Transcription

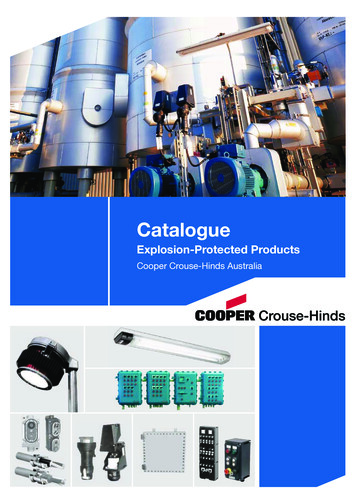

CatalogueExplosion-Protected ProductsCooper Crouse-Hinds Australia

Company ProfileFor more than a century, companies haverelied on Cooper Crouse-Hinds for solutionsthey can trust to grow their business.By integrating a comprehensive line of electrical andinstrumentation products with expert support,industry insights, and local availability,Cooper Crouse-Hinds enhances safety andproductivity in the most demanding industrial,harsh, and hazardous environments worldwide. Thisphilosophy is at the core of every product wedevelop and every solution we engineer.The more demanding theenvironment, the likely it is that youwill find our products in operation.Cooper Crouse-Hinds manufactures over100,000 products for NEC, IEC and ABSapplications across the globe, including Conduit and cable fittings Enclosures Motor Controls and Electrical Apparatus Industrial and Marine Lighting Plugs & Receptacles Signals and Alarms Wireless and Solar Power Commercial Fittings and Outlet Boxes Electronic components and protectionequipment for process controlJune, 2010Copyright Cooper Industries

Company ProfileAt Cooper Crouse-Hinds,innovation is in our DNA.As the electrical industry’s globalleader for hazardous environments, we’reconstantly pushing forward and looking ahead,advancing electrical and instrumentationproducts in new and innovative ways.We do this with a singular goal in mind —Enhancing Safety and Productivitythoughout your operation. It’s all fueled by afierce dedication to providing global solutions,worldwide reliability and intelligence andexpertise.Every new product or initiative must live up tothese uncompromising standards.Catalog LayoutWelcome to the enhanced and expandedCooper Crouse-Hinds catalog. This catalog includesproducts from the following 5 major product lines.Section 1Application ProtectionTechniquesSection 2Conduit and Cable FittingsSection 3Junction BoxesSection 4Industrial ControlSection 5LightingSection 6Plugs & ReceptaclesThe product information published in our catalogs and literaturehas been compiled with care and is sufficiently accurate for mostpurposes. It is subject to change without notice. Occasionally, itmay be necessary to modify the materials, finishes, or othercomponents of the product. These changes will in no wayreduce the performance or function for which the product isintended.All statements, technical information and recommendationscontained herein are based on information we believe to bereliable. The accuracy or completeness thereof are notguaranteed. In accordance with Cooper Crouse-Hinds’ Termsand Conditions of Sale, and since conditions of use are outsideour control, the purchaser should determine the suitability of theproduct for his/her intended use and assumes all risk and liabilitywhatsoever in connection therewith.All sales of Cooper Crouse-Hinds products are specificallysubject to the Terms and Conditions of Sale as shown on CooperCrouse-Hinds distributor or trade price sheets.Copyright Cooper IndustriesJune, 2010

About Our CatalogueMAJOR SECTIONS:Our Catalogue is divided into six major product sections:1Application Protection Techniques3Enclosures2456FittingsIndustrial ControlHazardous Area LightingHazardous Area Plugs & ReceptaclesA table of contents appears in the front of each section listingthe products contained in the section by both series prefix(e.g. DSEA) and general product type.PRODUCT INFORMATION:On the individual catalogue pages information is given for eachproduct family regarding application, features, compliances andcertification, options available and ordering information.To help make the catalogue easier to use, a common locationof the materials appearing on each page is used whereverpossible.MEASUREMENTS:All units of measurements shown in this catalogue are in metricunits of mm and kg (except where otherwise indicated).The product information published in our catalogues and literature is not guaranteed. It has been compiled with care and issufficiently accurate for most purposes. It is subject to changewithout notice. Occasionally, it may be necessary to modify thematerials, finishes, or other components of the products. Thesechanges in no way will reduce the performance or function forwhich the product is intended.All statements, technical information and recommendations contained herein are based on information and tests we believe tobe reliable. The accuracy or completeness thereof is not guaranteed. In accordance with Cooper Electrical Terms and Conditions of Sale, and since conditions of use are outside ourcontrol, the purchaser should determine the suitability of theproduct for his intended use and the purchaser assumes all riskand liability whatsoever in connection therein.June, 2010Copyright Cooper Industries

