Transcription

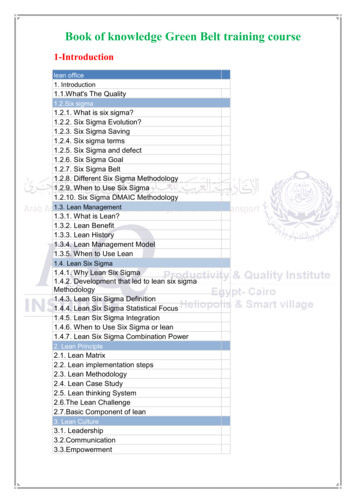

Lean Six Sigma GreenTrainingLeanBeltSix SigmaGreen BeltLEAN & SIX SIGMATOOLSPROJECT MGMT.TOOLSPROJECT SPECIFICTECHNICALITIESQCDMSTECHNICAL SIDE OFTHE PROJECTTECHNICAL SIDE OF THE TURESTATEGroupFacilitationSkillsPEOPLE SIDE OF THE PCopyright: QCDMS ConsultantsCopyright: QCDMS ConsultantsPEOPLE SIDE OF THEPROJECT2

Lean Six Sigma Yellow Belt Details(Already Covered)Day 11st halfIntroduction to Lean Lean Basics Lean 8 Waste Lean Yellow Belt trainingoverview LEAN GAME (ROUND 1)Lean Philosophy Lean Thinking - PDCA, VA/NVA/Waste, Muda, Mura Muri Lean Philosophy- One pieceflow, 1st time right, Kan Ban, QAvs. QC, Overall EquipmentEffectiveness and 6 Big losses Lean Methodology and ToolsWork cell , OEE and TotalPreventive MaintenanceLean Tools Classification of Lean Tools Process Understanding Tools SIPOC, Process Walk & ValueStream Mapping Process Metrics - Understandtype of metrics (Volume, Time,Process Complexity & Time) 2nd halfProblem Solving Tools - A3 ProblemSolving, 5 Why Analysis and FishboneDiagramData Collection and Analysis Tools Overview of 7 Quality Control Tools andBasics of Statistics (Average, Median,Mode & Percentile)Process Standardization Tools - 5S,Visual Management, Standard WorkLEAN GAME (ROUND 2)Organization Culture SWOT Analysis Culture and Continuous Improvement Exercise –Recipes of a Great CultureLean Leadership AttributesLeadership lessons from movies Employee engagement Overview of Change Management Developing People Servant Leadership Team Building Emotional IntelligenceDay 21st halfHoshin Kanri or Strategic Alignment Overview of 9 Steps of Strategy Deploymentaligning divisional or departmental purpose orvision to daily work Purpose, Vision, Mission and Values Voice of Customer and Voice of Business athigh level Organization Hierarchy and Teams Key Services or Key Processes Resource Allocation and Volumes Voice of Customer, Voice of Process and KPIsat Process level Dashboard (3-5 Year or Yearly Targets) Monitoring (Daily or Scheduled) Identifying sectional or divisional key processesand problems to improveDaily Management Huddle Meetings and Boards around Businessand Process KPIsExercise – Setting your Huddle BoardLeader Standard WorkDaily Problem Solving Finding Gaps Engaging Employees to make daily problemsolvingA3 Problem Solving methodology Background and basics of problem solving Case Study Trainees bring their problems and apply thelessons learned into their own scenarios A3 problem solving 11 step process- What isthe Problem - Background - UnderstandCurrent State - Data Collection - TemporarySolution - Root Cause Analysis -Solutions Action Plan - Checking Effectiveness –SustainmentNote- Utilize LEAN TOOLS as they fit into the problemsolving methodologyCopyright: QCDMS Consultants2nd halfRapid Process Improvement Methodology Case Study Trainees bring their process andapply the lessons learned into theirown scenarios Pre Event - Team Charter - SIPOC Voice of the Customer - ProcessWalks - Data Collection - DataAnalysis - Process Mapping (ValueStream Mapping) - Setting up aRapid Improvement Event (1/2 to 1day) with the team Lean Event- Current state agreement- Finding 8 Waste or Inefficiencies Root Cause Analysis - FindingSolutions- Action Plan- Target Settingon key process metrics Post Event- Completing Action Items- Standardizing the Improved Process- Sustainment - Process Monitoringkey process metrics- Huddle Boardand Process Improvementembedded in to existing HuddleCommunication (Meeting andBoards) StructureNote- Utilize LEAN TOOLS as they fit into theRapid Process Improvement methodologyLean Principles 5 Principles of Lean explainedEmbedding Lean in an organization Wrap up and Closure

Goal or Objective of the trainingGoal -Through Lean Six Sigma trainees will be able to engage and motivateteams and staff to remove Lean 8 waste and solve complex process problems.This will further improve Organization bottom line, quality, reduce deliverytimes, and enhance internal, product safety and Customer satisfaction.Trainees will be able to1. Embed culture of Lean Six Sigma across Organization2. Understands basics of Lean and Six Sigma3. Can lead Complex problem solving and process improvement projectswith the help of D-M-A-I-C or Toyota A3 Problem Solving methodologiesand Lean or Kaizen Event methodologies4. Learn about Project Management, Change Management, GroupFacilitation, Six Sigma Statistics, Complex Lean Tools like SMED, Time andMotion Studies, Capacity Studies and Layout Improvements5. Will bring a complex problem or a process and apply all the principles,methodologies, philosophies and tools into their own settingNote- Details of the training is on the next slide

