Transcription

INDD B31.1 92m2595512 0078031 7T0 MASME-B31.1ADOPTION NOTICEASME-B31.1, "Piping, Power," was adopted on October 3, 1994for use by the Department of Defense (DoD). Proposedchanges by DoD activities must be submitted to the DoDAdopting Activity: Commanding Officer, Naval ConstructionBattalion Center, Code 156, 1000 23rd Avenue, Port Hueneme,CA 93043-4301. DoD activities may obtain copies of thisstandard from the Standardization Document Order Desk, 700Robbins Avenue, Building 4D, Philadelphia, PA 19111-5094.The private sector and other Government agencies maypurchase copies from the American Society of MechanicalEngineers, 345 East 47th Street, New York, NY 10017.Custodians:Adopting ActivityArmy - MENavy - YD-1Air Force - 99Navy - YD-1FSC 4710DISTRIBUTION STATEMENT A. Approved for public release;distribution is unlimited.COPYRIGXT American Society of Mechanical EngineersLfensed by Information7Handling Services

M1IlIfill1III

tc)!@SI The American Society ofMechanical EngineersA NA M E R I C A NN A T IO N A LS T A N D A R DASME CODE FOR PRESSURE PIPING, B31ASME B31.1-2001(Revision of ASME B31.1-1998)Rc w5od By GLOBALENGEGDOCUMhCOPYRIGHT American Society of ecchanical EngineersLicensed by Information Handling ServiceseUAPsfASt

Date of Issuance: December 10, 2001Mandatory Date: June 10, 20027his Edition was approved by the American National Standards Instituteand designated ASME B31.1-2001 on July 2, 2001The 2001 Edition of this Code is being issued with an automatic update service thatincludes Addenda, Interpretations, and Cases. The next Edition is scheduled for publicationin 2004.The use of Addenda allows revisions made in response to public review comments orcommittee actions to be published on a regular basis; revisions published in Addenda willbecome effective 6 months after the Date of Issuance of the Addenda.ASME issues written replies to inquiries concerning interpretations of technical aspectsof the Code. The Interpretations are published in a separate supplement.Periodically certain actions of the ASME B31 Committee will be published as Cases.While these Cases do not constitute formal revisions of the Code, they may be used inspecifications, or otherwise, as representing considered opinions of the Comrnittee. TheCases are published in a separate supplement.The user of the Code will note that metric equivalents of U.S. Customary units appearthroughout this issue of the Code (except for Appendix II). The values stated in U.S.Customary units are to be regarded as standard.ASME is the registered trademark of The American Society of Mechanical Engineers.This code or standard was developed under procedures accredited as meeting the criteria for AmericanNational Standards. The Standards Comrnittee that approved the code or standard was balanced to assure thatindividuals from competent and concemed interests have had an opportunity to participate. le proposed codeor standard was made available for public review and comrnent which provides an opportunity for additionalpublic input from industry, academia, regulatory agencies, and the public.at-large.ASME does not "approve," "rate." or "endorse" any item, construction, proprietary device, or activity.ASME does not take any position with respect to the validity of any patent rights asserted in connection withany items mentioned in this document, and does not undertake to insure anyone utilizing a standard againstliabilty for infringement of any applicable Letters Patent, nor assume any such liability. Users of a code orstandard are expressly advised that determination of the validity of any such patent rights, and the risk ofinfringement of such rights, is entirely their own responsibility.Participation by federal agency representative(s) or person(s) affiliated with industry is not to be interpretedas govemment or industry endorsement of this code or standard.ASME accepts responsibility for only those interpretations issued in accordance with goveming ASMEprocedures and policies which preclude the issuance of interpretations by individual volunteers.No part of this document may be reproduced in any form,in an electronic retrieval system or otherwise.without the prior written permission of the publisher.The American Society.of Mechanical EngineersThree Park Avenue, New York, NY 10016-5990Copyright C 2001 byTHE AMERICAN SOCIETY OF MECHANICAL ENGINEERSAll Rights ReservedPrinted in U.S.A.COPYRIGET American Society of Mechanical EngineersLicensed by nformation Handlinq Services

