Transcription

The Use of RenewableFeedstocks for theProduction of Chemicals andMaterials - A Brief Overviewof ConceptsJoseph J. BozellNational Renewable Energy Laboratory1617 Cole BoulevardGolden, CO 80401

Visions“The U.S. is the Saudi Arabia of carbohydrates.”David Morris, Institute for Local Self Reliance“Moving from an economy based on geology toone based on biology.”USDA“Changes that will have effects comparable tothose of the Industrial Revolution are nowbeginning.”Phillip Abelson, Science

DOE Strategic Goals for the Useof Renewable Feedstocks Dramaticallyreduce,orevenend,dependence on foreign oil (a displacementand energy component) Spur the creation of a domestic bioindustry(an enabling and economic component) Integration of chemicals with fuels willsimultaneously address both goals.

The Biorefinery is FlexibleOutputs (Conversion)Inputs (Supply)CornPotatoesSorghumSoybeansApple pomaceJerusalem artichokeGuayuleBeet molassesSugar caneWoodResiduesBuilding blocks(Separation)StarchCelluloseLigninOther CarbohydratesOilsButadienePentanes, penteneBTXPhenolicsOrganic acidsFurfuralResorcinolLevulinic acidLevoglucosanPeracetic acidTetrahydrofuranAnthraquinoneSorbitol

Advantages to BiomassFeedstocks Lowered demand for diminishing crude oilsuppliesSustainabilityRecycling of CO2Lessened dependence on politically unstablenations for feedstock supplyNew types of complexity in building blocksFlexibility through biotechnology/bioprocessing asa growth industry

Projected Raw Material CostsOil /drytonneNatural Gas129122 ( 2.50/1000( 17.5/barrel)scf)CoalCornLignocellulosics3398 (kernels, 2.50/bushel)44 (poplar,switchgrass)19 (stover)94( 12.7/barrel)44 ( 6/barrel) /GJ3.1( 17.5/barrel)2.3( 12.7/barrel)1.2 ( 6/barrel)2.31.05.0 (kernels, 2.50/bushel)1.0 (stover)2.3 (poplar,switchgrass)L. R. Lynd, C. E. Wyman, T. U. Gerngross, Biotechnol. Prog., 1999, 15, 777

Feedstock/Building Block CostsMaterial /kg /lbSourceCellulose0.44 - 1.100.20 - 0.50Industrial sourcesLignin0.07 - 0.130.03 - 0.06Fuel valuexylose/arabinos e0.60 - 1.100.13 - 0.260.07 - 0.130.27 - 0.500.06 - 0.120.03 - 0.061NCGA estimat eNCGA estimat esucrose0.400.182lacto semaltose0.650.50 - 1.502.690.300.23 - inic acid0.18 - 0.260.08 - 0.12Industrial sourcesα-pinene5.502.50Chemica l Marketing Reporterβ-pinene6.382.90Chemica l Marketing ReporterPolymersCarbohyd ratesglucoseOther12M. B ols, “Carbohydrate Building Blocks”, Wiley-Interscience, New York (1996 )F. Lichtentha ler and S. Mon del, Pure App l. Chem., 1997 , 69, 1853 .

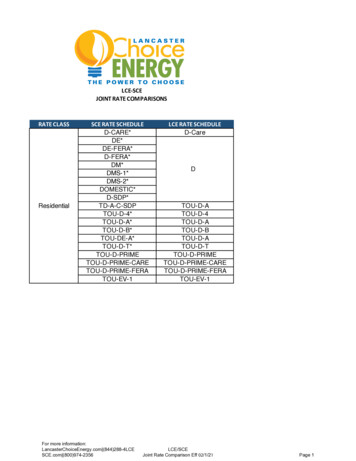

Meeting the organic chemical needs of North America frompetrochemical raw materialsChemicalEthylenePropyleneEthylene dichlorideBenzeneVinyl ydeTerephthalic acidEthylene oxideTolueneCumeneEthylene glycolAcetic acidPhenolPropylene oxideButadieneIsobutyleneAcrylonitrileVinyl acetateAcetoneButyraldehydeCyclohexaneAdipic acidNitrobenzeneBisphenol AAnnual production(109 A/CEH/2001NA/CEH/2001US/CEH/2001NA/CEH/1999Include in evaluation?xxNo Š from ethylenex Š first evaluation onlyNo Š from ethyleneNo Š from benzeneNo Š from benzenexx Š first evaluation onlyxNo Š from xylenexx - first evaluation onlyNo Š from benzenexxx - first evaluation onlyxxxxNo Š from acetic acidxxxxNo Š from benzeneNo Š from acetone

Production of aromatics from ligninAromaticBenzeneXyleneTerephthalic acidToluenePhenolTotalAromaticBTXTerephthalic acidPhenolTotalProduction (109 lb)20.413.811.111.15.0961.5Lignin required (109 lb)90.712.79.75113