Section 1 IndexExplosionProtectionTypical Installation Reference .1-2Quick Product Selector .1-3Product Materials Guide .1-4Explosion Protection Techniques .1-5Temperature Ratings & Gas Groups .1-8IP Ratings .1-9Combustible Compounds Reference .1-10Area Classification Comparison .1-12International Standards Reference Table .1-13CEAG IEC Ex Approved Products CEAG 805 Cat .1-14Copyright Cooper IndustriesJune, 20101-1

Typical Installation Reference1-2June, 2010Copyright Cooper Industries

Quick Product SelectorProductWeatherproofOnlyZone 1Zone 2Zones 21, 22Adaptors, Nipples,Plugs, Reducers &UnionsANM, NHM, PLM,REM, UNFA, UNYAANM, NHM, PLM,REM, UNFA, UNYAANM, NHM, PLM,REM, UNFA, UNYAAlarms, Audible& VisualEOLA, FRFB, FSFBEOLA, FRFB, FSFBEOLA, FRFB, FSFBADE1F, ADE4FTWAB, TWAX, TWAEADE1F, ADE4FTWAB, TWAX, TWAEADE1F, ADE4FTWAB, TWAX, TWAEConduit Fittings& SealsEYSA, FE, FT, FCEYSA, FE, FT, FCFC, FB, FHCControl Stations& Pilot LightsDSA, DSEADSA, DSEADSEACustom BuiltControl PanelsEJBA & GHG44EJBA & GHG44JBD, JBDCGHG 44JBWSmallJunction BoxeseAZK96, C30, C31GUA, GHG, PBECeAZK96, C30, C31GUA, GHG, PBECC30, C31, JBDC,GHG72, PBECPBWEJBA, GHG74,GUBA, JBE, JBEC,PBE, XLHEJBA, GHG74,GUBA, JBE, JBEC,PBE, XLHJBD, JBDCCable GlandsLarge JunctionBoxes, Enclosures &Marshalling BoxesLighting FixturesAB12, AEV, AEVBH,eLLK, eLLM, EVA,EVME, FZD, LEDEXIT, PX04, T100APanel BoardsCPBA, EJB, EJBA,GHG61FNO, GHG5,FSQA, PPPlugs & ReceptaclesCPBA, EJB, EJBA,GHG61FNO, GHG5,FSQA, PPDSA, DSEA, EBA,ESA, ELS, ELFS,GHG26, GHG273,GHG29, GHG61DSA, DSEA, EBA,ESA, ELS, ELFS,GHG26, GHG273,GHG29, GHG61EMA, ESDA, GHG61EMA, ESDA, GHG61Switches &Circuit BreakersMotor StartersAB12, AEV, AEVBH,eLLK, eLLM, EVM,EVME, FZD, LEDEXIT, NFMV, NLLK,NVMV, PX04, T100ACopyright Cooper IndustriesTWA, TUAAB12, AEV, AEVBH,eLLK, eLLM, EVM,EVME, FZD, LEDEXIT, NFMV, NLLK,NVMV, PX04, T100AJBDFNO, PP, GHG5DSEA, GHG26,GHG273, GHG29June, 20101-3

Product Materials GuideExd1-4ExplosionProof Stainless Steel Mild Steel Aluminium FRPPlugs and ReceptaclesStainless SteelHID Lighting FixturesDust IgnitionProofMild SteelFluorescent Lighting FixturesExtDNonSparkingAluminiumIncandescent Lighting Fixtures ExnFRPPanel BoardsStainless SteelControl StationsMild SteelSwitchesIncreasedSafetyFRPMotor Control EquipmentHigh Tensile BrassLarge Junction Boxes & EnclosuresCast IronAluminiumCast Iron SteelSmall Junction Boxes& Conduit FittingsExe Note: Not all types listed are suitable for Zone 1 hazardous locations. Consult catalogue listing pages for application and gas groupsJune, 2010Copyright Cooper Industries