CONTENTSForeword .Personnel .Introduction .Summary of Changes .Chapter I100100.1100.2Figures100.1.2(A)xvxixScope and DefinitionsGeneral .Scope.Definitions.1.I15100.1.2(B)100.1.2(C)Code Jurisdictional Lirnits for Piping - Forced Flow Steam GeneratorWith No Fixed Steam and Water Line.Code Jurisdictional Linits for Piping - Drum Type Boilers.Code Jurisdictional Limits for Piping - Spray Type Desuperheater.Chapter IIDesignPart 1Conditions and Criteria.Design Conditions.General.Pressure.Temperature.Ambient Influences.Dynamic Effects.Weight Effects.Thermal Expansion and Contraction Loads.Design Criteria .General.Pressure-Temperature Ratings for Piping Components.11Allowable Stress Values and Other Stress Limits forPiping Components.Allowances.Pressure Design of Piping Components.Criteria for Pressure Design of Piping Components.16Pressure Design of Components.Straight Pipe.Curved Segments of Pipe.Intersections.Closures.Pressure Design of Flanges and Blanks.Reducers.Other Pressure-Containing Components.Analysis of Piping 02102.1102.2102.3102.4Part COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling 2627282929

Part 08.4108.5108.6Part 2117.311831.Selection and Limitations of Piping Components31Pipe .31General .31Metallic Pipe .31Nonmetallic Pipe .32.Fittings, Bends, and Intersections .32Fittings .32Bends and Intersections . .32Pipe Couplings .32.Flexible Metal Hose Assembly .32.Valves .32General .33Marking .Ends .33Stem Threads .3333Bonnet Joints .Bypasses .3333.Safety, Safety Relief, and Relief Valves .Pipe Flanges, Blanks, Flange Facings, Gaskets, and Bolting .33Flanges .33Blanks .34Flange Facings .34Gaskets .3434.U. S. Customary Bolting .34Metric Bolting .35.Selection and Limitations of Piping Joints .35Piping Joints .35Welded Joints .35General .35Butt Welds .35.Socket Welds35Fillet Welds .35Seal Welds .35Flanged Joints .35.Expanded or Rolled Joints .35Threaded Joints . 3540. 40Flared, Flareless, and Compression Joints .40.40.40.40.41Caulked Joints .41.41.41.Brazed and Soldered Joints .41.41.41Limitations . 41Sleeve Coupled and Other Proprietary Joints .ivCOPYRIGHT American Society of Mechanical EngineersHandling ServicesLicensed by Inforation

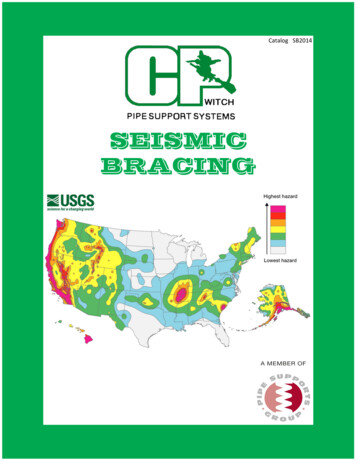

21.7121.8121.9121.10Part ion, leibility, and Supporting .Expansion and Flexibility .General .Stress Range .Local Overstrain .Flexibility .Properties .Analysis .Movements . .Cold Spring .Reactions .Loads on Pipe Supporting Elements .General .Supports, Anchors, and Guides .Design of Pipe Supporting Elements .General .Allowable Stress Values .Temperature Limitations . .Hanger Adjustments .Hanger Spacing .Springs .Fixtures .Structural Attachments .Loads and Supporting Structures .Requirements for Fabricating Pipe Supports .Systems .Design Requirements Pertaining to Specific Piping Systems .Boiler External Piping; in Accordance With Para. 100.1.2(A) - Steam,Feedwater, Blowoff, and Drain Piping .Blowoff and Blowdown Piping in Nonboiler External Piping .Instrument, Control, and Sampling Piping .Spray Type Desuperheater Piping for Use on Steam Generators andReheat Piping .Pressure Reducing Valves .Pressure Relief Piping .Piping for Flammable or Combustible Liquids .Piping for Flammable Gases, Toxic Gases or Liquids, or NonflammableNontoxic Gases .60Piping for Corrosive Liquids and Gases .62Temporary Piping Systems .62Steam Trap Piping .63Exhaust and Pump Suction Piping .63Pump Discharge Piping .63District Heating and Steam Distribution Systems .63Figures104.3.1 ement of Branch Connections .21Reinforced Extruded Outlets .24Types of Permanent Blanks .28.Typical Globe Valves .53Desuperheater Schematic Arrangement .58122.2122.3122.4122.5122.6122.7122.8vCOPYRIGHT American Society of Mechanical XngineersLicensed by Information Handlinq 4648484949494954545657575930

