Transcription

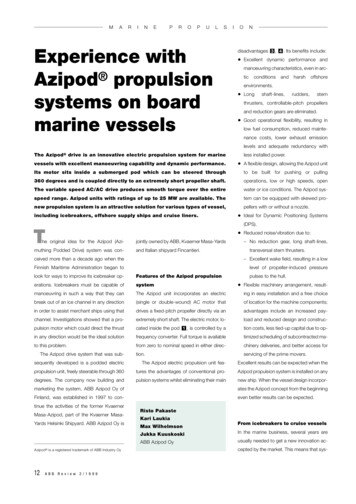

MARINEPROPULSExperience withAzipod propulsionsystems on boardmarine vesselsIONdisadvantages 3 , 4 . Its benefits include: Excellent dynamic performance andmanoeuvring characteristics, even in arcticconditionsandharshoffshoreenvironments. Longshaft-lines,rudders,sternthrusters, controllable-pitch propellersand reduction gears are eliminated. Good operational flexibility, resulting inlow fuel consumption, reduced maintenance costs, lower exhaust emissionlevels and adequate redundancy withAzipod Theless installed power.drive is an innovative electric propulsion system for marinevessels with excellent manoeuvring capability and dynamic performance. A flexible design, allowing the Azipod unitIts motor sits inside a submerged pod which can be steered throughto be built for pushing or pulling360 degrees and is coupled directly to an extremely short propeller shaft.operations, low or high speeds, openThe variable speed AC/AC drive produces smooth torque over the entirewater or ice conditions. The Azipod sys-speed range. Azipod units with ratings of up to 25 MW are available. Thetem can be equipped with skewed propellers with or without a nozzle.new propulsion system is an attractive solution for various types of vessel,including icebreakers, offshore supply ships and cruise liners. Ideal for Dynamic Positioning Systems(DPS).Tjointly owned by ABB, Kvaerner Masa-Yardsmuthing Podded Drive) system was con-and Italian shipyard Fincantieri.he original idea for the Azipod (Azi- Reduced noise/vibration due to:– No reduction gear, long shaft-lines,transversal stern thrusters.ceived more than a decade ago when the– Excellent wake field, resulting in a lowFinnish Maritime Administration began tolevel of propeller-induced pressurelook for ways to improve its icebreaker op-Features of the Azipod propulsionerations. Icebreakers must be capable ofsystemmanoeuvring in such a way that they canThe Azipod unit incorporates an electricing in easy installation and a free choicebreak out of an ice channel in any direction(single or double-wound) AC motor thatof location for the machine components;in order to assist merchant ships using thatdrives a fixed-pitch propeller directly via anadvantages include an increased pay-channel. Investigations showed that a pro-extremely short shaft. The electric motor, lo-load and reduced design and construc-pulsion motor which could direct the thrustcated inside the pod 1 , is controlled by ation costs, less tied-up capital due to op-in any direction would be the ideal solutionfrequency converter. Full torque is availabletimized scheduling of subcontracted ma-to this problem.from zero to nominal speed in either direc-chinery deliveries, and better access fortion.servicing of the prime movers.The Azipod drive system that was sub-pulses to the hull. Flexible machinery arrangement, result-sequently developed is a podded electricThe Azipod electric propulsion unit fea-Excellent results can be expected when thepropulsion unit, freely steerable through 360tures the advantages of conventional pro-Azipod propulsion system is installed on anydegrees. The company now building andpulsion systems whilst eliminating their mainnew ship. When the vessel design incorpor-marketing the system, ABB Azipod Oy ofates the Azipod concept from the beginningFinland, was established in 1997 to con-even better results can be expected.tinue the activities of the former KvaernerMasa-Azipod, part of the Kvaerner MasaYards Helsinki Shipyard. ABB Azipod Oy isAzipod is a registered trademark of ABB Industry Oy12ABB Review 2/1999Risto PakasteKari LaukiaMax WilhelmsonFrom icebreakers to cruise vesselsJukka KuuskoskiIn the marine business, several years areABB Azipod Oyusually needed to get a new innovation accepted by the market. This means that sys-

