Transcription

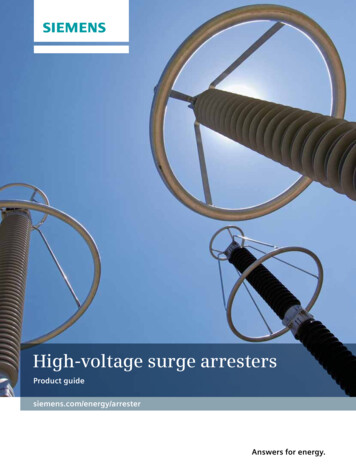

High-voltage surge arrestersProduct guidesiemens.com/energy/arresterAnswers for energy.

Definition of surge arrestersSurge arresters are used to protect high-voltage equipment in substations, such as transformers, circuitbreakers, and bushings, against the effects of overvoltages caused by incoming surges. Such overvoltagescan be caused by a direct or nearby lightning strike, an electromagnetic pulse, electrostatic discharge, orswitching operations in the power supply system as well as in devices. Some overvoltages are very high inenergy. The current from the surge is diverted through the arrester, in most cases to earth. Effective overvoltage protection requires different surge arrester types to be used according to the particular application.2

ContentsDefinition of surge arresters02Siemens surge arresters for any requirement04Always the best solution05History timeline06MOVs: the core of Siemens surge arresters08Silicone rubber09Porcelain10High-voltage station class surge arresters113EL silicone rubber surge arresters with Cage Design123EQ silicone rubber surge arresters with composite hollow core design143EP porcelain surge arresters16Standards and testing – reliability you can count on17Selection table and how to select a suitable surge arrester18Applications as line surge arresters23Early detection of relevant changes through efficient equipment monitoring24Product range263EL5 Surge arrester with silicone rubber housing and Cage Design 293EL1 Surge arrester with silicone rubber housing and Cage Design 333EL2 Surge arrester with silicone rubber housing and Cage Design 393EL3 Surge arrester with silicone rubber housing and Cage Design 473EP5 Surge arrester with porcelain housing553EP4 Surge arrester with porcelain housing613EP6 Surge arrester with porcelain housing693EP3 Surge arrester with porcelain housing773EQ1 Surge arrester with composite hollow core design853EQ4 Surge arrester with composite hollow core design933EQ3 Surge arrester with composite hollow core design101Accessories for surge arresters109Monitoring devices for surge arresters1093

Siemens surge arrestersfor any requirementExperience is most essential when it comes to reliability inmedium- and high-voltage applications. Siemens has beendesigning and manufacturing medium- and high-voltagesurge arresters for standard and special applications since1925. Continuous research and development, the wealthof Siemens know-how, and comprehensive worldwideexperience give Siemens surge arresters a leading edge inovervoltage protection. Their uncompromising qualityensures a long service life and reliability in anyapplication.Siemens surge arresters are an indispensable aid to insulation coordination in electrical power supply systems. Valu-able equipment such as transformers, circuit breakers,generators, motors, capacitors, traction vehicles, andbushings, as well as complete switchgear, is optimallyprotected against lightning and switching overvoltages.Siemens surge arresters have been designed to meet therequirements of a wide range of common installationenvironments, from arctic cold to the heat of the desertand the dampness of tropical climates. They are availablefor any application from 3 kV up to 1,200 kV includingspecial applications such as high-voltage direct current(HVDC) and FACTS systems as well as all kinds of compensation systems for electric power networks.Substation Bidingen 400 kVProtection of transformerSolution with 3EQ44

Always thebest solutionDevelopments in technology and practical experiencehave led to three different surge arrester designs: Surge arresters with porcelain housings Surge arresters with silicone housings Surge arresters with metal enclosuresSiemens provides each of these types in several versions,making it possible to find the optimal surge arrester forevery conceivable application and meet even specificdemands, such as High mechanical stability for outstanding seismic safety E xtremely reliable pressure relief behavior for use inareas requiring special protection E xcellent pollution layer characteristics for use incoastal and desert regions or in areas with extreme airpollution.All Siemens surge arresters feature a superior sealing system that reliably prevents moisture ingress to ensure thehighest possible degree of overvoltage protection anddecades of trouble-free service. Moreover, the choice ofmaterials used in the making of Siemens surge arresterscontributes to the protection of the environment.Substation Bidingen 400 kVProtection of switchgearSolution with 3EQ45