Explosion Protection TechniquesMany liquids, gases and dusts which are generated,processed, handled, and stored in industry are combustible.When ignited they may burn rapidly and with considerableexplosive force.The use of this certification will assist users in the selectionof the correct equipment for use in hazardous locations.In order to make a selection of equipment it is necessary tohave the hazardous area classification defined, as laid outin AS2430. However it is necessary for the classification tocontain details of the T rating and, for Zone 1, the Gasgroup of the hazardous material.Selection of EquipmentFigure 2 shows the techniques in common Australian usagetoday, and some typical applications.This does not mean that the other techniques are not usedand are not available in Australia or that they will not find increasing use there.The use of electrical apparatus in these areas is usuallynecessary to facilitate the handling or processing of thehazardous materials. To remove the possibility of ignitionbeing caused by the electrical apparatus, suitable precautions must be taken with both the equipment and the installation methods used in these hazardous areas.Improvements in electrical technology have resulted in thedevelopment of new and improved materials which havegiven rise to a considerable increase in the range of optionsavailable. These precautions are known today as Explosion Protection Techniques.Growth in mining, chemical, petrochemical and associatedindustries has encouraged the introduction of newtechniques, and the Policy of Standards Australia in following closely the I.E.C. recommendations, has led to the publishing of Australian Standards on these techniques.As a result of this the users of today have at their disposal apackage of techniques which allow additional considerationsuch as environment to be taken into account when choosing equipment for use in hazardous locations.A summary of the various techniques and their applicationin relation to area classification is shown in Figure 1.All these techniques, with the exception of Exm (hermetically sealed) and Exq (sand filled) are now covered by Australian Standards in relation to manufacture and certificationof equipment.The growth of the industries using explosion protectedequipment have given rise to an increased interest by companies in local manufacture of this equipment, with the result that there is available today a significant amount oflocally manufactured products using all of the techniques incommon use.In addition, this is supplemented by imported equipmentwhich is available locally and which carries Australian certification.The Operating EnvironmentWhen selecting equipment for use in hazardous locations, itis very easy to overlook the environmental effects on equipment.However, the operating environment can cause corrosion orsimilar degradation of equipment which could cause defective operation after a long period of service.For example, the use of plastic material in a spray booth orsolvent laden atmosphere should be avoided since thechemicals may attack the plastic materials.Conversely in the salt laden atmosphere experienced in offshore platforms and shipping applications, the use of plasticor stainless steel is preferable to aluminum.Crouse-Hinds Australia can give personal assistance, if required, when selection of materials is being made.In addition, Standards Australia runs a certification schemewhereby this equipment can be type tested and certified ascomplying with a particular Australian Standard.Copyright Cooper IndustriesJune, 20101-5

Explosion Protection Techniques1-6Liquids, Gases & VapoursZONE 0CONTINUOUSLY HAZARDOUS(eg storage tank)PROTECTION TECHNIQUES APPLICABLEZONE 1Ex iaEx sINTRINSIC SAFETYSPECIALFREQUENTLY HAZARDOUSUNDER NORMAL CONDITIONS(eg container filling area, or a pump alleyin a refinery petrol pump)PROTECTION TECHNIQUES APPLICABLEZONE 2Ex ibEx dEx eEx pEx sINTRINSIC SAFETYFLAMEPROOFINCREASED SAFETYPRESSURISED OR PURGEDSPECIAL PROTECTIONINFREQUENTLY HAZARDOUSUNDER ABNORMAL CONDITIONS(eg sealed container stored above 3min a plant)PROTECTION TECHNIQUES APPLICABLEEx nNON SPARKINGDusts, Fibres & FlyingsZONES 21 & 22DUST PRESENT IN AIROR SETTLED ON LEDGES ETC(eg grain handling areas, starch and/orflour mills)PROTECTION TECHNIQUES APPLICABLEEx tD DUST TIGHT ENCLOSUREJune, 2010Copyright Cooper Industries

