Transcription

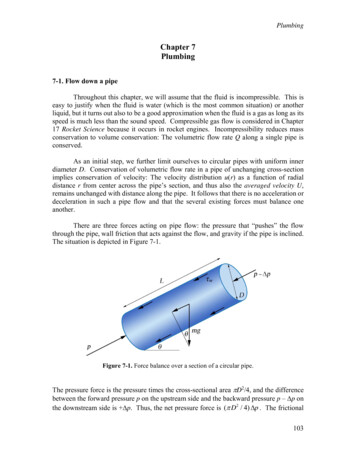

PlumbingChapter 7Plumbing7-1. Flow down a pipeThroughout this chapter, we will assume that the fluid is incompressible. This iseasy to justify when the fluid is water (which is the most common situation) or anotherliquid, but it turns out also to be a good approximation when the fluid is a gas as long as itsspeed is much less than the sound speed. Compressible gas flow is considered in Chapter17 Rocket Science because it occurs in rocket engines. Incompressibility reduces massconservation to volume conservation: The volumetric flow rate Q along a single pipe isconserved.As an initial step, we further limit ourselves to circular pipes with uniform innerdiameter D. Conservation of volumetric flow rate in a pipe of unchanging cross-sectionimplies conservation of velocity: The velocity distribution u(r) as a function of radialdistance r from center across the pipe’s section, and thus also the averaged velocity U,remains unchanged with distance along the pipe. It follows that there is no acceleration ordeceleration in such a pipe flow and that the several existing forces must balance oneanother.There are three forces acting on pipe flow: the pressure that “pushes” the flowthrough the pipe, wall friction that acts against the flow, and gravity if the pipe is inclined.The situation is depicted in Figure 7-1.Figure 7-1. Force balance over a section of a circular pipe.The pressure force is the pressure times the cross-sectional area D2/4, and the differencebetween the forward pressure p on the upstream side and the backward pressure p – p onthe downstream side is p. Thus, the net pressure force is ( D 2 / 4) p . The frictional103

Plumbingforce is the wall stress w times the peripheral area DL, while the gravitational force is theweight mg ( D2L/4)g times the sinus of the inclination angle . The overall forcebalance is: D24 p DL w g D2 L4sin ,which can be reduced to: p 4 w g sin .L D(7-1)The ratio p/L represents the pressure loss per unit length of pipe; in differential form, it is–dp/dx ( 0) with x being measured along the pipe. If we also write the pipe’s slope as therate of change elevation z with distance x,sin dz,dx(7-2)then the balance of forces (7-1) can be rewritten as: 4 wd p. gz Ddx (7-3)This is reminiscent of the Bernoulli Principle (4-7). The velocity term is absent because itis constant along the pipe, reducing the Bernoulli function to the two terms in theparentheses. The major difference is that the Bernoulli function is no longer held constantalong the flow but is steadily decaying because of wall friction. Integration over length Lof the pipe yields p p 4 L w g z g z D , x L x(7-4)since the wall stress w is constant under constant velocity. The negative term on the right,which represents the loss of energy per mass of the fluid, can be captured after division byg as an equivalent loss of height, and we define the head loss:hf 4L w. gD(7-5)The meaning is this: If the pipe were sloping downward by this height, the loss of potentialenergy would compensate the frictional loss, and the pressure would remain unchanged.104

