Transcription

Oasis PRiME HLB FoodApplications Notebook

SCIENTIST BIOSMichael S. Young, Ph.D.Principal Applications ChemistWaters CorporationDr. Young is a Principal Chemist and Applications Manager in the ScientificOperations division of Waters Corporation. He and his team of chemists developsample preparation methodology and LC-MS and GC-MS analysis methodologyfor food safety and environmental applications. Among his recent applicationsare innovative methods for veterinary drugs, mycotoxins, pesticides and relatedcontaminants in foodstuffs. Dr Young received his B.S. and Ph.D. in chemistryfrom the University of Massachusetts/Amherst. Prior to joining Waters in 1994,Dr. Young served as an GC-MS applications specialist, project manager, andlaboratory manager at several private environmental testing and consultingfirms. He is the author of numerous technical publications and a frequentspeaker at technical meetings and symposia.Dr. Jeremy ShiaSr. Product Marketing ManagerWaters CorporationDr. Jeremy Shia is the Product Manager of Sep-Pak and DisQuE samplepreparation devices. He is also responsible for the Food & Environment marketfor the Consumables Group. Prior to this he was a Senior Applications Chemistat Waters responsible for development of analytical methods for determinationof contaminants in food with focus on sample preparation. Dr. Shia hadpublished several application notes in food analysis with subjects ranging fromcarbohydrate and vitamin analysis, to multi-residue analysis of veterinary drugs,pesticides, and mycotoxins in various food matrices.Dr. Jeremy Shia has a Ph.D. degree in Chemistry from University ofMassachusetts at Lowell. Before coming to Waters, he worked for at MillenniumPharmaceuticals as scientist in analytical development department. Priorto working in pharmaceutical industry, He served as chemist and organiclaboratory manager in environmental laboratory.

SCIENTIST BIOSDimple ShahSenior ScientistWaters CorporationDimple Shah has a M.S. degree in Organic Chemistry from St.Xavier’scollege, Gujarat University, India. She also has a M.S. degree in Chemistryfrom University of Massachusetts at Lowell. She is working at WatersCorporation, Milford as a Senior Scientist in Food and Environment market.She is responsible for development of analytical methods for determination ofcontaminants in food and water on LC and Mass spectrometers. Her areas ofexpertise are LC, tandem quadruple, high resolution mass spectrometry andvarious chromatographic and mass spectrometry softwares. She has publishedseveral application notes on pesticides, veterinary drugs, mycotoxins, sugars,sweeteners, vitamins, and dyes.Kim TranApplication Chemist IIWaters CorporationMs.Tran joined Waters Corporation in 1999 and is currently an ApplicationChemist II in the Scientific Operations division. She develops samplepreparation methodology, LC-MS and GC-MS analysis methodology for foodsafety and environmental applications. Ms. Tran received her B.S in Biologyfrom Chestnut Hill College. After, she worked in a laboratory at a biotechnologycompany for 10 years. She designed, executed, and interpreted experimentsthat contributed to the drug development of PGG-Glucan. She also developedStandard Operating Procedures and trained personnel in the Quality ControlDepartment. She provided technical assistance in product development,evaluation characterization, transfer, validation and quality control testingof products.She performed and validated bio-analytical assays to determine theconcentration of the drugs and their metabolites in biological samplesfor clinical and pre-clinical studies by using LC-MS.

SCIENTIST BIOSDefeng HuangSenior Application SpecialistWaters Corporation AHQ teamMr. Huang joined Waters in 2013,with a focus on food and environmentalapplications, spending the majority of his time on technical support andapplication development. As a graduate of Shanghai Ocean University, with amajor in Food science and engineering, include theory and practice experience,Mr. Huang brings over 10 years of experience focusing on Food & Environmentanalysis, sample preparation, SPE knowledge and application, specifically onLC-MS/MS application. When he is not in the lab, Mr. Huang enjoys reading,swimming, as well as cheering on his favorite soccer team Manchester United.

