Transcription

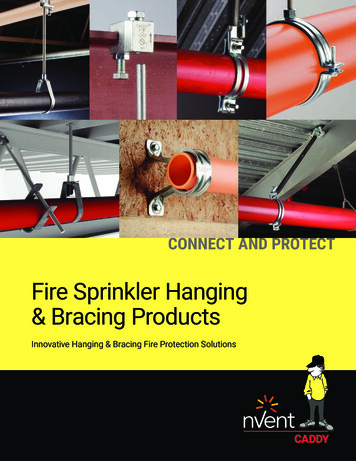

nVent CADDY PyramidRooftop Support System

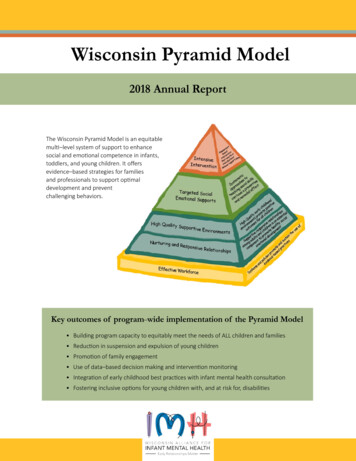

Plumbing & HVAC Applications?WhyBuynVentCADDYPyramidFOR ENGINEERS ANDCONSULTANTS:CHALLENGE: Properly support heavy loads Minimize the chance of point loading or abrading the roof membrane Ensure chemical compatibility with anything you place on the roof membraneNVENT CADDY PYRAMID SOLUTION: Pyramid offers a broad portfolio compatible with most roof surfaces, includingsingle-ply, bituminous, metal and spray foam Pyramid provides excellent load distribution with some of the industry’s bestload ratings Pyramid minimizes point loading and roof abrasion Pyramid is UV stable, corrosion resistant, and durable over an extensivetemperature rangeElectrical Applications2 nVent.com/CADDY

?WhyBuynVentCADDYPyramidFOR BUILDINGOWNERS:?WhyBuynVentCADDYPyramidFOR CONTRACTORS ANDINSTALLERS:CHALLENGE:CHALLENGE: Roofs not only protect some of the most valuable assets, theyoften represent a significant cost to replace and maintain Meet the project scope and stay within budget Provide a high quality installation Substandard materials and methods can increase the chanceof roof damage Need a fast and easy to install solution Increasingly, roofs are seen as prime real estate and are beingutilized for equipment placement, alternative energy systems,and as green spacePYRAMID SOLUTION: Adapt to a broad range of applications and roof materials Pyramid is designed to get installers on and off the roof quicklyPYRAMID SOLUTION: Pyramid creates an aesthetically pleasing, high quality solution Pyramid is extremely roof compatible Pyramid offers a broad portfolio of solutions that simplifymaterial management Pyramid is designed to minimize the chance of damage to roofs Pyramid is fast and easy to install, minimizing costs Pyramid provides an aesthetically pleasing, flexible engineeredsolution designed to meet the challenges of densely populatedroofsEquipment Support ApplicationsnVent.com/CADDY 3

Hot-dip galvanizedfor superior corrosionprotectionPyramid rooftop supports are a surfacemounted solution for supporting electrical andmechanical applications on a variety of roofsurfaces.UV stabilizedfor long lastingperformanceThey offer superior load capacity anddramatically reduce installation time byreplacing slow, heavy and labor-intensivemethods for support of pipe, conduit, duct,cable tray and equipment.Unlike wood blocks, Pyramid supports arespecifically designed for rooftop applications,incorporating unique materials and finishes thatprotect roof membranes and provide superiorcorrosion protection.Compatible with roofsurfaces includingsingle ply, bituminous,metal and spray foam oam bottom offers lowFabrasion interface for betterroof membrane protection“Our clients’ roofs are a significant investment. Protecting theseassets requires the use of engineered solutions that can withstandthe test of time, which is why we have standardized on the Pyramidfamily of roof top supports.”Chris Denman, Vice President and PartnerRoof Management, LLCadLo ingtRa Fewer supports required for the same load Less material, less laborad nLo butiotrisiD Minimizes point loading and stress concentrations Reduces likelihood of roof membrane damage Provides roof membrane compatibilityamFo ttomBoylitaQu nsYoDD vatiAC ont I n nenV and4 nVent.com/CADDY Eliminates the need for a separation sheet More than 14 years of designing and buildinghigh-quality rooftop support solutions Continuously innovating for over 110 years

