Transcription

Volume 2: Anchor Fastening Technical Guide 2011

North AmericanProduct TechnicalGuideVolume 2:Anchor FasteningTechnical GuideA guide to specificationand installation2011 Edition

PROFIS AnchorsoftwareAnchor design ata click.Hilti. Outperform. Outlast.At Hilti, we work hard to help build a betterworld. Hilti PROFIS Anchor represents thenext generation in anchor design software.PROFIS Anchor performs calculationsfor cast-in-place anchors and Hilti postinstalled anchors in accordance with theStrength Design provisions of ACI 318 andthe International Building Code. Ask yourHilti Field Engineer for details.

Anchor Fastening Technical GuideTable of ContentsIntroduction1.04Fastening Technology2.05Anchoring Systems3.014Construction Chemicals4.0353Reference5.0372Hilti North American Product Technical Guide Volumes 1 and 3 are also available.Contact your Hilti Field Engineer about them today.Hilti, Inc. (US) 1-800-879-8000 www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Anchor Fastening Technical Guide 2011 1

Anchor Fastening Technical GuideAnchoring Systems Table of duction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4About Published Load Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Our Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4Our Quality System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.12.3.22.3.32.3.42.3.52.3.6Fastening Technology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Base Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Base Materials for Fastening . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Concrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5Masonry Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6Autoclave Aerated Concrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Pre-tensioned/Pre-stressed Concrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Bonded Post-tensioned Concrete . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Admixtures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Evaluation of Test Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8Corrosion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10The Corrosion Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Types of Corrosion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Corrosion Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10Test Methods . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Hilti Fastening Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.93.1.9.93.1.103.1.113.1.123.1.133.1.14Anchoring Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Anchor Principles and Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Allowable Stress Design Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14Strength Design Terminology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16Anchors in Concrete and Masonry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Anchor Working Principles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17Anchor Behavior Under Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Anchor Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Allowable Stress Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Strength Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21Design Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26KWIK Bolt-TZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26KWIK HUS-EZ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34HIT-HY 150 MAX-SD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40Torquing and Pretensioning of Anchors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49Design of Anchors for Fatigue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49Design of Anchors for Fire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49Design of Post-Installed Reinforcing Bar Connections. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50Anchor Selection Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3.2.10Adhesive Anchoring Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57Adhesive Anchoring Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57The Hilti HIT System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58HIT-HY 150 MAX-SD Adhesive Anchoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60HIT-RE 500-SD Epoxy Adhesive Anchoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91HIT-TZ with HIT-HY 150 MAX or HIT-ICE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129HIT-HY 150 MAX Adhesive Anchoring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134HIT-RE 500 Epoxy Adhesive Anchoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178HIT-ICE Adhesive Anchoring System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 195HIT-HY 20 Adhesive System for Masonry Construction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 214HVA Capsule Adhesive Anchoring System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2242 Hilti, Inc. (US) 1-800-879-8000 www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Anchor Fastening Technical Guide 2011

