Transcription

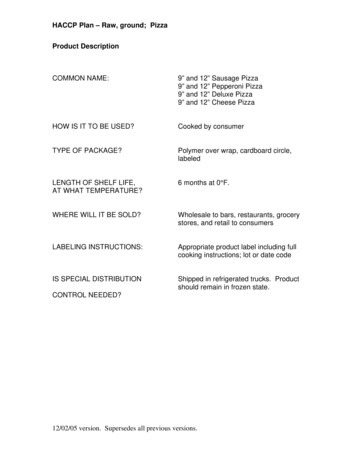

HACCP Plan – Raw, ground; PizzaProduct DescriptionCOMMON NAME:9” and 12” Sausage Pizza9” and 12” Pepperoni Pizza9” and 12” Deluxe Pizza9” and 12” Cheese PizzaHOW IS IT TO BE USED?Cooked by consumerTYPE OF PACKAGE?Polymer over wrap, cardboard circle,labeledLENGTH OF SHELF LIFE,AT WHAT TEMPERATURE?6 months at 0 F.WHERE WILL IT BE SOLD?Wholesale to bars, restaurants, grocerystores, and retail to consumersLABELING INSTRUCTIONS:Appropriate product label including fullcooking instructions; lot or date codeIS SPECIAL DISTRIBUTIONShipped in refrigerated trucks. Productshould remain in frozen state.CONTROL NEEDED?12/02/05 version. Supersedes all previous versions.

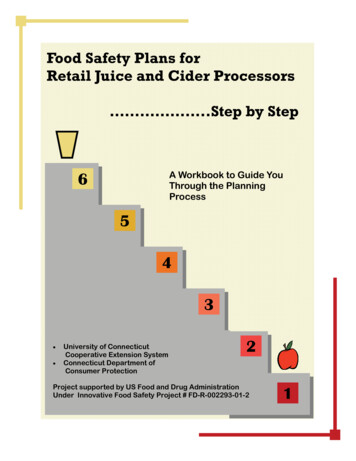

HACCP Plan – Raw, ground; PizzaDirections for Use of the Process Flow Diagram1. Examine the model Process Flow Diagram and determine which stepsyou actually use in your process. Cross out, white out, or delete allsteps that are NOT part of your process. Re-number steps asnecessary.2. Add any processing steps not already shown and make sure that eachnew step is assigned a number.12/02/05 version. Supersedes all previous versions.

HACCP Plan – Raw, ground; PizzaProcess Flow DiagramProcess Category: Raw, GroundProducts: Pepperoni. Sausage, Deluxe, and Cheese pizzas1. Receiving PackagingMaterials (cardboardcircle, shrink wrap).2. Receiving Raw andRTE Meat/Poultry3. Receiving of Non-meatand Non-poultryIngredients. (crust,cheese, vegetables, sauce,spice).4. Storage (ColdFrozen/Refrigerated)Raw and RTEMeat/Poultry7. TemperingFrozen Meat/PoultryIngredients8. Make Sauce for Pizzas9. Grind Cheese11. Portioning FoodIngredients12. CombiningIngredients (AssemblePizzas)6. Storage of PackagingMaterials13. Packaging andlabelingCCP 1B14. Finished productStorage15. Shipping or Retail12/02/05 version. Supersedes all previous versions.5. Storage of FoodIngredients, bothRefrigerated and NonRefrigerated10. Wash & CutVegetables