22.8.2(B)m131516.17.17.18Values of y .36Piping Flange Bolting, Facing, and Gasket Requirements . . . . . . .40. . . . .46Suggested Pipe Support Spacing .Carrying Capacities of Threaded ASTM A 36, A 575, and A 57647Hot Rolled Carbon Steel .54.61Minimum Wall Thickness Requirements for Toxic Fluid Piping .Stress Range Reduction Factors .Longitudinal Weld Joint Efficiency Factors .MaterialsGeneral Requirements .Materials and Specifications .Piping Components .Pipe Supporting Elements .Limitations on Materials .General .Steel .Cast Gray Iron .Malleable Iron .Ductile (Nodular) Iron .Nonferrous Metals .Nonmetallic Pipe .Deterioration of Materials in Service .Materials Applied to Miscellaneous Parts .Gaskets .Bolting mensional RequirementsMaterial Specifications and Standards for Standard and Nonstandard PipingComponents .Standard Piping Components .Nonstandard Piping Components .Referenced Documents .68686868Table126.1Specifications and Standards .69Chapter ication, Assembly, and ErectionWelding .General .Material .Preparation for Welding .Procedure .Qualification .Welding Records .Brazing .General .Materials .2Chapter Y12601COPYRIGHT American Society of Mechanical EngineersLicensed by Xnformation Handlinq Servicesvi

128.3128.4128.5128.6129129.1Preparation.Procedure .Qualification.Brazing Records.Bending and Forming.Bending .848484858585129.2Forning 8(C)127.4.8(D)127.4.8(E)Heat Treatment of Bends and Formed Components .85Requirements for Fabricating and Attaching Pipe Supports .86.86.86.86Welding Preheat .86.86.86.86Preheat Temperature .86.87Interruption of Welding . .87Postweld Heat Treatment .87.87.87Exemptions to Mandatory PWHT Requirements . 88Definition of Thickness Governing PWHT .88PWHT Heating and Cooling Requirements . 92Furnace Heating .92Local Heating .92Stamping .93Assembly .93General .93Alignment . .93Bolted Flanged Connections .93Packed Joints and Caulked Joints .93Threaded Piping .93Tubing Joints .94Butt Welding of Piping Components With Internal Misalignment .Welding End Transition - Maximum Envelope .Fillet Weld Size .Welding Details for Slip-on and Socket-Welding Flanges; SomeAcceptable Types of Flange Attachment Welds .80Minimum Welding Dimensions Required for Socket WeldingComponents Other Than Flanges .Typical Welded Branch Connection Without Additional Reinforcement .Typical Welded Branch Connection With Additional Reinforcement .Typical Welded Angular Branch Connection Without AdditionalReinforcement .81Some Acceptable Types of Welded Branch Attachment Details ShowingMinimum Acceptable Welds .82Typical Full Penetration Weld Branch Connections for NPS 3 andSmaller Half Couplings or Adapters .viiCOPYRIGHT American Society of echanical EngineersLicensed by Information Handling Services76777980808183

