Transcription

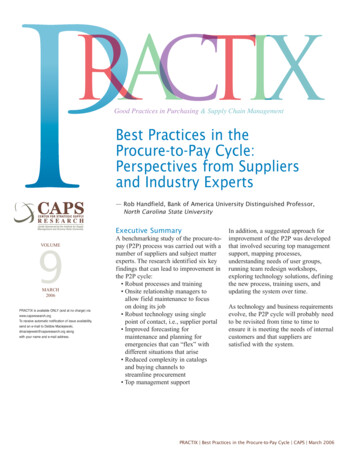

Best Practices in theProcure-to-Pay Cycle:Perspectives from Suppliersand Industry Experts— Rob Handfield, Bank of America University Distinguished Professor,North Carolina State UniversityExecutive SummaryVOLUME9MARCH2006PRACTIX is available ONLY (and at no charge) viawww.capsresearch.orgTo receive automatic notification of issue availability,send an e-mail to Debbie Maciejewski,dmaciejewski@capsresearch.org alongwith your name and e-mail address.A benchmarking study of the procure-topay (P2P) process was carried out with anumber of suppliers and subject matterexperts. The research identified six keyfindings that can lead to improvement inthe P2P cycle: Robust processes and training Onsite relationship managers toallow field maintenance to focuson doing its job Robust technology using singlepoint of contact, i.e., supplier portal Improved forecasting formaintenance and planning foremergencies that can “flex” withdifferent situations that arise Reduced complexity in catalogsand buying channels tostreamline procurement Top management supportIn addition, a suggested approach forimprovement of the P2P was developedthat involved securing top managementsupport, mapping processes,understanding needs of user groups,running team redesign workshops,exploring technology solutions, definingthe new process, training users, andupdating the system over time.As technology and business requirementsevolve, the P2P cycle will probably needto be revisited from time to time toensure it is meeting the needs of internalcustomers and that suppliers aresatisfied with the system.PRACTIX Best Practices in the Procure-to-Pay Cycle CAPS March 2006

Procure-to-Pay CycleIntroductionAs companies are seeking to move beyondprocurement into fully deployed supply chainsystems, a key challenge for many of them isin the area of improving efficiency in theirprocure-to-pay cycles for many of theircontracted services, especially in the area offacilities maintenance and onsite contractmanagement. There exist multiple challengesin environments where field associates areworking from manual or electronic systems,requisitioning onsite services for maintenance orother activities, and ensuring that thisinformation is captured effectively. In addition,there exist significant challenges to ensure thatthe proper service level agreement is fulfilled,the correct price is charged, the purchase order istransmitted correctly, the invoice matches, andfinally, that the supplier is paid the correctamount for the actual services delivered.While many enterprise systems claim thatthese elements are simply defined withintheir structural logic, the truth is that there aremany opportunities for error, and that without aFigure 1:Procure-to-PayGeneric“High-Level”Process MapThis benchmarking study sought to define andunderstand the best practices currently beingemployed by companies in the procure-to-paycycle for services. Specifically, the researchteam focused on learning and sharing bestpractices in the following areas, shown inFigure 1: Forecasting and Planning of Requirements Need Clarification/Specification Sourcing Decisions in Emergency/Non-Emergency Situations Contract PO Generation for Structuredor Unstructured Requirements Receiving of Services, Materials,and Documents Settlement and Payment inAccounts PayablePROCURE-TO-PAYGeneric “High-Level” Process MapSTARTForecastPlan Enablers: Finance, Legal, HR, IT2planned process for managing the procure-topay cycle, the organization may be bearingsignificant costs due to non-compliance tosystem or process Contract/POGenerationReceiveMaterial &DocumentsENDSettle &PaySupplierNeedFulfillmentPRACTIX Best Practices in the Procure-to-Pay Cycle CAPS March 2006

