Transcription

TechnologyHandbook

Value through technologyTo all our customers,We are pleased to share with you our most recent Technology Handbook. It provides a comprehensive overviewof our portfolio of advanced technologies – some 64 of them, each designed to provide sustainable solutions toyour business.Our ambition is to be the partner of choice for the design, engineering and construction of state-of the-artproduction units worldwide. We work continuously to increase the value of our technologies and expand ourknowledge to serve our customers better. Innovation is vital, and our internal technology experts and researchnetworks work closely with our development teams and plant operators to develop ideas and new approachesthat meet our clients’ needs. We stay close to the markets and customers we serve, allowing us to develop ourtechnological leadership for our customers’ benefit.A fundamental goal at Air Liquide Engineering & Construction is to provide our customers with competitivesolutions that are safe and reliable. Our aim is to make sure that our customers can secure the best possibleperformance from their operations and make the most efficient use of natural resources.Domenico D’EliaSenior Vice President Sales and TechnologyAir Liquide Engineering & ConstructionWe encourage you to contact us through our regional offices or one of our technology groups. Our experts andproject leaders will be at your disposal and ready to offer additional information to help your business grow andprosper.Technology HandbookAir Liquide Engineering & Construction3

Air LiquideThe world leader in gases, technologiesand services for Industry and HealthWe are present in 80 countries with approximately 65,000 employees, servingmore than 3.5 million customers and patients.Oxygen, nitrogen and hydrogen have been at the core of the company’s activitiessince its creation in 1902. They are essential small molecules for life, matter andenergy. They embody Air Liquide’s scientific territory.Air Liquide’s ambition is to lead its industry, deliver long-term performance andcontribute to sustainability. The company’s customer-centric transformationstrategy aims to achieve profitable growth for the long term. It relies on operationalexcellence, selective investments, open innovation and a network organizationimplemented by the Group worldwide. Through the commitment andinventiveness of its people, Air Liquide is helping to deliver a transition in energyand the environment, provide changes in healthcare and digitization, and delivergreater value to all its stakeholders.4Air Liquide Engineering & ConstructionTechnology Handbook

Air Liquide Engineering & ConstructionA technology partner of choiceAir Liquide Engineering & Construction, the engineering and constructionbusiness of the Air Liquide Group, builds the Group’s production units – mainly airgas separation and hydrogen production units – and supplies external customerswith its portfolio of technologies. Its industrial gas, energy conversion and gaspurification technologies enable customers to optimize the use of naturalresources.We cover the entire project life-cycle: from license engineering services /proprietary equipment, high-end engineering and design capabilities, as well asproject management, commissioning and execution. Its exclusive and innovativetechnologies are contributing to the transition of the energy sector.With more than 1,600 patents we are at work, connecting people and ideaseverywhere to create advanced technologies to solve customer issues.3Manufacturingcenters300New patentsfiled in 2017Technology Handbook15Operating centersand front-end offices1,600PatentsAir Liquide Engineering & Construction5

At the heart of innovationInnovation is one pillar of theAir Liquide Group’s strategyInventiveness, open-mindedness, sharing, agility and entrepreneurial mindsetare fundamental features of our innovation approach.Our Group innovation network is built on science, technologies, and dedicatedinvestments. It is focused on developing new approaches and services forcustomers and patients, accelerated by digital transformation. It is part of anopen ecosystem in which advances are rapidly shared across Air Liquide andwith our external scientific partners and start-ups.Innovation improves our customers’ experience, contributes to growth and to thecreation of a more sustainable world.We innovate across all our areas of activity, balancing its drive for innovation witha commitment to preserve and maintain core products. By combining thispragmatic approach with technical creativity, our teams deliver unique solutionsthat make a real difference to our customers. Here are just a few examples ofrecent innovations.6Air Liquide Engineering & ConstructionTechnology Handbook

