Transcription

K C023PotassiumCarbonateHandbook

Potassium Carbonate HandbookBackgroundIn 1986, two strong manufacturersin the chemical industry combinedin a joint venture to form theArmand Products Company theleading producer and marketer ofpotassium carbonate and potassiumbicarbonate in the world.From the Occidental ChemicalCorporation came the manufacturing capability for the production ofthe highest quality chemicals, withmarketing and technical serviceexpertise for product support.From the Church & Dwight Co.,Inc. came the sales and R&D functions to maintain the high level ofcustomer service that our customersrequire.As a market leader, the ArmandProducts Company provides thefacilities and manpower needed tomeet the requirements of our customers. Our two plants and fourreactors run in the continuousmode, assuring an uninterruptedsupply of potassium carbonate. Anadditional reactor is dedicated tothe production of potassium bicarbonate. This manufacturing facilityis located in Muscle Shoals, AL.Armand Products Company hasfull integration with a dedicatedproduction source of potassiumhydroxide, the key raw material formaking potassium carbonate.Potassium bicarbonate is producedby further carbonation of potassiumcarbonate. The Tennessee ValleyAuthority (TVA), one of the largestHandbookK2CO3electricity generators in the UnitedStates, supplies power to the MuscleShoals facility at a reasonably stablecost.Current capacity is 108,000 shorttons/year for potassium carbonateand 5,000 short tons/year for potassium bicarbonate. This placesArmand Products as the largestdomestic and international sourceof potassium carbonate, as well asthe only producer of potassiumbicarbonate in the U.S.In order to meet the requirements of the many diverse applications, each product is available inseveral different grades. Variouspackage forms are also available,ranging from bags to railcars.Smaller packages are availabledirectly from the plant or at manywarehouse and distribution pointsacross the country.Armand Products’ commitmentto quality and consistent performance is shown in its continuedgood standing as an ISO 9002 certified and OSHA Star facility.1

Armand Products CompanyTable of ContentsPage.1.3.4.6.8Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .l. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ll. Markets and Uses of Potassium Carbonate . . . . . . . . . . . . . . . . .lll. Manufacturing Process . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .lV. Grades of Potassium Carbonate . . . . . . . . . . . . . . . . . . . . . . . . .V. Materials of ConstructionA. Anhydrous Potassium Carbonate . . . . . . . . . . . . . . . . . . . . . 9B. Liquid Potassium Carbonate . . . . . . . . . . . . . . . . . . . . . . . . 10Vl. Shipping Packages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11Vll. Precautions in Handling Potassium Carbonate . . . . . . . . . . . . . . 13Vlll. Handling of Anhydrous Potassium CarbonateA. Bag, Drum and Bulk Handling . . . . . . . . . . . . . . . . . . . . . . 15B. Mechanical Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16C. Pneumatic Conveying . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18D. Bulk Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21lX. Handling of Liquid Potassium CarbonateA. Shipping Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22B. Unloading Tank CarsPlacement, Precautions and Cold Weather . . . . . . . . . . 22Unloading Through Bottom Valve . . . . . . . . . . . . . . . . . 24Top Unloading with Air Pressure . . . . . . . . . . . . . . . . . 26Preparing Car for Return . . . . . . . . . . . . . . . . . . . . . . . . 26C. Unloading from Tank TrucksMethods and Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . 27Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28D. Dilution of Potassium Carbonate Solution . . . . . . . . . . . . . 30E. Dissolving Anhydrous Material . . . . . . . . . . . . . . . . . . . . . 31F. Solution Storage with Dry Bulk Delivery . . . . . . . . . . . . . . . 31X. Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33XI. Methods of Analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47All recommendations and suggestions appearing in this booklet concerningthe use of our products are based upon tests and data believed to be reliable.However, as the actual use of our products by others is beyond our control,no guarantee, expressed or implied, is made as to the effects of such use, orthe results to be obtained, whether or not any use of our products is made inaccordance with recommendations or suggestions contained in this handbook or otherwise. Furthermore, information on the use of our products isnot to be construed as recommendation to use such products in the infringement of any patent. These suggestions should not be confused either withstate, municipal, or insurance requirements, or with national safety codes.2K2CO3Handbook