INTRODUCTIONOasis PRiME HLB Food Applications and Technical BriefsWhen testing for different classes of contaminants, food safety and testinglaboratories must develop sensitive and robust analytical methods for a varietyof complex food matrices. Historically, scientists have attempted to reduce matrixeffects by removing interferences such as lipids, phospholipids, and pigmentsfrom the extracts by using traditional solid phase extraction (SPE) sorbents suchas silic-based C18. While traditional SPE products have been successful at removingfats, it becomes very challenging to remove multiple major interferences from acomplex sample matrix.Oasis PRiME HLB has recently been used to quickly and efficiently remove all majorinterferences including fats and phospholipids, as well as pigments from foodmatrices, using the simple and fast pass-through protocol. This enables Oasis PRiMEHLB to be used as a powerful matrix removal tool for multi-residue analysis. Foodcontaminants, such as veterinary drugs, pesticides, mycotoxins, or other compoundspass through the sorbent without retention, while the Oasis PRiME HLB holds backinterferences leading to matrix effects reduction. In this booklet, we have collectedapplication notes to demonstrate how Oasis PRiME HLB cleans up challenging foodsamples, resulting in better accuracy, system uptime and method robustness.6Introduction

CONTENTSTABLE OF CONTENTSOasis PRiME HLB Cartridge for Effective Cleanup of Meat Extracts.8A Simple Cleanup Protocol Using a Novel SPE Device for UPLC-MS/MSAnalysis of Multi-Residue Veterinary Drugs in Milk.11Rapid, Simple, and Effective Cleanup of Seafood ExtractsPrior to UPLC-MS/MS Multiresidue Veterinary Drugs Analysis.21Oasis PRiME HLB Cartridges for Cleanup of Infant Formula ExtractsPrior to UPLC-MS/MS Multiresidue Veterinary Drugs Analysis. 27Simple and Effective Cleanup for UPLC-MS/MS Determinationof Veterinary Drug Residues in Egg.32Oasis PRiME HLB Cartridges for Rapid and Effective Cleanup of Avocado,a High Fat Matrix, Prior to APGC-MS/MS Analysis.38Oasis PRiME HLB Cartridges and DisQuE QuEChERS Productsfor UPLC-MS/MS Mycotoxin Analysis in Cereal Grains.43Rapid, Simple, and Effective Cleanup of Bovine Liver SamplesPrior to UPLC-MS/MS Multiresidue Veterinary Drugs Analysis.46Oasis PRiME HLB Cartridges for Rapid and Effective Removalof Chlorophyll from QuEChERS Spinach Extracts.51Oasis PRiME HLB Cartridges Now Available in Syringe Compatible Plus Format.55Table of Contents7

[ TECHNOLOGY[ APPLICATIONBRIEFNOTE] ]Oasis PRiME HLB Cartridge for Effective Cleanup of Meat ExtractsPrior to Multi-Residue Veterinary Drug UPLC-MS AnalysisMichael S. Young and Kim TranFats and phospholipids are significant potentialinstrument and column contaminants. OasisPRiME HLB Cartridges provide a rapid cleanupto remove these substances from meat extractsprior to LC-MS analysis.GOALTHE SOLUTIONTo demonstrate the effectiveness of theOasis PRiME HLB Cartridge for cleanup ofmeat extracts prior to UPLC -MS analysis.Pass-through cleanup with the Oasis PRiME HLB Cartridge.This procedure is highly effective for removal of both fatand phospholipid from meat extracts. Just as important,the recoveries of the veterinary drugs are not compromisedwith Oasis PRiME HLB Cartridge cleanup. The recoveriesare similar to those obtained using hexane defatting or C 18silica cleanup but Oasis PRiME HLB Cartridge cleanup ismore effective.BACKGROUNDWaters has developed an optimizedsample preparation and analysis protocolfor multi-class, multi-residue LC-MS/MSscreening of veterinary drug residues inmeat. The major constituents of a typicalmeat sample are water (up to 70%), protein(15–25%), fat (5–25%) and phospholipid(1–3%). During the sample pre-extraction,the protein is removed from the extractby precipitation and centrifugation.However, significant amounts of fat andphospholipid are co-extracted along withthe target veterinary drugs. The presenceof these co-extracted substances canlead to interference in the LC-MS analysis,contamination of the analytical columnand other components of the UPLCSystem, and contamination of the massspectrometer itself. Fats have traditionallybeen removed from meat extracts usingcumbersome hexane defatting steps or bythe use of reversed-phase sorbents such asC 18- silica. Although these techniques maybe effective for fat removal, neither of theseprocedures removes phospholipids.8EXPERIMENTALInitial Extraction. Typical pork samples (5 g, 15% fat) werefortified with representative compounds chosen from majorclasses of veterinary drugs. The homogenized meat sampleswere extracted with 10 mL of 80:20 acetonitrile/water with0.2% formic acid. The samples were vortexed for 30 seconds,shaken for 30 minutes, and then centrifuged at 12000 rpm for5 minutes.Oasis PRiME HLB Cartridge Cleanup. An Oasis PRiME HLBCartridge (3 cc, 60 mg) was mounted on a pre-cleanedvacuum manifold. No cartridge conditioning is required orwas performed. A 0.5 mL aliquot of the supernatant waspassed-through the Oasis PRiME HLB Cartridge andcollected. The collected sample was diluted three-fold withaqueous 10 mM ammonium formate buffer (pH 4.5) prior toUPLC-MS/MS analysis.Oasis PRiME HLB Cartridge for Effective Cleanup of Meat Extracts Prior to Multi-Residue Veterinary Drug UPLC-MS Analysis

