Transcription

2018 IJSRST Volume 4 Issue 9 Print ISSN : 2395-6011 Online ISSN : 2395-602XThemed Section: Science and TechnologyStudy of Effect of Etching Time and Concentration onMicrostructure of SG 400/12 Grade Ductile Cast IronNilesh T. Khot*, Anil S. Morkane*, Umesh V. Borkar*, Sanket S. Maske*, Prof. B. S. Kamble#*UG students at Department of Production Engineering, KIT’s College of Engg., Kolhapur, Maharashtra, India#Assistant Professor atDept.of Production Engg., KIT’s College of Engg., Kolhapur, Maharashtra, IndiaABSTRACTThe study of material microstructure is known as Metallography. This is very critical in estimating the materialproperties. Metallography can be a very useful quality control tool too. By examining the micrographs one candetermine the quality of the product. Micro structural examination is generally done on a sample whose surfacehas been grinded or polished to a mirror-like finish. SG cast iron is characterized by nodules-like graphitedistribution when seen under an optical microscope. The as-polished samples are also etched with variousetchants to look at the underlying phases (e.g. ferrite, pearlite, cementite), which also have an effect on theproperties of the SG cast-iron. If a casting has predominant ferrite phase, then it would be soft. Ample presenceof carbide will lead to a hard material. The study reported here deals with the etching of SG cast iron (400/12Grade) samples for short etching time (4 – 10 sec) and also for long etching time (30 sec and 60 sec). For thepurpose of observing the microstructure we have used Scanning Electron Microscope (SEM). The optimalsolution is taken by the use of regression analysis technique. Etching is the selective corrosion of the surfaceunder consideration to reveal the underlying features. The purpose of etching is to reveal certain features (e.g.grain boundary and phases) which are not visible in the as-polished condition.Keywords : Sampeling, Polishing, Etching, Microscopic examination, Nital, PicralI.INTRODUCTIONelectron microscopy. Using only metallographicMetallography has been described as both a sciencetechniques, a skilled technician can identify alloys,predict material properties and its performance andand an art. Traditionally, metallography has been thereliability. Thus metallography is used in materialsstudy of the microscopic structure of metals and alloysdevelopment, incoming inspection, production andusing optical metallographs, electron microscopes ormanufacturing control, and for failure analysis; inother surface analysis equipment. It can be moreother words, product reliability.precisely defined as the scientific discipline ofobserving and determining the chemical and atomicII. LITERATURE REVIEWstructure and spatial distribution of the constituents,inclusions or phases in metallic alloys. The surface of aS. Chakraborty et.al (1) have studied, the most commonlymetallographic specimen is prepared by variousused concentrations of Nital and Picral and has foundmethods of grinding, polishing, and etching. Afterthat with Etching for 10 sec, 2% Nital provides anpreparation, it is often analysed using optical oroptimum etch. For extended etching, Picral providesIJSRST184953 Received : 01 August 2018 Accepted : 13 August 2018 July-August-2018 [ 4 (9) : 247-252]247

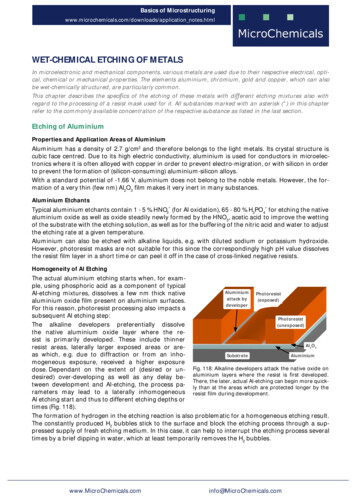

Nilesh T. Khot et al. Int. J. Sci. Res. Sci. Technol. 2018 July-August-201; 4(9) : 247-252an optimum etch at 70 sec of etching which can go upto 80 sec of etch and the concentration of Picral maybe between 3% - 4%. David A. Scott (3) had observedthat the grey cast iron contains 4% carbon and a littlephosphorus in early 20th century. Before etching, theoutlines of some of the thick graphite. T.M. Hegazy(4)has undergone study of effect of NaOH concentrationand etching duration on some properties of γirradiated PADC and it is revelled that bulk etchingrate shows weak dependence on the etching time.David P. B. Samuelsso (6) had used digital imageFigure 2. Speciman samples cut of SG Iron gradecorrelation technique (DIC). This method is mostly400/12 to carry out buffing operationused for determination of strains on a macroscopiclevel e.g. testing of a tensile test piece or any other testThe surface on which the polishing operations have topiece or component that is exposed to a load. And it isbe done, initially they are made free from burs andfound that it is possible to investigate strain-fields on asharp edges with the help of file. Manual polishingmicroscopic scale, different phases of cast irons andwith successively 100, 200, 300 and 400 grade sandtheir strain response during loading and to investigatepapers are used.the effect of eutectic cells and primary austenite onspecimensthe strain distribution. Donald Zipperianmetallography. To achieve the mirror like surfacefinish they are placed on the Buffing Machine.(7)hasenlisted different types of etchants used for etchingare mentioned. George Vander Voort (21) has studiednowAfter the semi finishing of thetheyarepreparedforactualthe microstructure of CI using different etchantsnamely Nital and Picral at various concentration andtime rates. Also discussed about the how to preparethe sample specimen for metallographic study withoutdamage.III. EXPERIMENTAL PROCEDUREFigure 3. Buffing MachineFor this experimental study, the most commonly usedFigure 1. Test Speciman of SG Iron grade 400/12Nitric acid and Picric acid were used as etchants. Nitaland Picral with 2% and 4% concentration were usedThe SG Iron material of grade 400/12 is taken aswith acid dipping dwell period of 4,10,30,60 secondssample under study. The initial material which in theperiod. The 2% Nital was prepared by adding 2 ml ofform of rod cut into the length 10 * Ø15 mm as shownconcentrated Nitric acid (HNO3) in 100 ml of 99%in Figure with the help Semi-automatic Hack SawEthanol. Similarly 3% and 4% Picral were prepared byMachine.adding 3 ml and 4 ml of picric acid in 100 ml 99%International Journal of Scientific Research in Science and Technology (www.ijsrst.com)248

