Transcription

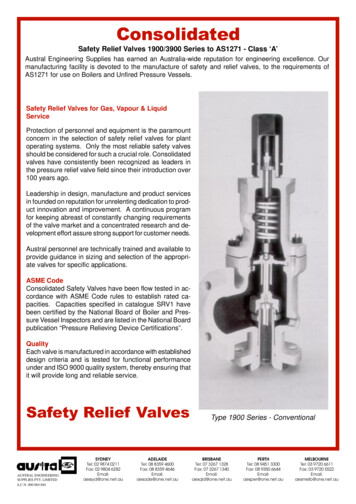

ConsolidatedSafety Relief Valves 1900/3900 Series to AS1271 - Class ‘A’Austral Engineering Supplies has earned an Australia-wide reputation for engineering excellence. Ourmanufacturing facility is devoted to the manufacture of safety and relief valves, to the requirements ofAS1271 for use on Boilers and Unfired Pressure Vessels.Safety Relief Valves for Gas, Vapour & LiquidServiceProtection of personnel and equipment is the paramountconcern in the selection of safety relief valves for plantoperating systems. Only the most reliable safety valvesshould be considered for such a crucial role. Consolidatedvalves have consistently been recognized as leaders inthe pressure relief valve field since their introduction over100 years ago.Leadership in design, manufacture and product servicesin founded on reputation for unrelenting dedication to product innovation and improvement. A continuous programfor keeping abreast of constantly changing requirementsof the valve market and a concentrated research and development effort assure strong support for customer needs.Austral personnel are technically trained and available toprovide guidance in sizing and selection of the appropriate valves for specific applications.ASME CodeConsolidated Safety Valves have been flow tested in accordance with ASME Code rules to establish rated capacities. Capacities specified in catalogue SRV1 havebeen certified by the National Board of Boiler and Pressure Vessel Inspectors and are listed in the National Boardpublication “Pressure Relieving Device Certifications”.QualityEach valve is manufactured in accordance with establisheddesign criteria and is tested for functional performanceunder and ISO 9000 quality system, thereby ensuring thatit will provide long and reliable service.Safety Relief ValvesAUSTRAL ENGINEERINGSUPPLIES PTY. LIMITEDA.C.N. 000 004 884SYDNEYTel: 02 9874 0211Fax: 02 9804 6282Email:aessyd@one.net.auADELAIDETel: 08 8359 4600Fax: 08 8359 4646Email:aesade@one.net.auType 1900 Series - ConventionalBRISBANETel: 07 3267 1328Fax: 07 3267 1340Email:aesqld@one.net.auPERTHTel: 08 9451 3300Fax: 08 9350 6644Email:aesper@one.net.auMELBOURNETel: 03 9720 6611Fax: 03 9720 5522Email:aesmelb@one.net.au