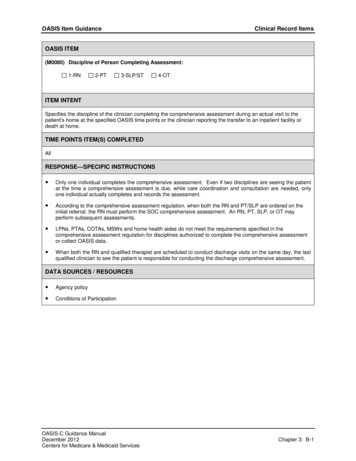

RESULTSLittle or no recovery loss was observed in the pass-through cleanup step for any of the tested compounds.Absolute recoveries (measuring mostly the effectiveness of the initial liquid extraction) averaged over 80% forthe tested compounds except for phenylbutazone (32%). These recoveries are consistent with C 18-silica cleanupbut no phospholipids are removed with C 18-silica. UPLC-MS/MS conditions and chromatograms are presentedin Figure 1. Figure 2 shows chromatograms that illustrate the effectiveness of the Oasis PRiME HLB Cartridge forphospholipid removal; greater than 90% more phospholipid is removed compared with C 18-silica cleanup. Usinggravimetric analysis it was also determined that the Oasis PRiME HLB Cartridge removed more than 90% of theco-extracted fat from the pork extract.Instrument:ACQUITY UPLC I-ClassColumn:1.7 µm CSH C18, 2.1 x 100 mm(p/n 186005297)30 CSample temp.:10 CDetection:MS:TQ-SInjection vol.:5 µL for 3 cc and 6 cc003452.7015% B initial to 40% B at 2.5 min,to 95% B at 3.9 min, hold to4.9 min, back to 15% B at5.0 min and hold to 7.0 minStandard needle for UPLC, 153453.45100023467 minPhenylbutazone50 µg/kg12343.44567 minDexamethasone50 µg/kg12341.09567 minEnrofloxacin50 µg/kg12341.56100054.28567 minSulfamerazine%Strong wash(solvent 3 and 6 cc): 50/30/20 water:ACN:IPA7 min25 µg/kg110006Penicillin%Weak wash(solvent 3 and 6 cc): 10/90 ACN:water10% MeOH210007 min50 µg/kg1%06Chloramphenicol%ACN with 0.1% formic acidCompound2%Water with 0.1% formic acidMobile phase B:Seal wash:50 µg/kg1100Mobile phase A:Needle:Oxytetracycline100Run time (flow rate): 7 minutes (0.04 mL/min)Gradient:1.04%Column temp.:100%UPLC Conditions25 µg/kg123456Precursor ion (m/z)Product ion (m/z)Cone voltage *321.1152.13017Oxytetracycline461.2426.230217 minCollision energy (eV)*Chloramphenicol ESI-, others ESI ionizationFigure 1. UPLC-MS/MS conditions and resulting chromatograms from a typical pork sample spiked at the levels indicated.9