MARINEPROPULSIONtematic work and feed-back are necessarybefore a new product can be installed on acommercial vessel, where it then has toshow a profit for its owner. When the Azipodconcept was first studied with a view tousing it on cruise liners, it became clearthat a step-by-step approach was necessary, with new design aspects reviewed ateach step: The Azipod unit installed on the waterway service vessel Seili proved that theidea itself was sound and showed that anAzipod system could be built and installed, is strong enough, and fulfils all thebasic requirements of a ship’s main propulsion. The first high-power propulsion unitinstalled on a commercial vessel, the11.4-MW arctic tanker Uikku, provedthe superior manoeuvring capabilitiesand efficiency of the concept, and hasprovided valuable in the experienceThe Azipod unit, in which an AC motor sits inside a submerged podthat can be freely steered through 360 degrees1high-power sector. The first pulling Azipod units were installed on board the icebreaker Röthel-tanker, the M/T Uikku 2 , built in 1978 inNorske Veritas) ice 10 class. In 1995 Uikku’sstein in 1995. The comparison withGermany. The conversion, involving an Azi-sister ship, the M/T Lunni, was similarly con-pushing types allowed some very usefulpod unit rated at 11.4 MW, was carried outverted. Both ships have been in heavy com-conclusions to be drawn.in 1993. The ship was built to ice class 1Amercial use since conversion. Their com-Super and the Azipod unit to DnV (Detbined operating hours total well overThese vessels, by rapidly increasing thecumulative operating hours of the Azipoddrive, provided information and feed-backthat was invaluable for later designs.16,000-dwt product tanker M/T Uikku with an 11.4-MW Azipodunit during turning tests in half-meter thick ice2On-board experienceM/S SeiliThe first joint R&D project was the conversion in 1990 of Seili, a waterway servicevessel owned by the Finnish Maritime Administration, into the world’s first Azipodpropelled ship. The Seili is still in service andits 1.5-MW unit has operated faultlesslysince the conversion.M/T Uikku and M/T LunniThe next ship to be equipped with theAzipod system was the 16,000-dwt productABB Review 2/199913

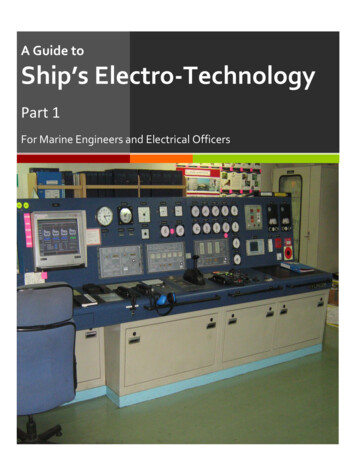

MARINEPROPULSIONsurpasses all other technologies. It has alsobeen tested with the Lunni. These testsshowed that although the Lunni was notdesigned to operate stern-first in heavy ice,it was able to operate in the toughest conditions found in Finnish waters without icebreaker assistance. Model and full-scaletests confirm that only 60 % of the powerneeded when attacking the ice bow-first isneeded for this mode of ice-breaking.MSV BotnicaIn February 1997 Finnyards Oy ordered two5-MW Azipod units for the multipurpose iceConventional marine diesel-electric power plant and propulsion system3breaker Botnica for The Finnish MaritimeAdministration. This ship operates in theGulf of Finland in winter and in the North Sea40,000, of which about 10,000 hours haveI/B Röthelsteinoil fields for the rest of the year. To performbeen in ice-infested waters. In 1997 UikkuAt about the time the M/T Lunni wasits offshore duties the ship has DnV Autrobecame the first western cargo ship to navi-converted an Austrian icebreaker, the I/Bdp-class1) equipment. The ship entered ser-gate the Northeast Passage. Uikku startedRöthelstein 5 , had two 560-kW Azipodvice in the North Sea in the summer of 1998.its journey in Murmansk in western Russiaunits installed. This small river icebreaker in-Excellent sea trial results showed that theat the beginning of September, arrivingtroduced a new ice-breaking technique byship is very well suited for offshore work.twelve days later in Providenya in easternattacking the ice with pulling propellers. TheThe Azipod units on the Botnica are the firstSiberia, south of the Bering Strait. The Uikkuicebreaker is driven stern-first, with the Azi-such units to be used for offshore appli-and the Lunni demonstrated the soundnesspod units pulling the vessel.cations.of the basic design and constructionchosen for the Azipod system.The ice-breaking concept of movingastern with pulling Azipod units demon-Supply ships for the Caspian Seastrates an ice-breaking capability thatIn November 1997 Kvaerner Masa-Yardsreceived an order for two small ice-breakingAzipod propulsion system and diesel-electric power plant.The Azipod system eliminates long shaft-lines, rudders,stern thrusters, controllable-pitch propellers and reduction gears.4supply ships, the Arcticaborg and the Antarcticaborg6 , each powered by two1620-kW Azipod units. The ice conditions inthe northern Caspian Sea are very severe,so the Azipod units will operate as icelathes.Cruising with the AzipodsystemThe ‘full-scale’ applications describedabove and the very extensive R&D programme that accompanied them, providedthe basis for the Azipod cruise liner conceptthat was finally realized at the end of 1995.1)14ABB Review 2/1999Det Norske Veritas Autro dynamic positioning class