PlumbingIn practice for calculations, it is preferable to use a dimensionless quantity, which is calledthe friction factor f:f 2 gD h f 8 w2 .2 UU L(7-6)Thus, the friction factor is a non-dimensional way of capturing the head loss or the wallstress. For a horizontal pipe, it is also a way to quantify the pressure drop per unit distance:f 2D p. U2 L(7-7)7-2. Viscous flow in a pipeThe preceding developments were tacit about the relationship between the wallstress w and the flow, particularly its averaged velocity U. A relationship between the twois to be expected as the wall stress is an outcome of the flow through the pipe. If there isno flow, there cannot be any stress against the wall, and the greater the flow is, the strongerthe stress should be. The relationship depends on the viscosity of the fluid as well as thenature of its flow, whether it is turbulent of not.If the flow is not turbulent, it is said to be laminar, which means that it flowssmoothly as thin slices sliding onto another. The differential equation governing themovement of fluid in the x-direction when the flow is steady (no time derivative) andunidirectional (only component u to the velocity) is (4-28a) reduced to:0 2u 2 u 1 dp 2 2 , dx y z (7-8)with pressure p being a function of distance x only since the remaining flow equations tellthat the only variation that p may have in other directions is a hydrostatic part, which hasno x-variation for an incompressible fluid and may be subtracted. The fact that the velocitydoes not vary in the downstream direction ( u / x 0 ) was also used in thesimplifications. The radially symmetric solution to this equation is:u ( y, z ) 1 dp 222 R y z u (r ) ,4 dx (7-9)in which r y 2 z 2 is the radial distance from the centerline (r 0) to the pipe wall (r R D/2). Use was also made of the relation . This solution for viscous flow ina pipe is called Poiseuille flow in credit to Jean Léonard Marie Poiseuille (1797-1869), aFrench physicist who studied blood flow in veins and capillaries.105

PlumbingThe averaged velocity is:U 1 R2 u dy dz 1 R2 R0u (r ) 2 rdr R 2 dp ,8 dx (7-10)which is half its peak at the center of the pipe (Figure 7-2), and the wall stress is: w dudr r RR dp .2 dr (7-11)Figure 7-2. Velocity distribution acrossthe pipe as a function of radial distance.The relationship between wall stress and averaged velocity follows by elimination of thefactor (-dp/dx) between the two: w 4 8 U U.RD(7-12)Finally, the friction factor can be determined:f 64 U D 64,Re(7-13)in which Re is the Reynolds number defined as:Re U D U D . (7-14)Unfortunately, the preceding relations are not valid for all flows but only for thosesufficiently slow to remain laminar. There is a threshold beyond which the flow transitionsto the turbulent regime and, for faster flows, becomes fully turbulent. Laboratoryexperiments reveal that the onset of turbulence begins around Re 2100. The value106

Plumbingremains imprecise because it depends on many details such as the manner by which thefluid is introduced at the entrance of the pipe and by which it is being gradually accelerated.7-3. Turbulent flow in a pipeBeyond Re 2100 and up to Re 4000, there is a transition zone, in which the flowis relatively unstable, oscillating in places between laminar and turbulent regimes. For Re 4000, the flow is no longer intermittent and is well established as a turbulent flow.In the turbulent regime, we know from Section 6-5 that the velocity profile in thevicinity of the wall is logarithmic. For a smooth wall, the velocity distribution with fromthe wall is given by (6-14a,b) as a function of the distance R–r from the wall:u (r ) u*2 ( R r )u (r ) u* lnu* ( R r ) 5.56 u*foru* ( R r ) 12(7-15a)foru* ( R r ) 12 .(7-15b) Toward the centerline line of the pipe, the logarithmic velocity profile from one side meetsthat from the opposite side, and the meeting of the two forms a cusp. Of course, no such acusp exists in reality, and the velocity profile is smoothly varying around r 0.Nevertheless, we assuming here as a first approximation that the flow is logarithmic all theway from the wall (thus neglecting the viscous sublayer) to the centerline (where we ignorethe cusp), and we will adjust the result afterwards based on laboratory data.Using expression (7-15b) all the way from r 0 to r R, we estimate the meanvelocity. After some algebra, we obtain:U 1 R2 R0u (r ) 2 rdr u* Ru* 3 5.56 u* .ln 2 (7-16)Since the turbulent stress is related to the friction velocity by w u*2 , it follows that w U 2 1 Du* 3 ln 2 2 5.56 2.(7-17)Note that this is an implicit relation since u*, which is the wall stress in disguise, occurs inthe denominator on the right-hand side. In terms of the friction factor, this expressionbecomes:107