[ TECHNOLOGY BRIEF ]CONCLUSIONS 100Oasis PRiME HLB Cartridges did not require conditioningor equilibration prior to use; a simple one-step SPEcleanup was effective.Oasis PRiME HLB Cartridge%Oasis PRiME HLB Cartridges removed greater than90% of fats and greater than 90% of phospholipids fromacetonitrile based extracts of pork.phospholipidsWhen used in the pass-through mode, Oasis PRiMEHLB Cartridges did not affect the recovery of the testcompounds but gave significant removal of fats andphospholipids from the extract.0100246 min4.58C18 Cartridge%0246 minFigure 2. Removal of phospholipids from meat extractscomparing Oasis PRiME HLB cleanup (upper trace) with C18 silica cleanup (lower trace).Waters, The Science of What’s Possible, UPLC, ACQUITY UPLC, and Oasis are registeredtrademarks of Waters Corporation. All other trademarks are the property of their respective owners. 2015 Waters Corporation. Produced in the U.S.A. May 2015 720005411EN AW-PDF10Waters Corporation34 Maple StreetMilford, MA 01757 U.S.A.T: 1 508 478 2000F: 1 508 872 1990www.waters.comOasis PRiME HLB Cartridge for Effective Cleanup of Meat Extracts Prior to Multi-Residue Veterinary Drug UPLC-MS Analysis

[ APPLICATION NOTE ]A Simple Cleanup Protocol Using a Novel SPE Device forUPLC-MS/MS Analysis of Multi-Residue Veterinary Drugs in MilkDeFeng Huang,1 Kim Van Tran,2 and Michael S. Young21Waters Technologies, Ltd., Shanghai, China; 2Waters Corporation, Milford, MA, USAAPPLICATION BENEFITS Enable simultaneously determination ofmulti-class of veterinary drugs using aninnovative solid phase extraction device.Simple, fast, pass-through SPE cleanupprior to UPLC-MS/MS analysis.The matrix interference from fatty/non-polarmaterials and phospholipids are removedtogether in one straightforward SPE cleanupfor longer column life and less maintenanceof the mass spectrometer.SUMMARYIn this experiment a new solid phase extraction (SPE)device, the Oasis PRiME HLB Cartridge, was used in thesample preparation of milk samples as a cleanup method formulti-residue veterinary drug analysis. The initial extractionand protein precipitation was done by adding acidifiedacetonitrile. The extract was cleaned up by pass-thru SPEusing the Oasis PRiME HLB Cartridge prior to UPLC-MS/MS analysis. Sample extraction, chromatographic and massparameters were all optimized. As a result, within the rangesof 0.1 to 10.0 µg/mL spiking concentrations, 9 classes of 72veterinary drugs including sulfonamides, fluoroquinolones,β-agonists, macrolides, glucocorticoids, amphenicols,β-lactams, cephalosporins, penicillin, and tetracyclines, thepercent recoveries are all within 50% to 130%, and the RSD 20% (n 5). This method is simple, rapid, and accurate,suitable for multi-residue veterinary drug analysis of milk.INTRODUCTIONWATERS SOLUTIONSACQUITY UPLC I-Class SystemXevo TQ-S Mass SpectrometerACQUITY UPLC BEH C 18 ColumnOasis PRiME HLB 3 cc 60 mg cartridgesTruView LCMS Certified VialsMassLynx v4.1 data system withQuanpedia databaseKEY WORDSOasis PRiME HLB, multi-residue, veterinarydrug, SPE, milk, UPLC-MS/MSMany veterinary drugs are used to treat animals grown forhuman consumption. The presence of excessive amounts ofdrug residues in animal products such as milk may representa health hazard. Therefore, effective and reliable analyticalmethods are required to identify and quantify drug residuesin animal products. Among the frequently used veterinarydrugs in the animal farms are sulfonamides, fluoroquinolones,β-agonists, macrolides, glucocorticoids, amphenicols,β-lactams, cephalosporins, and tetracyclines. Drug residuesin an animal’s bloodstream can be introduced into the milkof lactating animals and eventually transferred to humansby consumption of the milk. Among the consequences arepossible allergic reactions and the induced side effect of drugresistance. Therefore the monitoring of residual veterinarydrugs of milk plays a significant role in the assurance of foodsafety of dairy products. Currently the published methodsfrom official agencies and literatures are individual methodsbased on individual classes of compounds.A Simple Cleanup Protocol Using a Novel SPE Device for UPLC-MS/MS Analysis of Multi-Residue Veterinary Drugs in Milk11