127.4.8(F)Typical Partial Penetration Weld Branch Connection for NPS 2 and135.5.3Smaller Fittings .Typical Threaded Joints Using Straight Threads .8394Reinforcement of Girth and Longitudinal Butt Welds .Approximate Lower Critical Temperatures .Postweld Heat Treatment .788588Alternate Postweld Heat Treatrnent Requirements for Carbon andLow Alloy Steels .93Tables127.4.2129.3.2132132.1Chapter .5137.6137.7137.8Inspection, Examination, and TestingInspection and Examination .Inspection .Inspection and Qualification of Authorized Inspector for Boiler959595External Piping .Examination .Examiination Methods of Welds .Pressure Tests .General Requirements .Preparation for Testing .9999100Requirements for Specific Piping Systems .1009696Hydrostatic Testing . 100Pneumatic Testing . 101Mass-Spectrometer and Halide Testing . 101Initial Service Testing . 102Retesting Aftcr Repair or Additions . 102Tables136.4Mandatory Minimum Nondestructive Examinations for Pressure Welds136A.IWeld Imperfections Indicated by Various Types of Examination .or Welds to Pressure Retaining Components.Mandatory AppendicesAppendix ATable A-1, Carbon Steel .Table A-2, Low and Intermediate Alloy Steel .Table A-3, Stainless Steels.Table A-4, Nickel and High Nickel Alloys .Table A-5, Cast Iron .Table A-6, Copper and Copper Alloys.Table A-7, Aluminum and Aluminum Alloys.Table A-8, Temperatures 1200 F and Above.Table A-9, Titanium and Titanium Alloys .Appendix BTable B-1, Thermal Expansion Data.Table B-1 (SI), Thermal Expansion Data .Table C-1, Moduli of Elasticity for Ferrous Material .Appendix CTable C-1 (SI), Moduli of Elasticity for Ferrous Material .Table C-2, Moduli of Elasticity for Nonferrous Material.Table C-2 (SI), Moduli of Elasticity for Nonferrous Material .Appendix. DTable D-1, Flexibility and Stress Intensification Factors.Chart D-l, Flexibility Factor k and Stress Intensification Factor i .Chart D-2, Correction Factor c .Fig. D-1, Branch Connection Dimensions.Appendix FReferenced Standards .DiCOPYRXIGT American Society of Mechanical EngineersLicensed by nfomation andling 212222232252282322332342350

Appendix GAppendix HAppendix JNomenclature .Preparation of Technical Inquiries . .Quality Control Requirements for Boiler External Piping (BEP) .238244245Nommandatory pendix VIAppendix VIIRules for the Design of Safety Valve Installations .Rules for Nonmetallic Piping .Corrosion Control for ASME B31.1 Power Piping Systems .Recommended Practice for Operation, Maintenance, and Modificationof Power Piping Systems .Approval of New Materials .Procedures for the Design of Restrained Underground Piping .306Index .293304318ixCOPYR'GHT American Society of Hechanical EngineersLicensed by Information Handling Services247269289

FOREWORDThere are many instances where the Code serves towarn a designer, fabricator, or erector against possiblepitfalls; but the Code is not a handbook and cannotsubstitute for education, experience, and sound engineering judgment.Nonmandatory Appendices are included in the Code.Each contains infornation on a specific subject, andis maintained current with the Code. Although writtenin mandatory language, these Appendices are offeredfor application at the user's discretion.The general philosophy underlying this Power PipingCode is to parallel those provisions of Section I, PowerBoilers, of the ASME Boiler and Pressure Vessel Code,as they can be applied to power piping systems. TheAllowable Stress Values for power piping are generallyconsistent with those assigned for power boilers. ThisCode is more conservative than some other pipingcodes, reflecting the need for long service life andmaximum reliability in power plant installations.The Power Piping Code as currently written doesnot differentiate between the design, fabrication, andThe Code never intentionally puts a ceiling limit onconservatism. A designer is free to specify more rigidrequirements as he feels they may be justified. Con-erection requirements for critical and noncriticalpipingsystems, except for certain stress calculations and mandatory nondestructive tests of welds for heavy wall,high temperature applications. The problem involved isto try to reach agreement on how to evaluate criticality,and to avoid the inference that noncritical systemsdo not require competence in design, fabrication, anderection. Some day such levels of quality may bedefinable, so that the need for the many different pipingcodes will be overcome.versely, a designer who is capable of a more rigorousanalysis than is specified in the Code may justify aless conservative design, and still satisfy the basic intentof the Code.The Power Piping Committee strives to keep abreastof the current technological improvements in new materials, fabrication practices, and testing techniques; andendeavors to keep the Code updated to permit the useof acceptable new developments.xCOPRIGHrT American Society of Mechanical EngineersLicensed bynfomation Handling Sezxvces

