Transcription

THEPROPANETECHNICALPOCKETGUIDEwww.nypropane.com

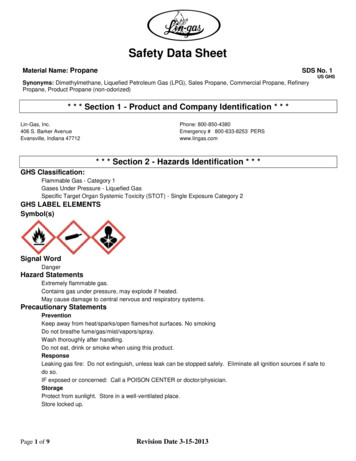

The Propane Technical Pocket GuideThe Propane Technical Pocket Guide is intended to bea general reference of information on preparing for theinstallation of propane systems. It provides key dataand answers important questions that are relevantto construction professionals planning to incorporatepropane in their construction projects.This guide is not intended to conflict with federal, state,or local ordinances or pertinent industry regulations,including National Fire Protection Association (NFPA)54 and 58. These should be observed at all times.The Propane Technical Pocket Guide must not beconsidered a replacement for proper training on theinstallation and start-up of propane systems. Propanesystem installations should always be performed bytrained propane professionals. For more informationgo to propanesafety.com.

Table of Contents2 PROFESSIONALLY ACCREDITED TRAINING3 PROPERTIES OF GAS6 VAPOR PRESSURE OF GAS7 DETERMINING TOTAL LOAD9 VAPORIZATION RATES11 CONTAINER LOCATION AND INSTALLATION14 PIPE AND TUBING SIZING16 GAS PIPING INLET POSITIONING17 CONVERSION FACTORS1

Professionally Accredited TrainingThe Propane Education & Research Council (PERC)provides free AIA-, NAHB-, USGBC-, and NARIapproved continuing education courses. Fulfill your CEUrequirements today at buildwithpropane.com/training.Energy Efficiency Go Green With Propane: An Overview of Propane Gas Systems forGreen Residential Construction Propane-Enhanced Renewable Energy Systems Residential Energy Performance Upgrades: An Energy, Economic,and Environmental Analysis Understanding the 2009 IECC Energy Code, Advanced EfficiencyPrograms, and Their Implications for Propane Energy and Environmental Analysis of Propane Energy Pod HomesGenerators Specifying Propane Standby Generators: Installation and ValueConsiderations Living Off-Grid: Power Generation and Storage BasicsHeating A Comparative Analysis of Residential Heating SystemsHydronic Heating in Rural Residential ApplicationsPropane Enhanced Solar Water HeatingRetrofitting Homes from Heating Oil to Propane: Efficiency,Economic, and Environmental Benefits Heating Oil Conversion: Exploring Propane as a Viable AlternativeEnergy SourceOutdoor Living Expanding Outdoor Living: Using Propane for Efficient andSustainable Outdoor Living Innovations With Propane Gas for Outdoor Residential UsePropane Systems Community Propane Tanks: Economical, EnvironmentallyResponsible Energy Without Geographic Limits Propane Gas Underground Systems: Residential InfrastructureRequirements and Energy BenefitsWater Heating A Comparative Analysis of Residential Water Heating Systems Water Heaters: Retrofitting from Standard Electric to Gas Tankless Condensing Tankless Water Heaters: Using Propane for the MostEfficient Water Heaters on the Market2

Properties of Propane and Natural Gas(Methane)Table 1A. Approximate Properties of Gases (English)PropaneNatural GasC3H8CH4-44-2590.504n/aWeight per Gallon of Liquidat 60 F, LB4.2n/aSpecific Heat of Liquid,Btu/LB at 60 F0.63n/aCubic Feet of Vapor per Gallonat 60 F36.38n/aCubic Feet of Vapor per Poundat 60 F8.6623.55Specific Gravity of Vapor(Air 1.0) at 60 F1.50.6Ignition Temperature in Air, F920–11201301Maximum Flame Temperaturein Air, F35952834Cubic Feet of Air Required toBurn One Cubic Foot of Gas23.689.57Limits of Flammability in Air,% of Vapor in Air-Gas Mix:(a) Lower(b) Upper2.159.6515Latent Heat of Vaporizationat Boiling Point:(a) Btu per Pound(b) Btu per Gallon184773219n/aTotal Heating Values AfterVaporization:(a) Btu per Cubic Foot(b) Btu per Pound(c) Btu per al Boiling PointSpecific Gravity of Liquid(Water at 1.0) at 60 F3 3