Plumbingf 8 w U 2 1 Re ln 48 f 3 5.56 2 2 2.This is usually re-packaged for ease of calculations in terms of 1/11 1 Re ln f 2 2 4f2f : 3 5.56 2 or, after performing the numerical evaluations with 0.40, 1 0.88ln Ref f 0.89 .(7-18)Based on laboratory data with smooth pipes, the coefficients should be adjusted as follows: 1 0.87 ln Re f 0.80 .f(7-19)This adjustment makes up for the fact that we were quite approximate in our use of thevelocity profile.For a rough wall, the roughness height z0 supersedes the viscosity as the factor inthe logarithmic velocity profile, according to (6-13):u (r ) u* lnR r.z0(7-20)Assuming again that this is valid from wall to centerline, we deduce the average velocity:U 1 R2 R0u (r ) 2 rdr u* R 3 ln , z0 2 (7-21)which we relate to the stress using w u*2 : w 108 2U 2 D 3 ln 2 z0 2 2,(7-22)

Plumbingwhich is a purely quadratic relationship between stress and averaged velocity. In terms ofthe friction factor, this becomes:f 8 2 D 3 ln 2z0 2 2,which is independent of the Reynolds number and can be recast as: D 1 1.94 0.88ln .f z0 (7-23)The empirical relation obtained from laboratory data on rough pipes, to which we couldcompare (7-23) does not use the roughness height z0 as defined in Section 6-5 and whichgoes into the logarithmic profile, but uses the height of the averaged roughness element,denoted e and which is about 20 times as large z0. With z0 e/20, (7-23) becomes:1 D 0.71 0.88ln .f e Adjustment of the numerical coefficients to fit laboratory data leads to:1 D 1.14 0.87 ln .f e (7-24)Assembling all the information, on laminar flow, turbulent flow in smooth pipes,and turbulent flow in rough pipes, we obtain the so-called Moody Chart, reproduced hereas Figure 7-3. It provides the friction factor f as a function of the Reynolds number Re UD/ of the flow, and the relative roughness e/D of the inner pipe wall.To avoid the reading of imprecise numbers from a graph or to automate calculationsin a computer program, the following formulas are recommended:f 64Re For Re 2100, use the laminar formula: For 2100 Re 4000: Transitory and unstable situation to be avoided. For 4000 Re, use the so-called Colebrook-White formula that recapitulates bothturbulent cases: e19.29 1.14 0.87 ln (7-26) D Re f f (7-25)109

PlumbingFigure 7-3. The Moody Chart, which gives the friction factor as a function of the Reynolds numberand pipe roughness.110

PlumbingIt is interesting to use the Moody Chart to the drinking from a straw to answer thequestion of how much sucking pressure is spent on overcoming gravity and how is spenton friction. For this, we set the following four variables (Figure 7-4): the inner diameter Dof the straw, its length L, the elevation H from the surface of the beverage to the mouth,and the flow rate Q.Figure 7-4. Drinking from a straw, with pertinent notation.If the person drinks a cup-full of about 600 cm3 in 45 seconds, Q 1.33 x 10-5 m3/s, and ifthe inner diameter of the straw is 8 mm, the averaged velocity of the beverage in the strawis U (1.33 x 10-5 m3/s)/(5.03 x 10-5 m2) 0.27 m/s. This makes the Reynolds number beabout Re (0.27 m/s)(0.008 m)/(1.14 x 10-6 m2/s) 1860, which falls in the laminar regimebecause it is less than 2100. Thus, the friction factor is f 64/Re 0.034. For a strawlength of L 24 cm, the frictional pressure drop according to (7-7) is:f U 2 L2 D0.034 (1000 kg/m3 )(0.27 m/s) 2 (0.24 m) 37.2 Pa .2(0.008 m) p In comparison, the pressure difference due to gravity over an elevation H 16 cm is: p g H (1000 kg/m3 )(9.81 m/s 2 )(0.16 m) 1570 Pa .Thus, we see that only 2% of the sucking pressure to be applied by the mouth to the strawis to overcome friction, with the remaining 98% being needed to overcome gravity.A second application is the estimation of the power needed to flow municipaldrinking water over 1km of underground steel piping.(to be continued)111