Lean Six Sigma Green Belt DetailsDay 3Embedding culture of Lean Six Sigma inOrganization GANTT Chart, Lean Planning Sheet, ProjectSelection, Prioritization and detailed stepsto create a “Structure” around ContinuousImprovement Overview of Project management, Changemanagement and Group Facilitation skills Roles and Responsibilities of differentstakeholdersLean Six Sigma Basics Re-cap of Lean, 14 Principles of ToyotaProduction System, Toyota's 10Management Principles, House of TPS,Theory of Constraints, Taguchi Loss ofFunction, Hidden Factory and a Lean gameto re-cap 2 days of Lean Yellow Belt,Principles, Philosophies, Tools (Process,Problem, Data Collection & ProcessStandardization) and methodologies, Learn about Six Sigma basics, DMAIC(DEFINE-MEASURE-ANALYZE-IMPROVECONTROL) phases and principle, Basicstatistics, Histogram, Variance, StandardDeviation, Process Capability, Sigma levels,DPO, DPMO, Defects or Variation, Types ofVariation (Common or Special), Accuracyand Precision, Basics of Lean Six Sigma- DMAIC stepsDay 4Day 5Define stageAnalyze stageBe able to clearly DEFINE a Be able to ANALYZE Complex data, Large data baseproblem or process issue analysis, Root Cause Analysis, 8 Waste Analysis andComplete detailed ProjectVariation Analysis. After finding probable root causesCharter, Clear Problemor sources of variation, be able to create Test Plans toStatement, GANTT Chart, Kanofurther analyze and find root cause/s or Lean 8 wasteModel, Customer Survey, Criticalthemes,to Quality, Critical to Delivery Exercises to analyze and summarize complex data,and Critical to Cost,Root Cause Analysis and Lean 8 Waste themes,Improve stageMeasure stage Be able to IMPROVE - Engage teams to come out with Can MEASURE complex data,effective solutions, through SMART Action Plans, WBSunderstand Type of Data and(Work Breakdown Structure), FMEA (Failure Modecan create Data collectionEffects and Analysis), 5S and Mistake Proofing,plans. Understands the Exercise to learn complex Lean Tools to improve principles of y f(x), canSMED or Quick Change Over, Kan Ban, OEE (Overallcomplete detailed SIPOCs toEquipment Effectiveness), TPM (Total Productivefind sources of variation inMaintenance) and Layout Improvement,Supplier, Input, Process,Control StageOutput and Customer. CanBe able to create a CONTROL Plan to ensure problemdeep dive into the sources of does not come back - Learn to create Control Charts,variation, can completeProcess Monitoring tools with the help of 7 QC Tools,Gemba Walks, and collectStatistical Process Control, Control Plans, Standarddata or necessary information, Operating Procedures and Skills Development Plan, Exercises to learn 7 QC Tools, Report Out and Close OutTime and Motion Study andLearn to compile complete DMAIC Problem Solving orCapacity Study,Process Improvement methodology with the help of A3Problem Solving and Lean Six Sigma Report out template,Copyright: QCDMS Consultants

Our trainees came from following organizationsMANUFACTURINGSERVICEPUBLIC SERVICEHEALTHCARE4Copyright: QCDMS Consultants

Pictures from our training sessionsSHARING MY KNOWLEDGE WITH TRAINEESLEARNING THROUGH GAMESTRAINEES SHARING THEIR EXPERIENCESGROUP DISCUSSIONSCopyright: QCDMS Consultants

About Us “We Challenge the Status Quo” Self Reliance& SpeedEmail – qcdmsconsultants@gmail.comCell – 416 571 8770 About Charanjit (CJ) Singh BawaPassionate, Results-Driven Professional and Public SpeakerPMP, Black Belt, Mechanical Engineer (specializing in Automotive)24 Years of Lean six sigma , Change Management & project managementexperienceCoached over 5500 employees on Lean White, Yellow, Green Belt trainings andEmbedding Lean in complete organizationCoached more than 150 Improvement project teamsHuge cost savings and cost avoidances , improve quality and enhanced moraleCoached 55 leadership teams to embed LeanIndustries served – Automotive (OEM- Daewoo & Honda), Auto PartsManufacturing, Service & Public servicePMP from PMI USA, Lean Six Sigma Black Belt from ASQ USA & ADKAR changemanagement certified from PROSCI, USAServices we provideEmbedding Lean Strategy for complete organizationLean White Belt Training (Process or Problems), Yellow Belt Training and Green BeltTrainingCoaching on Lean Events and Rapid Improvement EventsOther Trainings like Change Management , Hoshin Kanri and Lean Tools trainings asdesired by CustomersOur Business Model Training & AwarenessCoaching through experiential Learning (Your Processes)Simplified approach for easy learningTransfer our knowledge to your team ( Speed)Creating self reliant teamsCopyright: QCDMS Consultants

Lean Six Sigma Green Belt Details Day 3 Day 4 Day 5 Embedding culture of Lean Six Sigma in Organization GANTT Chart, Lean Planning Sheet, Project Selection, Prioritization and detailed steps to create a “Structure” around Continuous Improvement Overview of Project ma