Nilesh T. Khot et al. Int. J. Sci. Res. Sci. Technol. 2018 July-August-201; 4(9) : 247-252ethanol respectively. Every time freshly prepared9etchant were used for each study.1011Table .1 Experimental parameters and EtchantEtching 30460After the preparation of specimen, these are dipped in54the etchants of various concentrations. Then the10microstructural images are observed under SEM30(Scanning Electron Microscope).67Nital4%860(a)(b)(c)(d)Figure 4. Samples etched with 2%Nital with 4sec, 10 sec, 30 sec and 60Sec dwell time period withmagnification 100X(a)(b)(c)(d)Figure 5. Samples etched with 4%Nital and with 4sec, 10 sec, 30 sec and 60Sec dwell time period withmagnification 100X(a)(b)(c)(d)Figure 6. Samples etched with 2%Picral and with 4sec, 10 sec, 30 sec and 60Sec dwell time period withmagnification 100XInternational Journal of Scientific Research in Science and Technology (www.ijsrst.com)249

Nilesh T. Khot et al. Int. J. Sci. Res. Sci. Technol. 2018 July-August-201; 4(9) : 247-252(a)(b)(c)(d)Figure 7. Samples etched with 4%Picral and with 4sec, 10 sec, 30 sec and 60Sec dwell time period withmagnification 100XTable .2 Percentage of Nodularity and nodules observed under SEMEtchant2% Nital4% NitalEtching%NodulesEtching%NodulesTime (sec)Nodularity(%)Time 98.830829.8308510.560809.1608710.1Etchant2% Picral4% PicralIV. MICROSTRUCTURAL OBSERVATIONSconcentration and time of 30 and 60 sec there is clearThe magnified images from the etched samples with 2% visibility of Ferritic grain boundry. There is clearNitric acid are as shown in figure 4. It is clearly observation of Pearlitic matrix with 9.40% pearlite &observed changes in the pearlite and Ferritic grain82.50% Ferrite.boundry visibility with an increase in the etchingtime from 4 sec to 60 sec. Figure 4a clearly showsThe magnified images from the etched samples with 2%signs of Insufficient etching concentration with noPicric acid are as shown in figure 6. There is no sign ofany clear visibility of phase as well as Ferritic grainvisibility of Ternary phosphorous eutectic (carbides)boundry. With increase in etching holding time thein structure. With increase in etching holding timemicrostructural contrast also increase. With 2% Nitalthere is visible Contrast among the different phaseconcentration and etching holding time of 4 to 60 sec.,with increased darkness. With 2 and 4% Nitric andan average of 9.7% Nodules are observed .SimilarlyPicric acid Ternary phosphorous eutectic (carbides)magnified images from the etched samples with 4%are not observed in structure.Nitric acid are as shown in figure 5. Here also it isobserved that there is increased contrast with increaseV. CONCLUSIONin acid concentration and etching holding time. Anaverage of 9.3% Nodules are observed with 4% NitalShorter period etching duration of 4 sec and 10 secconcentration and time of 4 to 60 sec. With 4% Nitalwith 2% Nitric acid visualises clear phases andInternational Journal of Scientific Research in Science and Technology (www.ijsrst.com)250