Armand Products Companyl.HandbookIntroductionPotassium carbonate is one of themost important inorganic compounds used in industry eventhough it is as old as recorded history. Potassium carbonate was leachedfrom ashes in Pompeii and mixedwith slaked lime for soapmaking.The increase in the use of this alkaliparalleled the growth of westerncivilization. So much wood wasconsumed in the production ofpotassium carbonate that the forestsof Europe were threatened. At thetime of the French Revolution,LeBlanc’s invention allowed sodiumcarbonate to be substituted on ageneral basis.The potassium carbonate thatwas recovered from ashes becamethe prime potassium compoundbefore 1870. During these earlytimes, potassium hydroxide (KOH,caustic potash) was made frompotassium carbonate by reactionwith calcium hydroxide. However,the recovery of potassium chloridein 1860 from “rubbish salt” in theStrassfurt, Germany salt mineschanged this methodology. Todaypotassium hydroxide is producedthrough the electrolysis of potassium chloride brine. Subsequently,the KOH is carbonated with carbondioxide to form potassium carbonate.K2CO3 is the chemists’ short-wayof representing potassium carbonateor PotCarb as it is commonly calledtoday. Although it is known by several other names, the chemical formula is the most definitive way toconfirm this compound. Some ofalternate nomenclature that may beused includes: PC, carbonate ofpotash, pearl ash and carbonic acid,dipotassium salt.In everyday chemical technology, the choice between potassiumand sodium carbonate is decided onK2CO3the economics or some desiredphysical / chemical property. Theprincipal reasons to utilize potassium carbonate are:t source of potassium iont buffered alkalinityt greater solubility for potassium vs. sodium carbonatet potassium ion is more reactivethan sodium iont replacement for sodium sensitive applicationst enhances fluxing properties ofglasst depresses freeze point ofwater, allowing cold temperature applicationsIn the past, the use of a hydratedpotassium carbonate (16% water)was preferred to the more deliquescent anhydrous form. Technologyhas since spurred improvements inseveral areas, thereby fostering theacceptance of the anhydrous granular form of potassium carbonate.These improvements include thedevelopment of other PotCarbprocesses and enhancements in theareas of packaging, dry bulk handling and storage facilities.One commonly used methodproduces a calcined PotCarb thatrequires several additional processing steps after its liquid phase reaction between caustic potash andcarbon dioxide. The final step beinga heat treatment where the temperature is raised sufficiently to driveoff the water of crystallization. Twodifferent ion exchange methodseach employ a multi-step processthat requires several raw materialsand also yields several by-products.A more practical approach for supporting the use of anhydrous potassium carbonate is the developmentof the fluidized bed reactor. This3

Armand Products Companyll.process allows the direct, one-stepmanufacturing of an anhydrousmaterial that needs no furtherrefinement. Typically there is muchgreater customer demand for drymaterial, however, since PotCarb itis readily soluble, aqueous solutionsdo not present a challenge. ArmandProducts is well positioned to meetthe demands of today’s customerswith its four state-of-the-art fluidized bed reactors and its liquidPotCarb capabilities.4Markets and Uses ofPotassium CarbonateThe potassium carbonate market isdivided between the glass industryand other numerous applications.Product is shipped throughout theUnited States and into internationalregions.Video glass accounts for 44% ofpotassium carbonate usage, whilespecialty glass and ceramics use10%. The main reason that relatively expensive potassium carbonate isused in place of soda ash in glassapplications is that it is more compatible with the required lead, barium and strontium oxides. Thesespecialty glasses possess theimproved properties of greater electrical resistivity, higher index ofrefraction, greater brilliance or luster, lower softening point and awide temperature working range. Inaddition, potassium carbonateallows improved behavior of manycolorants in glass.Potassium carbonate has a widevariety of uses outside of the glassindustry. Major applications thataccount for 46% of the PotCarbproduced include but are not limited to: potassium silicate, pharmaceuticals, food, detergents andcleaners, photographic chemicals,agricultural, gas purification, rubberadditives, polymer catalysts, potassium bicarbonate, cement and textiles.A more complete summary ofthe various uses of potassium carbonate is given in the followingtable:K2CO3Handbook