HACCP Plan – Raw, ground; PizzaDirections for Use of the Hazard Analysis Form1. Make sure that every step shown on the Process Flow Diagram is entered in theHazard Analysis Form. Make sure that each step has the same name and number inboth the Process Flow Diagram and the Hazard Analysis Form.2. Check the three categories of hazard (Biological, Chemical, Physical) shown for eachstep.a. If you think a listed hazard is not reasonably likely to occur, leave it in column2 (Food Safety Hazard) and enter “No” in column 3 (Reasonably likely tooccur?). Then provide a reason in column 4.b. If you think there are no relevant hazards for a particular category, deletethe listed and hazard and write “none” in column 2, write “No” in column 3, andcross out any information in columns 4 – 6.c. If you think that a relevant hazard should be added at a step, describe thehazard in column 2 (Food Safety Hazard). Then determine whether thehazard is reasonably likely to occur and put the answer in column 3. Thenprovide, in column 4, a reason for deciding whether or not the hazard isreasonably likely to occur.i. For example, following an SSOP, SOP, or approved formulation maymake a hazard unlikely to occur, or a supplier may provide a letter ofguarantee stating that the hazard should not be present.ii. On the other hand, a history of outbreaks or contamination related to ahazard would mean that the hazard IS reasonably likely to occur.Columns 5 and 6 can be left blank if a hazard is NOT reasonably likely tooccur.If the hazard IS reasonably likely to occur: fill in columns 5 and 6.iii. In column 5, list measures that could be applied to prevent, eliminate,or reduce the hazard to an acceptable level. NOTE: at least one ofthese measures must be either a Critical Control Point (CCP) at thepresent step, or a CCP at a later step.iv. Finally, if the hazard is controlled by a CCP at the present step, enterthe CCP number in column 6. The accepted numbering system is tonumber the CCP’s in order, followed by either B, C, or P to indicate whattype of hazard is being controlled. For example, if the 2nd CCP in aprocess controlled a physical hazard, it would be entered as CCP -2P.d. I f you agree that a listed hazard is relevant, no changes are necessary.12/02/05 version. Supersedes all previous versions.