Impact of products on fuelproduction (113x109 lb)(1/0.25) 453x109 lb lignocellulosic feedstock required,(453x109 lb lignocellulosic feedstock)(0.75) 339x109 lb of sugar available(339x109 lb of sugar as glucose)(92/180) 174x109 lb of EtOH possible(174x109 lb of EtOH)(454g/lb)(1ml/0.816 g)(1l/1000ml)(0.264 gal/l) 25.5x109 gal EtOH possibleU. S. gasoline consumption: 136x109 gal/yr (EIA)Making products in the biorefinery that meet thecurrent aromatic organic chemical needs of the U. S.could enable EtOH production equivalent to almost19% of our current supply.What is the impact on fuel supplies if the biorefinerymakes products? Significant, and potentially verylarge

Schematic of the Chemical Industry

Key Issues in Chemical Production Supply: Where does the starting feedstock come from?How much is there? How long will it last? How is itobtained?Separation: What are the primary components of thefeedstock? How is one component obtained apart from theothers?Conversion: How are the components transformed intoproducts? Which processes are most useful? Whatproducts are most useful?

How Will Biomass beIncorporated? Duplication of products and structures:biomass is used to prepare knownpetrochemical derivatives relatively easy,but economically badDuplication of properties: biomass is usedto duplicate desirable marketplaceproperties relatively difficult, but muchgreater economic opportunity

The NREL Clean epulplignocellulosicfeedstocksolublesphase separationaqueoushemicelluloseorganiclignin

Typical Clean e50%hemicellulose25% lignin20%50%hemicellulose25%U. S. patent 5,730,837 95% recovery of each fraction with 5% cross contaminationSeparate, isolable cellulose, lignin, and hemicellulose fractionsSuccessful with a wide range of biomass raw materialsUseful as a “front end” for a forest biorefineryEconomically viable

Mechanism of Levulinic Acid FormationOHHOHOO-H2 OHOH2 COHOHany C6 containing feedstock:paper, paper sludge, ag fibers,wood, etc.H2 C-H2 OH3 CCHO H2 OOHOH2 COOHCHOhydroxymethylfurfuralOO O CHOOHCHOH3 CH3 COOHOHCHOO O CH(OH)2OHH3 CH3 COO O CHOCOOH HCOOHlevulinic acidJ. Horvat, B. Klaic, B. Metelko, V. Sunjic, Tetrahedron Lett., 1985, 26, 2111Cost: 4.00 - 6.00/lbDifficult separation

Is Levulinic Acid a Viable Primary ChemicalBuilding Block? Primary building blocks: C2H4, C3H6,BTX, etc.Their preparation from raw materials(petrochemicals) is simple, one step,and high yieldingThey are inexpensiveUnit operations using these materialslead to a large family of chemicalproducts Primary building block:levulinic acidIts preparation from rawmaterials (carbohydrates) issimple, one step and highyieldingIt is inexpensiveThere are no unit operationsbased on levulinic acid thatlead to a large family ofchemical productsThus, developing a family of chemicals from cheap levulinicacid would lead to a new carbohydrate based unit op forthe chemical industry!

Reaction MatrixRenewable feedstocks(carbohydrate and lignin e from cellulose or starchOOCOOHHOOC1, β-ketoadipic acidHOOCCOOH2, 2-ketoglutaric acidNH2HOOCCOOH3, glutamateOHCOOHHOOCglutaric acidHOOCCOOHnylon-4polymers2-hydroxyglutaric acidOHnew version

Renewables Based Polyesters – 2O , 175-185o CCOOH HOHOOC2-ketoglutaric acidcatalystOHFormation of an insoluble polymerwithin 5 hours1,4-BDOOOOOOOOOOOPossible initially formed units?OHOOCOHOCOOH HOOOHCCOOHOHOOHOOCOHCOOH-H2 OHOOCOOHCOOH

Glycal Based Bolaform ResearchSchematicnew carbohydrate based bolaformschain length variationchain structure variation: stereochemistry,branching, heteroatomsORFerrier chemistryOROOROROorganometallic ROtransformationsstructureORself assemblyORglycal based bolaformsorganometallictransformationscovalently stabilized monolayer membraneslong lived catalyst supportsstructurally defined catalystselectronic devicesnew nanostructurespredictable macromolecular arraysmacroporous Si catalyst templatesOROglycalscovalent linkagesbolaform based monolayer membranespredictive models?shapeORORmembrane supported bioactive moleculesbiomimetic lipid/enzyme systemsinfection control - hospitalsbiosensors, detectorsbioactive filtersair qualityhighly defined catalyst systemscellular recognition, carbohydrateoligomersnew methods of functionalizationnew structural/electronic units in sugarscurrent progressphase 1 - establish baselinesapproximate timephases of workphase 2 - bolaform properties and self assemblyphase 3 - stabilization of membranes, bioactive systems

Hypothetical assembly processSingle moleculeMultimolecular arrayLarge scale folding to tubesT. Shimizu, Macromol. Rapid Commun. 2002, 23, 311

Vinyl chloride 16.9 NA/CEH/2002 No Š from ethylene Ethylbenzene 15.9 NA/CEH/2002 No Š from benzene Styrene 14.0 NA/CEH/2000 No Š from benzene Methanol 9.77 NA/CEH/2001 x Xylene 13.8 NA/CEH/1999 x Š first evaluation only Formaldehyde 11.4 NA/CEH/2003 x Terephthalic acid 11.1 NA/CEH/1999 No Š from