Rooftop Supports: Load Distribution115 lbs350 lbs500 lbs570 lbs770 lbs1000 XXXXXXXXXXXXXXXXXXPyramid and other alternative solutionswere tested at various loads using apressure sensitive mat. These graphicsshow the static load transferred to theroof membrane. There are two keyfindings from the tests:1. At a given load, Pyramid offerssuperior load distribution to manyalternatives4681012141618202. Pyramid covers a broader range ofload ratings than many alternativesProductMTHE TAKEAWAY:PYRAMID IS A SUPERIORROOFTOP SUPPORT SOLUTION.XProduct does not supportload ratings at this levelnVent.com/CADDY 5

Pyramid ST Strut-Based SupportsPyramid STAdjustable Strut SupportsPyramid ST Strut-Based Supports offer an ideal solution formounting electrical and mechanical applications to strut. Superiorload distribution and a low abrasion foam interface combine toensure that the roof membrane is protected despite varying roofsurfaces and shifting caused by expansion and contraction. Provides superior load distribution, even with varyingrooftop surfacesAllows elevation changes of up to 18" offthe roof surface with 10" or 16" of usablestrut length. Ready to use out of the box, saving installation time and labor Height adjustability provides effective navigation of pipe, conduit,duct and cable tray around obstructions Compatible with roof surfaces including single ply, bituminous,metal and spray foam Multiple sizes and load ratings offer the ability to tailor thesolution to the application Foam bottom offers low abrasion interface for better roofmembrane protection Hot-dip galvanized and UV stabilized for long lastingperformance Supports green building requirements; thermoplastic basesare made from recycled material and can contribute to earningLEED creditsMaterial: Polyethylene, Polypropylene, SteelFinish: Hot-dip galvanizedTemperature: –50 to 150 FStatic Load Safety Factor: 3:1Part NumberStrut LengthHeightStatic LoadPSA10CH1310"6" – 13"1,000 lbPSA16AH1816"7" – 18"1,500 lbPyramid STFixed Strut SupportsPyramid STBridge AssembliesProvides a fixed-height mounting platformwith 6", 10", or 16" of usable strut length. Provides superior support for pipe, conduit, duct, cable trayand equipment Multiple sizes and load ratings offer the ability to tailor thesolution to the application Easy to transport to the roofStrut LengthHeightStatic LoadPSB24A24"5.6"2,000 lbPSB30A30"5.6"2,000 lbPSB36A36"5.6"2,000 lb1,000 lbPSB42A42"5.6"3,000 lb1,500 lbPSB48A48"5.6"3,000 lb1,500 lbPSB60A60"5.6"3,000 lbStrut LengthHeightStatic LoadPSF6C6"4.8"300 lbPSF10C10"4.8"1,000 lbPSF10D10"6.4"PSF16C16"4.8"6.4" Multiple sizes and load ratings offer the ability to tailor thesolution to the applicationPart NumberPart Number16" Ideal for supporting multiple pipe runs, cable tray and airhandling unitsMaterial: Polyethylene, Polypropylene, SteelFinish: Hot-dip galvanizedTemperature: –50 to 150 FStatic Load Safety Factor: 3:1Material: Polyethylene, Polypropylene, SteelFinish: Hot-dip galvanizedTemperature: –50 to 150 FStatic Load Safety Factor: 3:1PSF16DProvides a fixed-height mountingplatform off the roof surface with24" to 60" of usable strut length.Static loads are assumed to be uniformly distributed.“We have standardized on Pyramid ST Series Supportsfor our cable tray installations. They are extremely simpleto use and provide a lower total installed cost than woodblocks, concrete slabs, and other engineered solutions.”Alain Lemaire, Achatset Réalisation G2EI6 nVent.com/CADDY TIPFor complete information on all parts, visit:nVent.com/CADDY