Design Features for 1900SeriesReduction of Valve Bonnet PressureTo eliminate excess bonnet pressure and ensure goodvalve opening and closing action, and Educator Tube isprovided.Educator tube reduces bonnet pressure by pullingdischarging fluids out of the bonnet faster then ispossible for the discharging fluids to enter past theguiding surfaces, acting as a siphon due to the drawingeffect of the flow through the outlet side of the valve.Features of the Educator Tube Increases the lifting force when the valve opens. Tends to break slight corrosive deposits or surface film. Allows the valve to operated satisfactorily against highback pressures. Assures positive full rated valve capacity at low overpressure. Makes a uniform response to blowdown controladjustment. Assures stability of valve life and capacity duringoperation.Fixed High CapacityThe Consolidated valve features full rated capacitiesregardless of the adjusting ring position.The adjusting ring in the Consolidated safety relief valvecan be pre-set to predetermined positions prior to puttingthe valve in service to obtain optimum valve performance.Presetting reduces the necessity of popping the valve inservice to ascertain that the ring has been properly setfor the necessary lift and relieving capacity.The carefully developed contours of the Consolidatedvalve huddling chamber and secondary orifice, togetherwith redirection of the flow stream through 1800, providesthe greatest possible lifting force. The lifting forces arenot dissipated and are at their maximum at the full liftposition.Resistance to Discharge Piping StrainsThe threaded section holding the valve nozzle into thevalve body is at the lowest possible point in aConsolidated safety relief valve. This reducestransmission of any distortion of the inlet neck of the body,to the nozzle.Also, the valve disc is mounted in the disc holder an ashouldered radius to ensure alignment of the disc withthe seating surface of the nozzle, thus assuring tightnessat the valve seat.AUSTRAL ENGINEERINGSUPPLIES PTY. LIMITEDA.C.N. 000 004 884SYDNEYTel: 02 9874 0211Fax: 02 9804 6282Email:aessyd@one.net.auADELAIDETel: 08 8359 4600Fax: 08 8359 4646Email:aesade@one.net.auSimple Blowdown AdjustmentAdjustment of Consolidated safety relief valve blowdownor reseating pressure, is by means of a single adjustingring. The simplicity and advantages of this adjustment areobvious when comparing valves having two or more adjusting rings, each of which affects valve action, as wellas blowdown.Nozzle made from Investment Casting/ForgingThe nozzle provides uniform and flawless materialconsistency.Spindle Pocket ConnectionThe Inconnel snap ring and groove design makes itvirtually impossible to remove the spindle from the discholder accidently. Minimum effort is required to disassemble during maintenance.Maximum Seat TightnessConsolidated safety relief valves seats are precisionmachined and lapped to an optical flatness. This assurespositive seating and prevents loss of contained media.InterchageabilityAll Consolidated flanged safety relief valves may beconverted from standard conventional type to bellows type,O-ring seat seal type, liquid trim type or Thermoflex disctype, requiring a minimum number of new parts.Quality MaterialAll consolidated valves are made to ASTM/ASMEspecifications and rigid inspections, assuring highestdegree of quality, guaranteed to more than satisfy therequirements of AS1271.BRISBANETel: 07 3267 1328Fax: 07 3267 1340Email:aesqld@one.net.auPERTHTel: 08 9451 3300Fax: 08 9350 6644Email:aesper@one.net.auMELBOURNETel: 03 9720 6611Fax: 03 9720 5522Email:aesmelb@one.net.au

Construction:1900 Series - Conventional DesignThis standard rugged configuration is equipped with corrosion resistant stainless steel trim and a carbon steelbody, bonnet and cap. The components are top guidedwith a 2:1 ration, providing for free and repeatable action.The flat disc seat provides for easy maintenance,remachining and lapping.The exclusive “Educator Tube” minimises bonnet cavitypressure which ensures good valve opening and closingaction under adverse conditions.The nozzle is bottom inserted and rigidly held in position,providing a corrosion resistant path of flow to the valveand corrosion resistant seating surfaces.Unless other stated the valve is always supplied with ascrewed cap. The exceptions to this would be where codeAS1271 requires levers for stream, air and hot waterservice. Refer to the SRV-1 Catalogue for available typesof caps, levers and accessories.1900-30 Series-Bellows DesignType 1900SeriesThis valve is the same as the conventional design except that a bellows has been added. When the bellowsis installed, the educator tube is removed.A bellows is added to the conventional valve to deal withany of several situations:(1) If back pressure at the valve outlet is excessive,variable of fluctuates more than 10% of a nominalvalue.(2) If built up back pressure exceeds 10% of the setpressure.(3) If the fluid is a slurry or of a highly viscous nature.(4) If the fluid is corrosive to the upper works of the valve,the bellows isolates the bonnet chamber.Conventional valves can be easily converted to a bellows design or vice versa through the use of retrofit kits.All Consolidated 1900-30 valves are balanced bellowsdesign, meaning that they fully compensate for the effects of back pressure.Unless otherwise stated the valve is always supplied witha screwed cap. The exception to this would be whereCode AS1271 requires levers for steam, air and hot water service. Refer to the SRV-1 Catalogue for availabletypes of caps, levers and accessories.Type 1900-30SeriesAUSTRAL ENGINEERINGSUPPLIES PTY. LIMITEDA.C.N. 000 004 884SYDNEYTel: 02 9874 0211Fax: 02 9804 6282Email:aessyd@one.net.auADELAIDETel: 08 8359 4600Fax: 08 8359 4646Email:aesade@one.net.auBRISBANETel: 07 3267 1328Fax: 07 3267 1340Email:aesqld@one.net.auPERTHTel: 08 9451 3300Fax: 08 9350 6644Email:aesper@one.net.auMELBOURNETel: 03 9720 6611Fax: 03 9720 5522Email:aesmelb@one.net.au