19251989Siemens begins developingsurge arresters. The firstdevices are of the so-calledcathode drop type.The 3EQ2 surge arrester forsystems of up to 550 kV isone of the first high-voltage surge arresters withcomposite polymer hollowcore housing.18471971The ten-employee companyTelegraphen-Bauanstaltvon Siemens & Halske(Telegraph ConstructionCompany of Siemens &Halske) begins operationon October 12, 1847, ina back building in Berlin.Development of the firstgas-insulated and metalencapsulated surge arresterfor gas-insulated switchgear (GIS).19001866Werner von Siemens discovers the dynamo-electricprinciple, which enableselectricity to be put to practical use. The dynamo canconvert mechanical energyinto electrical energy in aneconomical way. Its invention lays the foundation fortoday’s world of electricalengineering.19631992The first surge arrester forsystems of up to 550 kV islaunched. The pulley wheelelectrodes are replaced byceramic-bonded shuntresistors and a series sparkgap. The surge arrestercomprises three columns inparallel and has a resistivecapacitive control.Continually pushing theenvelope, Siemens develops a high-voltage surgearrester with a compositepolymer housing for systems of up to 800 kV. Itwas originally developedas a suspended mountedHVDC valve arrester withseveral parallel metal oxidecolumns in a commonhousing.1982Siemens’ first gapless metaloxide arrester, a GIS surgearrester, is delivered for the123 kV grid in Inchicore, asuburb of Dublin.History timelineSiemens is a pioneer in many fields of the electricity and digitization markets. Experience is most essentialwhen it comes to reliability in medium- and high-voltage applications. Since 1925 Siemens has been manufacturing high-voltage surge arresters up to rated voltages of 1,200 kV – for standard and specialized applications. Our permanent research and development and the concerted know-how in our factories give our surgearresters a leading edge in overvoltage protection. Our uncompromising quality ensures the long service lifeand reliability of each application.6

1998The polymer-housed medium-voltage/distributionclass arresters of the 3EKfamily, which features CageDesign , a unique solutionwith direct silicone moldingon the metal oxide varistors, is introduced.2003Completion of the first linearrester project, an orderfrom KELAG, one of theleading energy serviceproviders in Austria.200720113EL2, the first line arresterfor 550 kV applications, isdelivered to Sochi, a city inRussia.Siemens introduces itsnew range of long rodinsulators.20002010200620082010Development of the 3EQ5,a new surge arrester conceptwith composite housing(type A) for extra highvoltage applications in800 kV DC and 1,200 kV ACtransmission systems.The first externally gappedline arrester (EGLA), whichincreases the reliability ofa 144 kV overhead line, issupplied to the South Korean power provider KEPCO.The world’s first 1,200 kVsubstation arrester withcomposite polymer hollowcore technology is delivered to Power Grid Corporation of India.20102000Development of the firstGIS arrester for systems ofup to 800 kV.Siemens launches thearrester condition monitor,an innovative monitoringsolution with unique features.As a pioneer in the field of silicone rubber insulation and one of the few suppliers with comprehensive inhouse research and development capabilities in this technology, Siemens has been providing surge arresters with silicone rubber housing for more than 30 years and has gathered excellent service experience fromeven the most severe climatic and environmental conditions. Today, silicone rubber is among the mostwidely used materials for high-voltage outdoor equipment.7

MOVs: the core ofSiemens surge arrestersThe main task of an arrester is to protectequipment from the effects of overvoltages. During normal operation, anarrester should have no negative effecton the power system. Moreover, thearrester must be able to withstand typicalsurges without incurring any damage.Nonlinear resistors fulfill these requirements thanks to the following properties:Nonlinear resistors made of metal oxide(MO) have proven especially suitable forthis use. The nonlinearity of MO resistorsis considerably high, which is why MOarresters do not need series gaps. Siemenshas many years of experience withgapless MO arresters in low-voltagesystems, distribution systems, and transmission systems. L ow resistance during surges, so thatovervoltages are limitedSiemens metal oxide varistors (MOVs)provide a high energy absorption capability and a very low protection level. Thismeans they absorb a high amount ofenergy while avoiding thermal runaways.The MOVs are characterized by their highlong-duration current impulse withstandcapability – an indirect measure of theirsingle impulse energy absorption capability. Siemens surge arresters are less proneto self-heating and consequent selfdestruction, and they maintain their characteristics throughout their lifetime. H igh resistance during normal operation to avoid negative effects on thepower system S ufficient energy absorption capabilityfor stable operationWith this kind of nonlinear resistor, thereis only a small flow of current when continuous operating voltage is beingapplied. When there are surges, however,excess energy can quickly be removedfrom the power system by a high discharge current.p.u. UrIEC power-frequencyvoltage vs. time (U-t)characteristic (TOV)1.301.25Preheating to 60 C prior 010,000t/s8