Pyramid ST Strut-Based SupportsAlso Available:Pyramid 50 Foam-BasedSupportSUPPORT ACCESSORY:RIGD Single Piece StrutClamp for Pipe/Rigid ConduitMaterial: SteelFinish: Stainless Replaces slow and labor-intensive installation methods Supports pipe, conduit, cable tray and equipment on roofs andbelow raised floors One piece break apart strut clamp (1/2" thru 4" pipe size) Easily increase load capacity by combining similar Pyramidsupports Fits into open side of strut channel Protects the roof membrane while absorbing shock andvibration, without absorbing water Metal cover protects against weather and other environmentalconditions, such as bird damageLength Conforms with Manufacturers Standardization Society(MSS) SP-58 (Type 59)USC Universal Strut Clampfor Pipe/ConduitMaterial: SteelFinish: Hot-Dip GalvanizedMaterial: Polyethylene, Polypropylene, SteelStatic Load Safety Factor: 3:1Part Number Includes thread impression and captured screwHeightStatic Load Compatible with 3/8" thru 12" pipe sizeFinish: Electro-galvanizedRPS50H4EG10 3/8"4"50 lbRPS50H6EG10 3/8"6"50 lbFinish: Hot-dip galvanizedRPS50H4HD10 3/8"4"50 lbRPS50H6HD10 3/8"6"50 lb Consists of two clamps, nut and bolt Fits into open side of strut channel Conforms with Manufacturers Standardization Society(MSS) SP-58 (Type 59)nVent.com/CADDY 7

Pyramid RL Roller-Based SupportsPyramid RL Roller-Based Supports offer an ideal solution formechanical piping systems. Long-lasting performance is ensuredby providing polymeric rollers for corrosion free rotation. PyramidRL Roller-Based Supports are specially designed to avoidformation of flat spots and seized rollers during expansion andcontraction. Superior load distribution and a low abrasion foaminterface combine to ensure that the roof membrane is protecteddespite uneven roof surfaces and shifting caused by expansionand contraction. Polymeric rollers ensure corrosion free rotation Foam bottom offers low abrasion interface for better roofmembrane protection Compatible with roof surfaces including single ply, bituminous,metal and spray foam Ready to use out of the box, saving installation time and labor Hot-dip galvanized and UV stabilized for long lastingperformance Supports green building requirements; thermoplastic basesare made from recycled material and can contribute to earningLEED creditsPyramid RL Fixed Roller SupportsProvides a fixed height roller to support upto 6" schedule 40 nominal pipe. Roller-based support designed specifically for rooftopapplications Roller capability allows longitudinal movement of pipe, resultingfrom thermal expansion or contractionMaterial: Polyethylene, Polypropylene, SteelFinish: Hot-dip galvanizedTemperature: –50 to 150 FStatic Load Safety Factor: 3:1Part NumberPipe SizeHeightStatic LoadPRF22" Max5.80"100 lbPRF33" Max6.25"250 lbPRF66" Max6.25"600 lbSUPPORT ACCESSORY:Pyramid RL Adjustable RollerSupportsRetainer StrapAdjustable height allows elevationchanges up to 16" off the roof for up to 6"schedule 40 nominal pipe.Provides additionalsupport to ensure thatthe pipe stays in-linewith the roller. Prevents pipe from being dislodged from roller supports Height-adjustable roller-based support designed specifically forrooftop applications Innovative twist-lock design allows for easy installationwithout requiring hardware removal Height adjustability allows for effective navigation of pipe aroundobstructionsMaterial: SteelFinish: Hot-dip galvanizedMaterial: Polyethylene, Polypropylene, SteelFinish: Hot-dip galvanizedTemperature: –50 to 150 FStatic Load Safety Factor: 3:1Part NumberPipe SizePRS22" MaxPRS33" MaxPart NumberPipe SizeHeightStatic Load6" MaxPRA3H123" Max6" – 12"250 lbPRA6H166" Max6 1/2" – 16"600 lbPRS68 nVent.com/CADDY