Consolidated Safety-Relief VApplicationsSteel FlangRefineryPetroChemical andChemical ProcessingHydrocarbonProcessingPressure VesselsHeat ExchangersPiping1900 Series1900-30 SeriesReactorsCodesCryogenic PlantsProcess SteamCompressorStationsASME Section III and VIIIASME Section III and VIIIAS1271 Class AAS1271 Class AInlet SizesInlet RatingsOutlet SizesOutlet RatingsTemperature Range25mm through 300mm flangedANSI Class 150 through 250050mm through 400mm flangedANSI Class 150 and 300-2670C to 8150C25mm through 300mm flangedANSI Class 150 through 250050mm through 400mm flangedANSI Class 150 and 300-2670C to 8150CSet Pressure Range35kPag to 41380kPag70kPag to 41380 kPagOrifice SizesFifteen Sizes: D through WFifteen Sizes: D through WStandard Materials:Base/BonnetDisc/NozzleSpringWCC carbon steel316 st.st.‘CR’ alloy steelWCC carbon steel316 st.st‘CR’ alloy steel316L st.st. BellowsOptions:Liquid ServiceDouble Seal Soft SeatSour Gas Service-NACESteam ServiceBalancing Piston1900 LS and DL1900DA1900 SG1900 TD-1900-30 LS and DL1900-30 DA1900-30 SG1900-30 TD1900-35Features:Conventional design.Balanced bellows design.Flat seat, top guided, highcapacity, conforming to API 520,526 abd 527.Available in a wide range ofmaterials of construction.Flat seat, top guided, highcapacity, conforming to API 520,526 and 527.Available in a wide range ofmaterials of construction.Adjustable blowdown 5% to 10%.Adjustable blowdown 5% to 10%.Thermal ReliefLiquefied GasStorageHeat TransferFluidsPipelinesProcess SteamInjectionCompressorsReceiversHeadersPressure ReducingStationsOff Shore DrillingFor more information refer catalogueSRV-1SRV-1