Properties of Gas(Continued)Table 1B. Approximate Properties of Gases (Metric)PropaneNatural GasC3H8CH4-42-1620.504n/a504n/aSpecific Heat of Liquid,Kilojoule/Kilogram at 15.56 C1.464n/aCubic Meter of Vapor per Literat 15.56 C0.271n/aCubic Meter of Vapor per Kilogramat 15.56 C0.5391.470Specific Gravity of Vapor(Air 1.0) at 15.56 C1.500.56PROPERTYInitial Boiling Point, CSpecific Gravity of Liquid(Water at 1.0) at 15.56 CWeight per Cubic Meterof Liquid at 15.56 C, kg493–604705Maximum Flame Temperature inAir, ºCIgnition Temperature in Air, ºC1,9801,557Cubic Meters of Air Required toBurn One Cubic Meter of Gas23.869.57Limits of Flammability in Air, %of Vapor in Air-Gas Mix:(a) Lower(b) Upper2.159.65.015.0Latent Heat of Vaporization atBoiling Point:(a) Kilojoule per Kilogram(b) Kilojoule per Liter428216509n/aTotal Heating Values AfterVaporization:(a) Kilojoule per Cubic Meter(b) Kilojoule per Kilogram(c) Kilojoule per Liter92,43049,92025,14037,70655,533n/a4

Table 1C. Energy Content and Environmental Impactof Various Energy SourcesPropane(per ft3)MethanePropane(per gallon)Fuel OilElectricityEnergy tu/gal3,413Btu/kWhCO2 emissions ltipliers*1.1511.0921.1511.1583.365*Source Energy Multiplier is the total units of energy that go intogeneration, processing, and delivery for a particular energy source toproduce one unit of energy at the site.5 5

Vapor Pressure of GasVapor pressure can be defined as the force exerted by a gasor liquid attempting to escape from a container. This pressuremoves gas along the pipe or tubing to the appliance burner.Outside temperature greatly affects container pressure.Lower temperature means lower container pressure. Too low acontainer pressure means that not enough gas is able to get tothe appliance.The table below shows vapor pressures for propane and butaneat various outside temperatures.TEMPERATUREºFºCTable 2. Vapor PressuresApproximate Vapor Pressure, PSIG .6-40-40(0,25)84.5-30-34,4 (0,55) (0,31)13.59.24.91.9-20-28,9 (0,93)(0,63) (0,34) (0,13)2016963.5-10-23,3(1,4)(1,1) (0,62) (0,41) (0,24)282215117.30-17,8(1,9)(1,5)(1,0) (0,76) 0) (0,23)47362823187.420-6,7(3,2)(2,5)(1,9)(1,6)(1,2) 01129582569032,2 037,8 (13,5) (11,6) (9,4)(8,5)(6,9)(4,8)2201851651481308011043,3 (15,2)(12,8) (11,4) (10,2) (9,0)(5,5)Table adapted from LP-Gas Serviceman’s Handbook 2,0)36(2,5)45(3,1)

Determining Total LoadThe best way to determine Btu input is from the appliancenameplate or from the manufacturer’s catalog. Add the inputof all the appliances for the total load. If specific appliancecapacity information is not available, Table 3A below will beuseful. Remember to allow for appliances that may be installedat a later date.If the propane load in standard cubic feet per hour (SCFH)is desired, divide the Btu/hr load by 2,488 to get SCFH.Conversely, the Btu/hr capacity can be obtained from SCFHby multiplying the SCFH figure by 2,488.Figuring the total load accurately is most important because ofthe size of the pipe and tubing, the tank, and the regulator willbe based on the capacity of the system to be served.Table 3A. Gas Required for Common AppliancesAPPLIANCEWarm Air FurnaceSingle FamilyMultifamily, per UnitHydronic Boiler, Space HeatingSingle FamilyMultifamily, per UnitHydronic Boiler, Space and Water HeatingSingle FamilyMultifamily, per UnitRange, Freestanding, DomesticBuilt-In Oven or Broiler Unit, DomesticBuilt-In Top Unit, DomesticWater Heater, Storage, 30 to 40 gal. TankWater Heater, Storage, 50 gal. TankWater Heater, Tankless2.5 GPM3 GPM4 GPMWater Heater, Domestic, Circulating or Side-ArmRefrigeratorClothes Dryer, Type 1 (Domestic)Gas Fireplace Direct VentGas LogBarbecueGas LightTable adapted from Newport Partners, 2011.ApproximateInput 40,000–80,0001,400–2,8007 7