Innovation in actionCryocap , CO₂ cold capture systemCryocap enables the capture of CO₂ released duringhydrogen production via a cryogenic process.The first industrial deployment of this technology wasmade in Port-Jérôme, France, at the largest steammethane reforming hydrogen production unit operatedby Air Liquide.A full portfolio of solutionsfor the LNG marketWe offer customers a suite of highly efficient and provenLNG technologies based on our own proprietaryprocesses using plate fin heat exchangers technology.World’s largest plantsfor industrial gas productionCryogenic Technology CenterAt our Cryogenic Technology Center in Vitry-sur-Seine,France, innovations related to cryogenic technologytopics are developed, tested and demonstrated in anaccelerated innovation cycle, thus being ready for earlyindustrialization.SMR-X, a zero steamhydrogen plant solutionSMR-X enables zero steam hydrogen production, with4% natural gas fuel savings and 4% reduced CO₂emissions compared to conventional installations.We have designed and assembled the largest single trainair separation unit ever built. With a total capacity of 5,800tons of oxygen per day (at mean sea level), the unit willsupply industrial gases to the Secunda site for Sasol inSouth Africa. We have also designed and built units forthe global-scale hydrogen production site in YanbuIndustrial City in Saudi Arabia with a total capacity of340,000 Nm3 per hour.Gas POx contributing to clean airOur natural gas partial oxidation technology (GasPOx)enables the reduction of carbon, NOx and CO emissionscompared to conventional syngas solutions.The technology has been successfully proven in a firstreference project in Germany.Technology HandbookAir Liquide Engineering & Construction7

Our commitment to safetyWe have one goal with respect to health, safety, the environment and security:to achieve zero accidents and zero environmental incidents.We ensure that every action we undertake, from initial design to construction, reflectsour goal of ensuring safety and protecting the environment.In pursuit of this goal, we strive to: Provide a safe and secure work environment Prevent all injuries, damage to the environment and damage to property Identify and reduce risks and exposure to hazards in a sustainable way Improve our Health, Safety, Environment and Security performance continuously Enforce Air Liquide Life Saving RulesEmbodying a safety-first culture Our safety commitment applies not only to our employees, but also to our contractors,customers, adjacent facilities and local communities. We ensure that safety is the responsibility of everyone and is a part of the Air LiquideEngineering & Construction culture driven by our behavioral-based ACT (ActivelyCaring Together) program. In this way, we are all safety leaders, and all share acommitment to the golden rule of safety first. We will not hesitate to stop an activity of whatever nature (design, engineering,construction execution, or manufacturing) if it is not safe or if there is any suspicionthat it may result in an accident or incident, now or in the future.8Air Liquide Engineering & ConstructionTechnology Handbook

Our commitmentto sustainabilityWe strive to contribute to a more sustainable world.In line with Air Liquide's Corporate Sustainability Program and in order to contribute toa cleaner industry, transportation and enabling cleaner production, we offer acomprehensive portfolio of environmentally-optimized, efficient and easy-to-usesolutions for our customers: Cryogenic CO2 capture technology. Methanol production from CO2 rich feedstock and hydrogen. Wide experience in the use of LNG, deployed as clean fuel. Our Liquefin technologyoffers 10% efficiency gain vs. state-of-the-art. Our SMR-X for export steam free H2 production reduces natural gas use and CO2emissions by about 5% compared to conventional steam reforming. Our vast oleochemicals portfolio is a key-enabler to produce clean chemicals.Supporting sustainability also involves actions in our own activities in engineering,manufacturing or on our sites to minimize environmental impact, leveraging newways of digital transformation.Technology HandbookAir Liquide Engineering & Construction9