Procure-to-Pay CycleSymptoms and Root Causes: ASupplier’s View of the P2P ProcessResearchers first began by identifying the truecustomer of the P2P process: the supplier whowishes its invoice to be paid quickly. Manyorganizations are seeking to build and extendrelational capital with suppliers by building trustand becoming the “customer of choice.” Thecapital gained through this approach can resultin preferred supplier delivery priorities,information sharing, participation on suppliercouncils, and other important rewards. Animportant element in becoming a customer ofchoice is to enable rapid payment and equitableand ethical treatment of suppliers.To address some of the major problemsidentified by suppliers, researchers scheduleda series of interviews with a group of suppliers,to identify their experiences with the currentprocure-to-pay process with some of theirmajor customers.SYMPTOMSFREQUENCY OF RESPONSESIssue/OpportuntiyTOTALManual workarounds and high manpower7Long cycle time/Late payments/Aged invoices6No central point of contact5PO/Invoice match problem5Not enough funds on PO4Emergency work never properly recorded3Figure 2:Symptoms Identified by SuppliersAs shown in Figure 2, the most commonsymptoms experienced by suppliers involvehigh manual workarounds required to addressproblems, long cycle times for payment, nocentral point of contact, and a problem withmatching the PO and invoice. Some of thetypical responses from suppliers in thesecategories involved having to contact accountspayable multiple times, having to re-submitinvoices, and waiting 90 or more days in somecases for payments.3Root CausesSuppliers interviewed also noted a number ofroot causes associated with the P2P problems.As shown in Figure 3, the most common rootcauses were associated with the lack of aformally designed P2P process, the lack of acentral relationship management, or problemsassociated with supplier interfaces with SAP.Other reasons included the increased complexityassociated with SAP catalog and line items, andthe lack of a forecasting process.ROOT CAUSEFREQUENCY OF RESPONSESIssueTOTALPoorly designed process8No relationship manager/point of contact6Lack of system/portal interface5Too much complexity in SAP catalog/line items5No forecast or plan in place4Too many suppliers drive complexity1Figure 3:Root Causes Identified by SuppliersAs can be seen from these examples — thefundamental root causes are 1) a lack ofa process with designated roles and 2) specificprocesses associated with different internal andexternal functions are not defined. Maintenancepeople, buyers, planners, schedulers, accountspayable, project planners, and others are not“in sync.” Further, the system is not designed tobe able to withstand the various approachesin which people are entering data and requestinginformation. When too many people are notusing the system in a unified manner, it is nowonder that the system rejects the input andcauses problems. This indicates that either thetolerances of such systems must be changed,or that the manner in which the system is usedmust be changed.PRACTIX Best Practices in the Procure-to-Pay Cycle CAPS March 2006

Procure-to-Pay CycleRecommended SolutionsThese same set of issues were identified inrecommended solutions suggested by suppliers.The suppliers recommended that their customersexplore the solutions shown in Figure 4.RECOMMENDED ACTIONSFREQUENCY OF RESPONSESRecommended ActionTOTALRedesigned P2P process deployed7Dedicated relationship management position7Develop supplier portal using SAP Interface7Spend analysis and catalog item reduction initiative7Senior executive workshop to describe requirements4Develop standard forecasting process4Develop supply base reduction initiative1Figure 4:Recommended Actions Suggested by SuppliersThe top four elements that were identified aspossible solutions included redesigning the P2Pprocess, developing a dedicated relationshipmanager to work with suppliers on key areasof interface, exploring the use of a supplierportal using the CATS interface in SAP, andreducing catalog items through spend analysis,limiting the inherent complexity of enteringinformation into the SAP system.These responses by and large provide significantinsights into the problems and complexitiesassociated with improving the P2P cycle froma supplier’s perspective. Unfortunately, theseissues also translate into significant problemsfor the purchasing organization, which is oftenlost in translation when the need for P2Pimprovement is communicated to a seniormanagement team.Late payment and excessive workaround toobtain payment in a timely manner will definitelyincrease the cost to serve for companies with a“broken” P2P process. Typical problems that canoccur when a malfunctioning P2P process is not4fixed include one or more of the following events: Deteriorating response time from supplierswho have no motivation to improveperformance or respond quickly to customerswho fail to pay them for 90 days or more. Lower service levels from suppliers whomay choose to service their more profitablecustomers first in their cost-to-serve model. Deterioration as the customer of choice inthe mind of supplier’s senior management,which further breaks down trust andstrategic alignment. Delivery delays. Higher pricing due to the costs attributedto late payment and excessive manpowerallocated to the account. Increased manpower on non-value-addedactivities (e.g., chasing payments) to thedetriment of other value-added activitiesthat can improve customer service. Loss of the supplier as a critical linkin the supply chain. Higher costs internally for the purchasingcompany, which must also dedicate APpeople and buyers to non-value-addedactivities.Subject Matter Expert Insightsinto the P2P ProcessA number of senior procurement executivesfrom a variety of different industries were alsointerviewed to understand their responses to thesame problems associated with the P2P cycle.Each of these individuals provided a differentperspective on how to improve the P2P process,but their combined thoughts resulted in somecommon themes that validated many of thesuppliers’ suggested recommendations as well.Robust Processes and TrainingA critical element identified by all of thesubject matter experts was the need to developstandardized processes and training around theP2P process. Specifically, roles and duties ofthe different people involved in the process mustbe clearly defined. In addition, training shouldemphasize how invoices and requests should bePRACTIX Best Practices in the Procure-to-Pay Cycle CAPS March 2006