[ APPLICATION NOTE ]The goal of combining these individual methods into one multi-class method is difficult to accomplish due to theunavailability of a robust universal sample preparation procedure. Creating one single LC-MS/MS instrumentalmethod for multiple classes of veterinary drugs poses certain degree of challenge as well.EXPERIMENTALUPLC ConditionsSystem:ACQUITY UPLC I-ClassColumn:ACQUITY UPLC BEH C18,1.7 µm, 2.1 x 100 mmInjection volume:5 µLTemperature:45 CMobile phase A:10 mM ammoniumacetate in water (pH 5.0)Mobile phase B:10 mM ammoniumacetate in methanolFlow rate:0.45 mL/minGradient:2 %B initial and holdto 0.25 minutes, lineargradient to 99 %B at12.25 minutes, hold to13.0 minutes, back to2 %B at 13.01 minutes,hold and re-equilibrateuntil 17 minutesMS conditions for UPLCInstrument:Xevo TQ-SMode:Electrospray (ES andES-)Capillary:3.5 kVSource temp.:150 CCone gas:150 L/hrDesolvation temp.:600 CDesolvation gas:1000 L/hrCollision gas (Argon):0.15 mL/minThis method utilizes Waters’ new and novel OasisPRiME HLB Solid Phase Extraction Device. This newSPE can retain the majority of phospholipids andfats in milk. By combining with protein precipitationtechnique, it can effectively remove most interferencefrom the milk matrix.Using the Xevo TQ-S System and including theveterinary drug analysis parameters in the QuanpediaDatabase establishes a highly efficient total solutionfor the multi-residue analysis of veterinary drugsin milk.SAMPLE PREPARATIONSample extraction:In 1 mL of milk, add 4 mL of 0.2% formic acid (FA) inacetonitrile (ACN), mix well. Centrifuge for 5 min at10,000 rpm. Aliquots of the supernatant are used forSPE cleanup.Solid phase extraction (SPE) cleanup:Prepare the 3 cc Oasis PRiME HLB Cartridge(p/n 186008056) by passing through 3 mL 0.2% FAin ACN. Note: this conditioning step is only required tofacilitate subsequent gravity loading, it is not necessaryif a sample is processed with minimal vacuum.Pass the supernatant through the cartridge andcollect. Evaporate to dryness under a gentle nitrogenstream. Reconstitute the solution in 1 mL 5% methanolin water. Filter the extract and transfer to a vial forUPLC-MS/MS analysis.UPLC-MS/MS cone and collision parameters, as wellas MRM transitions used for this study are presentedin Table 1.12A Simple Cleanup Protocol Using a Novel SPE Device for UPLC-MS/MS Analysis of Multi-Residue Veterinary Drugs in Milk