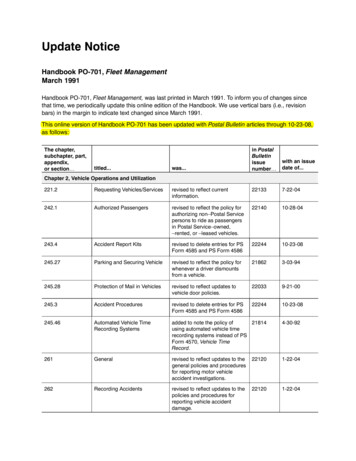

TABLE OF CONTENTS10Air Liquide Engineering & ConstructionTechnology Handbook

AIR GASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12Yango – Standard Air Separation Unit . . . . . . . . . . . . . . . . . . . . . . . . . .Sigma – Standard Air Separation Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . .Vacuum Swing Adsorption (VSA)On-Demand Oxygen Generation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Nitrogen Generation System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Large Air Separation Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1314151617RARE GASES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18Krypton/Xenon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19Helium Extraction and Liquefaction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20CO₂ CAPTURE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23Cryocap H₂ – Cryogenic CO₂ Separation . . . . . . . . . . . . . . . . . . . . . 24Cryocap Oxy – Cryogenic CO₂ Separationfor Oxycombustion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25HYDROGEN & SYNGAS GENERATION . . . . . 26Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Steam Methane Reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Small-Scale Standard Hydrogen Plant . . . . . . . . . . . . . . . . . . . . . . . . . .SMR-X – Zero Steam Hydrogen Production . . . . . . . . . . . . . . . . .ATR – Autothermal Reforming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Gas POX – Natural Gas Partial Oxidation . . . . . . . . . . . . . . . . . . . . . . .Lurgi MPG – Multi-Purpose Gasifier . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lurgi FBDB – Fixed Bed Dry Bottom Coal Gasification . . .Rectisol – Syngas Purification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .272829303132333435HYDROGEN & SYNGAS SEPARATION . . . . . 36Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Pressure Swing Adsorption (PSA) – Hydrogen PurificationCO Cold Box – Methane Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CO Cold Box – Partial Condensation . . . . . . . . . . . . . . . . . . . . . . . . . . . .Liquid Nitrogen Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydrogen Separation Membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Hydrogen Liquefier . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .37383940414243CHEMICALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lurgi Methanol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lurgi MegaMethanol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lurgi MTP – Methanol-to-Propylene . . . . . . . . . . . . . . . . . . . . . . . . . . .G2G – Gas-to-Gasoline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lurgi / Nippon Kayaku Acrylic Acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Methyl Acrylate (Synthomer Licensed) . . . . . . . . . . . . . . . . . . . . . . . . . .Ethyl Acrylate (Synthomer Licensed) . . . . . . . . . . . . . . . . . . . . . . . . . . . .Butyl Acrylate (Synthomer Licensed) . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-Ethylhexyl Acrylate (Synthomer Licensed) . . . . . . . . . . . . . . . . . .Butene-to-crude Butadiene (Mitsubishi BTcB Process) . . . .Butadiene Extraction (BASF NMP Licensed) . . . . . . . . . . . . . . . . . .Distapex – Aromatics Extractive Distillation . . . . . . . . . . . . . . . . . .Lurgi/Edgein Melamine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4546474849505152535455565758NATURAL GAS TREATMENT . . . . . . . . . . . . . . . . . . . . . 60Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Acid Gas Removal - Amine Wash . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Acid Gas Removal - Omnisulf . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Acid Gas Removal - Purisol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CO₂ Removal - Cryocap NG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CO₂ Removal - Membranes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Natural Gas Liquids Recovery – Turbo-booster . . . . . . . . . . . . . . .Natural Gas Liquids Recovery – Membranes . . . . . . . . . . . . . . . . . .Nitrogen Rejection Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .616263646566676869OLEOCHEMICALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Seed Crushing and Extraction-Lurgi Sliding Cell Extractor .Natural Oil Refining . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lurgi Biodiesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fatty Acid Methyl Ester Distillation/Fractionation . . . . . . . . . . . . .Methyl Ester Hydrolysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Glycerin Distillation and Bleaching . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fatty Acid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Fatty Alcohol “LP3” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bio Propylene Glycol (BASF Licensed) . . . . . . . . . . . . . . . . . . . . . . . . . .Sorbitol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8384858687888990919293CUSTOMER SERVICES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Engineering Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Remote Support Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .On-Site Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Spare Parts Services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Customer Service Agreements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9596979899100CONTACTS102. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .LIST OF ABBREVIATIONS AND ACRONYMS. . . .104SULFUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70Oxynator / OxyClaus for Sulfur Recovery Units (SRU) . . 71Sulfur Recovery Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72Emission-Free Sulfur Recovery Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73LNG . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Turbofin (Nitrogen Refrigerant Cycle) . . . . . . . . . . . . . . . . . . . . . . . . . .Smartfin (Single Mixed Refrigerant Cycle) . . . . . . . . . . . . . . . . . . . .Liquefin (Dual Mixed Refrigerant Cycle) . . . . . . . . . . . . . . . . . . . . . . .Boil-Off Gas Reliquefaction Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Bunkering Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .757677787980Technology HandbookAir Liquide Engineering & Construction11