Pyramid H-FramePyramid H-Frame Series Support System is a fast and economicalsolution for a variety of rooftop applications where support heightand width exceed those of the Pyramid ST or Pyramid RL series.It provides an ideal support solution for duct, large diameter pipeor cable tray. Superior load distribution and a low abrasion foaminterface combine to ensure that the roof membrane is protecteddespite varying roof surfaces and shifting caused by expansionand contraction. Foam or rubber bottom offers low abrasion interface for betterroof membrane protection Compatible with roof surfaces including single ply, bituminous,metal and spray foam Provides superior load distribution, even with varyingrooftop surfaces Rubber rooftop interface ideal for solar panel array installationsPyramidH-Frame Post Base Mounting hardware pre-installedin basesMaterial: Polyethylene, Polypropylene, SteelFinish: Hot-dip galvanizedTemperature: –30 to 130 FStatic Load Safety Factor: 3:1PartNumberRooftopInterfaceStrutTypeHeightLength /WidthStaticLoadPHBFoamA4.60"12 3/8"750 lbPHBRRubberA4.66"12 3/8"750 lb Hot-dip galvanized and UV stabilized for long lastingperformance Accepts standard strut channelsPyramidH-Frame Kit Supports green building requirements; thermoplastic basesare made from recycled material and can contribute to earningLEED credits Kit includes 2 post bases with pre-installedmounting hardware, 6 bolts, 6 strut nuts,and 2 L-brackets to complete H-frameSUPPORT ACCESSORY:PYRAMID H-FRAMEHARDWARE KIT Kit includes 6 bolts, 6 strut nuts,and 2 L-brackets to build custommulti-tier H-frame assembliesMaterial: SteelFinish: Hot-dipgalvanizedPart NumberScrew DiameterHFRMHDWM12Material: Polyethylene, PolypropyleneTemperature: –30 to 130 FStatic Load Safety Factor: 3:1PartNumberRooftopInterfaceStrutTypeHeightLength /WidthStaticLoadPHKFoamA4.60"12 3/8"1,500 lbPHKRRubberA4.66"12 3/8"1,500 lbStatic load represents 750 lb (3,335 N) per post base. The end user mustselect and evaluate the strut framing to ensure the assembled H-framecan properly support the applied load.nVent.com/CADDY 9

