convection ovens/cryogenic cooling chambers, pressure testingsystems, asphalt testing equipment, and sealant testers, as well as grips, fixtures,load train components, extensometers, ultrasonic reference standards, and more.Come to ATS for all of your materials testing concerns, and you can rest assuredthat the equipment delivered to your facility will precisely meet all of your needs andexpectations.Applied Test Systems3www.atspa.com

Series 3110/3210Based on the original seriesof ATS furnaces, our Series3110 Tube and 3210 Split TubeFurnaces are by far our mostpopular line. These furnaceshave been carefully designed andrefined over many years to makethem one of the most reliableand efficient laboratory furnacesavailable on the market today.Standard construction featuresinclude low K-factor vacuumcast ceramic fiber insulation forsuperior energy retention andrigid structure, stainless steelshell and end flanges for bothdurability and appearance, andlaboratory-replaceable heatingelements manufactured understrict quality-controlled conditionsin our own factory.All Series 3110/3210 furnacesare built-to-order to your specificrequirements, with a wideselection of available diameters,lengths, mounting arrangements,and accessory equipment, in avariety of configurations, includingisothermal, gradient, adiabatic,and others.Available options and accessoriesinclude heat-equalizing liners,extensometer slots and mountingflats, thermocouples, end caps,viewports, gas ports, cast bronzeor brass heating elements, retorts,and more.Applied Test Systems4www.atspa.com

Series 3110/3210: Other sizes supplied on request Length & zone constructionmade to order Heating elements andtemperature range:Nichrome: 1850 F (1000 C)Kanthal A1: 2200 F (1200 C) NRTL Listed (in standard configurations,selected sizes only, with approved control system)Creep Testing FurnacesFor the ultimate in precise temperaturecontrol and uniformity, ATS furnacescan be combined with our exclusiveWinCCS II computer creep system.This industry-leading hardware/software package automates everyaspect of the creep testing process,including control, data acquisition,archiving, analysis, report generation,and much more. (See Bulletin 2020for more information.)Typical Heatup CurveUniformity Curves2200120020001100(Isothermal and Gradient Furnaces)Temperature ( C)FurnaceSpecimen65006606706807000690Top of nace SpecificationsSize: 3" ID x 10" ODHeated Length: 12"Power: 3120 WattsLoad: 1/2"Ø x 30" Lg.Stainless Steel Rod600400Temperature ( C)Temperature ( 12753012903.0 F(1.6 C)Gradient curve: Large gradientachieved with three-zone furnaceand appropriate control system.1000Bottom of Furnace1215Temperature ( F)200015(Temperatures recorded at 1/2"increments from top of furnace.)300200Furnace invertical positionRestrictions apply.See above.Isothermal curve: Three-zonefurnace in a creep testing setupunder WinCCS II digital control.Time (min)Applied Test Systems5www.atspa.comDistance from Top (cm)800Distance from Top (in.)900

Series 3150/3160For basic laboratory and testingapplications, ATS Series 3150 Boxand 3160 Split Box Furnaces arean ideal choice. Used in testinginstallations around the world,these furnaces are unmatched inquality construction and affordableprices.As the box-style counterpartsto our Series 3110/3210 tubeand split tube models, thesefurnaces share a number ofthe same advanced design andconstruction features, includinglow K-factor vacuum-cast ceramicfiber insulation for superior energyretention, a rugged stainlesssteel shell for both durability andappearance, and laboratoryreplaceable heating elementsmanufactured under strict qualitycontrolled conditions in our ownfactory. Additionally, Series 3150laboratory box furnaces featurea full-opening door with doublepivot hinge for unrestricted accessto the heating chamber.ATS Series 3150/3160 furnacesare available in a number ofstandard sizes, or they can be builtto-order to your specifications. Avariety of options and accessoriescan be utilized to suit all of yourtesting needs, including load trainports, thermocouples, viewports,gas ports, offset or removablehinges, custom heating elements,muffles, liners, and more.Applied Test Systems6www.atspa.com

Series 3150/3160: Other sizes and zone arrangementssupplied on request Heating elements and temperaturerange:Nichrome: 1850 F (1000 C)Kanthal A1: 2200 F (1200 C)Typical Heatup 0600300Furnace SpecificationsSize: 12"W x 12"H x 12"DPower: 5100 WattsLoad: None400200100200000102030405060708090Time (min)Applied Test Systems7www.atspa.comTemperature ( C)Temperature ( F)7001200

Series 3310/3320ATS Series 3310 High-TemperatureTube and 3320 High-TemperatureSplit Tube Furnaces offer areliable solution for requirementsthat demand temperatures up to3272 F (1800 C). These furnacesare also an ideal choice for lowertemperature applications wheretime is critical, due to the rapidheat-up and cool-down rates madepossible by superior componentsand years of refinement indesign.A l l AT S h i g h - t e m p e r a t u r efurnaces utilize Kanthal Super molybdenum disilicide (MoSi 2)heating elements for improvedresistance to oxidation, longerelement life, easier replacementof failed elements, faster heat-up,and greater resistance to thermalshock. Additional constructionfeatures include low K-factorvacuum-cast ceramic fiberinsulation for superior energyretention and rigid structure, aswell as a stainless steel shell andend flanges for both durability andappearance.A wide selection of standardsizes, mounting arrangements,and accessory equipment isavailable, and custom designinquiries are always welcome.Available options and accessoriesinclude extensometer slots andmounting flats, end caps and portplugs, thermocouples, viewports,ceramic retorts, and more.Applied Test Systems8www.atspa.com

Series 3310/3320: Other sizes and multiple-heat-zonefurnaces supplied on request Furnaces must be oriented vertically;see page 12 for horizontal hightemperature tube furnace options Heating elements:Kanthal Super (MoSi2)Note: These furnaces operate at low voltageand high current, requiring a transformer andcurrent-limiting device in the control system.ATS high-temperature tube and split tube furnaces for service to 3272 F (1800 C),referred to as “3310A” and “3320A” respectively, are engineered on an individualbasis in order to optimize element size and arrangement based upon your specificrequirements. Consult an ATS sales engineer for more 00Exterior TemperaturesTest Temperature ( C)1210132014301540165090801757015060Furnace Size:4" ID x 14" OD6" Heated Lg.1251002000504022002400260028007501200600Shell Temperature ( C)Shell Temperature ( 30354045Time (min)Test Temperature ( F)Applied Test SystemsFurnace SpecificationsSize: 2" ID x 12" ODHeated Length: 8"Power: 1960 WattsLoad: None9www.atspa.comTemperature ( C)Temperature ( F)10501800

Series 3330/3330SFor applications where availabletesting space is severelyrestricted due to specimen sizeor other factors, ATS Series 3330and 3330S High-TemperatureFurnaces offer an ideal low-profilesolution. These furnaces featurehighly compact constructionw h i l e m a i n t a i n i n g e ff i c i e n ttemperature capabilities up to3000 F (1650 C). Due to a smallinternal working volume, rapidheat-up and cool-down rates areattainable for testing of ceramics,metal alloys, composites, andother materials, using either flator round specimens.Standard construction featuresinclude large-diameter KanthalSuper molybdenum disilicide(MoSi2) heating element

temperature tube furnace options Heating elements: Kanthal Super (MoSi 2) Note: These furnaces operate at low voltage and high current, requiring a transformer and current-limiting device in the control system. ATS high-temperature tube and split tube furnaces for service to 3272 F (1800 C), referred to as “3310A” and “3320A” respectively, are engineered on an .