Determining Total Load(Continued)A variety of mechanical systems are available for spaceheating and water heating in homes. These systems havevarying energy sources and varying efficiency levels. Table 3Bbelow provides simple calculations that allow contractors andhomeowners to estimate the dollars per million Btus depending on the equipment type, efficiency, and energy price. The“ /MMBtu” figure can be compared across different optionsto evaluate them.Table 3B. Operating Costs and Equipment Efficienciesof Residential Space and Water Heating SystemsSPACE HEATINGPricing EstimationFormula( /MMBtu)Typical EquipmentEfficiency Ranges forNewer SystemsPropane(furnace or boiler)(10.9 x /gal)(AFUE/100)AFUE: 78–98Natural Gas(furnace or boiler)(10 x /therm)(AFUE/100)AFUE: 78–98Fuel Oil(furnace or boiler)(7.2 x /gal)(AFUE/100)AFUE: 78–95ElectricResistance293 x /kWhCOP: 1.0Electric Air SourceHeat Pump(1000 x /kWh)HSPFHSPF: 7.7–13.0Electric GroundSource Heat Pump(293 x /kWh)COPCOP: 3.0–4.7WATER HEATINGPricing EstimationFormula( /MMBtu)TypicalStorage WaterHeater EnergyFactors (EF)TypicalInstantaneousWater HeaterEnergy Factor(EF)Propane(10.9 x /gal)/EF0.59–0.67*0.82–0.98Methane(10 x /therm)/EF0.59–0.70*0.82–0.98Fuel Oil(7.2 x .51—ElectricResistance(293 x /kWh)/EFElectric Air SourceHeat Pump(293 x /kWh)/EF*Residential and commercial units are available with thermal efficienciesup to 96%.8

Vaporization RatesThe factors affecting vaporization include wetted surface areaof the container, liquid level in the container, temperature andhumidity surrounding the container, and whether the containeris aboveground or underground.The temperature of the liquid is proportional to the outside airtemperature, and the wetted surface area is the tank surfacearea in contact with the liquid. Therefore, when the outside airtemperature is lower or the container has less liquid in it, thevaporization rate of the container is a lower value.To determine the proper size of ASME storage tanks,it is important to consider the lowest winter temperatureat the location.See page 10 for more information.9 9

Vaporization Rates for ASMEStorage TanksA number of assumptions were made in calculating the Btufigures listed in Table 4, below:1 The tank is one-half full.2 Relative humidity is 70 percent.3 The tank is under intermittent loading.Although none of these conditions may apply, Table 4 can stillserve as a good rule of thumb in estimating what a particulartank size will provide under various temperatures. This methoduses ASME tank dimensions, liquid level, and a constantvalue for each 10 percent of liquid to estimate the vaporizationcapacity of a given tank size at 0 F. Continuous loading isnot a very common occurrence on domestic installations,but under continuous loading the withdrawal rates in Table 4should be multiplied by 0.25.Table 4. Maximum Intermittent Withdrawal Rate(Btu/hr) Without Tank Frosting* If Lowest OutdoorTemperature (Average for 24 Hours) Reaches .TEMPERATURETank Size, Gallons (l)150 (568)250 (946)500 (1893)1000 (3785)40ºF4 C214,900288,100478,800852,80030ºF-1 C187,000251,800418,600745,60020ºF-7 C161,800216,800360,400641,90010ºF-12 C148,000198,400329,700587,2000ºF-18 C134,700180,600300,100534,500-10ºF-23 C132,400177,400294,800525,400-20ºF-29 C108,800145,800242,300431,600-30ºF-34 C107,100143,500238,600425,000*Tank frosting acts as an insulator, reducing the vaporization rate.10