Pyramid Equipment SupportsPyramid Equipment Support KitPyramid Equipment Support is a fast, flexible and innovativesystem for supporting heavy-duty mechanical services onrooftop surfaces. Superior load distribution and a low abrasionfoam interface combine to ensure that the roof membrane isprotected despite varying roof surfaces and shifting caused byexpansion and contraction. Supports green building requirements; thermoplastic basesare made from recycled material and can contribute toearning LEED creditsIncludes all post bases, hardware andframing needed for an out of the boxsolution to construct a 1 m or 2 mequipment support. Kit includes post-base assemblies, frame and equipmentsupport clamps Assembles and adjusts to size and height in minutes by oneperson with one toolSUPPORT ACCESSORY:PYRAMID EQUIPMENT SUPPORTCLAMPClamp to secure heavy-dutymechanical equipment when creatinga custom frame out of strut. Innovative crossbar and equipment-support clamps enablequick assembly Integral foam pad provides gentle interface for all roof types Hot-dip galvanized and UV stabilized for long lastingperformance Assembled support can be lifted as one unit and easily relocated Ideal for use with strut channel type A and square tube tocreate custom equipment supports Slotted design offers fast and easy installationMaterial: SteelFinish: Hot-dip galvanizedPart NumberStrut TypePECA Available in 4- or 6-post base configurationsMaterial: Steel, Polypropylene, PolyethyleneFinish: Hot-dip galvanizedTemperature: –30 to 130 FHeight: 12" – 18"Length: 62 ic LoadPEK4B12" x 4 pc49 1/2"575 in21,120 lbPEK6B12" x 6 pc85 1/2"862 in2,240 lb2Static load must be stable and uniformly distributed across frame.Pyramid Equipment SupportPost BaseIndividual post base with heightadjustable leg 12" to 18" gives you theflexibility to create your own equipmentsupport with strut. Ideal for use with strut channel type A and U-shaped brackets tocreate custom equipment supports Height adjustable Innovative base design evenly distributes load to help preventdamage to roof membrane Base is manufactured from UV-stabilized thermoplastic materialMaterial: Steel, Polypropylene, PolyethyleneFinish: Hot-dip galvanizedTemperature: –30 to 130 FStatic Load Safety Factor: 3:110 nVent.com/CADDYPartNumberHeightLength /WidthSurfaceAreaStaticLoadPEB12" – 18"12"144 in2750 lb

Pyramid Equipment SupportsPyramid Equipment SupportFrame Extension KitPyramid Equipment SupportHeight ExtensionHeight extension used to lift the frame upto 36" off the roof surface. Allows creation of custom equipment support lengths byattaching the Pyramid Extension Kit in series to a PyramidEquipment Support Kit Increases the height between theequipment support frame androof deck Kit includes two post-base assemblies, frame and equipmentsupport clamps for easy attachment to a Pyramid EquipmentSupport Kit Inserts directly into PyramidEquipment Support Bases Square tube and cross bars provide superior load and deflectioncapabilities over standard strut profiles Assembles and adjusts to size and height in minutes by oneperson with one tool Innovative crossbar and equipment-support clamps enablequick assemblyWAHMaterial: SteelFinish: Hot-Dip GalvanizedPart NumberHHeightAPost Base Heightwith ExtensionWWidthPEH3122.38"30" – 36"2.36" Integral foam pad provides gentle interface for all roof types Hot-dip galvanized finish provides superior corrosion protectionMaterial: Steel, Polypropylene, PolyethyleneFinish: Hot-dip galvanizedTemperature: –30 to 130 FHeight: 12" – 18"Length: 62 ic LoadPEKEF12" x 2 pc49 1/2"288 in²1,120 lb“Labor represents over 50% of the costs on our projects.We chose to standardize on Pyramid EquipmentSupports for our air handling unit installations,because one person can easily assemble and locate thesupport unit where required on the roof. This is a verywell designed product that saves installation time &keeps me under budget.”Ulf Engel, Dipl. –Ing. (FH) ROKO-KlimatechnikStatic load must be stable and uniformly distributed across frame.Pyramid Equipment Support Frame Extension must be used inconjunction with a Pyramid Equipment Support Kit.nVent.com/CADDY 11