HandbookK2CO3Used especially intitanium dioxidefrits for applianceindustryCERAMICSSource of K2O foralkali barium, leador strontium silicaglasses used in theproduction of television tubes, illuminating ware,tubing, laboratoryglass, optical glass,tableware, andgiftware. Usedalone or withNa2CO3.GLASSRaisin dryingDehydratingagentsRocket fuelsTerephthalic ninhibitorBrewing beerOriental noodlesCattle feedadditiveAlfalfa dryingEffervescent mineral waterOxalic acidChocolate”alkalyzing” or”Dutch” processingof cocoa powderFOODSpecial leaveningagentsPrinting FabricsDyeing TextilesDry ColorsInksDYES PIGMENSPotassium salts ofphosphates,silicates, persulphates, permanganates, andpotassium l cleanersLiquid soapsBoiler atural gassynthesishydrogensynthetic natural gaspetrchemicalproductsdry icechemicals fromhydrocarbongasesMolten carbonates for removalof sulfur dioxide from fluegasesRemoval of carbon dioxide andother acid gasesby absorption in asolution of potassium carbonate.With the following materials:GASPURIFICATIONPOTASSIUM CARBONATE APPLICATIONSRubber additivesFireproof coolantas in anti-freezefor exposed steelcolumnsMolten saltsElectroplatingFlameproofingPhotographyFire extinguishersRefrigerationPerfume and toiletarticlesTanning leatherOTHERArmand Products Company5

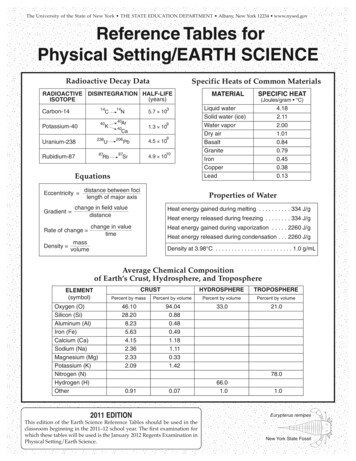

Armand Products Companylll.Manufacturing ProcessArmand Products’ PotassiumCarbonate is manufactured in a fluidized bed reactor at its productionfacility in Muscle Shoals, AL. Thisresults in a product that is anhydrous, making it unnecessary toperform any further processing toeliminate hydrated water (calcining). Armand Products’ PotassiumCarbonate (PotCarb) is a white,dense, free-flowing granular material which is easy to handle andstore.The process starts with potassiumchloride, obtained from theCanadian province ofSaskatchewan. Through an electrolytic conversion of the KCl salt,potassium hydroxide (causticpotash, KOH), chlorine (Cl2) andhydrogen (H2) are produced. Thehydrogen is a fuel source while thechlorine has numerous importantand varied applications. Liquidcaustic potash and carbon dioxideare the only raw materials requiredfor producing PotCarb.The dry potassium carbonate caneasily be dissolved in water to forma liquid solution. Typically a 47%solution is recommended as thiscapitalizes on the highest concentration with the lowest freezingpoint (3 F). This minimizes handling problems during colderweather.The chemical equation for thisprocess is simply:t Largest domestic facility, utilizing four reactors in twoplants;t Dry and liquid forms availablein various packaging units;t Vertically integrated with onsite production of liquid caustic potash (KOH), the key rawmaterial;t Geographical location in proximity to Gulf and Easterncoast ports, allowing for timely export shipments;t Electric power for raw materialconversion and plant operations is readily available froma nearby TVA plant.As a side note, potassium carbonate cannot be made by the Solvayprocess used for sodium carbonate(Na2CO3).The flow diagram for the manufacturing process is shown on thenext page:2 KCl 2 H2O 2 KOH H2 Cl22 KOH CO2 K2CO3 H2OThe favorable logistics of this production facility cover a wide spectrum of advantages:6K2CO3Handbook