Anchor Fastening Technical GuideAnchoring Systems Table of 133.3.143.3.153.3.163.3.173.3.183.3.19Mechanical Anchoring Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241HDA Undercut Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 241HSL-3 Heavy-duty Expansion Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 253HSL Heavy-duty Expansion Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262KWIK Bolt TZ Expansion Anchor (KB-TZ). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 267KWIK HUS-EZ (KH-EZ) Carbon Steel Screw Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280KWIK Bolt 3 (KB3) Expansion Anchor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 291KWIK HUS (KH) Carbon Steel Screw Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 315HCA Coil Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 324HDI and HDI-L Drop-in Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 327HDI-P Drop-in Anchor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331HCI-WF/MD Cast-in Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 332HLC Sleeve Anchor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 336KWIK-CON II Fastening System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 340Metal Hit Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 346HPS-1 Impact Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347HTB TOGGLERÆ Bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 349HLD KWIK Tog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 350HSP/HFP Drywall Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 351IDP Insulation Anchor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.34.54.5.1Construction Chemicals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353Chemical Systems Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 353Crack Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354CI 060 Crack Injection System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 354Repair Mortar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356RM 700 EP Epoxy Repair Mortar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 356RM 710 EP Lo-Temp Mortar. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 358RM 800 PC Cement Repair Mortar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 360Grout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362CB-G MG Multipurpose Grout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 362CB-G PG Precision Grout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 364CB-G EG Epoxy Grout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 366Fire Protection Steel Spray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 368CFP-S WB Fire Protection Steel Spray (Intumescent Coating) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35.2.45.35.3.15.3.25.3.35.3.4Reference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372Approvals and Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372ICC-ES (International Code Council) Evaluation Reports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372COLA (City of Los Angeles) Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372Miami-Dade County Approvals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372Underwriters Laboratories Listings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372FM Global Approvals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 372Reference Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373ASTM Standards for Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 373ASTM Plating Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374Federal Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374ANSI Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 374Technical References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375Metric Conversions and Equivalents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 375Mechanical Properties of Materials. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 376Bolt Thread Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 377Concrete Reinforcing Bar Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 378Terms and Conditions of Sale . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 383Hilti, Inc. (US) 1-800-879-8000 www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Anchor Fastening Technical Guide 2011 3

Anchor Fastening Technical Guide1.0 Introduction1.1 About Published Load Values1.3 Our PurposeThe Anchor Fastening Technical Guide is intended toWe passionately create enthusiastic customers and builda better future!supplement the Hilti Product and services catalog withtechnical information for the designer or specifier. Technicaldata presented herein was current as of the date of publication (see back cover). Load values are based on testing andanalytical calculations by Hilti or by contracted testing laboratories using testing procedures and construction materialsrepresentative of current practice in North America. Variationsin base materials such as concrete and local site conditionsrequire on-site testing to determine actual performance at anyspecific site. Data may also be based on national standards orprofessional research and analysis.Note that design values published in reports issued byapproval agencies (e.g., ICC-ES, COLA, etc.) may differfrom those contained in this publication.For information regarding updates and changes, pleasecontact Hilti,Inc. (US) Technical Support at 1-800-879-8000or Hilti (Canada) Corporation at 1-800-363-4458.1.2 UnitsTechnical data is provided in both fractional (Imperial) andmetric units. Metric values are provided using the InternationalSystem of units (SI) in observance the Metric ConversionAct of 1975 as amended by the Omnibus Trade andCompetitiveness Act of 1988. Data for metric products, suchas the HSL and HDA anchors, is provided in SI units withconversions to Imperial engineering units (inches, pounds, andso forth) given in parentheses. Data for fractional products(e.g. the KWIK Bolt 3) is provided in imperial engineeringunits with the SI metric conversions shown in parentheses.Additional information may be found in Section 5.3.1 MetricConversions and Equivalents, provided in this producttechnical guide.Enthusiastic CustomersWe create success for our customers by identifying theirneeds and providing innovative and value-added solutions.Build a better futureWe embrace our responsibility towards societyand environment.1.4 Our Quality SystemHilti is one of a select groupof North American companiesto receive the ISO 9001 andISO 14001 Certifications. Thisrecognition of our commitmentto quality ensures our customersthat Hilti has the systems andprocedures in place to maintainour position as the world market leader, and to continuallyevaluate and improve our performance.That s Total Customer Satisfaction!For Technical Support, contact Hilti,Inc. (US) at 1-800-8798000 or Hilti (Canada) Corporation at 1-800-363-4458.4 Hilti, Inc. (US) 1-800-879-8000 www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Anchor Fastening Technical Guide 2011