Procure-to-Pay Cycleprocessed, the reasons why deviation from theprocess is unacceptable, and the consequencesinvolved with deviating from the process.This ensures that everyone not only is compliant,but understands the need and rationale behindthe compliance. Part of the process redesigneffort should also focus on simplifying processesto reduce complexity. If there is no need for aspecific channel for purchasing, then eliminate it.Onsite Relationship ManagersAn important point that many respondents notedwas the need to establish dedicated roles aroundonsite relationship managers from procurementwho are available to manage invoices, serviceentries, and the like. The simple fact is thatmany maintenance and project managers do notthink in terms of procurement, but rather arefocused on people, equipment, and schedules;they do not have the time or patience requiredto ensure that the correct entries are put into aP2P system. The relationship manager can alsoact as the liaison between the supplier and themaintenance organization to ensure promptpayment, resolution of issues, and improvementof processes.Simplified Online Portals toMinimize Human InterventionA number of subject matter experts describedthe need to eliminate the manual interventionof multiple untrained individuals enteringinformation into systems such as SAP. ManyERP systems have modules for purchasingand plant maintenance, but they all requiresignificant configuration. On the other hand,a number of “bolt-on” packages are alsoavailable, but the experts advise against thesedue to the high probability of interface issuesassociated with deployment.Improved Forecasting for Maintenanceand Planning for Emergencies that Can“Flex” with Different Situations that AriseThe need to improve forecasting processes isa critical element in ensuring that maintenance5needs are met. While maintenance is oftenan emergency, there are many scheduledmaintenance activities that can be plannedand communicated to suppliers. Even inemergency situations, having a plan in placewith a designated supplier can avoid manyof the problems that occur downstream in theP2P cycle. Too often, data, invoices, serviceentries, and other key elements are enteredincorrectly due to a fundamental lack ofplanning and forecasting. These elementsneed to be incorporated into the design ofnew P2P systems.Reduced Complexity in Catalogs and BuyingChannels to Streamline ProcurementMany of the experts also emphasized the need toreduce complexity, both in the interface systemsas well as in the predefined procurement buyingchannels. There is no need for users to havemultiple channels for procurement. However,establishing the credibility for users to only beable to use these channels also requiressignificant management support.Rolling Out the InitiativeIn re-engineering the procure-to-pay process,suppliers and experts recommend that executivesapply the following approach:1. Secure top management support for theinitiative and budgeting for the project.Develop a list of key benefits and deliverablesthat will occur as a result of the improvements.Document the cost of leaving the system“broken” in its current state.2. Map existing processes and problems with theP2P cycle. Identify where the breakdowns areoccurring and why they are occurring.3. Understand the needs and requirements of theuser groups. Many of the people involved —maintenance, planning, project management,suppliers, accounts payable, buyers, etc. —have specific issues that prevent them fromusing the existing syste

Procure-to-Pay Cycle: Perspectives from Suppliers and Industry Experts — Rob Handfield, Bank of America University Distinguished Professor, North Carolina State University Executive Summary A benchmarking study of the procure-to-pay (P2P) process was carried out with a number of suppliers and subject matter experts. The research identified six keyFile Size: 247KBPage Count: 6People also search forprocure to pay cycle pptsap procure to pay cycleprocure to pay definitionprocure to pay process flow