Silicone rubberAs a pioneer in the field of silicone rubberinsulation and one of the few supplierswith comprehensive in-house researchand development capabilities in this technology, Siemens has been providingsurge arresters with silicone rubber housing for more than 25 years and has gathered excellent service experience fromeven the most severe climatic and environmental conditions. Today, siliconerubber is among the most widely usedmaterials for high-voltage outdoorequipment.Siemens silicone rubber-housed surgearresters are polymer-housed arrestersthat use silicone rubber as the only insulating material. The exclusive use of silicone has proven to be the best solutionin several studies: Silicone rubber ishighly hydrophobic. While there are manypolymeric materials with similar initialhydrophobic properties, most of them,such as EPDM alloy rubber, lose theirhydrophobicity after a relatively shortperiod. Only genuine silicone rubber asused by Siemens is capable of maintaining its hydrophobicity throughout itsentire lifetime. This ensures the long service life of Siemens surge arresters withsilicone rubber housing. Even the mostsevere ambient conditions, such as saltfog in coastal regions or dust-laden aircausing serious contamination in anindustrial area, cannot impair the hydrophobicity of silicone rubber. This materialproperty reliably prevents conductivemoisture from forming on the arrestersurface, thus averting surface currentsand discharges. Moreover, genuine silicone is highly fire-retardant and selfextinguishing, and it is neither subject toerosion nor sensitive to UV radiation. Thisensures the long-term stability of thehousing material.There are several characteristics that setthe silicone elastomers used by Siemensapart from other organic insulatingmaterials.As a matter of principle, Siemens only usesHTV (high-temperature vulcanized) or LSR(liquid silicone rubber) silicone elastomers.These types of silicone help maintain theproperties mentioned above.Characteristic damage onEPDM insulators due tonatural UV radiationChalkingThe –Si–O– backbone of silicone rubberhas a higher bonding energy than the–C–C– backbone of EPDM. Silicone rubber has a lower carbon proportion thanEPDM. Consequently, silicone rubberboasts inherently better chemical andphysical resistance, better UV resistance,and lower flammability than EPDM.Consider these facts: S ilicone rubber is highly stable underthe influence of ultraviolet radiation(sunlight), ozone, and nitrogen oxide.Its stability beats that of EPDM-basedalloy rubbers. T he hydrophobic performance of a silicone rubber surface remains excellentthroughout the entire arrester servicelife, whereas EPDM-based alloy rubbers lack this critical requirement.Cracking T he hydrophobicity of silicone rubberreturns after a corona discharge,which assures reliable long-termperformance. T he arcing resistance of silicone rubber is higher as compared to EPDMbased alloy rubbers. T he flame-retardant properties of silicone rubber comply with IEC 60707 andUL94 V-0 (i.e. self-extinguishing, noburning drips, probe does not burn).Moisture S ilicone rubber is resistant to all common organic and nonorganic cleaningagents and solvents. S ilicone rubber performs well in anambient temperature range of –60 Cto 200 C. No other polymeric material can beat silicone rubber.POWERSIL Hydrophobic effect on Siemens 3ELsurge arrester due to alignment ofmethyl groups in silicone polymers.9

PorcelainSiemens porcelain surge arresters featurea directional pressure relief device thatensures maximum protection in the caseof an overload. Thanks to the excellentsealing of its surge arresters, Siemens hasrecorded decades of trouble-free servicelife without failures or moisture ingress.Both ends of a porcelain surge arresterhousing are equipped with aluminumflanges that are cemented to the housing.Sulfur cement is the first choice for thispurpose. It has favorable mechanical properties and also proves advantageous overPortland cement, which is quite commonin the insulator industry. The main advantage of sulfur cement is that it can be10brought into contact with aluminum during manufacturing without causing anycorrosion, and it can be quickly processed,since it almost reaches its full mechanicalstrength directly after application.The design of the flanges and the endsections of the porcelain housings is keyto the strength of the entire housing. Thisis why these parts of Siemens arrestersare designed in a way that ensures thatthe cement joint is mechanically strongerthan the porcelain itself. This enablesmaking full use of the porcelain’s strengthwhen specifying the permissible mechanical head loads of the arrester housing.