Anchor Fastening Technical GuideFastening Technology 2.02.1 Base Materials2.1.1 Base Materialsfor FasteningThe design of modern buildings requires fastenings to bemade in a variety of base materials. To meet this challenge,fastener manufacturers have developed many productsspecifically targeting certain types of base materials. Theproperties of the base material play a decisive role in thesuitability and performance of a fastener. The designer mustcarefully match the type of fastener with the base material toobtain the desired results. There is hardly a base material inwhich a fastening cannot be made with a Hilti product.2.1.2 ConcreteConcrete is a mineral building material which is made fromthree basic ingredients; cement, aggregate and water. Specialadditives are used to influence or change certain properties.Concrete has a relatively high compressive strength comparedto its tensile strength. Thus, steel reinforcing bars are cast inconcrete to carry the tensile forces, and this combination isreferred to as reinforced concrete.Cement is the binding agent which combines with water andaggregate and hardens through the process of hydration toform concrete. Portland cement is the most common cementand is available in several different types, as outlined in ASTMC 150, to meet specific design requirements.The aggregates used in concrete consist of both fineaggregate (usually sand) and coarse aggregate graded byparticle size. Different types of aggregates can be used tocreate concrete with specific characteristics. Normal weightconcrete is generally made from crushed stone or gravel.Lightweight concrete is used when it is desirable to reducethe dead load on a structure or to achieve a superior fire ratingfor a floor structure. Lightweight aggregates are made fromexpanded clay, shale, slate or blast-furnace slag. Lightweightinsulating concrete is used when thermal insulating propertiesare a prime consideration. Lightweight insulating aggregatesare manufactured from perlite, vermiculite, blast-furnaceslag, clay or shale. Sand lightweight concrete is made fromlightweight aggregate and natural sand. All concrete witha unit weight between 85 and 115 pcf is considered to bestructural lightweight concrete. The ASTM specification andunit weight for each of these concretes is summarized asfollows:ASTMConcreteTypeAggregate GradingSpecificationConcrete UnitWeight pcfNormal WeightASTM C 33145-155Sand LightweightASTM C 330105-115All LightweightASTM C 33085-110LightweightASTM C 33215-90Insulating ConcreteThe type and mechanical properties of concrete aggregatehave a major influence on the behavior of drill bits used to drillanchor holes. The harder aggregates cause higher bit wearand reduced drilling performance.The hardness of concrete aggregate can also affect the loadcapacity of power-actuated fasteners and anchors. Drivenfasteners or studs can generally penetrate soft aggregates(shale or limestone), but hard aggregates (like granite) near thesurface of the concrete can adversely affect the penetrationof a fastener or stud and reduce its load capacity. The effectof aggregate mechanical properties on anchor performanceis less well understood, although in general harder/denseraggregates such as granite tend to result in higher concretecone breakout loads, whereas lightweight aggregates producelower tension and shear capacities.Values for the ultimate strength of fasteners in concreteare traditionally given in relation to the 28-day uniaxialcompressive strength of the concrete (actual, not specified).Concrete which has cured for less than 28 days is referredto as green concrete. Aggregate type, cement replacementssuch as fly ash, and admixtures could have an effect on thecapacity of some fasteners, and this may not be reflected inthe concrete strength as measured in a uniaxial compressiontest. Generally, Hilti data reflects testing with commonaggregates and cement types in plain, unreinforced concrete.In questionable cases, consult with Hilti Technical Support.In view of the significantly lower strength of green concrete(less than 28-day cure), it is recommended that anchors andpower-actuated fastenings not be made in cast-in-placeconcrete which has cured for less than 7 days, unless sitetesting is performed to verify the fastening capacity. If ananchor is installed in green concrete, but not loaded until theconcrete has achieved full cure, the capacity of the anchorcan be based on the strength of the concrete at the time ofloading. Power-actuated fastening capacity should be basedon the concrete strength at the time of installation.Cutting through concrete reinforcement when drilling holesfor anchors should be avoided. If this is not possible, theresponsible design engineer should be consulted first.Hilti, Inc. (US) 1-800-879-8000 www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Anchor Fastening Technical Guide 2011 5

