Transcription

This program is our highlyrecommended Program. Online Benchmark Six Sigma Black BeltOnline Lean Six Sigma Black Belt Training from MBB Experts. Absolutelybest in class. Learn effortlessly and retain it for long. 200 Batchesconducted.5000 ProfessionalsTrained40 Industry Sectorscovered.12 Batches every yearsince 2001

Benchmark Six Sigma provides training from Lean Six Sigma Green Belt up to MBB since2007. We train 250 plus professionals on these programs every monthAbout Us

We work with clients in many Industrysectors. Some selected clients areshown here.FMCG – P&G (US),Pharma - PerrigoSearch – GoogleFacility Management – JLL (US)Liquor – Diageo (ItalyE-commerce - AmazonAircrafts – BoeingMaps – Here MapsFootwear – Bata (multiple locations)Electrical - KirloskarIT Products - AdobeTelecom – France TelecomWho do wework with?Digital Marketing - SapientCredit Cards – American ExpressEnergy – SuzlonBanking – JP Morgan Chase, Bank Dhofar (Muscat), Maubank (Mauritius)Construction – William Hare (UK)Elevators - KoneCargo - CMACGMAgro Products – Syngenta, Indofoods (Indonesia)Software – Siemens InfosoftMany more tsMost of the global leadersthat we worked with werethe first client in the specificIndustry Domain.

Few Basics aboutLean Six Sigma Lean Six Sigma presents theworld’s best business problemsolving methods in a singlecapsule. The goal of Lean SixSigma Green Belt and Black Beltprograms is not only to helpparticipants build competencebut also to gather practicableunderstanding so that they canapply the learning at theirworkplace. Lean Six Sigma delivers resultsthrough two methodologiesDMAIC and DMADV The Lean Six Sigma DMAICsequence (Define, Measure,Analyze, Improve, Control) is animprovement system for existingprocesses or products forenhanced performance. The Six Sigma DMADV process(Define, Measure, Analyze,Design, Verify) is animprovement system used todevelop new processes orproducts at Six Sigma qualitylevels. It can also be employed ifa current process requiresbreakthrough improvements

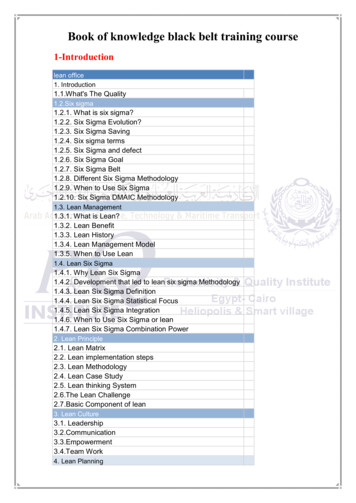

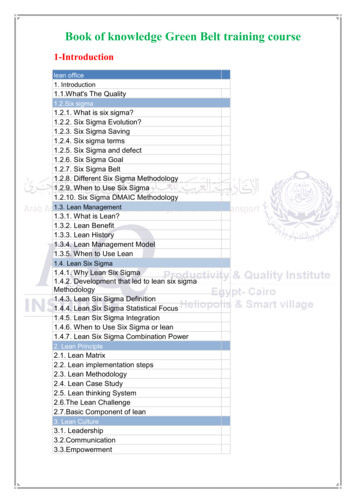

Benchmark Six Sigma are Globally Accepted and recognized byExemplar Global since 2009. Benchmark Six Sigma programs have very high industryacceptance with Global Leaders like Google, Amazon, Boeing andP&G as client.Lean Six SigmaBlack BeltGlobal Acceptance andBody of Knowledge Exemplar Global started in US and Australia in 1989. Its principaloffices are located in Sydney, Australia, and Milwaukee, Wisconsin,in the United States. Additional offices in Brazil, Malaysia,Singapore, South Africa, Indonesia, Seoul, South Korea, China andVietnam. Exemplar Global is part of ASQ family. Benchmark Six Sigma started Lean Six Sigma programs in 2001while boards started offering accreditation much later in 2008 or2009 Next few slides show the Lean Six Sigma Black Belt Body ofKnowledge used by Benchmark Six Sigma.