MARINEPROPULSIONBased on the good results obtained withthe Uikku and Lunni, Miami-based CarnivalCruise Lines chose in the autumn of 1995 toinstall the Azipod system on its two Fantasyclass vessels Elation and Paradise. Each ofthese ships has two 14-MW Azipod units.The largest cruise ships ever ordered areRoyal Caribbean International’s Voyager ofthe Seas and her sister vessel Eagle II,each with two 14-MW Azipod units andone 14-MW Fixipod (Fixed Podded Drive, anon-rotating Azipod unit). With the Azipodpropulsion units and four 3-MW bowthrusters, the giant ships will be able to stayin a designated position in winds of up to18 m/second from any direction.New ordersThe biggest customer for the new driveshas been the co-developer of the AzipodI/B Röthelstein. The two 560-kW units of this small river icebreakerare the first pulling-type Azipod units to be installed.5concept, Kvaerner Masa-Yards, with eightships delivered and a further seven on order.Recent contracts include new customersMasa-Yards shipyard (formerly Wärtsilägest series of purpose-built cruise shipssuch as Meyer Werft in Germany and Fin-Marine) in Helsinki in 1986. Over the yearsever constructed. A total of eight ships ofcantieri in Italy.the Fantasy class has grown to be the big-the same design have been built. For theMeyer Werft and ABB signed majorcontracts in September 1998 for two cruisevessels, each equipped with 2 19.5-MWAzipod units. The Vantage-class vessels willArcticaborg and Antarticaborg ice-breaking supply ships, each poweredby two 1,620-kW Azipod units, in the building dock.These vessels are driven stern-first when operating in severe ice conditions.6be built for Royal Caribbean International atMeyer Werft in Germany. These are themost powerful Azipod units on order.In September 1998 ABB received anorder from the Italian shipyard Fincantieri fora cruise vessel which will be built for HollandAmerican Line (HAL) and will be delivered inthe year 2000. The Rotterdam-class vesselwill feature an ABB main power plant with amedium-voltage distribution system andtwo Azipod units rated at 15.5 MW each.These are the first Azipod units to be installed at an Italian shipyard.Carnival turns to the Azipod systemCarnival Cruise Lines (CCL) ordered its firstFantasy-class ships from the KvaernerABB Review 2/199915

