Transcription

SETUP REDUCTION / QUICKCHANGEOVER

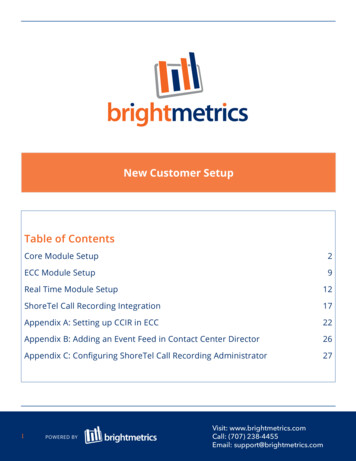

Setup Time Drives Batch Size:The Economic Order Quantities (EOQ) model determines the mosteconomic lot/batch size for a production run.Changeover Cost Inventory Carrying CostVariableCostInventory Carrying CostChangeover CostFixed CostEOQPrinciples for Implementing LeanManufacturingIncreasing Lot/Batch Size

Setup Reduction or QuickChangeover Definition: Minimizing the time from last good piece of the currentproduct run to first good piece of the next (different) product run. STEPS IN A CHANGEOVER: (1) Preparation; (2) Remove/InstallTooling; (3) Change Machine Settings; (4) Make Trial Pieces & Adjust.Percent of time of changeover50%Preparation, after-process adjustment,checking, return to storage of parts,tools, fixtures30%15%15%5%Removing parts, blades, jigs, etc.;mounting same for next lotMachine settings, measurementsMaking trial pieces and adjustingPrinciples for Implementing LeanManufacturing

Quick Changeover: Visual ControlsPrinciples for Implementing LeanManufacturing

Quick ChangeoverClearly labeledcutter size and styleAll regular routercuts needed in thisworkcell stored atrouter table.Principles for Implementing LeanManufacturing

Three Stages of Quick Changeover1. Separate Internal andExternal Setup2. Convert Internal Setup toExternal Setup3. Streamline Internal andExternal ElementsSetup ReductionPrinciples for Implementing LeanManufacturing

Stage 1: Separate Internal and External SetupSeparate Internal andExternal SetupConvert Internal Setup toExternal SetupStreamline Internal andExternal ElementsSetup ReductionPrinciples for Implementing LeanManufacturing Develop and implementchangeover checklists. Perform function checks on partsand tools before changeover Isolate transportation of tools,parts, and materials.

Stage 2: Convert Internal Setup to External SetupSeparate Internal andExternal SetupConvert Internal Setup toExternal SetupStreamline Internal andExternal ElementsSetup ReductionPrinciples for Implementing LeanManufacturing Prepare operatingconditions in advance Standardize functions Use intermediary jigs

Stage 3: Streamline Internal and ExternalElementsSeparate Internal andExternal Setup Implement parallel operationsConvert Internal Setup toExternal Setup Eliminate the need foradjustments Use functional clampsStreamline Internal andExternal Elements Mechanize functionsSetup ReductionPrinciples for Implementing LeanManufacturing

Transition Steps to Quick ChangeoverPreliminaryStep 1Step 2Step 3Internal andExternal Setupnot differentiatedSeparate Internaland ExternalSetupConvert InternalSetup to ExternalSetupStreamline allaspects of SetupoperationsExtExtExtExtProcess WalkAnalysisPreparationStandardizationManagement ofparts and toolsJigsIntExtIntExtIntParallel operationsIntIntIntClampsLess adjustmentsMechanizationPrinciples for Implementing LeanManufacturing

No/Low Cost Solution: Positioning PinsPositioningPinsPositioningPinsPrinciples for Implementing LeanManufacturing

No/Lo Solution: One-Turn MethodsPear-Shaped Hole MethodTighten HereAttach andRemove HerePrinciples for Implementing LeanManufacturing

Other Functional ClampsPrinciples for Implementing LeanManufacturing

Principles for Implementing Lean . Principles for Implementing Lean Manufacturing. Quick Changeover: Visual Controls Principles for Implementing Lean Manufacturing. Quick Change