Nilesh T. Khot et al. Int. J. Sci. Res. Sci. Technol. 2018 July-August-201; 4(9) : 247-252nodules. With extended etching duration period of 30[9]Diploma work No. 47/2011, September 2003,sec with 4% Nitric acid gives optimum and clearChemical Etching, PACE Technologies, Volumemicrostructure visibility. Picric acid provides betterII, Issue 5.results with 4% and 4 sec etching duration time.[10] B.S. Motagi, Ramesh Bhosle, July 2012, Effect ofHeatVI. REFERENCESTreatmentonMicrostructureandMechanical Properties of Medium Carbon Steel,International Journal of Engineering Research[1]S. Chakraborty and S. Nadimuthu, Novemberand Development, Volume 2, Issue 1, Page No.2013, Study Of Etchants in Grey Cast Iron –7-13.Effect Of Etching Time, Indian Foundry Journal,volume-59, No. 11, Page No. 19-25.[2][3][11] F. Hairer, A. Karelová, C. Krempaszky, E.Werner, T. Hebesberger, A. Pichler, EtchingCast Iron Handbook, Edited by Joseph R. Davis,TechniquesASM International.Characterization Of Complex Phase Steels ByE.E.T. ELSawy,, M.R. EL-Hebeary, I.S.E. ElLight Microscopy, Page No. 50-54.Mahallawi, July 2017, Effect of ructural[12] Francesco Iacoviello, Daniela Iacoviello, VittorionDi Cocco, Alberto De Santis, Laura D Agostino,microstructure and wear characteristics of greylassification of ductile cast iron specimens basedcast iron for sugar industries applications,on image analysis and support vector machineVolume-320.XXIV Italian Group of Fracture Conference, 1-3https://doi.org/10.1016/j.wear.2017.07.007March 2017, Urbino, e of Ancient and Historic Metals.[13] Jacques Lacaze, Jon Sertucha, Lena MagnussonAberg, Microstructure of As-cast Ferritic-[5]Chemical Etching, Donald Zipperian, QualityPearlitic Nodular Cast Irons ISIJ 1606, ISIJMatters Newsletter,Pace Technologies, Vol. 2,International, Vol. 56 (2016), No. 9, pp. 1606–Issue 5, 2003.1615[6][7]T.M. Hegazy, M.Y. Shoeib, G.M. Hassan,[14] Abhijit Malage, Priti P. Rege, Manoj J. Rathod,September 2013, Study on the effect of NaOHconcentration and etching duration on someAutomaticquantitativeanalysisofmicrostructure of ductile cast iron using digitalproperties of g-irradiated PADC, BENI - SUEFimage processing Association of Metallurgicaluniversity journal of basic and applied sciencesEngineers of Serbia (AMES) Scientific paper2, page No. 36-40.UDC: 620.18:669.13Deborah A. Redford, Brian H. Clarkson, MarkJensen, March 1986, The effect of different[15] Brij Kumar Dhindaw,Effect of ProcessingParameters on the Mechanical Properties ofetching times on the sealant bond strength, etchHeavy Section Ductile Iron Hindawi Publishingdepth, and pattern in primary teeth, TheCorporation, Journal of Metallurgy, VolumeAmerican Academy of Pediatric Dentistry, Vol.2015, Article ID 931535, 11 pages8 No. 1.[8][16] TâniaNogueira Fonseca Souzaa,b, Rogéria AlvesDavidP.B.Samuelsson,Analysisofmicrostructural strain-fields in grey cast cob,MariaTeresaDiploma work No. etlina,MicrostructuralCharacterization of Nodular Cast Iron withInternational Journal of Scientific Research in Science and Technology (www.ijsrst.com)251

Nilesh T. Khot et al. Int. J. Sci. Res. Sci. Technol. 2018 July-August-201; 4(9) : 247-252Niobium Additions Materials Research. 2014;Cast Iron Microstructure And Its Mechanical17(5): 1167-117Properties” International Journal of Engineering[17] teels-https://vacaero.com/information-Research and Applications (IJERA) ISSN: 22489622 www.ijera.com Vol. 3, Issue 3, May-Jun2013, teels.html[18] George Vander Voort, Microstructure of ostructure-of-ferrous-alloys.html[19] Cees van de velde, Etchants used to revealingthe Microstructure of Ductile Cast Ironhttp://www.ceesvandevelde.eu/etchants.html[20] George Vander Voort. Metallographic html[21] George Vander Voort. Safety in themetallography Laboratory.VAC ] Miss. Shilpa Godbole, Dr. (Mrs).V. Jayshree“Microstructure analysis of SGI using hybridimage processing approach” ISSN: 2278 – 1323[23] Mrs.VasuShinde,Mrs.B.Ravi“Effectoforientation , thickness and composition onproperties of Ductile iron castings’’InternationalJournal of Cast Metals Research 2012 VOL 000[24] AlexEscobar,DiegoCelentano,MarcelaCruchaga and Bernd Schulz “On the Effect ofPouring Temperature on Spheroidal GraphiteCast Iron Solidification”Received: 31 December2014 / Accepted: 27 March 2015 / Published: 20April 2015[25] Lisa Shifani Madtha, Prof.B.R Narendra Babu“Experimental Behavioural Study Of DuctileInternational Journal of Scientific Research in Science and Technology (www.ijsrst.com)252

an optimum etch at 70 sec of etching which can go up to 80 sec of etch and the concentration of Picral may be between 3% - 4%. David A. Scott (3) had observed that the grey cast iron contains 4% carbon and a little phosphorus in early 20th century. Before etching, th