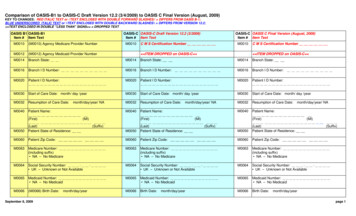

ulfaguanidineSulfamerazineIon ModePrecursor (m/z)CV (V)Product (m/z)CE (V)RT (min)ESI 220.125143.0242.2ESI 220.125160.115ESI 277.125140.046ESI 277.125168.125ESI 302.225164.115ESI 302.225284.212ESI 240.225148.120ESI 240.225222.112ESI 226.125107.026ESI 226.125125.026ESI 228.230118.025ESI 228.230154.115ESI 262.225185.122ESI 262.225202.118ESI 425.220125.925ESI 425.220377.218ESI 734.530158.130ESI 734.530576.520ESI 786.420108.935ESI 786.420174.030ESI 407.440126.225ESI 407.440359.420ESI 422.230101.020ESI 422.230174.120ESI 869.525174.245ESI 869.525696.540ESI 916.560101.145ESI 916.560174.140ESI 460.734426.218ESI 460.734444.218ESI 444.730410.318ESI 444.730427.314ESI 277.13092.025ESI 277.130156.015ESI 285.02092.028ESI 285.020155.915ESI 285.02092.028ESI 285.020155.915ESI 251.03092.027ESI 251.030156.015ESI 311.13692.032ESI 311.136156.020ESI 215.02091.822ESI 215.020156.013ESI 265.13592.025ESI le. 1 Analyte MS parameters and retention time.13

[ APPLICATION NOTE nEnrofloxacinIon ModePrecursor (m/z)CV (V)Product (m/z)CE (V)RT (min)ESI 281.02091.8273.34ESI 281.020155.915ESI 279.135124.125ESI 279.135186.015ESI 271.13092.025ESI 271.130156.015ESI 254.13092.025ESI 254.130156.015ESI 281.13592.025ESI 281.135156.015ESI 281.03592.035ESI 281.035156.022ESI 268.02091.826ESI 268.020155.915ESI 215.02091.822ESI 215.020156.013ESI 315.020108.025ESI 315.020156.018ESI 250.033108.025ESI 250.033156.016ESI 301.13292.230ESI 301.132156.116ESI 250.033108.025ESI 250.033156.016ESI 301.13292.230ESI 301.132156.116ESI 256.03192.025ESI 256.031156.015ESI 279.120123.920ESI 279.120186.015ESI 268.03092.028ESI 268.030156.013ESI 291.340123.030ESI 291.340230.230ESI 263.235189.130ESI 263.235245.115ESI 332.142288.118ESI 332.142314.122ESI 358.23896.025ESI 358.238314.120ESI 400.330356.220ESI 400.330382.220ESI 321.140232.030ESI 321.140303.135ESI 360.325316.320ESI 5Table. 1 Analyte MS parameters and retention time.14A Simple Cleanup Protocol Using a Novel SPE Device for UPLC-MS/MS Analysis of Multi-Residue Veterinary Drugs in Milk

NameFlumequineLomefloxacinMarbofloxacinNalidixic acidNorfloxacinOfloxacinOrbifloxacinOxolinic olThiamphenicolAmoxicillinPenicillin oloneIon ModePrecursor (m/z)CV (V)Product (m/z)CE (V)RT (min)ESI 262.135202.0356.67ESI 262.135244.015ESI 352.139265.122ESI 352.139308.116ESI 363.13572.020ESI 363.135320.015ESI 233.130187.025ESI 233.130215.0154.323.696.33ESI 320.140233.025ESI 320.140276.1204.00ESI 362.325261.330ESI 362.325318.320ESI 396.140295.1224.39ESI 262.032216.0305.44ESI 262.032244.019ESI 334.142290.119ESI 334.142316.119ESI 386.245299.127ESI 3.99ESI .920ESI-354.120290.012ESI 366.227114.020ESI 366.227349.18ESI 351.123114.035ESI ESI 361.340163.125ESI 361.340342.220ESI 393.320355.210ESI 7.83ESI 363.435121.125ESI 363.435327.3157.19ESI 373.220355.111ESI 373.220357.112ESI 375.225357.3107.92ESI 361.225147.0207.21ESI 361.225343.210ESI 435.425397.315ESI 435.425415.357.78ESI 5.3Table. 1 Analyte MS parameters and retention time.15