High-voltage station classsurge arrestersSiemens provides three surge arrester productfamilies for standard and special AC applicationsfrom 3 kV up to 800 kV, which are describedin this brochure: 3EL surge arresters with silicone housing,Cage Design 3EQ surge arresters with silicone housing,composite hollow core design3EP surge arresters with porcelain housing11

3EL silicone rubber surgearresters with Cage DesignDesign featuresCage of FRP rodsEnd fittingsMetal oxideblocksSilicone rubbersheds directlymolded onmetal oxideblocks and onend fittingsSiemens’ Cage Design ensures highmechanical strength and safe overloadperformance. It is characterized by theuse of silicone and fiberglass-reinforcedplastic (FRP) rods as housing materials.Reliability is guaranteed by the directmolding of the silicone rubber onto theMO blocks and the FRP rods. This ensuresthe total embedding of all componentsfree of bubbles and gaps, thus preventingany partial discharge or moisture ingress.The MO blocks of 3EL surge arresters areenclosed by a cage made of prestressedFRP rods, which leads to a rigid, reinforced structure ensuring high mechanical strength. The high tensile strength ofthe FRP rods is used to hold the arrester’sMO blocks in place tightly. This is whyCage Design arresters are among themechanically strongest polymer arrestersavailable on the market and at the sametime ensure minimal use of material andvery low weight. As the MO blocks areneither enclosed in a sealed mechanicalshell nor wrapped in hard material, noexcess pressure will develop in the caseof an overload or the extremely rare12event of an arrester short circuit. Thearc can escape directly through the softsilicone housing, and the ejection ofinternal parts that could damage otherequipment nearby is prevented almostcompletely.Long service lifeSilicone is the only polymeric materialthat maintains its hydrophobicitythroughout its lifetime: Water and pollution do not form a continuous conductivefilm on its surface. This reduces surfacecurrents and the risk of a flashover, especially in polluted and coastalenvironments.Other polymeric materials may be hydrophobic, too, but they lose this propertyafter a short period of time. Unlike otherpolymeric materials such as EPDM, forexample, the silicone used for our 3ELarresters is also fire-retardant and selfextinguishing, and it is neither subject toerosion nor sensitive to UV radiation. Thisensures the long-term stability of thehousing material.

Low weight: flexible andeasy installationThe use of FRP and silicone as housingmaterials also makes Siemens 3EL arresters extremely lightweight, allowing easytransport and flexible installation. Theuse of 3EL surge arresters helps reducethe required strength and weight of arrester supports and the need for heavyinstallation equipment.ApplicationsThe 3EL series of surge arresters coversa wide range of common installationrequirements including station and linesurge arresters for the protection ofswitchgear, transformers, and otherequipment in high-voltage systems ofup to 550 kV. 3EL surge arresters canbe installed at all mounting angles(e.g. horizontally, vertically, or suspendedfrom the transmission line as line surgearrester). Mechanically strong enough tomeet common mechanical requirementsand with sheds that are resistant to damage resulting from transport, installation,storms, earthquakes, and vandalism, 3ELsurge arresters are perfectly suited forinstallations that demand low weight andindestructibility of the arrester.Horizontal cut of a cage designarrester13

3EQ silicone rubber surgearresters with compositehollow core designDesign featuresDirectionalpressure reliefdeviceCage of FRP rodsEnd fittings withdirectional pressurerelief device andsealing systemMetal oxide blocksFRP tubeSilicone rubber shedsdirectly molded onFRP tubeDirectionalpressure reliefdeviceSiemens’ innovative composite hollowcore design uses silicone and a FRP hollow core as housing materials. Theadvantages of this design are more thancompelling, as it offers the perfect combination of cost savings and safety forsubstations. The direct molding of thesilicone rubber onto the FRP hollow coreensures reliability, while an excellentspecial sealing of the flanges at bothends of the surge arrester effectivelyprevents partial discharges and moistureingress. The combination of silicone rubber and fiberglass-reinforced hollow core14also allows an enormous load carryingcapacity for the structure. Hence, 3EQsurge arresters are the perfect choice forthe replacement of existing post insulators in substations of up to 800 kV.The composite hollow core design provides a very high degree of safety: In thecase of an overload or the extremely rarecase of an arrester short circuit, the arcescapes directly through directional pressure relief devices, internal parts are notejected, and the housing does not break.