Armand Products CompanyFlow Chart of Manufacturing ProcessHandbookK2CO37

Armand Products CompanyIV.Grades of Potassium CarbonateArmand Products produces potassium carbonate in granular and liquid form to satisfy the requirementsof its customers. Each material conforms to the high standards ofchemical purity and physical properties essential for our extensive andvaried customer base. ArmandProducts’ anhydrous potassium carbonate is white, dustless, dense,free-flowing granular product.Several grades of dry PotCarb thatdiffer in their typical granulationranges are available. In addition, awater solution in the form of a 47%solution is typically provided.The chemical parameters includ ed in the standard sales specifi cations for Anhydrous PotassiumCarbonate are:Requests can be made through theArmand Products’ Technical Servicestaff for the following literature:(not specification items)K2CO3KOHKClH2ONaK2SO4AsFeHgNiHeavy Metals (as Pb)Physical Properties:Sales Specificationproduct grade sheets listing parameters and their limitsParticle SizeTypically material is between 18and 80 mesh for granular andthrough 325 mesh for groundmaterial.Technical Informationdata sheets covering chemicaland physical propertiesBulk Density75 - 84 lb/ft3 (granular, varies bygrade); 37 lb/ft3 (extra fine)Melting Point891 CSolubility in Water112 grams in 100 grams water at20 CAppearanceWhite, granular, free-flowing8K2CO3Handbook

Armand Products CompanyV.Materials of ConstructionIron, steel, stainless steel, rubberlined steel or phenolic lined steel isrecommended.If heated to 120 F, the potential foriron contamination exists.Polyethylene drums can be used forliquid storage and handling atambient temperatures.Aluminum, zinc, brass, bronze, andcopper are NOT recommended dueto the potential for a reaction.Experience with the various polymeric materials of construction islimited. Additional data based oncustomers’ own experiences shouldbe considered. The weight of thePotCarb must be factored into thestructural constraints of polymericmaterials. The following information is therefore offered as a startingpoint:t Polyethylene and propylenecan be used if not exposed totemperatures beyond that recommended for each polymer.Possible deformation of polymer surface may occur.Caution is advised duringprocesses that generate heat,e.g., solubilization of drypotassium carbonate.t Polyester is NOT recommended.t Polyvinyl chloride (PVC) hasbeen reported to be acceptablebut caution is advised for possible embrittlement. Regularinspection and proper usageprocedures may allow goodservice from this material.HandbookK2CO3A. ANHYDROUS POTASSIUM CARBONATEPipingPneumatic systems require 4 inchminimum piping with four footradius curves. Gravity feed systemsshould be 6 inch diameter or larger.ValvesButterfly or slide gate valves are typical, however, the butterfly type arepreferred for humid conditions.BlowersPneumatic unloading requires blowers that are generally 500 - 600 CFMand operate at 10 lbs. of pressure. Inhumid conditions, the transfer airshould be pulled through a desiccant bed to provide dry transfer air.The dryer should be checked periodically and replaced as needed.Storage SilosCapacity should hold at least 1.5times the size of a normal shipment. A dry air purge in wet humidconditions will ease the handling ofproduct. A 45 slope to the silo bottom is recommended. A bag houseis recommended for filtering outdust from the transfer air during thepneumatic unloading of product.Storage silos should be steel, linedsteel or stainless. A more thoroughdiscussion of the recommendationsfor bulk storage can be found insection VIII.D.9