HACCP Plan – Raw, ground; PizzaHAZARD ANALYSIS – RAW PIZZA – Pepperoni, Sausage, Deluxe, and Cheese Pizza’s1. Process Step1, Receiving and 6.Storage – Packagingmaterials2. Receiving – RawMeat/ Poultry2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurBiological –Contamination withmeat, other biologicalmaterialsNoChemical – Non-foodgrade materialsNoPhysical – NoneBiological Presence ofPathogens:Salmonella, Listeriamonocytogenes,Staphylococcusaureus;if beef E. coli0157:H7; if poultryCampylobacterjejuni/coliNoYesChemical – NonePhysical – NoneNoNo12/02/05 version. Supersedes all previous versions.Visual inspection forcontainer integrity,contamination, atreceiving makeshazard unlikelyLetters of guaranteeare received from allsuppliers ofpackaging materials.Visual inspectionRaw meat is a knownsource of pathogens.5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?Hazard will be controlled by alater CCP that limits exposure ofpathogens (if present) totemperatures allowing growth.Product is labeled (CCP) toinstruct consumers to fully cookproduct (and thereby killpathogens). Letter of guaranteeis on file for each supplier ofground or tenderized beefdocumenting the application of atleast one intervention stepagainst E. coli O157:H7.6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step2a. Receiving –RTEMeat/ Poultry3. Receiving – Nonmeat and Non-poultryIngredients: Crust,Cheese, Vegetables,Sauce, Spice.2. Food ylococcus ringens andClostridium botulinum(spore-formingpathogens that survivecooking)Chemical – NonePhysical – NoneBiological: PathogensSalmonella, E. coli0157:H7, Listeriamonocytogenes,Staphylococcus aureus,Clostridiumperfringens,Clostridium botulinum3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurNoNoNoNo(Cheese,Crust, Sauce,Spice)12/02/05 version. Supersedes all previous versions.Letters of guaranteeindicating that eachproduct made by anapproved processor.Receiving SOPminimizes risk ofaccepting productthat has beenmishandled such thatspore-formingpathogens couldgerminate and grow.Letters ofGuarantee arereceived from allsuppliers of foodingredients thatindicate theingredients are froman approved source.Receiving SOPensures thatingredients are notaccepted if theyhave been improperly5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurYes(Vegetables)4. Storage (Cold –Frozen/Refrigerated)– Raw Meat/PoultryChemical – Ingredientsnot being added orused as intended.Ingredients containingundesirable substancesNoPhysical – NoneBiological: Presence orgrowth of pathogens(see list above)NoYes(Presence)No(Growth)12/02/05 version. Supersedes all previous versions.handled.5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?Vegetables are stored separatelyfrom other food components andwashed prior to furtherprocessing. Hazard will becontrolled by a later CCP thatlimits exposure of pathogens (ifpresent) to temperaturesallowing growth. Product islabeled (CCP) to instructconsumers to fully cook product(and thereby kill pathogens).Approvedformulations arefollowed; letters ofguarantee arereceived from allsuppliers of foodadditives, crust,sauce, cheese etc.Raw meat is a knownsource of pathogens.Pathogens areunlikely to grow ifraw meats arestored according toHazard will be controlled by alater CCP that limits exposure ofpathogens (if present) totemperatures allowing growth.Product is labeled (CCP) toinstruct consumers to fully cook6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurthe SOP for storage.4a. Storage (Cold –Frozen/Refrigerated)– RTE Meat/Poultry5. Storage – FoodIngredients, bothrefrigerated and nonrefrigerated7. Tempering FrozenMeat/PoultryIngredientsChemical - NonePhysical – NoneBiological: PathogensListeriamonocytogenes,Staphylococcus aureus,Clostridiumperfringens,Clostridium botulinumChemical – NonePhysical – NoneBiological - NoneChemical – NonePhysical – NoneNoNoNoBiological – Presence orgrowth of pathogens(see list above)Yes(Presence)No(Growth)Chemical – NonePhysical - None5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?product (and thereby killpathogens).Pathogens areunlikely to grow ifthe product ismaintained at propertemperature (SOPfor storage).NoNoNoNoNoNoNo12/02/05 version. Supersedes all previous versions.Raw meat is a knownsource of pathogens.Tempering doneunder conditions notconducive to growth.Hazard will be controlled by alater CCP that limits exposure ofpathogens (if present) totemperatures allowing growth.Product is labeled (CCP) toinstruct consumers to fully cookproduct (and thereby killpathogens).6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step8. Make Sauce forPizzas9. Grind Cheese2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurBiological - NoneChemical – NonePhysical - NoneBiological – Pathogencontamination viaequipment and workersNoNoNoNoChemical – Cheese is apotential allergen;cleaning/sanitizingchemical residuesNoPhysical – ForeignmaterialsNo12/02/05 version. Supersedes all previous versions.SSOP makescontamination viaequipment andworkers unlikely tooccur.Application ofcorrect labelprevents inadvertentconsumption ofallergen byconsumer.Operational SSOPprevents crosscontamination ofallergenic agents.Pre-op SSOP makespresence of chemicalresidues unlikely tooccur.No history ofproblem. Visualobservation forforeign materialsduring processing,5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step10. Wash & CutVegetables2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurBiological - Pathogencontamination viaequipment and workers.No(Contamination)Presence of pathogensYes(Presence)Chemical – NonePhysical – ForeignmaterialNoNo12/02/05 version. Supersedes all previous versions.inspection ofequipment duringcleaning make hazardunlikely.SSOP makescontamination viaequipment andworkers unlikely tooccur.No history ofproblem. Visualobservation forforeign materialsduring processing,inspection ofequipment duringcleaning make hazardunlikely.5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?Hazard will be controlled by alater CCP that limits exposure ofpathogens (if present) totemperatures allowing growth.Product is labeled (CCP) toinstruct consumers to fully cookproduct (and thereby killpathogens).6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step11. Portioning FoodIngredients2. Food SafetyHazardBiological – Presenceor growth of pathogens(see list above);Pathogen contaminationvia equipment andworkers3.4. Basis ofReasonably Reasonably likelylikely toto occuroccur5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?Raw meat is a knownsource of pathogens.Pathogens arereasonably likely togrow if temperatureand time of exposureto unsafetemperatures arenot controlled.SSOP makescontamination viaequipment andworkers unlikely tooccur.Hazard will be controlled bylimiting exposure of pathogens(if present) to temperaturesallowing growth during theportioning, assembly, andpackaging/labeling (CCP) steps.Product is labeled (CCP) toinstruct consumers to fully cookproduct (and thereby killpathogens).Raw meat is a knownsource of pathogens.Pathogens arereasonably likely togrow if temperatureand time of exposureto unsafetemperatures arenot controlled.SSOP makescontamination viaHazard will be controlled by bylimiting exposure of pathogens(if present) to temperaturesallowing growth during theportioning, assembly, andpackaging/labeling (CCP) steps.Product is labeled (CCP) toinstruct consumers to fully cookproduct (and thereby ation)12. CombiningIngredients(Assemble Pizzas)Chemical – NonePhysical – NoneBiological – Presence orgrowth of pathogens(see list above);Pathogen contaminationvia equipment -12/02/05 version. Supersedes all previous versions.6. CriticalControl Point