Pyramid Crossovers and WalkwaysThe Pyramid Crossovers portfolio includes ladders, towers,bridges and platforms that can be combined to provide a safe andclear rooftop walkway. Individual pieces can be easily assembledto meet custom application needs. Superior load distribution anda low abrasion foam interface combine to ensure that the roofmembrane is protected despite varying roof surfaces and shiftingcaused by expansion and contraction.Pyramid Crossover Ladders, 50 Aluminum construction designed to withstand harshenvironments Pyramid bases provide superior loaddistribution and roof membranecompatibilityLadders at a 50 angle ranging from twosteps with a height of 20" to six steps witha height of 60". Standard angle ladders provide easychanges in elevation Walking surfaces with serrated tread provides maximumslip resistance and drainage Foam bottom offers low abrasioninterface for better roof membraneprotection Modular design allows for easily configurable heights andlengths to address varying applications Stairs, platform and ladders are easily assembled yielding laborsaving, quick installations and level adjustments Interchangeable standard components for flexibility whileproviding safe access over piping, duct, equipment or otherutilities on a roof surface Compliant with OSHA, Cal/OSHA and ANSI standardsMaterial: Aluminum, Polypropylene, PolyethylenePart NumberHeightWidthDepthStep L50S6102"52.4"61.3"10"“Our projects often require theinstallation of crossovers, walkways,and platforms to allow for easy and safeaccess across and over varying rooftop structures. We have standardizedon the Pyramid family because they areengineered to be sturdy and durable butare also extremely simple to install.”PyramidCrossover Ladders, 90 Ladders at a 90 angle ranging in heightfrom 20" to 60". Vertical Ladders ideal for tight spacesTyler Doyle, Project ManagerEnvironmental Roofing and Waterproofing Pyramid bases provide superior loaddistribution and roof membranecompatibility Foam bottom offers low abrasioninterface for better roof membraneprotectionMaterial: Aluminum, Polypropylene, Polyethylene12 nVent.com/CADDY Part NumberHeightWidthDepthStep 4"3"12"

Pyramid Crossovers and WalkwaysPyramidCrossover Support TowersPyramidCrossover BridgeSupports for walkway systems ranging inheight from 20" to 60".Bridge span with handrails connectseasily in series and to Pyramid CrossoverLadders to provide an effective walkway. Additional support towers ideal forsupporting long walkways at varyingheights Pyramid bases provide superior loaddistribution and roof membranecompatibility Foam bottom offers low abrasioninterface for better roof membraneprotection Standard bridge spans that can becombined to create custom pathwaylengthsMaterial: AluminumPart 080"52.9"2"Length40"PyramidCrossover Bridge Turn KitMaterial: Aluminum, Polypropylene, PolyethylenePart NumberWidth42"Provides supports, pathway and handrailsto make a 90 turn at heights ranging from20" to 60". Turn bridges allow for configurationsbeyond a straight pathway, “L”, “U” or “Z”pathways can be created by using turnbridgesPyramidCrossover Platform Pyramid bases provide superior loaddistribution and roof membranecompatibilityProvides four height adjustable legsand the ability to interlock sections forcustomizability. Foam bottom offers low abrasioninterface for better roof membraneprotection Height adjustable interlocking platformsallow for quick and easy installationof a custom pathway across rooftopsurfaces Protect roof surfaces by providing aclearly defined pathwayMaterial: Aluminum, Polypropylene, PolyethylenePart NumberHeightWidthDepthPCP3611" – 14"36"36"Material: Aluminum, Polypropylene, PolyethylenePart "47.1"PCB36H60102"52.5"47.1"PyramidGuardrail KitProvides extra handrails for creatingcustom configurations. Use an extra guardrail kit to block offthe end of a pathway or create custompathway configurations while ensuringall safety criteria are metMaterial: AluminumPart NumberPCGKLength42"nVent.com/CADDY 13

Pyramid EZ Rubber-Based SupportsFeature a wide platform base design to provide reliable support anddistribute load across roof surface. These versatile supports arefast and easy to install compared to wood blocks and metal straps. Quick height adjustment accommodates for uneven roofsor sloped condensate lines No tools or fasteners needed; fast snap-on installation Design sheds water and helps reduce pipe corrosion Roof-friendly; made of UV-stabilized EPDM materialMaterial: EPDM-SBR rubberPart NumberRigid Conduit/Pipe SizeHeightUltimateStatic LoadRPSE1H241"1 3/4" – 4"170 lbRPSE1H571"5" – 7"170 lbRPSE2H462"4" – 6"250 lbRPSE4H464"4" – 6"400 lbUltimate load at 1/4" (6.35 mm) deflection. Contact project or roofingengineer for maximum allowable load on individual project roof system.14 nVent.com/CADDY “As a roofing membranemanufacturer, the products that wechoose for our own roof must reflect thesame level of quality and durability as ourbrand. We chose the Pyramid EZ SeriesRooftop Support System during our officeroof renovation to replace the originalwood blocks that held up the gas lines.They were economical, simple to install,and contributed to the general aestheticsof the roof. Just like our installingcontractor said, ‘These nVent CADDYSupports are pretty sweet!’”Jerry Beall, Product and TechnicalSpecialist FiberTite Roofing Systems,Seaman Corporation