Armand Products CompanyB. LIQUID POTASSIUMCARBONATEPipelinesA two inch minimum pipelinewith a 3 inch minimum on the suction side of the pump is recommended. Long sections of outdoorpiping should be heat traced andinsulated. Experience has demonstrated that flanged connectionswith alkali-resistant gaskets willminimized the potential for leaks.All piping should be installed witha slight slope to ensure completedrainage. Loops and pockets are tobe avoided.PumpsCentrifugal and rotary types withall iron construction may be used. Adeep packing gland is desired toprevent leakage at the pump shaft.Graphite/asbestos packing materialis recommended for potassium carbonate solution service.ValvesGlobe, angle, gate, and plugvalves may be employed to controlflow rates and for line shutoffs.Valve construction of cast iron,steel, and stainless steel (Type 316and 304) is recommended.tamination is critical. However, rubber does not withstand high temperatures.Storage tanks in cold climatesshould be insulated with 2 inchesof polyurethane insulation to maintain pumpable conditions andshould have an internal or externalheat source to make temperatureadjustments.Some plastics are also acceptablefor small tank construction (generally less than 10,000 gallons). Polypropylene, polyethylene, PVC,CPVC and FRP can be used. Polypropylene is the most commonlyused plastic for storage tanks.Further discussion with ourTechnical Service staff on the appropriate materials of construction andequipment for handling potassiumcarbonate is encouraged.Storage TanksFabrication specifications requireat least 3/8 inch wall thickness forunits larger than 10,000 galloncapacity and a 1/4 inch wall forsmaller capacities. The withdrawalpipe connection should be a fewinches above the bottom of thetank. To facilitate tank cleaning, adrain connection should beinstalled at the lowest point in thetank.Rubber or phenolic based epoxiescan be used for lining steel storagetanks where prevention of iron con10K2CO3Handbook

Armand Products CompanyVl.Shipping PackagesSHIPMENT OF POTASSIUMCARBONATEPotassium carbonate can be shippedin various types and sizes of packaging. Armand Products’ TechnicalService is available to discuss allpossible options and can assist thecustomer in determining the mostadvantageous method to receivethis product. Examples of the typical containers available are:t 50 and 100 pound multiwallpaper bagst 400 pound fiber drumst 2000 pound bulk bagst hopper and pneumatic truckst hopper and pneumatic railcarsFactors that determine the typeof package include the quantity tobe used, as well as the customer’slocation, unloading system andstorage facilities. Since bulk shipments can be made in trucks andrailcars, it is better to determine themost advantageous delivery methodthrough an economic survey foreach individual case.BAG AND DRUMSHIPMENTThe multiwall kraft bags used byArmand Products are constructedwith a polyethylene moisture barrier to better protect product qualityduring storage. Fiber drums can befurnished with a polyethylene linerupon request. Bag and drum specifications are available from ArmandProducts’ Technical Service department.Although receipt of the materialin bags or drums may not offer theeconomic advantage of bulk, thereare other factors which may promptthe choice of this type of packaging.HandbookK2CO3The use of bags or drums simplifiesdistribution when potassium carbonate is used in small quantities atseveral locations. Individual packages also eliminate the necessity ofbatch weighing potassium carbonate for various requirements. Noexpensive or elaborate equipment isneeded to unload or handle baggedor drummed potassium carbonateshipments. The use of drums andbags makes potassium carbonateavailable to even the smallest industrial consumer.Trucks and rail cars for this serviceare checked internally for the presence of moisture, previously loadedmaterial, and general surface deterioration.BULK BAG SHIPMENTThis larger form of individual packaging offers a unique advantage forthose that meet the space requirements but do not have the capabilityto unload and store truck or rail carshipments. Typically each bag isfilled with 2,000 pounds of potassium carbonate. For truckload quantities however, different weights can befilled to meet the customer’s batchrequirements. These bulk bags aremade of a woven polypropylene fabric with a polyethylene liner as amoisture barrier. This is considered aone trip package to ensure the safehandling integrity of the bag and tomaintain product quality. Bulk bagsfilled with a metric ton (2205pounds) of product have become thepreferred package for export shipments.11