MARINEPROPULSIONM/S Elation. This cruise liner, owned by Miami-based Carnival Corporation, has two 14-MW Azipod units.7two most recent units in the series, theare equipped with three 1.5-MW tunnelchanges were minor: instead of runningElation and the Paradise, CCL decided to fitthrusters in the bow and three in thecables to the propeller motors, the cablesthe Azipod propulsion concept on the basisstern. Two rudders are also mounted in thewere routed to the Azipod units and cablingof its proven operation on service vesselsstern.work could be reduced since much of theand product tankers.At the time it was designed, the Fantasyclass represented the state of the art in pro-equipment on the previous vessels did nothave to be installed.Conventional propulsionpulsion and control technology. Today, mostChanges to the steel construction weremachinerynew cruise vessels are equipped with elec-avoided. For example, shaft tunnels insideIn a conventional marine drive system thetric propulsion.the ship were turned into freshwater tanks.propulsion machinery consists of a diesel-CCL and Kvaerner Masa-Yards wereThe main changes made included a newelectrical power plant connected to a bus-determined to remain in the technologicalconstruction for the Azipod unit wells andbar. Power is directed to the propellers withforefront and in 1995 CCL chose to installhead boxes to allow the Azipod units totwo 14-MW cycloconverter controlled pro-Azipod propulsion in their ships instead ofrotate 360 , and cover plates for the threepeller motors. The drive system providesthe conventional propulsion arrangementstern thrusters that had been eliminated.smooth torque and speed control over theused previously. Two 14-MW Azipod unitsAll equipment and castings related to theentire speed range.were subsequently installed on the M/Sshaft lines were removed. The hydraulic sys-Elation and M/S Paradise 7 . Electricaltem for the steering gear was replaced byTo ensure manoeuvrability, the ships16ABB Review 2/1999

MARINEPROPULSIONthe Azipod hydraulic system. The coolingpellers. The Azipod unit was slightly inclinedacteristics). Ship behaviour calculationswater system for the propulsion motors wasdownwards (six degrees) in order to obtainduring extreme manoeuvring were per-extended to the Azipod room.a good inflow for the propeller. The resultsformed. An analysis of the black-out situ-A summary of the changes in propulsionobtained from model tests predicted an im-ation was carried out, involving Azipodof the Elation compared with earlier ships inprovement in propulsion efficiency of severalsystem behaviour, dimensioning of thethe Fantasy series is given in Table 1.percent.emergency network and the startingsequence of the steering motors.Design aspects of the installedSteel structureAzipod propulsion systemThe structural dimensioning was based onprevent any failure in one pod from stoppingSeveral aspects have to be taken into con-two basic load conditions: maximum con-the other. The Azipod units are mechani-sideration when applying the Azipod con-tinuous loading in normal service and ex-cally, electrically and hydraulically inde-cept: hull form, Azipod location, motortreme loading (abnormal operation, eg, if thependent.design parameters, propeller design andcontrol of the Azipod system fails). A keystrength, hydrodynamic details, structuraldesign aspect was the adjustment of theLayout modifications on boardstrength, vibration design and tuning, steer-dynamic behaviour. The excitation forcesthe ‘Elation’ing logic and operation modes, ship char-and moments were known from earlier pro-Changes to the layout were kept to a mini-acteristics such as course stability and heel-jects. The excitation level is low due to themum. The propeller motor room, which wasing, behaviour in black-out situations andgood wake field. The steel structure of theno longer needed, actually offers newredundancy.Redundancy was studied in order toAzipod unit and ship hull was dimensioneddesign possibilities because it makes avail-The Azipod turning shaft is located in thesuch that the resonances are avoided inable an additional 1200 m2 of space. Thissame place as the old vertical rudder shaft.critical areas and at full power. Specialspace is as wide as the ship (32 m), 20 m inThis allows full azimuthing angles andemphasis was placed on the Azipod unitlength and two decks high, the height of theenough clearance to the baseline as well asattachment to the hull.propeller motors. In the case of the Elation,sideways. The Azipod unit attachment tothis room was used for additional wastethe ship’s hull was designed on the basis ofSteering systemthe model tests and ‘full-scale’ experience.Steering of the Azipod units is carriedAn incinerator and a grey water treatmentThe synchronous electric propulsion motorout by an electro-hydraulic steering systemplant were installed in the propeller motordesign values, power and torque curves8 . A total of four hydraulic motors give therooms of the original design, and the oldwere kept the same as those of the sisterpod sufficient turning speed and redun-shaft tunnels were converted into fresh-vessels, although savings in propulsion effi-dancy. The steering logic had to be re-water tanks. Changes in the layout of theciency were expected.thought (eg, the stability of the Azipodmachinery spaces were minimal comparedunits, steering angles versus ship speed,with the sister vessels. This was an advan-power limitations and crash stop char-tage for the shipyard and the owner.Propellershandling equipment.The fixed-pitch propeller diameter, at 5.2meters, is the same as on the sistervessels. These propellers are the mostpowerful pulling propellers ever built. Newoperating modes created new challengesTable 1:Change in propulsion of the earlier Fantasy-class cruise ships andthe M/S Elation, which is fitted with Azipod unitsfor the design. The task was successfullyFantasyPowerElationPowerPropulsion2 14 MW282 14 MW28Bow thrusters3 1.5 MW4.5 MW3 1.5 MWStern thrusters3 1.5 MW4.5 MWnoneRudders2performed with the help of detailed hydrodynamic and FEM2) calculations as wellas model tests.The hydrodynamic optimization pro-MWMW4.5 MWcedure resulted in inward rotating pronone372)MW32.5 MWFinite Element MethodABB Review 2/199917