Pyramid Universal Support Captive stainless steel nuts allow for custom attachment methodsto the support base including easy attachment of stainless steelstrut, threaded rod or other project-specific hardware yramid 25PPipe and Conduit Support Lightweight plastic construction Foam bottom offers low abrasion interface for better roofmembrane protection UV resistant, designed and tested for outdoor use Compatible with roof surfaces including single ply, bituminous,metal and spray foam Rounded edges to help protect the roof membrane Provides superior load distribution, even with varyingrooftop surfaces No tools or fasteners needed for installationMaterial: Acrylonitrile Butadiene Styrene Multiple sizes and load ratings offer the ability to tailor thesolution to the applicationPart NumberHeightStatic LoadPPRPS25H43 5/8"25 lb Base is manufactured from UV-stabilized thermoplastic materialPPRPS25H65 5/8"25 lb Supports green building requirements; thermoplastic basesare made from recycled material and can contribute to earningLEED creditsMaterial: Polyethylene; Polypropylene; Stainless Steel 18–8Temperature : –50 to 150 FStatic Load Safety Factor: 3:1PartNumberPBU6PBU10PBU16Length8"12 1/2"19"Width6"8"8"Height4"4"4"ThreadSize(3) 3/8"–16(2) 3/8"–16(2) 3/8"–16UltimateStatic Load3001,0001,500“The Pyramid family allows us tostreamline our project operations whiledelivering an aesthetically pleasingproduct for our clients.”Kyle Laubach, VP of OperationsEnvironmental Roofing and WaterproofingnVent.com/CADDY 15

nVent CADDY Pyramid Tool-Free SupportsThe nVent CADDY Pyramid Tool-Free series offers a uniquelabor saving solution for supporting electrical and mechanicalapplications on a variety of roof surfaces. The nVent CADDYPyramid Tool-Free series restrains pipe, conduit, or cable traywithout the need for metal hardware such as strut clamps orinstallation tools. Superior load distribution and a low abrasionfoam interface combine to ensure that the roof membrane isprotected despite varying roof surfaces and shifting caused byexpansion and contraction. Push-in fasteners install without the need for additional toolsor hardware Ready to use out of the box, saving installation time and labor Plastic fasteners and base will not corrodenVent CADDY PyramidTool-Free Cable TraySupport KitProvides a fixed height support4" (102 mm) off the roof surfacefor cable tray. Kits come in 5.5",10" or 16" (140 mm, 254 mm, or406 mm) lengths with securingpins included.nVent CADDY PyramidTool-Free Pipe Support KitProvides a fixed height support4" (102 mm) off the roof surfacefor outside pipe diametersbetween 0.50" – 2.38"(12.7 – 60.3 mm). Kits comein 5.5", 10" or 16" (140 mm,254 mm, or 406 mm) lengths.nVent CADDY PyramidTool-Free Pipe ClampTwo sizes of clamps allow foroutside pipe diameters between0.50" – 2.38" (12.7 – 60.3 mm)to be restrained on top of thenVent CADDY Pyramid Tool-Freeseries base.16 nVent.com/CADDYnVent CADDY PyramidTool-Free Cable Tray PinAllows for perforated cable tray tobe secured on top of nVent CADDYPyramid Tool-Free series bases.