A reliable, sturdy, andeconomic choiceSiemens 3EQ composite hollow coredesign surge arresters are virtually indestructible. While the composite hollowcore design provides the highest possiblemechanical strength and enables thesupport of high bending moments, thesilicone rubber insulation is ideal foroutdoor applications in severe environmental conditions. No matter how toughenvironmental and operating conditionsmay be, 3EQ arresters assure 100% reliable pressure relief performance andprovide the ultimate in protection. Theyare shatterproof and retain at least75 percent of their mechanical strengtheven after pressure relief, and they provide the greatest stability, even duringearthquakes.Reduced spacerequirementsWhenever space is at a premium, 3EQsurge arresters can even be mounteddirectly over a transformer to supportconnectors without any danger to neighboring equipment. Their unique composite hollow core design ensures maximumstability, even if an arrester should »blowout« after overloading. Pressure relief isabsolutely reliable – there is no danger toequipment in the direct vicinity, no partswill be ejected, and the emerging arc willsafely burn between the ends of the pressure relief device.Longevity and reliabilityThe silicone rubber housings of 3EQsurge arresters provide the best possiblelong life performance for high-voltagesurge arresters. They make use of all theadvantages of vulcanizing silicone rubbersheds onto an FRP hollow core, providingenhanced safety and meeting everyrequirement.With their silicone rubber housings, thearresters enjoy all-around protection. Thesilicone rubber shed provides a reliabledefense against snow, sandstorms,ozone, high-level UV radiation, sea salt,soot, and acid rain in industrial regions.Only genuine silicone rubber is capableof maintaining its hydrophobic propertiesthroughout its entire service life – and isresistant to UV radiation. The siliconerubber of the 3EQ surge arresters reliablyprevents the formation of films of wateror dirt. Surface currents resulting fromconductive layers of accumulated dirt areeliminated.Horizontal cut of a compositehollow core design arresterApplicationsSiemens 3EQ composite hollow coredesign surge arresters will go the extramile. They meet highest mechanicaldemands and are ideally suited for challenging environments, such as areas withheavy seismic activity or extremely highwind loads.3EQ surge arresters boast a prolongedservice life, because they are absolutelyshatterproof and feature reliable overloadperformance with no hazardous splintersbeing ejected even under maximum pressure. These arresters can be installedclose to costly system components. 3EQcomposite hollow core design arrestersare virtually indestructible during transportation, installation, storms, and earthquakes, and they are immune tovandalism.15

3EP porcelainsurge arrestersDesign featuresDirectionalpressure reliefdeviceCage of FRP rodsEnd fittings withdirectional pressurerelief device andsealing systemMetal oxide blocksPorcelain housingDirectionalpressure reliefdeviceSiemens’ 3EP porcelain-housed surgearresters are the ideal choice for highmechanical performance requirementsat voltage levels of up to 800 kV. With aseismic qualification of 0.5 g that isguaranteed up to 800 kV, they suit environments with even the most challengingmechanical requirements, such as heavyseismic activity and extremely high windloads.3EP surge arresters ensure maximumprotection in an overload situation thanksto a specially designed directional pressure relief device. In the case of an overload or the extremely rare case of anarrester short circuit, the arc escapeseasily through the pressure relief devices.No pressure is built up inside the arresterand no internal parts are ejected, whichprevents damage to surroundingequipment.16The excellent sealing system of 3EP surgearresters prevents failures or moistureingress and guarantees decades of troublefree service. The use of nonporoussulfur cement instead of corrosive Portland cement for bonding protects theMO blocks and prevents aging effects.The MO blocks of 3EP surge arresters areenclosed by a rigid, reinforced cage madeof FRP rods. The high tensile strength ofthe FRP rods is used to hold the arrester’sMO blocks in place tightly.ApplicationsThanks to their high degree of safety andreliability, Siemens 3EP porcelain-housedsurge arresters can be installed in closeproximity to costly system components.3EP composite hollow core design arresters are virtually indestructible duringtransportation, installation, storms, andearthquakes, and they are immune tovandalism.