Explosion Protection TechniquesExplosion Protection Techniques Commonly Used in AustraliaEx iIntrinsic SafetyEx dFlameproofEx eIncreasedSafetyEx nEx nREx pNon SparkingRestrictedBreathingContainmentAvoidance ofignition sourceAvoidanceInstrumentation andprocess control equipmentPower equipment, high energy switching& HID lightingFluorescent lighting, junction boxesand marshalling boxesZone 2 only.Lighting and junction boxes cannot be usedwith internal components that arc or sparkExclusionof the hazardControl cubicles, instrumentationand electric motorsEx sSpecialEquipmentProved by testunable to causeignitionSpecially tested for specific applications(not widely used)Ex tDDustExcludingIgnition ProofExclusionof the dustAll electrical equipment utilised inDIP locationsNote:Pressurised EnclosureEnergylimitation1-7The Australian Wiring Rules AS3000 applies to all installations.Section 9 of AS3000 specifically refers to AS2381 for the special requirements for hazardous areas.Copyright Cooper IndustriesJune, 2010

Temperature Ratings & Gas Groups1-8T Ratings (temperature ratings)The Maximum Surface Temperature of Electrical Equipmentmust not exceed the Ignition Temperature of the HazardousSubstance, therefore the temperature rating of the equipment selected must be lower than the Ignition Temperatureof the Hazardous Substance present in the areaMax SurfaceTemperatureNECTable 500-3 (d)IECT Class3000CT2T24500CT12800CT2A230 CT2C2000CT3260 C002150CT2BT2D1800CT3A160 CT3C1200CT4A850CT6165 C001350C1000CT1T3T3BGas GroupsGas Groups and their Representative Gases are as follows:IECGroupIIIAIIBT4T4T5T5T6A "T" rating is assigned to equipment after testing to establish the maximum temperature reached during normal operation and under a 10% overload.Example:The components of the T ratings are:AMBIENT TEMPERATURE . 40 CTEMPERATURE RISE . 80K (Kelvin)(from test results)MAX. SURFACE TEMP. 120 CTherefore since the manufacturer is guaranteeing that thesurface temperature will not exceed the "T" rating theequipment would be assigned a T4 (135 C) rating.IIB (H2)IICRepresentativeGasMethane(underground CAWhile Gas Groups are shown on all forms of Protection theyreally only have any significance on Exd Flameproof type ofProtection where the dimensions of the flamepath vary according to the Gas Group.The table shows these differences.Gas GroupIIIAIIBIICFlamepath DimensionsWidth (mm)Max Gap (mm)12.50.212.512.5250.40.150.04The surface where the temperature is measured can varyaccording to the Type of Protection, for example.Exd Flameproof is taken on the exterior surface.Exe Increased Safety is taken on the internal componentsExn Non-Sparking is taken on the internal components unless the equipment is Certified as a "Restricted BreathingEnclosure" in which case it can be taken on the exteriorsurface.June, 2010Copyright Cooper Industries

Ingress Protection (IP) RatingsDegree of Protection Provided By EquipmentThe first numeral indicates protection ofpersons against access to dangerousparts and protection of internal equipmentagainst the ingress of solid foreign objects.XOIProtection unspecified (untested)123456No special protection providedProtection of hand against accidentalaccess to dangerous parts,and protection of equipment against objects larger than Ø 50mm*Protection of fingers against accessto dangerous parts and protection ofequipment against objects larger thanØ 12mmProtection against objects larger thanØ 2.5mm (eg tools, small wires)Protection against objects larger thanØ 1mm (eg tools, small wires)Protection against entry of dustin sufficient quantity to interfere withsatisfactory operation of equipmentComplete protection against entryof dust*This dimension applies to the smallest of the three mutuallyperpendicular dimensions of the object against which protectionis provided‘Flash’ symbol indicates dangerous parts (live or moving)P1-9The second numeral indicates protectionof internal equipment against harmfulingress of water.XOProtection unspecified (untested)12345678No special protection providedProtection against drops of waterfalling verticallyProtection against drops of waterfalling vertically when the object is tiltedby up to 150 from it’s normalposition (in any direction)Protection against spraying waterat up to 600 from the verticalProtection against splashing and spraying water from all practicabledirectionsProtection against a low pressure jetof water from all practicable directionsProtection against heavy seas or astrong jet of water from all practicabledirectionsProtection against immersionProtection against submersion(test subject to agreement, but no lesssevere than numeral 7)Note: The symbols shown in the above chart have been compiled for easy explanation only. They are not part of the IPcode and must not be used instead of the IP code. The chart should be used in conjunction with the AS1939 Classification ofDegrees of Protection provided by Enclosures for Electrical Equipment.The fact that electrical equipment is certified as being of a particular type of Explosion Protection does not mean that itautomatically has a degree of protection against weather or environment. Therefore if equipment is to be used in an outdoorenvironment care should be taken to ensure that it has appropriate IP Rating, as shown in the table.Copyright Cooper IndustriesJune, 2010