HACCP Plan – Raw, ground; Pizza1. Process Step2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurtion)13.Packaging/LabelingChemical – NonePhysical - NoneBiological – Presence orgrowth of pathogens(see list above);Pathogen contaminationvia equipment tion)14. Finished ProductStorageChemical – NonePhysical - NoneBiological – Growth ofpathogens (see listabove)NoNoNoChemical – NoneNo12/02/05 version. Supersedes all previous versions.5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?6. CriticalControl Pointequipment andworkers unlikely tooccur.Raw meat is a knownsource of pathogens.Pathogens arereasonably likely togrow if temperatureand time of exposureto unsafetemperatures arenot controlled.SSOP makescontamination viaequipment andworkers unlikely tooccur.SOP for finishedproduct storagemakes this hazardunlikely to occur.Product is handledaccording to SOP forHazard will be controlled bylimiting exposure of pathogens(if present) to temperaturesallowing growth during theportioning, assembly, andpackaging/labeling steps.Product is labeled to indicatethat it is raw, not RTE, alongwith validated cookinginstructions, and the safe foodhandling statement.1B

HACCP Plan – Raw, ground; Pizza1. Process Step15. Shipping or Retail2. Food SafetyHazard3.4. Basis ofReasonably Reasonably likelylikely toto occuroccurPhysical - NoneNoBiological – NoneNoChemical – NoneNoPhysical - NoneNo12/02/05 version. Supersedes all previous versions.Finished ProductStorageProduct is handledaccording to SOP forFinished ProductStorageProduct is handledaccording to SOP forFinished ProductStorageProduct is handledaccording to SOP forFinished ProductStorageProduct is handledaccording to SOP forFinished ProductStorage5. If Yes in Column 3,What Measures Could beApplied to Prevent,Eliminate, or Reduce theHazard to an AcceptableLevel?6. CriticalControl Point

HACCP Plan – Raw, ground; PizzaDirections for Using the HACCP Plan Form1. Examine your Hazard Analysis form to determine which steps are CCP’s and what type of hazard (Biological, Chemical, orPhysical) each CCP controls.2. Check to see whether each CCP is already listed on the HACCP Plan Form. If a CCP is not already listed, enter the CCPnumber and step in the column labeled “CCP # and Location”.3. For CCP’s already listed on the model form, examine the Critical Limits listed. In the HACCP Plan Form for some HACCPcategories there will be several options for Critical Limits. If this is the case, choose the Critical Limits that will work best inyour plant and cross out, white out, or delete the other Critical Limits and the Monitoring Procedures that go with them. It maybe helpful to check the “Monitoring Procedures and Frequency” column during your decision-making. For CCP’s already onthe model form, supporting scientific documentation is already included in your manual.4. If you are adding a new CCP, you will need to determine the scientifically valid Critical Limits to be used with the CCP. Youmust also obtain scientific information supporting your choice of Critical Limits. Consult your inspector or universityextension specialists for help.5. Examine the “Monitoring Procedures and Frequency” column for each CCP. If you wish to change the procedure and/or thefrequency, check with your inspector or a university extension specialist for help. If a change is OK, you will need to writedown your reasoning for making the change and include this reasoning in your HACCP manual.6. Examine the “HACCP Records” column. If you are using different forms for record-keeping in this HACCP Plan, please putthe correct form title(s) in the “HACCP Records” column.7. The verification activities listed in the “Verification Procedures and Frequency” column are required by the regulation.However, you may choose to do additional activities; for example, for verification, beef jerky samples may be sent to the labeach quarter for water activity and Moisture : Protein Ratio testing. If you do any additional verification activities, enter themin the “Verification Procedures and Frequency” column. If you choose to use a frequency for the required verificationactivities that is different than the frequency shown, you must provide written justification for the different frequency. Consultyour inspector or university extension specialists for help.8. We suggest that you make no changes in the “Corrective Actions” column. Be sure to have a form for documenting correctiveactions that you take. A corrective action form is included in this model.12/02/05 version. Supersedes all previous versions.