[ APPLICATION NOTE ]NameTriamcinolone tiofurCephapirinIon ModePrecursor (m/z)CV (V)Product (m/z)CE (V)RT (min)ESI 395.4ESI 395.430357.0307.9530375.010ESI 348.240139.935ESI 348.240158.0203.36ESI 456.130167.020ESI 456.130396.2103.43ESI 524.235241.1165.25ESI 424.235152.0203.68ESI 424.235292.216ESI 524.235241.1165.25ESI 424.235152.0203.68ESI 424.235292.216ESI ESI Table. 1 Analyte MS parameters and retention time.RESULTS AND DISCUSSIONTHE OPTIMIZATION OF SAMPLE PREPARATIONMilk matrix is complicated. It contains large amounts of proteins and phospholipids, which interferes with thedetection of target analytes. It is essential to cleanup the complex matrix of milk and to release the analytes fromthe effect of matrix.For the initial extraction and protein precipitation, 3:1 and 4:1 ratios of acetonitrile and milk were evaluated at both0.2% and 1.0% formic acid concentrations. Results indicated that 1.0% formic acid in acetonitrile and milk at ratioof 4:1 gives the best effect of protein precipitation. However, 1% formic in acetonitrile has negative impact on therecoveries especially for the basic analytes like sulfonamides (see Figure 1). This could be because the more acidiccondition gives rise to a higher degree of ionization of the sulfonamides with resulting solubility decrease in thehigh organic solvent. Therefore, 0.2% formic acid in acetonitrile mixed with milk at a 4:1 ratio was chosen for thefinal extraction and protein precipitation.16A Simple Cleanup Protocol Using a Novel SPE Device for UPLC-MS/MS Analysis of Multi-Residue Veterinary Drugs in Milk

0.2% FA1.0% FA120.0100.080.060.040.020.00.0Figure 1. The comparison of recovery of sulfonamides for using 0.2% and 1.0% formic acid.The large amount of phospholipids in milk not only becomes matrix interference for target analyte analysis, butalso increases the cost and time of instrument maintenance. The use of Oasis PRiME HLB can remove the fat andphospholipids in sample matrix. As a result, the numbers of samples that could be analyzed are greatly increasedbefore maintenance. In Figure 2, the effect of phospholipids removal by using SPE cleanup is compared to themilk sample only by protein precipitation. The sample after protein precipitation still has significant phospholipidspresent in the matrix that are mostly removed by the SPE cleanup.Figure 2. The chromatograms of phospholipids removal between milk samples processed by protein precipitation andcleanup by Oasis PRiME HLB.17

[ APPLICATION NOTE ]0.1 ug/LNameRecovery(%)0.5 ug/L1.0 ug/LRSD (%)n 5Recovery(%)RSD (%)n 510.0 ug/LRecovery(%)RSD (%)n 5Recovery(%)RSD (%)n 5MatrixEffect at10.0 0.392.89.280.27.866.57.00.15Table. 2 The spike recoveries and precision (%RSD) of antibiotics in milk.18A Simple Cleanup Protocol Using a Novel SPE Device for UPLC-MS/MS Analysis of Multi-Residue Veterinary Drugs in Milk

0.1 ug/LNameRecovery(%)0.5 ug/LRSD (%)n 5Recovery(%)1.0 ug/L10.0 ug/LRSD (%)n 5Recovery(%)RSD (%)n 5Recovery(%)RSD (%)n 5MatrixEffect at10.0 .99.8Nalidixic 4.974.816.3100.72.90.24Oxolinic 13.20.15Penicillin 1.515.491.513.20.09Cephapirin19

[ APPLICATION NOTE ]CONCLUSIONS An analytical method was created for determination of multi-residueveterinary drugs in milk including 72 compounds in 9 drug classes.Reasonable recoveries were obtained in the range of 50% to 130%with precision (RSD) 20% (n 5) for all compounds.The Oasis PRiME HLB Cartridge was shown to effectively removephospholipids and fats from milk. The sample preparation is simple,effective, and suitable for handling large numbers of samples in dailyroutine analysis.Waters Quanpedia Database contains all the liquid chromatographicmethods, mass parameters, and quantitation method for veterinarydrug analysis. It was very useful for developing this method.Waters, The Science of What’s Possible, UPLC, Xevo, MassLyn

be effective for fat removal, neither of these procedures removes phospholipids. THE SOLUTION Pass-through cleanup with the Oasis PRiME HLB Cartridge. This procedure is highly effective for removal of both fat and phospholipid from meat extracts. Just as important, the recoveries of the veterinary drugs are not compromised

![Algorithms AppendixI:ProofbyInduction[Sp’16]](/img/13/98-induction.jpg)