Armand Products CompanyBULK SHIPMENTBulk quantities of potassium carbonate may be shipped in coveredhopper cars, pneumatic unloadingcars, hopper trucks, or self-unloading pneumatic trucks. The choicedepends on the quantity used, aswell as the customer’s location,unloading system and storage facilities. Details of the various optionscan be discussed with TechnicalService personnel.Covered hopper cars are speciallydesigned to handle products such aspotassium carbonate and providethe most satisfactory method ofbulk shipment. These self-discharging cars are equipped with weatherproof hatches and three or four bottom outlet gates which provide protection from outside contamination. The bottom outlets are normally of the Enterprise or slidinggate type, measuring 13 x 24 or 13x 42 inches, with a clearance of 6 to9 inches over the rail that will varywith car design. Hopper cars, normally available in 70 and 95 toncapacities, can be readily adapted tomechanical unloading systems.Pressure differential (PD) railroadcars are available to customers whohave an appropriate pneumatic sys-12K2CO3tem in place to handle unloading.Those who have a potential interestin receiving PD bulk railcar shipments are invited to discuss thisoption with Armand Products’Technical Service.Motor truck shipments havebeen found practical for bulk potassium carbonate, particularly wherethe distance is not excessive andthe customer’s consumption orlocation will not allow rail deliveries. The amount of material thatcan be carried is usually restrictedby the road limitations of the statesthrough which the haul is made,with a typical maximum weight of45,000 pounds. Truck designs canvary but hopper bottom dischargeor self-unloading pneumatic trucksare typical.The development of self-unloading trailers now enables consumers ofas little as 100 tons per year toreceive potassium carbonate in bulkwithout the necessity of providingcostly unloading equipment. Thetank-type trailer available for this service carries a self-contained unloading system which blows the materialinto the customer’s bin. (Figure 1,Page 15) It is operated by the driver, who makes the complete delivery. The receiving equipmentrequired by the customer is relativelysimple in structure and is easy toinstall. It consists of a vertical transmission line made with a four inchstandard pipe and four foot radiusbends with a tank vent through a filter system to remove dust.Since shipments of potassiumcarbonate will be 20-23 tons by thisservice, a minimum storage capacityof 30-35 tons will usually be adequate for most plants. Conventional silos, tanks or existing storagefacilities can easily be adapted forthis system. The facility must bemoisture-tight and requires a storage tank vent dryer.Anhydrous and liquid forms ofHandbook

Armand Products CompanyVll.Precautions in HandlingPotassium Carbonatepotassium carbonate are recognizedas OSHA hazardous substances. Thischemical material is alkaline andmay cause severe irritation by allroutes of exposure.Before starting to work withPotCarb, the user should be awareof its properties, understand whatsafety precautions to follow, andknow how to act in case of contact.Some general guidelines are listedbelow.t Read and understand the current MSDS for complete andupdated information.t Locate and periodically checkeyewash fountains and safetyshowers in all areas wherepotassium carbonate is handled.t Seek medical attention immediately after first-aid measuresare applied.ROUTES OF EXPOSUREPotCarb can be irritating to theskin and to a severe degree if incontact with the eyes. Tissuedestruction may follow if not properly treated. Inhalation of airborne concentrations of dust, mistor spray may cause damage to theupper respiratory tract and even tothe lung tissue which could resultin chemical pneumonia, dependingupon the severity of exposure.Ingestion may cause irritation tothe mucous membranes of themouth, throat, esophagus andstomach, with severity dependanton the quantity involved.There are no known chroniceffects associated with potassium carbonate. However, acute consequences may occur, depending on theHandbookK2CO3length of exposure and whether proper treatment is rendered in a timelyfashion.OVERVIEW OF FIRST AIDMEASURESImmediately administer the first aidmeasure described below, then seekprofessional medical attention.Eyes - Flush eyes with largeamounts of water for at least 15minutes, holding lids apart toensure flushing of the entire surface. Washing eyes within severalseconds is essential to achievemaximum effectiveness.Skin - Wash contaminated areaswith plenty of water. Removecontaminated clothing andfootwear. Do not remove gogglesif the eyes are not affected. Washclothing before reuse. Discardfootwear which is contaminatedon the inner surface.Inhalation - Remove to fresh air. Ifbreathing is difficult have atrained person administer oxygen. If respiration stops givemouth-to-mouth resuscitation.Digestion - Never give anythingby mouth to an unconscious person. If swallowed, do not inducevomiting. Give large quantitiesof water or several glasses of milkif available. If vomiting occursspontaneously, keep airway clear.13