HACCP Plan – Raw, ground; PizzaHACCP PLANPROCESS CATEGORY: Raw, PizzaProduct example: Pepperoni, Sausage, Deluxe, and Cheese Pizza’sCCP# and LocationCritical Limits1B (1st part)Packaging/Labeling1. Meat internaltemperature of 41 –50 F and returnedto refrigeration(meat internaltemperature of 41 For lower) within 4hours.ORMonitoring Proceduresand Frequency1. Using a calibratedthermometer, theestablishment owner ordesignee will measure thefollowing temperatures:a.each pizza meatcomponent (in bulkprior to assembly)The warmesttemperature willbe recorded in thelog.b. At the end of eachlot, thetemperature fortwo wrappedpizzas heldtopping-to-toppingwith thethermometerbetween thepizzas.c. Within 4 hoursafter the start ofeach lot, thetemperature fortwo wrapped12/02/05 version. Supersedes all previous tion LogThermometerCalibrationLogVerification Procedures andFrequencyEstablishment owner ordesignee will review the CCPMonitoring Form, CorrectiveAction Log, and ThermometerCalibration Log once per week.Establishment owner ordesignee will calibrate allthermometers to a knownstandard monthly.Thermometers will becalibrated to 2 F or takenout of operation as stated inthe SOP. Calibration actionsare recorded in theThermometer Calibration Log.Establishment owner ordesignee will observemonitoring of temperature atleast once per month.Corrective ActionsIf a deviation from acritical limit occurs, theestablishment owner ordesignee is responsiblefor corrective actionprotocol as stated in9 CFR 417.31.2.3.The cause of thedeviation will beidentified andeliminated.The CCP will be undercontrol after thecorrective action istaken.Measures to preventrecurrence areestablished.4. No product that isinjurious to health orotherwise adulteratedas a result of thedeviation will bepermitted to entercommerce.

HACCP Plan – Raw, ground; PizzaHACCP PLANPROCESS CATEGORY: Raw, PizzaProduct example: Pepperoni, Sausage, Deluxe, and Cheese Pizza’sCCP# and LocationCritical LimitsMonitoring Proceduresand Frequencypizzas heldtopping-to-toppingwith thethermometerbetween thepizzas.2. Meat internaltemperature of 41 –75 F and returnedto refrigeration(meat internaltemperature of 41 For lower) within 2hours.2. Using a calibratedthermometer, theestablishment owner ordesignee will measure thefollowing temperatures:a.each pizza meatcomponent (in bulkprior to assembly)The warmesttemperature willbe recorded in thelog.b. At the end of eachlot, thetemperature fortwo wrappedpizzas heldtopping-to-toppingwith thethermometerbetween the12/02/05 version. Supersedes all previous versions.HACCPRecordsVerification Procedures andFrequencyCorrective Actions

HACCP Plan – Raw, ground; PizzaHACCP PLANPROCESS CATEGORY: Raw, PizzaProduct example: Pepperoni, Sausage, Deluxe, and Cheese Pizza’sCCP# and LocationCritical LimitsOR3. Product exposedto a roomtemperature of 4150 F and returnedto refrigeration(meat internaltemperature of 41 For lower) within 4hours.ORMonitoring Proceduresand Frequencypizzas.c. Within 2 hoursafter the start ofeach lot, thetemperature fortwo wrappedpizzas heldtopping-to-toppingwith thethermometerbetween thepizzas.3. Using calibratedthermometers, theestablishment owner ordesignee will measure:a. the room temperatureat the start of each lotb. the room temperatureat the end of each lotc. within 4 hours after thestart of each lot, thetemperature for twowrapped pizzas heldtopping-to-topping with acalibrated thermometer12/02/05 version. Supersedes all previous versions.HACCPRecordsVerification Procedures andFrequencyCorrective Actions