Plumbing7-4. Water hammerHave you ever heard a loud clang or clatter coming from the plumbing system ofthe building in which you are, like a hammering noise? This is called water hammer, aphenomenon caused by a sudden variation in pipe flow, such as upon the quick closing ofa faucet or valve in a pipe with fast moving water. The sudden halt of fast moving watergenerates a shock wave that triggers compressibility effects and travels across the systemback and forth until its energy dissipates. The nature of the compressibility is two-fold;there is compressibility of the water itself (weak but not zero) as well as elasticity in thepipe material (widening and shrinking of its cross-section). A compressibility wave is asound wave because it generates frequencies in our audible range, which we perceive asnoise. Because it severely stresses the pipes and also because of its unwelcome noise,water hammer is something to be avoided. The remedy is to place somewhere along thesystem an air chamber that can accommodate the compressibility effects in gentle fashion.The physics of water hammer can be described relatively simply by means of a onedimensional model retaining only the axial variability of the flow in the downstreamdirection and ignoring variations across the pipe (Mohamed Ghidaoui et al., 2005). Forthis, we can start by integrating the equations of motion in the two transverse directions inorder to retain only the axial direction and time, but it is tricky because of the distortingpipe geometry. It is easier as well as more intuitive to return to the basic principles of massconservation and momentum balance.We define the along-pipe direction as the x-axis, A as the cross-sectional area of thepipe, and U as the averaged flow velocity through A. The mass balance is relativelystraightforward to state. The accumulation over time of mass dm dV Adx in the stretchof pipe from position x to x dx is equal to the mass flux AU entering at x minus thatexiting at position x dx:d ( Adx) AU x AUdtx dx.In the limit dx 0, this can be recast as1 d ( A) U 0, A dt x(7-27)in which d / dt / t U / x stands for the material derivative. Both density andcross-sectional area A change with pressure p in the pipe. We are led to define:1 d dA .c 2 dp A dp112(7-28)

PlumbingThe first term arises from the compressibility of the water whereas the second term fromthat of the pipe. So defined, the (positive) quantity c happens to be the sound speed of thewater plus pipe wall combination. Because water is weakly compressible and the pipematerial weakly elastic, the quantity 1/c2 is tiny, which makes c be a large speed, muchlarger than the water velocity:c U .(7-29)In practice, the sound speed ranges from 100 to 1400 m/s depending on the watertemperature and especially the elasticity of the pipes, with the higher values being mostlikely, while the flow velocity will never exceed 10 m/s, with a few meters per secondbeing most common (Ghidaoui et al., 2005). Another way of stating (7-29) is that the waterflow in the pipe is very subsonic (Mach number 1).With definition (7-28) becomes:1 dp U 0. c 2 dt x(7-30)The momentum balance likewise follows. The accumulation over time ofmomentum (dm)U ( dV)U AUdx in the stretch of pipe from position x to x dx is equalto the momentum flux ( AU)U entering at x minus that exiting at position x dx plus thesum for pushing forces and minus the braking forces:d ( AU dx) AU 2 AU 2xdtx dx pA x pA x dx (dm) gdz ( Ddx) w ,dxin which p is the pressure, g the gravitational acceleration, dz/dx the slope of the pipe axiswith respect to the horizontal (positive upward), and w the frictional wall stress against theinner pipe surface Ddx. Doing the same algebra as for the mass conservation equation,we can recast this equation as1d ( AU ) U pdz AU A g A D w .dt x xdxThen using (7-27) and after division by A, it can be reduced to:dU1 pdz D w g .dtdx A x(7-31)Equations (7-30)-(7-31) can be simplified by introducing the piezometric head h, defineddifferentially as1Delicate point: The difference pA pAin the limit dx 0 is A p / x rather than ( pA) / x becausexx dxof the axial contribution of the pressure on the slanted pipe wall.113