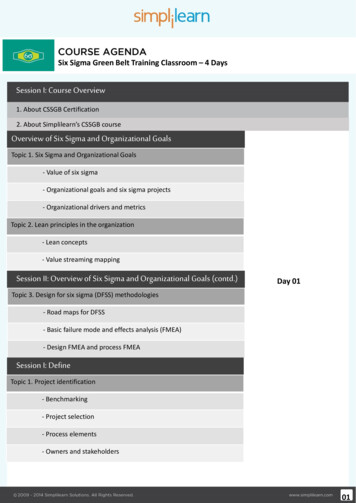

Competency 1Lead DMAIC/ DMADVProjects –Apply LeadershipPerformance CriteriaLearning Expected1.1: Understand leadership responsibilitiesin the deployment of Six Sigma: Providing resources Managing change Communicating ideasDescribe the responsibilities of executive leaders and how they affect thedeployment of Six Sigma in terms of providing resources, managing change,communicating ideas, etc.Describe and use various techniques for facilitating and managing organizationalchange.1.2: Describe and identify organizationalroadblocks: Lack of resources Management support Recovery techniques Change management techniques1.3: Use team formation theories: Team types and constraints Team roles Team member selection Launching teamsDescribe the impact an organization’s culture and inherent structure can have onthe success of Six Sigma, and how deployment failure can result from the lack ofresources, management support, etc.; identify and apply various techniques toovercome these barriers.Describe and apply techniques that motivate team members and support andsustain their participation and commitment.Facilitate the team through the classic stages of development: forming, storming,norming, performing and adjourning

Competency 2Lead DMAIC/DMADVProjects – Manage ProjectsPerformance CriteriaLearning Expected2.1: Define benchmarking,performance and financialmeasures: Best practice Competitive Collaborative Score cards KPI’s COQ ROI NPVDefine and distinguish between various types of benchmarking, including bestpractices, competitive, collaborative, etc.Business performance measures2.2: Utilize time managementfor teams.Employ various time management techniques including publishing agendas withtime limits on each entry, adhering to the agenda, requiring pre-work by attendees,ensuring that the right people and resources are available, etc.2.3: Understand managementand planning toolsDefine, select and apply tools such as: affinity diagrams, tree diagrams, processdecision program charts (PDPC), matrix diagrams, interrelationship diagrams,prioritization matrices and activity network diagrams.2.4: Collect customer datausing various methods: Surveys Focus groups Interviews observationsUse various methods to collect customer feedback (e.g., surveys, focus groups,interviews, observation) and identify the key elements that make these toolseffective.Define various business performance measures, including balanced scorecard, keyperformance indicators (KPIs), the financial impact of customer loyalty, etc.Define financial measures, such as: revenue growth, market share, margin, cost ofquality (COQ), net present value (NPV), return on investment (ROI), cost-benefitanalysis, etc.

Performance Criteria3.1: Outline processelements: Components BoundariesLearning ExpectedDefine and describe process components and boundaries.3.1: Understand teamIdentify and use appropriate communication methods (both within the team and fromthe team to various stakeholders) to report progress, conduct milestone reviews andsupport the overall success of the project.facilitation: Team motivation Team stages Teamcommunication Team DynamicsCompetency 3Lead DMAIC/DMADVProjects –Coaching3.2: Define and useteam performanceevaluation and reward3.3: Analyze customerdata using variousmethods: Graphical Statistical Qualitative toolsIdentify and use various techniques (e.g., coaching, mentoring, intervention, etc.) toovercome various group dynamic challenges, including overbearing/dominant orreluctant participants, feuding and other forms of unproductive disagreement,unquestioned acceptance of opinions as facts, groupthink, floundering, rushing toaccomplish or finish, digressions, tangents, etc.Measure team progress in relation to goals, objectives and other metrics that supportteam success and reward and recognize the team for its accomplishments.Use graphical, statistical, and qualitative tools to analyze customer feedback.Assist in translating customer feedback into project goals and objectives, includingcritical to quality (CTQ) attributes and requirements statements.

Performance CriteriaLearning Expected4.1: Identify resistanceto change.Conduct an analysis to find restrainers and drivers to change.4.2: Implement a plan to Outline steps taken that address issues identified at analysis, discussing:counter resistance to Stakeholder managementchange Communications plans Organizational readiness for changeCompetency 4Lead DMAIC/DMADVProjects – Facilitate Change4.3: Identify customers: Identify customers ClassifycustomersIdentify and classify internal and external customers as applicable to a particularproject, and show how projects impact customers.