Armand Products CompanyPROTECTIVE EQUIPMENTOSHA requires employers to supplyprotective equipment for employees. When handling potassium carbonate, the following protectiveequipment is recommended:t Wear suitable goggles for eyeprotection during the handling of potassium carbonatein any form. The gogglesshould be close-fitting to prevent the entry of liquids, yetprovide adequate ventilationto prevent fogging.Additionally, care should be takento avoid the simultaneous presenceof potassium carbonate and limedust. This chemical combinationwhen in contact with moisture inthe form of water or perspirationwill cause the formation of a veryirritating and corrosive material,namely caustic potash (KOH).Workmen must carefully wash andremove dust from one of thesechemicals before working in an areawhere the other chemical is beinghandled.t Wear gloves coated with rubber, synthetic elastomers, PVCor other plastics to protect thehands while handling potassium carbonate. Gloves shouldbe long enough to cover wellabove the wrist.t Potassium carbonate causesleather to disintegrate. For thisreason, wear rubber boots.Wear the bottoms of trouserlegs outside the boots. DoNOT tuck in.t Wear cotton clothing for someprotection of the body. Wearrubber aprons or a rain suitfor additional protection.t Wear shirts or jackets withlong sleeves and with the collar tightly fastened.t Wear hard hats to aid in theprotection of the head, faceand neck.t Wear NIOSH-approved respirators for protection from dustsand mists.14K2CO3Handbook

Armand Products CompanyVlll.Handling of Anhydrous Potassium CarbonateA. BAG AND DRUMHANDLINGAn efficient system for unloadingbagged or drummed potassium carbonate depends on the volume tobe handled and the distance it mustbe carried. Lightweight two-wheelhand trucks, with a wide lip onwhich bags are laid horizontally, arecommonly used where a small volume is involved. Larger tonnagemay justify roller conveyors, eitherfreeturning or powered, or portablebelt conveyors. Power lift trucks andpallets may be used to store bags ordrums and distribute them to pointsof usage.Bags should be piled flat to avoidpackage distortion and load insecurity. Since potassium carbonate ishygroscopic, the best possible storage conditions should be provided.Damp floors, leaky roofs, and moiststorage conditions in general mustbe avoided. Moisture absorption willcause lumping of potassium carbonate and consequently a reduction inthe alkalinity. To minimize this condition, the quantity of materialstored should be limited and the oldest material should be used first. Fordrum users, a good in-plant practiceis to keep the cover secured exceptwhen withdrawing material. Thisminimizes moisture pick-up by thehygroscopic potassium carbonate.BULK MATERIALHANDLINGGranular anhydrous potassium carbonate can readily be transferred ina conventional conveying system ora pneumatic conveying system. In aconventional system, atmosphericconditions have only a negligibleeffect on moisture pickup duringproduct handling. However, theanhydrous material must be shielded from rain and snow. It is recommended that the product be transferred in one continuous operationand used before caking occurs.In pneu

Armand Products Company Handbook K 2 CO 3 3 Potassium carbonate is one of the most important inorganic com-pounds used in industry even though it is as old as recorded histo-ry. Potassium carbonate was leached from ashes in Pompeii and mixed with slaked lime for soapmaking. The increase in th