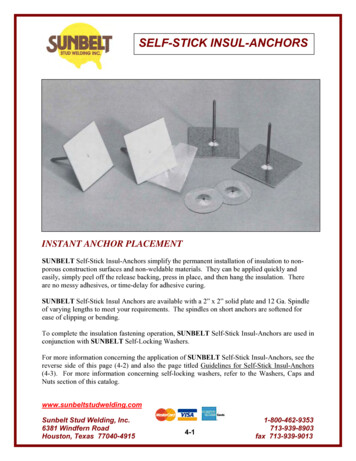

Fastening Technology2.1 Base Materials2.1.3 Masonry Materials8"Masonry is a heterogeneous building material consisting ofbrick, block or clay tile bonded together using joint mortar.The primary application for masonry is the construction ofwalls which are made by placing masonry components inhorizontal rows (course) and vertical rows (wythe). Masonrycomponents are manufactured in a wide variety of shapes,sizes, materials and both hollow and solid configurations.These variations require that the selection of an anchoring orfastening system be carefully matched to the application andtype of masonry material being used. As a base material,masonry generally has a much lower strength than concrete.The behavior of the masonry components, as well as thegeometry of their cavities and webs, has a considerableinfluence on the ultimate load capacity of the fastening.When drilling holes for anchors in masonry with hollowcavities, care must be taken to avoid spalling on the insideof the face shell. This could greatly affect the performanceof toggle type mechanical anchors whose length must bematched to the face shell thickness. To reduce the potentialfor spalling, holes should be drilled using rotation only (i.e.hammering action of the drill turned off).2.1.3.1 Concrete BlockConcrete block is the term which is commonly used to refer toconcrete masonry units (CMU) made from Portland cement,water and mineral aggregates. CMUs are manufacturedin a variety of shapes and sizes using normal weight andlightweight aggregates. Both hollow and solid load bearingCMUs are produced in accordance with ASTM C90.NominalMinimum face-shellMinimum webThicknessAThicknessAin. (mm)in. (mm)in. (mm)3 (76) and 4 (102)3/4 (19)3/4 (19)Width of Unit6 (152)1 (25)1 (25)8 (203)1-1/4 (32)1 (25)10 (254)1-3/8 (35)1-1/8 (29)7-5/8"7-5/8"8"16"Nominal Size(usually fictitious)15-5/8"Modular Size(actual)CMU sizes generally refer to the nominal width of the unit(6", 8", 10" etc.). Actual dimensions are nominal dimensionsreduced by the thickness of the mortar joint.Concrete block construction can be reinforced, wherebyreinforcing bars are placed vertically in the cells andthose cells are filled with grout to create a compositesection analogous to reinforced concrete. If all cells,both unreinforced and reinforced, are filled with grout,the construction is referred to as fully grouted. If only thereinforced cells are grouted, the construction is referred toas partially grouted. Horizontal reinforcing may be placed inthe wall via a bond beam, which is always grouted. Ladderreinforcement may also be placed in the mortar bed betweencourses. Grout typically conforms to ASTM C476 and hasa compressive strength of at least 2,000 psi. Concretemasonry units have a compressive strength which mayrange from 1,250 to over 4,800 psi, although the maximumspecified compressive strength of the assembled masonrywill generally not exceed 3,000 psi. In general, both chemicaland mechanical anchors may be used in grouted CMU. Ifvoids are present or suspected, mechanical anchors shouldnot be used, and chemical anchors should only be installedin conjunction with a screen tube to prevent uncontrolled flowof the bonding material. In hollow CMU, anchor strength isgenerally assumed to be derived from the face shell thickness,which can be variable.1-1/4 (32)B 12 (305)1-1/2 (38)1-1/8 (29)1-1/4 (32)BAdapted from ASTM C 90.A Average of measurements on three units taken at the thinnestpoint.B This face-shell thickness is applicable where the allowable designload is reduced in proportion

Anchor Fastening Technical Guide 1.0 Introduction 4 Hilti, Inc. (US) 1-800-879-8000 www.us.hilti.com I en español 1-800-879-5000 I Hilti (Canada) Corp. 1-800-363-4458 I www.hilti.ca I Anchor Fastening Technical Guide 2011 1.1 A bout Published Load Values The Anchor Fastening Technical G