NVENT CADDY PYRAMID TOOL-FREE PIPE SUPPORT KIT Push-in clamps install without the need for additional toolsor strut clamps Ready to use out of the box, saving installation time and labor Plastic clamps and base will not corrode pipe Clamps come in two different sizes to fit project needs Base includes multiple holes to accommodate a variety ofclamp sizes and configurations Additional clamps can be purchased separately for additionalpipe runs Foam bottom offers low abrasion interface for better roofmembrane protection Provides superior load distribution, even with varyingrooftop surfacesMaterial: Polyethylene; Polypropylene; NylonTemperature: –50 to 150 FStatic Load Safety Factor: 3:1Number ofClamps Includes Compatible with roof surfaces including single ply, bituminous,metal and spray foam Multiple sizes and load ratings offer the ability to tailor thesolution to the applicationMaximumClamp mberLength 1L1Length 2L2Length 3L3WidthWHeightHAPTF68"–3.2"6"4"3.2"PTF1012 57 Easy to transport to the roofPTF2C123 Supports green building requirements; thermoplastic basesare made from recycled material and can contribute to earningLEED creditsBSurfaceAreaUnitWeightStaticLoadF0.8"41 in²0.6 lb300 lb6.4"0.8"92 in²1.0 lb1,000 lb9.6"0.8"142 in²2.0 lb1,500 lbLength 2 represents maximum pipe center to pipe center using PTF2C clamps. Length 3 represents maximum pipe center to pipe center using PTF1C clamps.L2AL3WHL1FBNVENT CADDY PYRAMID TOOL-FREE PIPE CLAMP Push-in clamps install without the needfor additional tools or strut clamps Clamps come in two different sizes tofit project needs Plastic clamps and base will notcorrode pipeMaterial: NylonTemperature: –50 to 150 FPartNumberPTF1CPTF2COuterDiameterOD0.50" – 1.32"0.84" – ght0.025 lb0.045 lbnVent.com/CADDY 17

NVENT CADDY PYRAMID TOOL-FREE CABLE TRAY SUPPORT KIT Push-in pins install without the need for additional tools Plastic pins and base will not corrode Pins and mounting holes accommodate most perforatedcable tray Ready to use out of the box, saving installation time and labor Additional pins can be purchased separately Foam bottom offers low abrasion interface for better roofmembrane protection Provides superior load distribution, even with varyingrooftop surfaces Compatible with roof surfaces including single ply, bituminous,metal and spray foam Multiple sizes and load ratings offer the ability to tailor thesolution to the application Easy to transport to the roof Supports green building requirements; thermoplastic basesare made from recycled material and can contribute to earningLEED creditsMaterial: Polyethylene; Polypropylene; NylonTemperature: –50 to 150 FStatic Load Safety Factor: 3:1Surface AreaUnitWeightStaticLoadF41 in²0.6 lb300 lb4"92 in²1.0 lb1,000 lb4"142 in²2.0 lb1,500 2 1/2"8"PTF16P19"8"WHLNVENT CADDY PYRAMID TOOL-FREE PIPE CLAMP Push-in pins install without the need foradditional tools Plastic pins and base will not corrodeLØ18 nVent.com/CADDY Pins and mounting holes accommodatemost perforated cable tray Supports green building requirements;thermoplastic bases are made fromrecycled material and can contributeto earning LEED creditsMaterial: NylonTemperature: –50 to 150 FPart NumberPTFPDiameterØ0.79"LengthL1.65"

NVENT CADDY PYRAMID ROOFTOP ANCHOR SYSTEMnVent CADDY Pyramid Rooftop Anchor Systems help ensure thesafety and protection of your rooftop mechanical and electricalequipment applications. The system fastens directly to the roofdeck. The anchor is permanently sealed to the roof membrane,creating a watertigh

Pyramid H-Frame Series Support System is a fast and economical solution for a variety of rooftop applications where support height and width exceed those of the Pyramid ST or Pyramid RL series. It provides an ideal support solution for duct, large diameter pipe or cable tray. Superior load distribution and a low abrasion foam