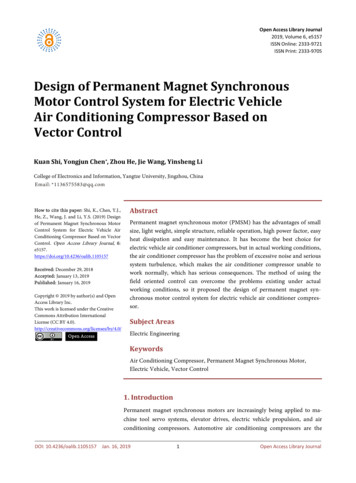

MARINEPROPULSIONduring harbour manoeuvres. The absenceof the stern thrusters and the rudders6makes a big difference to passenger com-7fort.5ConclusionsRecent experience with the combination84of diesel-electric power plant and Azipodpropulsion system has shown the concept3to be an attractive solution for various types2of vessels. The improved total efficiency, in9addition to other advantages, such as1enhanced manoeuvrability, redundancy, re-10duction of equipment, simplicity and theproven reliability of the design, can be realized in most ship projects. The suitability ofthe concept for cruise ships is obvious, andhas been proved by the successful sea trialswith M/S Elation.8Main components of an Azipod unitThe feasibility analysis for a new projectshould always be carried out together with12345Fixed pitch propellerBearing, shaft sealsShaft lineInstallation blockHydraulic steering unit678910Slipring unit (power/data transmission)Ventilation unitAir coolingElectric motorBearingthe shipbuilder. This is because the Azipodpropulsion concept changes not only theway ships can be designed and operatedbut also how they are built.Results of ‘M/S Elation’Fantasy-class vessels. The ability to turn thesea trialsship quickly gives the master a better margin for manoeuvring in tight situations andEfficiencyincreases the safety of the ship.Good results were recorded during the seaThe other important feature in a ship is itstrial in December 1997 in the Gulf of Finland.crash stop performance. The test was per-AuthorsThe increase in propulsion efficiency com-formed by reversing the propellers. An ad-Risto Pakastepared with the other Fantasy-class shipsditional safety feature of an Azipod-pro-Kari Laukiawas 8 %. The hull lines are the same on thepelled ship in the case of a crash stop is thatMax WilhelmsonElation as on the previous ships in the Fan-the ship can be steered towards the desiredJukka Kuuskoskitasy series. The only changes were the localstopping point.ABB Azipod Oymodification around the Azipod units andLaivanrakentajantie 2the closing of the stern tunnels for thePassenger comfortFIN-00980 Helsinkithrusters.A reduction in noise and vibration was alsoFinlandobserved during the sea trials. This is mainlyTelefax: 358 10 22 26060Manoeuvrabilitydue to the very good wake field of the pul-E-mail:The manoeuvrability of a ship is best dem-ling propeller and the resulting reduction inristo.pakaste@fiazi.mail.abb.comonstrated by its full-speed turning circle. Thepressure pulses from the propeller to thekari.laukia@fiazi.mail.abb.comdiameter of the turning circle of the Elationhull. Passengers notice the biggest differ-max.wilhelmson@fiazi.mail.abb.comis about 30 % smaller than for the previousence in the confined area operations andjukka.kuuskoski@fiazi.mail.abb.com18ABB Review 2/1999

In the marine business, several years are usually needed to get a new innovation ac-cepted by the market. This means that sys-Experience with 3 4 Azipod propulsion systems on board marine vessels The Azipod drive is an innovative electric propulsion system for marine vessels with