Container Location and InstallationOnce the proper size of the ASME storage tank has beendetermined, careful attention must be given to the mostconvenient yet safe place for its location on the customer’sproperty.The container should be placed in a location pleasing to thecustomer but not conflicting with state and local regulationsor NFPA 58, Storage and Handling of Liquefied PetroleumGases. Refer to this standard and consult with your propaneprofessional to determine the appropriate placement ofpropane containers.In general, storage tanks should be placed in an accessiblelocation for filling. Aboveground tanks should be supportedby concrete blocks of appropriate size and reinforcement.All propane storage tanks should be located away fromvehicular traffic.For ASME containers, the distance from any building openings,external sources of ignition, and intakes to direct-vented gasappliances or mechanical ventilation systems are a criticalconsideration. See Figures 5 and 6 on pages 12 and 13,respectively.Refer to NFPA 58 for the minimum distances that thesecontainers must be placed from a building or other objects.1111

1200–20galw.c.25 ft(min)10 ft (min)10 ft(min)125gal –500w.c.10 ft(min)Window airconditioner(source ofignition)125Underc.gal w.2. The distance may be reduced to no less than 10 ft for a single containerof 1200 gal (4.5 m3) water capacity or less, providedsuch container is at least 25 ft from any other LP-Gas containerof more than 125 gal (0.5 m3) water capacity.25 ft(min)5 ft (min)Under 125gal w.c.10 ft (min)(Continued)1. Regardless of its size, any ASME tank filled on site must belocated so that the filling connection and fixed maximumliquid level gauge are at least 10 ft from any external sourceof ignition (e.g., open flame, window AC, compressor), intaketo direct-vented gas appliances or intake to a mechanicalventilation system.50110 ft (min)Intake to directvent applianceCentral ACcompressor(source of ignition)Container LocationFigure 5. Aboveground ASME containers. Reproduced with permission from NFPA58-2011, Liquefied Petroleum Gas Code, Copyright 2010, National FireProtection Association. This reprinted material is not the complete and officialposition of the NFPA on the referenced subject, which is represented only bythe standard in its entirety.

Figure 6. Underground ASME containers. Reproduced with permission from NFPA58-2011, Liquefied Petroleum Gas Code, Copyright 2010, National FireProtection Association. This reprinted material is not the complete and officialposition of the NFPA on the referenced subject, which is represented only bythe standard in its entirety.13 13Nearest line of adjoiningproperty that can bebuilt upon2000or lessgal w.c.10 ft (min)(Note 1)1. The relief valve, filling connection, and fixed maximum liquidlevel gauge vent connection at the container must be at least10 ft from any exterior source of ignition, openings intodirect-vent appliances, or mechanical ventilation air intakes.Central ACcompressor(source of ignition)10 ft (min)(Note 1)10 ft (min)(Note 1)Intake to directvent appliance10 ft (min)(Note 2)10 ft (min)(Note 2)Crawl space opening,window, or exhaust fan2. No part of an underground container can be less than 10 ftfrom an important building or line of adjoining property thatcan be built upon.Window airconditioner(source of ignition)

14Table 7. Pipe Sizing Between Second-Stage Regulator and 35899710712014115517525554163278811461 9161723531-1/4 1946242335251-1/2 in.(1.61)Nominal Pipe Size, Schedule 47466667892 800990361055813148191303 in.(3.068)Adapted with permission from NFPA 58-2011, Liquefied Petroleum Gas Code, Copyright 2010, National Fire Protection Association. This reprintedmaterial is not the complete and official position of the NFPA on the referenced subject, which is represented only by the standard in its entirety.Note: Capacities are in 1000 221105060336287161137304186083/4 in.(0.824)4029120010201/2 in.(0.622)Piping 2511726132301545819250280083-1/2 80116335184312153526817390184 in.(4.026)MAXIMUM UNDILUTED PROPANE CAPACITIES BASED ON 10.0 PSI INLET PRESSURE AND 1.0 PSI PRESSURE DROP. (BASED ON A 1.52 SPECIFIC-GRAVITY GAS.)