AIR GASESWe have the experience, flexibility and capacity to provide a wide rangeof air separation units through standard plants, customized offeringsand other cryogenic liquefaction technologies. Our strength lies in ourability to adapt our plants performances, safety and constructiondesign philosophy to each project/customer specifics.12Air Liquide Engineering & ConstructionTechnology Handbook

AIR GASESApplicationSteel making (basic oxygen furnaces, blastfurnaces, electric arc furnaces), chemicals(ethylene oxide, ammonia, etc.)FeedstockAir Energy (electrical or steam)ProductOxygen from 99.6% to 99.8% purityand up to 50 barCo-productNitrogen, liquid oxygen, liquid nitrogen, liquidargon, compressed dry airCapacity330 to 770 tpdEconomicsSpecific energy: 400 to 600 kWh/tCapex: 22 to 30 mm USDYango – Standard Air Separation UnitDescriptionThe Yango air separation unit is basedon air compression, adsorption purification,cryogenic distillation of main components andinternal compression of high pressure products.Yango is a standardized, highly packaged ASUsolution to support short-time-to-start-upprojects.Several process schemes are available tooptimize both Capex and Opex depending oncustomer product requirements, energy costand customer process integration potential.Air CompressionNitrogenventPrecooling& Front EndPurificationHP GANHP GOXLP GAN➂➃➆➀➇➅➄LOX To StorageReferencesLIN To StorageContactHeat Exchange & Distillation➁Air Liquide Engineering & Construction offersoptimized solutions in terms of constructionstrategy, operating philosophy and reliability. 20AirColdBoosting Production➀ Main Air Compressor➁ Adsorbers➂ Aftercooler➃ Booster Air Compressor➄ Expander booster➅ Main exchanger➆ Distillation Column➇ Sub-coolerairgases@airliquide.comTechnology HandbookAir Liquide Engineering & Construction13

AIR GASESApplicationSteel making (oxygen boosting, electric arcfurnace), chemicals (ethylene oxide, etc.),glass, non-ferrous metals, waste watertreatment, pulp and paperFeedstockAir Energy (electrical)ProductOxygen up to 99.8% purityCo-productNitrogen, liquid oxygen, liquid nitrogen,liquid argon, compressed dry airSigma – Standard Air Separation UnitDescriptionSigma units are based on air separationwith the following steps: air compression,adsorption, purification, cryogenic distillationof main components, internal compression.Several process schemes are availableto optimize both Capex and Opex dependingon customer product requirements.The Sigma units are designed to reduceconstruction and time to production with a highlypackaged architecture.Air CompressionNitrogenventPrecooling& Front EndPurificationHP GANHP GOX➂➆➇➅Some liquid co-production could be available torefill backup liquid storages.➄110 to 380 tpd 40LIN To StorageEconomicsContactCapex: 5 to 9 mm USD14Air Liquide Engineering & Constructionairgases@airliquide.comTechnology HandbookLP GAN➃➀LOX To StorageSpecific energy: 280 to 460 kWh/tHeat Exchange & Distillation➁ReferencesCapacityAirColdBoosting Production➀ Main Air Compressor➁ Adsorbers➂ Aftercooler➃ Booster Air Compressor➄ Expander booster➅ Main exchanger➆ Distillation Column➇ Sub-cooler

AIR GASESApplicationSteel making, glass, pulp and paper, wastewater treatment, miningFeedstockAir Energy (electrical)ProductOxygen from 90% to 93% purityCo-productNoneCapacity40 to 130 tpdEconomicsVacuum Swing Adsorption (VSA)On-Demand Oxygen GenerationDescriptionAir compression& Vacuum generationVSA uses the process of air separationby adsorption. The basic principle of airseparation by adsorption relies on the useof specific zeolite adsorbents for the selectiveadsorption of nitrogen over oxygen and argon.Oxygen compression& n features: Compact design layout Fully packaged and pre-tested skids Minimized schedule, erectionand start-up times Automatic and unattended operation➇➄➃Capitalization of more than 20 yearsof operating and maintenance experience.Specific energy: 265 kWh/tReferencesCapex: 1 to 6 mm USD 100➀ Air Filter➁ Air Blower➂ Adsorber(s)➃ Vacuum Pump➄ Exhaust➅ Oxygen Booster➆ Gas buffer➇ Liquid oxygen tankContactairgases@airliquide.comTechnology HandbookAir Liquide Engineering & Construction15