Plumbingdh dp dz , g(7-32)which is a way of capturing the pressure minus its hydrostatic component in terms of aheight. With (7-6) to express the ratio w/ in terms of the flow velocity U, (7-32) to replacep in terms of h, and finally A D2/4, Equations (7-30) and (7-31) reduce to:dh dz c 2 U 0dt dt g x hdUf g U2, x 2 Ddt(7-33a)(7-33b)where f is the friction factor encountered at the end of Section 7-1. We now have acomplete set of equations since (7-33a,b) form a 2-by-2 set of differential equations for thetwo remaining variables U and h, each function of x and t.A last and major simplification can be made by taking advantage of the fact thatthe flow velocity U and therefore also the vertical velocity w dz/dt are both much slowerthan the sound speed c, as already noted in (7-29). With very little approximation, thematerial derivative reduces to its first term, the partial derivative with respect to time, andwe obtain: h c 2 U 0 t g x U hf g U2. t x 2 D(7-34a)(7-34b)The solution in the frictional case is fairly complicated because of the nonlinearityof the U2 term (and indirectly also from the fact that, if the pipe is not too rough, f varieswith the Reynolds number and therefore U), but for a moderate length, friction may beneglected. The solution is then a simple sine wave: x h( x, t ) H cos t , c U ( x, t ) x gHcos t c c (7-35)with amplitude H and angular frequency . The wave propagates along the pipe at speeddx/dt c because the phase remains unchanged at that speed.7-5. What happens when the pipe changesThe preceding considerations restricted the attention to pipes with uniform diameterD; they also ignored any possible bend, elbow or tee along the pipe. In a sharp curve, the114

Plumbingcentrifugal force generates a secondary circulation, and the added velocity componentincreases the amount of friction. Where the pipe diameter D changes, conservation ofvolumetric flow rate forces the velocity to adjust, which by virtue of the Bernoulli Principlecauses a pressure modification. Therefore, there are many other ways by which pressuremay vary along a pipe other than wall friction in straight uniform sections.7-5-a. Venturi and orificeIn a constriction (reduced cross-section), the flow velocity has to increase toaccommodate an unchanged volumetric flowrate. In the notation of Figure 7-5: If A2 A1,then U2 U1 so Q A1U1 A2U2. If this occurs over a relatively short horizontal distance,friction is not significant effect and there is no gravitational effect. The Bernoulli Principleholds and reduces to:p1 U12 p2 U 22 ,2 2(7-36)Figure 7-5. Pressure drop in a constricted pipe, called the Venturi effect.assuming an incompressible fluid. The change in velocity causes a pressure difference: p p1 p2 U222 U21 Q2 11 2 2 0.2 A2 A1 (7-37)This pressure difference can be made visible by letting the fluid rise in two manometers,one upstream at the larger cross-section and the other at the narrowest section. With noflow inside the manometer tubes, the pressure is hydrostatic, and the height differencebetween the two is found to be:h p Q 2 11 2 2 0. g 2 g A2 A1 (7-37)115

PlumbingThis pressure drop can be put to use to create a spray. As shown in Figure 7-6, apressurized air flow is severely constricted to the point of creating a sub-atmosphericpressure which is able to suck a liquid from a side reservoir. The sucked fluid disintegratesinto droplets upon entering the fast airflow, and out comes a mist. Such mist generatorsare utilized to spray fertilizer on a field, paint on an object, water on hair, and in countlessother applications.Figure 7-6. A Venturi device to generate a spray. The constrictedairflow reaches a sub-atmospheric pressure that sucks liquid from aside reservoir, the liquid disintegrates into droplets, and a mist flowsout the nozzle.Force required to hold a firefighting nozzlePressure drop due to an orifice; definition of the loss coefficient K; possibility ofmeasuring the flow rate from the pressure drop.7-5-b. Bends, elbows and teesTables and graphs for K values.7-5-c. ValvesK values.7-6. Give and take energy: Pumps & turbinesPumps & compressorsTurbinesLubrication: viscous flow in wedge116

PlumbingThought problems7-T-1. Question7-T-2. Question7-T-3. In the application to the drinking with a straw (Figure 7-4), the elevation H wastaken from the surface of the beverage to the mouth. Why not from the bottom tip ofthe straw?Quantitative Exercises7-Q-1. Question7-Q-2. Question7-Q-3. Question117

Plumbing 105 In practice for calculations, it is preferable to use a dimensionless quantity, which is called the friction factor f: 22 28f w gD h f UL U . (7-6) Thus, the friction factor is a non-dimensional way of capturing the head loss or the wall stress. For a horizontal pipe, it