995749251770Tubing Length, 6159988547412014100143123756636311511150Adapted with permission from NFPA 58-2011, Liquefied Petroleum Gas Code, Copyright 2010, National Fire Protection Association. This reprintedmaterial is not the complete and official position of the NFPA on the referenced subject, which is represented only by the standard in its entirety.*Table includes losses for four 90 bends and two end fittings. Tubing runs with larger numbers of bend and/or fittings shall be increased by an equivalentlength of tubing to the following equation: L 1.3n where L is the additional length (ft) of tubing and n is the number of additional fittings and/or bends.**EHD (Equivalent Hydraulic Diameter) A measure of the relative hydraulic efficiency between different tubing sizes. The greater the value of EHD, the greaterthe gas capacity of the tubing.35542623251812111899151972513EHD** FLOWDESIGNATIONTable 8. Maximum Capacity of CSST*129112696033281492001179961533025128250IN THOUSANDS OF BTU/HR OF UNDILUTED PROPANE AT A PRESSURE OF 11-INCHES W.C. AND A PRESSURE DROP OF 0.5-INCH W.C.(BASED ON A 1.52 SPECIFIC GRAVITY GAS)1079057502623118300

Gas Piping Inlet PositioningJust like tanks, propane pressure regulators come withpipe-size and installation-distance requirements. Regulatorsinstalled on the gas piping system at the side of buildingscannot be placed closer than 3 feet horizontally from anybuilding opening, such as a window well, that’s lower thanthe installed regulator. Nor can they be placed closer than5 feet from any source of ignition, such as an ACcompressor. Additional regulations, as well as regulatormanufacturer’s instructions, may apply. Check with apropane professional first to ensure you comply with interiorgas piping inlet positioning requirements.16

Conversion FactorsMultiplyByTo Obtain0.03943.28080.155010.764InchesFeetSq. InchesSq. Cubic FeetCubic FeetCubic FeetCubic InchesPints (US)Gallons (US)PoundsTons (US)LENGTH AND AREAMillimetersMetersSq. CentimetersSq. MetersVOLUME AND MASSCubic MetersLitersGallonsCubic cm.LitersLitersKilogramsTonnesPRESSURE AND FLOW RATEMillibarsOunces/sq. in.Inches w.c.BarsKilopascalsKilograms/sq. cm.Pounds/sq. in.Liters/hr.Cubic .03534.403Inches w.c.Inches w.c.Pounds/sq. in.Pounds/sq. in.Pounds/sq. in.Pounds/sq. in.AtmospheresCubic ories, kgWattsBtuMegajoules17 17

Conversion FactorsMultiplyByTo Obtain25.40.30486.45160.0929MillimetersMetersSq. CentimetersSq. 1Cubic MetersLitersGallonsCubic cm.LitersLitersKilogramsTonnesLENGTH AND AREAInchesFeetSq. InchesSq. FeetVOLUME AND MASSCubic FeetCubic FeetCubic FeetCubic InchesPints (US)Gallons (US)PoundsTons (US)PRESSURE AND FLOW RATEInches w.c.Inches w.c.Pounds/sq. in.Pounds/sq. in.Pounds/sq. in.Pounds/sq. in.AtmospheresCubic 0314.69628.3160.2271MillibarsOunces/sq. in.Inches w.c.BarsKilopascalsKilograms/sq. cm.Pounds/sq. in.Liters/hr.Cubic ories, sTherms18

Temperature ConversionTable 9. Temperature Conversion F C F C F 12.27021.114060.020-6.78026.715065.6All trademarks shown are the property of their respective owners.1919

Notes20

nfo@propane.comPO Box 760Clifton Park, NY 12065www.nypropane.comScan this code to connect to training.Need a code reader?Download one at ScanLife.com.Propane Education & Research Council1140 Connecticut Ave. N.W., Suite 1075Washington, DC 20036 Propane Education & Research Council 01/12The Propane Education & Research Council was authorized by the U.S.Congress with the passage of Public Law 104-284, the Propane Educationand Research Act (PERA), signed into law on October 11, 1996. The missionof the Propane Education & Research Council is to promote the safe,efficient use of odorized propane gas as a preferred energy source.

Living Off-Grid: Power Generation and Storage Basics Heating A Comparative Analysis of Residential Heating Systems Hydronic Heating in Rural Residential Applications Propane Enhanced Solar Water Heating Retrofitting Homes from Heating Oil to