AIR GASESApplicationLNG terminal, crude oil refinery, electronicsFeedstockAir Energy (electrical)ProductNitrogen (gaseous, liquid)with 100 ppm to 1 ppb O₂Co-productLOX high purityCapacity500 Nm3/h to 70,000 Nm3/hof nitrogenEconomicsNitrogen Generation SystemDescriptionThis nitrogen generation system is basedon air separation with the following steps:air compression, adsorption, purification,cryogenic distillation of main components.Cold ProductionResidualrich gas( 35% O₂)Heat ExchangeGaseous N₂to CustomerDistillationLIN to backup➂➃Some liquid co-production could be availableto refill backup liquid storages.Systems often include backup vaporizersand storage designed as per customer’srequirements (availability and reliability).➁➅These systems are safe, reliable and easy-tooperate and maintain.ReferencesCapex: 2 to 11 mm USD 100Contactairgases@airliquide.comAir Liquide Engineering & ConstructionFront End PurificationSeveral process schemes are availableto optimize both Capex and Opex dependingon customer product requirements.Specific energy: 175 to 280 KWh/t16Air CompressionTechnology Handbook➄➀➀ Air Compressor➁ Adsorbers➂ Heater➃ Main exchanger➄ Distillation Column➅ Expander

AIR GASESApplicationSteel making (basic oxygen furnaces, blastfurnaces, electric arc furnaces), gasmonetization (gas-to-methanol, -propylene,-liquids), coal gasification, chemicals(ethylene and propylene oxide, etc.), cleanpower (IGCC, oxycombustion)Large Air Separation UnitDescriptionLarge air separation units are based onadsorption purification, cryogenic distillationof main components and internal compressionof high pressure products.ProductFrom the small standard of a few hundred tonnesper day to Mega ASU complexes (multi-train)of more than 15,000 tonnes per day, Air LiquideEngineering & Construction offers optimizedsolutions in terms of construction strategy,operating philosophy and reliability.Oxygen up to 99.8% purityand 100 baraReferencesCo-product 4000Nitrogen, rare gases (Kr, Xe, He, Ne), liquidoxygen, nitrogen and argon,compressed dry airContactFeedstockAir Energy (electrical or steam)CapacityUp to 6,000 tpdairgases@airliquide.comAir CompressionNitrogenventPrecooling& Front EndPurificationAirColdBoosting ProductionHeat Exchange & DistillationHP GAN➁HP GOX➂LP GAN➃➆➀➇➅➄LOX To StorageLIN To Storage➀ Main Air Compressor➁ Adsorbers➂ Aftercooler➃ Booster Air Compressor➄ Expander booster➅ Main exchanger➆ Distillation Column➇ Sub-coolerEconomicsSpecific energy: 160 to 500 kWh/tCapex: 40 to 300 mm USDSeveral processes are available to optimizeeconomics depending on productrequirements, energy cost and processintegration.Technology HandbookAir Liquide Engineering & Construction17

RARE GASESOur technologies for rare gases use the most efficient, safe and reliableprocesses to achieve optimal production or extraction of products.Our solutions are fully integrated into existing plants providing optimalcost and energy efficiencies.18Air Liquide Engineering & ConstructionTechnology Handbook