ASME CODE FOR PRESSURE PIPING, B31OFFICERSLE. Hayden, Jr, ChairB. Holbrook, Vice ChairP. Stampt, SecretaryCOMMITTEE PERSONNELH. A. Ainsworth, Consultant, Sudbury, MassachusettsR J. Appleby, Exxon Mobile Upstteam Res. Co., Houston, TexasA. E. Beyer, Bechtel Corp., Houston, TexasK. C. Bodenhamer, Williams Energy Services, Tulsa, OklahomaJ. D. Byers, Mobile E & P Technology, Highland Village, TexasJ. S. Chin, ANR Pipeline Co., Detroit, MichiganD. M. Fox, Texas Utilities-Pipeline Services, Dallas. TexasJ. W. Frey, Reliant Energy Co., Houston, TexasD. R. Frikken, Solutia, Inc., Gerald. MissouriP. L Gardner, Consultant, Wilmington. DelawareR. R. Hoffmann, Federal Energy Regulatory Commission, Washington, District of ColumbiaG. A. Jolly, Edward Vogt Valve Co., Jeffersonville. IndianaJ. AL Kelly, Willbros Engineers, Inc., Tulsa, OklahomaW. J. Koves, UOP LLC, Des P]aines, IllinoisK. K. Kyser, Frick York Intemational, Waynesboro, PennsylvaniaJ. E. Meyer, Middough Association, Inc., Cleveland. OhioF. Michalopoulos, General Engineering and Commercial Co., Kozani. GreeceT. J. O'Grady I, Veco Alaska, Inc., Anchorage, AlaskaR. G. Payne, ABB-Combustion Engineering, Windsor, ConnecticutP. Pertuit m, Black Mesa Pipeline, Inc., Flagstaff. ArizonaJ. T. Powers, Parsons Energy & Chemicals, Houston, TexasE. R. Rinaca, Virginia Power Co. Glen Allen, VirginiaM. J. Rosenfeld, Kiefner &Associates, Inc. Worthington, OhioR. J. Silvia, Process Engineers and Constructors, Inc., Warwick, Rhode IslandW. J. Sperko, Sperko Engineering Services, Inc., Greensboro, North CarolinaG. W. Spohn m, Coleman Spohn Corp., Cleveland, OhioR. W. Straiton, Consultant, Spring, TexasA. L Watkins, The Perry Nuclear Power Plant, Perry, OhioR. B. West, State of Iowa, Div. of Labor Services, Des Moines, IowaP. A. Bourquin, Er-Officio Member, Consultant, Pleasantville, New YorkP. D. Flenner, Er-Officio Member, Consumers Energy Co. Covert, MichiganR. W. Haupt, Ex-Officio Member, PressuTe Piping Engineering Associates, Inc. Foster City, CaliforniaW. B. McGehee, Ex-Officio Member, Consultant, Houston, TexasA. D. Nance, Er-Officio Member, A. D. Nance Associates, Inc., Evans, GeorgiaW. V. Richards, Er-Officio Member. Consultant, Lincolnshire, IllinoisB31.1 POWER PIPING SECTION COMMITEA. D. Nance, Chair, A.D. Nance Associates Inc., Evans, GeorgiaE. F. Suumers, Jr., Vice Chair, Babcock & Wilcox Construction Inc. Barberton, OhioxiCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

P. D. Stumpf, Secretay ASME International. New York, New YorkL A. Ainsworth, Sudbury, MassachusettsP. S. Barbam, City Public Service, San Antonio, TexasW. R. Brot, McGowan Broz Engineers, Inc., Bellevue, WashingtonJ. H. Casiglia, Tbe Detroit Edison Co., Detroit, MichiganR. D. Delpito,

INDD B31.1 92 m 2595512 0078031 7T0 M ASME-B31.1 ADOPTION NOTICE ASME-B31.1, "Piping, Power," was adopted on October 3, 1994 for use by the Department of Defense (DoD). Proposed changes by DoD activities must be submitted to the DoD Adopting Activity: Commanding Officer, Naval Construc