Valves - For Gas, Vapour and Liquid Serviceed Valves3900 SeriesPilot OperatedSteel Screwed Valves1990/3990 SeriesType 19821990/3990 SeriesASME Section VIIIASME Section III and VIIIASME Section III and VIIIASME Section III and VIIIAS1271 Class AAS1271 Class AAS1271 Class AAS1271 Class A25mm through 300mm flangedANSI Class 150 through 150050mm through 250mm flangedANSI Class 150 and 300-10C to 2040C100kPag to 25850 kPag15mm to 50mm flangedANSI Class 150 through 250025mm through 65mm flangedANSI Class 150 and 300-2670C to 8150C3990: -2450C to 5930C35kPag to 39896 kPag15mm through 50mm NPT/BSP3445 kPag limit20mm through 65mm NPT/BSP340kPag Limit1990: -280C to 4260C70 kPag to 3448kPag15mm through 50mm NPT/BSP55172 kPag Limit20mm through 65mm NPT/BSP2758 kPag limit1990: -280C to 4260C3990: -2450C to 59.0C35 kPag to 55172 kPagFourteen Sizes: D through TThree: Dual outlets full boreSeven Sizes: 12 through 486mm2 Five Sizes: 78 through 902mm2Seven Sizes: 12 through 486mm2WCC carbon steel316 st.st.316 st. st.316st.st./WCC carbon steel316 st.st.‘CR’ alloy steel3990 all 316 st.st.304 st.st./WCC carbon steel304 st.st.‘CR’ alloy steel316 st.st/WCC carbon steel316 st.st.‘CR’ alloy steel3990 all 316 st.st.Use VMF PiltoStandardSG1Use VMF-3S PilotUse Backflow Preventer1990 LS/ 3990 LS1990 DA / 3990DA1990 SG1990-1982 LS1982-1990 LS / 3990 LS1990 DA / 3990 DA1990 SG1990-Single or dual outlet.Dual seat, nozzle guided.Main valve - WCC carbon steelbase/cover plate, all trim parts316 st.st. as standard. All 316st.st. construction available.Pilot Valve - all 316 st.st.External adjustment for setpoint and blowdown.Convenational only, no bellowsavailable.Conventional only, no bellowsavailable.Flat seat, locally guided, all trimparts are 316 st.st. as standard.Flat seat, top guided, all trim parts Flat seat, locally guided, all trimare stainless steel as standard,parts are 316 st.st. as standard.high capacity.Fixed blowdown 7% to 20%.Adjustable blowdown 7% to 10%.Fixed blowdown 7% to 20%.Conventional only, no bellowsavailable.Less than 2% blowdown.POSRV-b1 & B2SRV-1 & AULO3SRV-1SRV-1 & AULO 3

Consolidated Safety-Relief Valves - Options1900 Soft Seats (DA)The Double Seal Soft SeatThe double seal design incorporates the merits of both a soft seat anda metal seat design valve. The 450 metal seat provides the loadbearing surface for transmitted spring force, the slotted O-ring retainerallows the O-ring to be pressurised. This O-ring seal design can beused throughout the full pressure range of the valve. For pressure/temperature ratings of the seal, refer to Section 5 of catalogue SRV1.Tightness: Consolidated O-ring seat valves are bubble tight at 95% ofset pressure over 690 kPag.Consolidated O-ring seat seal provide positive closure at servicepressures closer to the set pressure than is possible with metal-tometal seats, assuring continuous, trouble-free service and completevalve tightness after numerous “pops”.The 1900 O-ring design features a secondary metal-to-metal seatwhich becomes effective if O-ring integrity is lost due to external fire orother causes. The retainer is lapped to the nozzle at assemblyassuring seat tightness.1900 Liquid Trim Valves (LS)The 1900 LS option is designed for liquid service and is certified toASME Code Section VIII. The adjusting ring and disc holder aredesigned to allow the valve to achieve full lift without valve chatter.Application Guidelines If the fluid remains liquid while flowing through the valve, use liquidtrim. If flowing fluid flashes going through the valve, use liquid trim. If in a two-phase fluid the volume of gas at inlet is greater than orequal to the volume of liquid, then liquid trim is not necessary. When valves are used for thermal relief applications to preventexcessive pressure caused by thermal expansion of trapped liquids,use liquid trim. All 1900 Series valves can be supplied with liquid trim internals,additionally conventional valves can be converted.For more information refer to Catalogue SRV-1.1900 Sour Gas Service (SG)Conventional Valves (2) Bellows Valves (2)Part NameBellowsSG1SG10SG5SG15NANAMonel316LSpin

Consolidated safety relief valves seats are precision machined and lapped to an optical flatness. This assures positive seating and prevents loss of contained media. Interchageability All Consolidated flanged safety relief valves may be converted from standard conventional type to bellows type, O-ring seat seal type, liquid trim type or Thermoflex discFile Size: 646KBPage Count: 9