RARE GASESApplicationProduction of Krypton & Xenon mixtureconcentrated at 98%FeedstockLiquid oxygen stream from a largeAir Separation Unit ( 3,000 tpd)ProductKrypton Xenon Mixture at 98%Co-productNoneCapacityFrom 4,000 Nm3 /annumup to 20,000 Nm3 /annumEconomicsOpex : small size- Power: depending on the ASU integration :500 kWh/h - 1000 kWh/h- Cooling water gaseous nitrogen(negligible quantity compared to ASUutilities)Krypton / XenonDescriptionLiquid oxygen from ASU(s) is first treatedin a primary module, named “Extraction coldbox,” which aims to remove contaminants suchas N₂O and partially CnHm before entering in afirst set of cryogenic separation to produce apre-concentrated mixture.Oxygen returnto ASULiquid Oxygenpurge from ASUExtraction cold boxHydrocarbons& contaminantspurificationKrypton-Xenon ficationCryogenicSeparationsecondaryKrXe mixturestorageThe secondary module, named “Krypton-Xenonupgrader,” treats the pre-concentrated mixturethrough a hydrocarbons purifier before enteringinto the final concentrated cryogenic separationin order to produce a krypton-xenon mixtureenriched at 98% (rest is oxygen).Filling stationCompression& VaporisationunitCylindersThis concentrated cryogenic mixture (typicallyKr 91%, Xe 7%, O₂ 2%) is then compressed andvaporized to fill gas cylinders at 150 barg.Final separation (pure Kr, pure Xe) is doneoutside the ASU plant in a dedicated laboratory.Note: Krypton-Xenon production iseconomically favored for large ASU( 4000 tpd) or for multi ASUs due to the lowKrypton and Xenon content in the air(resp. 1.1 ppm, 0.086 ppm).Capex: small sizeMain features:5 - 15 mm USD (EP) Integration with ASU Low power consumption Pre-assembled packagesor skid units to ease the erectionReferences 10Contactraregases@airliquide.comTechnology HandbookAir Liquide Engineering & Construction19

RARE GASESApplicationPure liquid helium production and loadinginto ISO containersFeedstockNatural gas or impure helium gas extractedas non-condensable side-product from LNGunits or impure helium gas extracted fromnitrogen rejection unitsProductLiquid heliumCo-productNoneCapacityUp to 20 tpd (one train)EconomicsThe highly efficient process combined withthe vapor recovery system allows for a veryhigh helium recovery( 99%).Helium Extraction and LiquefactionDescriptionThe impure helium feed gas is purified in a firstsection, where N₂, CH4, H₂, CO, Ar, O₂, water andCO₂ are separated from helium.It is composed of a cryogenic partialcondensation unit, a hydrogen removal systemand a Pressure Swing Adsorber (PSA) unit.Air Liquide Engineering & ConstructionHelium LiquefactionN₂ purgeAirHelium RichFeed GasThen, the pure gaseous helium is cooledand liquefied via a helium cycle and the useof cryogenic expanders with a highly optimizedcryogenic exchanger arrangement. Expandersare based on a proprietary technology usingstatic gas bearing, ensuring high reliability andefficiency.Helium Storageand LoadingLiquid helium is continuously produced andstored in tanks. The unit is equipped with loadingbays to fill ISO containers. All helium vapors fromthe containers are collected and recycled withinthe unit.Contactraregases@airliquide.comCapex: 40 to 300 mm USD20Helium PurificationTechnology HandbookVapor Recovery SystemPure liquidheliumCompressorCryogenic UpgraderH₂ RemovalPSADryersOffgas RecycleHe LiquefierHe Cycle CompressorHelium StorageLoading BaysLiquid NitrogenGasbagVapor Recycle

Technology HandbookAir Liquide Engineering & Construction21

CO2 CAPTURECryocap is a technological innovation for CO₂ capture usinga cryogenic process involving low temperatures, around -50 C,combined with membranes separation, that is unique in the world.It can be adapted to specific applications combining a varietyof Air Liquide technologies: the capture of CO₂ producedby thermal power plants (Cryocap Oxy), or hydrogen productionunits (Cryocap H₂).22Air Liquide Engineering & ConstructionTechnology Handbook

OverviewHydrogen& SyngasGenerationH2 or SyngasCryocap H2#24CO2 for CCSCarbon-free Flue GasOxycombustionCryocap Oxy#25CO2 for CCSTechnology HandbookAir Liquide Engineering & Construction23

CO2 CAPTUREApplicationCO₂ capture fromH₂ production plantsFeedstockOffgas from H₂ plantProductCO₂Co-productH₂CapacityFrom 500 to 2,000 tpdEconomicsOpex Capex:- 45

Our SMR-X for export steam free H2 production reduces natural gas use and CO2 emissions by about 5% compared to conventional steam reforming. Our vast oleochemicals portfolio is a key-enabler to produce clean chemicals. Supporting sustainability al