Competency 5 - aLead DMAIC/DMADVProjects – DefinePerformance CriteriaLearning Expected5.1: Outline process elements: Components BoundariesDefine and describe process components and boundaries. Recognize howprocesses cross various functional areas and the challenges that result forprocess improvement efforts.5.2: Identify owners andstakeholders: Process owners Suppliers Internal customers External customersIdentify process owners, internal and external customers, and otherstakeholders in a project.5.3: Analyze customer datausing various methods: Graphical Statistical Qualitative toolsUse voice of the customer analysis tools such as quality function deployment(QFD) to translate customer requirements into performance measures.5.4: Outline the project charterand project statement: Project elements Problem statementDefine and describe elements of a project charter and develop a problemstatement, including baseline and improvement goals.5.5: Develop the project scopeusing: Definitions Pareto charts Process mapsUndertake the development of project definition/scope using Pareto charts, andprocess maps.

Performance Criteria5.6: Develop the project metrics using: Primary metrics Consequential metrics Key project metricsLearning ExpectedUndertake the development of primary and consequential metrics (e.g.,quality, cycle time and cost) and establish key project metrics that relate tothe voice of the customer.5.7: Apply project planning tools: Ghantt charts CPM PertUse project tools such as Gantt charts, critical path method (CPM), andprogram evaluation and review technique (PERT) charts, and activitynetwork diagrams.5.8: Record project documentation: Spreadsheets Story boardsProvide input and select the proper vehicle for presenting projectdocumentation (e.g., spreadsheet output, storyboards, etc.) at phasereviews, management reviews and other presentations.5.9: Define and utilize project risk analysis: Purpose Benefits ImpactsDescribe the purpose and benefit of project risk analysis, includingresources, financials, impact on customers and other stakeholders.5.10: Project milestones: Objectives vs outcomes Lessons learned OpportunitiesDescribe the objectives achieved and apply the lessons learned to identifyadditional opportunities.5.11: Define, select and use managementplanning tools.Define, select, and use affinity diagrams, interrelationship digraphs, treediagrams, prioritization matrices, matrix diagrams, process decisionprogram (PDPC) charts, and activity network diagrams.5.12: Calculate process performanceCalculate process performance metrics such as defects per unit (DPU),rolled throughput yield (RTY), cost of poor quality (COPQ), defects permillion opportunities (DPMO) sigma levels and process capability indices.Competency 5 - bLead DMAIC/DMADVProjects – DefinePresent findings in a clear, concise manner.

Competency 6.Lead DMAIC/DMADVProjects – MeasurePerformance Criteria6.1 Define and describe measurementand metrology: Continuous data Discrete data Elements of metrology Calibration Traceability to reference standards Standards and measurementdevicesLearning ExpectedDefine and describe measurement methods for both continuous anddiscrete data.6.2 Identify use of measurement systemsin enterprise.Identify how measurement systems can be applied in marketing,sales, engineering, research and development (R&D), supply chainmanagement, customer satisfaction and other functional areas.6.3: Describe and apply basic probabilityconcepts: Independence Mutually exclusive Multiplication rulesDescribe and apply concepts such as independence, mutuallyexclusive, multiplication rules, etc.6.4: Implement a measurement systemsanalysis tool.Calculate, analyze, and interpret measurement system capabilityusing repeatability and reproducibility (GR&R), measurementcorrelation, bias, linearity, percent agreement, andprecision/tolerance (P/T).6.5:Use appropriate software for analysisand project completionUnderstand advanced techniques for analysis using statistical andother data analysis software.6.6: Measure Tollgate reviewPresent findings of the measure stages in a concise manner.Define and describe elements of metrology, including calibrationsystems, traceability to reference standards, the control and integrityof standards and measurement devices, etc.