Combustible Compounds Reference1-10Compoundacetaldehydeacetic acidacetoneacetylacetoneacetyl chlorideacetyleneacrylonitrileallyl chlorideallyleneammoniaamphetamineamyl acetateamyl methyl ketoneanilinebenzenebenzaldehydebenzyl chlorideblue water enebutyl acetatebutlyaminebutyldigolbutyl methyl ketonebutyraldehydecarbon disulphidecarbon monoxidechlordimethyl hanolchloroethylenechloromethanechloropropanecoal tar naphthacoke oven dronaphthalenediacetone alcoholdiaminoethanediamyl etherdibutyl dichloropropanediesel fueldiethylaminediethylaminoethanoldiethyl etherdiethyl oxalatediethyl sulphatedihexyl ethyl etherdipropyl etherdioxaneepoxypropaneJune, (400)370379430TempGasClass thanolethyl acetateethyl acrylateethylbenzeneethyldigolethylene425ethylene oxideethyl formateethyl mercaptanethyl methyl etherethyl methyl ptanehydrogenhydrogen sulphideisopropyinitratejet fuelskerosenemethaldehydemethane (firedamp)methane (industrial)methanolmethoxyethanolmethyl acetatemethyl acetoacetatemethyl olmethyl ropyl methyl uryl ss IAIIAIIBIIBIIAIIAIIAIIAIIAIIAIIBIIAIIACopyright Cooper Industries

Combustible Compounds ReferenceCombustible dust-air mixtures have different ignition temperatures. The surface temperature of the equipment inareas with a risk of dust explosion mayreach 2/3rd of the minimum ignitiontemperature of the surrounding dust-airmixture at the maximum and with a5mm thick layer of dust must be at least780K below the minimum ignition temperature of the dust (glow temperaDust Type(name of Milk Powder (Full e (grinding dust)Petrol cokePolyvinyl acetatePolyvinyl iumManganeseZincCopyright Cooper Industriesture). It is therefore the owner’s job to ensurethat the cleaning and maintenance intervals ofinstallations with a dust risk are scheduled sothat no dust layers thicker than 5mm are allowed to form. At higher dust deposits the minimum ignition temperature (glow temperature)of the dusts are reduced dramatically. Examples for the ignition and glow temperaturescan be taken from the table below.Minimum Ignition Temperatureof a Dust Layer(glow temperature)Minimum Ignition Temperatureof a Dust Cloud370500460580in acc. with IEC61241-2-1 proc. ANatural Product Chemical Technical Product Examplesin acc. with IEC61241-2-1 proc. 40500280430220385280Metal 610330570June, 20101-11

Area Classifications - Comparison1-12Classification Comparison TableIECIEC & NECAustraliaZone 0Liquids, Gases & VapoursClass 1,Div 1Zone 1Zone 2Zone 20Dusts & FibresZone 21Zone 22Zone 20FlyingsNECZone 21Zone 22Class 2,Div 1, Div 2Class 3Area Groups Comparison TableNECAIECAcetyleneIIBEthyleneIIB H2DIIADIRepresentative GasIICBCJune, 2010GAS GROUPIHydrogenPropaneMethane(underground mining)Copyright Cooper Industries