Standards and testing –reliability you can count onTestsStandardizationSiemens surge arresters have beendesigned and tested in compliance withthe latest IEC 60099-4, IEEE C62.11,and GB 11032 standards. All type testsare performed by independent, PEHLAcertified laboratories; reports are available on request. Please contact yourSiemens representative for details.The aim of the IEC’s Technical Committee37 (TC 37) as well as the IEEE’s SurgeProtective Device Committee (SPDC) isthe standardization of surge arrester testing and application. The TC 37 developsthe standards IEC 60099-4, IEC 60099-8(EGLA), IEC 60099-9 (HVDC), and theapplication guide IEC 60099-5, while theSPDC develops the standard IEEE C62.11and the application guide IEEE C62.22.Both committees include representativesof manufacturers, utilities, test field labs,and universities.Moreover, every single surge arrester thatleaves the Siemens factory undergoes aroutine test and is delivered with aroutine test certificate.Quality AssuranceSiemens meets all requirements ofISO 9001:2008, ISO 14002:2004, andBS OHSAS 18001:2007. All Siemenssuppliers need to be certified accordingto ISO standards or will be audited bySiemens.Siemens R&D experts are members ofboth bodies, thus playing an importantrole in the definition of the standards.They also share their expert knowledgein electrical power systems in CIGRE, theinternational council on large electricsystems, which participates in the development of international standards.To maintain sustainable quality improvement, Siemens introduced corporatequality guidelines that contribute to eachstep of the quality process.The test field is certified by the»Deutsche Akkreditierungsstelle«(Germany’s national accreditation body)according to DIN EN ISO/IEC 17025Test generator supplying bothimpulse voltages (1.2/50 µsand 250/250 µs) and impulsecurrents (8/20 µs and 30/60 µs)UHV arrester preparedfor testing in theHV test laboratory17

Selection tableSystemHighest voltageof the system UsNeutral earthingelectricalTemporaryovervoltages (TOV)ArresterEnvironmentCont. operating voltage Uc,min – Rated voltage Ur1Rated voltage UrCont. operating voltage UcRated voltage Ur2Lightning currentstressNominal discharge currentInEnergy (linedischarge, switchingovervoltages)Line discharge classInsulation level, safetymargin, distance(protective zone)LI protective levelSI protective levelGround flash density,magnitude oflightning strikesActive part specifiedLength of housing, number of units,flashover distance (withstand voltages)Altitude of erectionCreeping distance,shape of shedsmechanicalShort-circuit currentMechanical forces(short-circuit current,bending and tensileloads)Diameter, material, length ofunits (number of units)Seismic stressRated short-circuitcurrent Is, mechanicalloads SLL and SSLHousingFig. 1: Configuration procedure for an MO surge arrester18Pollution

How to selecta suitable surge arresterThis section describes the general approach to selectingtypical arresters for overvoltage protection in high-voltagesystems. For a detailed description of how to configure asurge arrester, please refer to the handbookMetal-Oxide Surge Arresters in High-Voltage PowerSystems – Fundamentals.1The requirements for a surge arrester emerge from twobasic requirements: It should provide adequate protectionwith a sufficient safety margin, which means that overvoltages at the device to be protected must always remainbelow its withstand voltage. Furthermore, the surgearrester should be dimensioned for stable continuousoperation, which means that the arrester must remainelectrically and thermally stable under all conditions whilehandling all long-term, temporary, and transient stressresulting from network operation.These two requirements cannot be fulfilled independently.A reduction of the protective level automatically means ahigher degree of specific electrical stress during continuous operation, and conversely, the continuous operatingvoltage of an arrester cannot be increased arbitrarily without raising its protective level as well. Both operatingpoints are for a given type of MOV strictly associated witheach other through the voltage-current (U-I-) characteristic curve.Step 1:Selection of the continuous operatingvoltage and the rated voltage.The first step is to define the minimally required continuous operating voltage Uc,min. This must be as high as thecontinuous phase-to-earth voltage of the system. Here,»continuously« applied voltage means every voltage thatoccurs within an uninterrupted period of more than 30minutes. The type of neutral earthing of the system isdecisive in determining the continuous operating voltage.In isolated or resonant earthed neutral systems, the voltage of a healthy phase against ground takes on the valueof the phase-to-phase voltage in the case of a one-phaseearth fault (earth fault factor k 1.73). Since resonantearthed neutral systems are operated quite commonly fortime periods of more than 30 minutes in this condition,the continuous operating voltage of the arrester must, inthis case, have the value of the highest voltage of the system, Us.Solidly earthed neutral system:Uc,min Us/ 3Isolated or resonant earthed neutral system:Uc,min UsThe definition of the minimally required continuous operating voltage, a factor which usually has a value of 1.25,helps achieve a rated voltage Ur 1.25 · Uc,min. This is thelowest necessary rated voltage of the arrester.Table »Typical rated voltages Ur for highest voltages ofthe system Us « on page 27 lists typically applied ratedvoltages.Volker Hinrichsen: »Metal-Oxide Surge Arrest

Surge arresters are used to protect high-voltage equipment in substations, such as transformers, circuit breakers, and bushings, against the effects of overvoltages caused by incoming surges. Such overvoltages can be caused by a direct or nearby lightning stri