Performance Criteria7.1: Undertake hypothesis testing: Basics Tests for means, variances, andproportions Paired-comparison tests Single-factor analysis of variance(ANOVA) Chi squareLearning ExpectedDefine and distinguish between statistical and practical significance andapply tests for significance level, power, type I and type II errors. Determineappropriate sample size for various test.Define and describe paired-comparison parametric hypothesis tests.Define terms related to one-way ANOVAs and interpret their results and dataplotsDefine and interpret chi square and use it to determine statisticalsignificance.Competency 7Lead DMAIC/DMADVProjects –Analyze7.2: Select and use contingency tables.Select, develop and use contingency tables to determine statisticalsignificance.7.3: Ability to handle non-normal data.Recognition of non-normal data.7.4: Use various tools and techniques toanalyse data: Gap analysis Root cause analysis Waste analysisSelect, develop and use various non-parametric tests, including Mood’sMedian, Levene’s test, Kruskal-Wallis, Mann-Whitney, etc.Use various tools and techniques (gap analysis, scenario planning, etc.) tocompare the current and future state in terms of pre-defined metrics.Define and describe the purpose of root cause analysis, recognize the issuesinvolved in identifying a root cause, and use various tools (e.g., the 5 whys,Pareto charts, fault tree analysis, cause and effect diagrams, etc.) forresolving chronic problems.Identify the 7 classic wastes (overproduction, inventory, defects, overprocessing, waiting, motion and transportation) and other forms of wastesuch as resource under-utilization, etc.7.5: Analyze Tollgate reviewPresent findings of the analyze stages in a concise manner.

Performance Criteria8.1: Define and Describe Design ofExperiments (DOE): Basic terms Main effects Design principles Planning experiments One-factor experiments Two-level fractional factorialexperiments Full factorial experimentsLearning ExpectedDefine and describe basic DOE terms such as independent and dependent variables,factors and levels, response, treatment, error, repetition, and replication.Interpret main effects and interaction plots.Apply to design the DOE principles, including power and sample size, balance,repetition, replication, order, efficiency, randomization, blocking, interaction,confounding, resolution, etc.Plan, organize and evaluate experiments by determining the objective, selecting factors,responses and measurement methods, choosing the appropriate design, etc.Design and conduct completely randomized, randomized block and Latin squaredesigns and evaluate their results.Competency 8Lead DMAIC/DMADVProjects – Improve/ DesignDesign, analyze and interpret these types of experiments and describe how confoundingaffects their use.Design, conduct and analyze full factorial experiments.8.2: Select and apply variousreduction, elimination and mitigationtools: Waste elimination Cycle-time reduction Kaizen and kaizen blitz Risk analysisSelect and apply tools and techniques for eliminating or preventing waste, including pullsystems, kanban, 5S, standard work, poka-yoke, etcUse various tools and techniques for reducing cycle time, including continuous flow,single-minute exchange of die (SMED), etc.Define and distinguish between these two methods and apply them in various situations.Use tools such as feasibility studies, SWOT analysis (strengths, weaknesses,opportunities and threats), PEST analysis (political, environmental, social andtechnological) and consequential metrics to analyze and mitigate risk.8.3: Develop plans for implementingimproved process.Develop plans for implementing the improved process (i.e., conduct pilot tests,simulations, etc.), and evaluate results to select the optimum solution.

Competency 9Lead DMAIC/DMADVProjects –Control/ ValidatePerformance Criteria9.1: Using other tools for control andmaintenance: TPM Visual factory Measurement system reanalysis Control planLearning ExpectedDefine the elements of TPM and describe how it can be used tocontrol the improved process.9.2: Understanding how to sustainimprovements: Lessons learned Training plan deployment Documentation Ongoing evaluationDevelop a control plan for ensuring the ongoing success of theimproved process including the transfer of responsibility from theproject team to the process owner.Define the elements of a visual factory and describe how they canhelp control the improved process.Review and evaluate measurement system capability as processcapability improves, and ensure that measurement capability issufficient for its intended use.Document the lessons learned from all phases of a project andidentify how improvements can be replicated and applied to otherprocesses in the organizationDevelop and implement training plans to ensure continued support ofthe improved process.9.3: Financial Review/ValidationDevelop or modify documents including standard operatingprocedures (SOPs), work instructions, etc., to ensure that theimprovements are sustained over time.Describe methods of Savings/Improvement validation by anindependent entity (Financial Analyst)

Selected list ofclients

Some recent feedbackTo enquire furtheror to register, pleasecontact us

Contact for Online Lean Six Sigma Black BeltAnisha KhannaMarketing ManagerTo enquire furtheror to register, pleasecontact usBenchmark Six SigmaEmail: anisha@benchmarksixsigma.orgPhone: 91 8010959575

Lean Six Sigma Lean Six Sigma presents the world’s best business problem solving methods in a single capsule. The goal of Lean Six Sigma Green Belt and Black Belt programs is not only to help participants build competence but also to gather practicable understandin