International Standards Reference S/NZS60079.0AS2380.1Electrical equipment for explosive gas 1AS2380.2Electrical equipment forexplosivegas atmospheresFlameproof Enclosure ‘d’AS/NZS60079.2AS2380.4Electrical equipment for explosive gas atmospheresPressurised Roomsor Pressurised Enclosures ‘p’CenelecStandardEN60079-0Electrical apparatus for potentiallyexplosive atmospheresGeneral RequirementsEN60079-1Electrical apparatus for potentially explosive atmospheresFlameproof Enclosure ‘d’EN60079-2Electrical apparatus for potentially explosive atmospheresPressurised Enclosure ‘p’IEC StandardIEC60079-0Electrical apparatus for explosivegas atmospheresPart 0 - General RequirementsIEC60079-1Electrical apparatus for explosivegas atmospheresConstruction & verification test offlameproof enclosures of electricalapparatusIEC60079-2Electrical apparatus for explosivegas atmospheresElectrical apparatus type of protection ‘p’AS/NZS60079.5Electrical equipment for explosive gas atmospheresPowder Filling ‘q’EN60079-5Electrical apparatus for potentially explosive atmospheresPowder Filling ‘q’AS/NZS60079.11AS2380.7Electrical equipment for explosive gas atmospheresIntrinsic Safety ‘i’EN60079-11Electrical apparatus for potentially explosive atmospheresIntrinsic Safety ‘i’IEC60079-11Electrical apparatus for explosivegas atmospheresIncreased Safety ‘i’EN60079-18Electrical apparatus for potentially explosive atmospheresEncapsulation ‘m’IEC60079-18Electrical apparatus for explosivegas atmospheresEncapsulation ‘m’AS/NZS60079.7AS2380.6Electrical equipment for explosive gas atmospheresIncreased Safety ‘e’EN60079-7Electrical apparatus for potentially explosive atmospheresIncreased Safety ‘e’AS/NZS60079.15Electrical equipment for explosive gas atmospheres. Explosionprotection techniquesType of protection ‘n’ non sparkingEN60079-15Electrical apparatus for explosivegas atmospheresElectrical apparatus withtype of protection ‘n’AS/NZS61241.1Electrical equipment for explosive dust atmospheresElectrical apparatus protected byenclosuresEN61241-1Electrical apparatus for use in thepresence of combustible dustElectrical apparatus protected byenclosuresAS/NZS60079.18Electrical equipment for explosive gas atmospheresType of protection ‘m’AS60529Electrical apparatus for use inthe presence of combustible dustCopyright Cooper IndustriesEN60529Specification for degrees of protection provided by enclosures(IP Code)IEC60079-5Electrical apparatus for explosivegas atmospheresPowder Filling ‘q’IEC60079-7Electrical apparatus for explosivegas atmospheresIntrinsic Safety ‘e’IEC60079-15Electrical apparatus for explosivegas atmospheresElectrical apparatus withtype of protection ‘n’IEC61241-1Electrical apparatus for use inthe presence of combustible dustElectrical apparatus protected byenclosuresIEC60529Classification of degrees ofprotection provided by enclosures(IP Code)June, 20101-13

CEAG IEC Ex Approved Products - CEAG 805 CatalogueProduct Description1-14GHG960 Exe FRP glands & plugsCapri ADE series metal glandsGHG273 series lighting switchesGHG791 series small JBGHG791 series small JB with terminalsGHG7311 & GHG7312 terminal boxesGHG72100 & GHG72110 terminal boxesGHG74 series terminal boxesGHG723 series light alloy terminal boxesC30 & C31 small JB in aluminumNXTS stainless steel JBEx-Cell stainless steel JBSTB stainless steel JBGHG74 stainless steel series terminal boxesGHG791 motor terminal boxesGHG72100 motor terminal boxesGHG745 motor terminal boxesGHG746 motor terminal boxesGHG411 series push button control stations in FRPGHG432/4 series push button control stations FRPGHG413 series push button control stations in light alloyGHG414 series push button control stations in SSGHG44 series push button control stations FRPGHG44X33 series push button control stations SSGHG292/ 293 RCU in FRPGHG295 / 294 RCU in light alloyESF - Nortem control stationsGHG61 distribution panel in FRPGHG61 distribution panel in SSGHG61 components - breakersGHG61 components - fuseGHG61 components - isolators 20 - 180AGHG61 components - contactorsGHG61 components - DOLGHG61 components - contactorsGHG61 components - manual motor starterGHG61 components - thermal over current relayGHG61 components - over voltage arrestorGHG61 components - star-delta timer relayGHG61 components - multi-function relayGHG61 empty enclosures FRP (not for sale as stand alone item)GHG61 empty enclosures SS (not for sale as stand alone item)June, 2010EJB Nortem enclosure IIB, IP651Zones221 / 22 Ref No.CEAG 805 Cat8.2 to 8.68.10 to 8.189.4 to 9.57.4 to 7.7IEC ExCertificate No.IECEx PTB 05.0004XIECEx LCI 05.0004XIECEx BKI 07.0036IECEx BKI 07.00347.12 to 7.14IECEx BKI 07.00347.17 to 7.19IECEx BKI 05.00057.14 to 7.167.20 to 7.257.28 to 7.317.23 to 7.357.38 to 7.477.48 to 7.617.62 to 7.697.70 to 7.717.72 to 7.737.74 to 7.747.75 to 7.757.76 to 7.779.6 to 9.12IECEx BKI 05.0004IECEx BKI 05.0006IECEx BKI 07.0034IECEx BKI 07.0026IECEx BKI 08.0010IECEx BKI 08.0004IECEx BKI 08.0010IECEx BKI 05.0006IECEx BKI 07.0034IECEx BKI 05.0005IECEx BKI 05.0006IECEx BKI 05.0006IECEx BKI 04.00039.13 to 9.19IECEx BKI 04.00039.26 to 9.30IECEx BKI 04.00039.20 to 9.249.42 to 9.459.48 to 9.78IECEx BKI 04.0003IECEx BKI 07.0023IECEx BKI 07.00239.112 to 9.118IECEx BKI 07.00119.126 to 9.127IECEx BKI 07.00279.120 to 9.12511.2 to 11.1111.12 to 11.1511.16 to 11.2911.30 to 11.3111.32 to 11.3311.34 to 11.3611.37 to 11.3911.40 to 11.4311.48 to 11.50IECEx BKI 07.0011IECEx BKI 06.0007IECEx BKI 06.0007IECEx BKI 07.0038UIECEx BKI 07.0035UIECEx BKI 06.003/4/6UIECEx BKI 06.0038UIECEx BKI 06.0038UIECEx BKI 06.0038UIECEx BKI 06.0038U11.51 to 1152IECEx BKI 06.0038U11.55 to 11.55IECEx BKI 06.0038U11.53 to 11.5411.56 to 11.5711.60 to 11.6111.62 to 11.6311.74 to 11.85IECEx BKI 06.0038UIECEx BKI 06.0038UIECEx BKI 06.0007IECEx BKI 06.0007IECEx BKI 07.0018Copyright Cooper Industries

CEAG IEC Ex Approved Products - CEAG 805 CatalogueProduct DescriptionStabex Mini hand torch lightStabex HF hand torch lighteLLK92 series zone 1, 2, 21 & 22 fluorescent lighteLLB200 series recessed fluorescent lightAB12 EX d series fluorescent lightEVF Ex d series fluorescent lightnLLK98 series zone 2, 21, 22 fluorescentEXIT N - LED emergency EXIT LightAB12 Ex d NAV 70, 70W HPSAB51 Ex d pendant light fitting for Incandescent, halogen & MVEVI 200 / EVI 500 Ex d Incandescent and HID to 250Wminus control gearEVQ Ex d Induction lamp EQ55 and EQ85EV Ex d HID well glass series with integral control gearFZD Ex d light weight HID floodlight with integral control gearPX Ex d HID flood HID with integral control-gearKFL Vessel lightEx-Link plugs and receptaclesGHG511 series 16A Plugs & SocketsGHG512 series 32A Plugs & SocketsGHG514 series 63A Plugs & SocketsGHG515 series 125A Plugs & SocketsCopyright Cooper Industries1Zones221 / 22 Ref No.CEAG 805 Cat1.6 to 1.91.6 to 1.9IEC ExCertificate No.IECEx BKI 08.002IECEx BKI 08.0032.13 to 2.25IECEx BVS-09.00332.47 to 2.5IECEx BKI 07.0008X2.26 to 2.37IECEx BKI 08.00172.51 to 2.54IECEx BKI 07.0033X 3.8 to 3.15IECEx BKI 06.0003 5.13 to 5.14IECEx BKI 07.0028X 5.18 to 5.19IECEx BKI 07.0031X 2.56 to 2.615.8 to 5.95.15 to 5.175.20 to 5.225.24 to 5.295.30 to 5.335.46 to 5.486.6 to 6.44IECEx BKI

Cooper Crouse-Hinds Pauluhn 1616 N Main St Pearland, TX 77581 (281) 485-4311 FAX: (281) 485-4398 crouse.pauluhn@cooperindustries.com Cooper Crouse-Hinds Airport Lighting 1200 Kennedy Road Windsor, CT 06095 (860) 683-4354 FAX: (860) 683-4354 chalptechsupport@cooperindustries.com Cooper Crouse