HACCP Plan – Raw, ground; PizzaHACCP PLANPROCESS CATEGORY: Raw, PizzaProduct example: Pepperoni, Sausage, Deluxe, and Cheese Pizza’sCCP# and Location1B (2nd part)Packaging/LabelingCritical LimitsMonitoring Proceduresand Frequencybetween the pizzas4. Product exposedto a roomtemperature of 41 75 F and returnedto refrigeration(meat internaltemperature of 41 For lower) within 2hours.4. Using calibratedthermometers, theestablishment owner ordesignee will measure:Product must belabeled with allrequiredinformation,including validatedcooking instructionsand a list ofEstablishment owner ordesignee will select 5packaged pizzas fromeach production lot andobserve to ensure labelingrequirements are met.HACCPRecordsVerification Procedures andFrequencyCorrective ActionsCCPMonitoringFormEstablishment owner ordesignee will review CCPMonitoring Form at least oneper week.If a deviation from acritical limit occurs, theestablishment owner ordesignee is responsiblefor corrective actionprotocol as stated in9 CFR 417.3a. the room temperatureat the start of each lotb. the room temperatureat the end of each lotc. within 4 hours after thestart of each lot, thetemperature for twowrapped pizzas heldtopping-to-topping with acalibrated thermometerbetween the pizzas12/02/05 version. Supersedes all previous versions.Establishment owner ordesignee will observe person

HACCP Plan – Raw, ground; PizzaHACCP PLANPROCESS CATEGORY: Raw, PizzaProduct example: Pepperoni, Sausage, Deluxe, and Cheese Pizza’sCCP# and LocationCritical LimitsMonitoring Proceduresand Frequencyingredients.Safe Food Handlinglabeling must also beapplied to all pizzas.HACCPRecordsVerification Procedures andFrequencyperforming monitoring activityonce per month.Establishment owner ordesignee will select threelabels intended for use fromlabel storage and will comparethem with product formulationto assure accuracy of labelsonce per quarter year.Corrective Actions1.Establishmentowner or designeewill determine causeof deviation andinstitute preventiveactions.2.The CCP will be undercontrol after thecorrective action istaken.Measures to preventrecurrence areestablished.3.4.Sign and date at initial acceptance, modification, and annual reassessment.SignedDateSignedDate12/02/05 version. Supersedes all previous versions.Establishmentowner will ensurethat proper labelingis applied to allaffected productprior to shipment orsold. Establishmentowner or designeewill segregate andhold all affectedproduct.

HACCP Plan – Raw, ground; PizzaDateProductIDNo.ofPizzasCCP Monitoring Form: Critical Limits are meat temperatures and labelingPizza or Room StartPizza or Room EndPizza Temp.Label Present andTemperatureTemperatureWithin 2 or 4 hoursCorrect?after Start of Lot*Temp./Time / InitialsInitialsDevn.fromCriticalLimit?(Y yes, N no)Pre-shipment / pre-usereviewSignature/Date* Temperature measurement not necessary if pizza/room temperature does not exceed 41ºF.Verification Activities (for up to three weeks) associated with these batches. Indicate Type of activity: DOT Direct Observation of Temperature monitoring (monthly), DOL Direct Observation of Labeling monitoring(monthly), CAL thermometer calibration, or RR Records Review (weekly).Type of activity:Result (9 Acceptable):Date/Time:Initials:12/02/05 version. Supersedes all previous versions.Type of activity:Result (9 Acceptable):Date/Time:Initials:Type of activity:Result (9 Acceptable):Date/Time:Initials:

HACCP Plan – Raw, ground; PizzaRaw, Pizza ModelCorrective Action LogProduct:Date / Time:Deviation:Lot ID:Responsible Person:Cause of Deviation:Cause of DeviationEliminated By:CCP Under ControlAfter CorrectiveActions Taken:Preventative Measures:Product Disposition:Verification (Records Review) by and Date:12/02/05 version. Supersedes all previous versions.

HACCP Plan – Raw, ground; PizzaThermometer Calibration LogDateTimeTest ReferenceTherm. Therm.ID#ReadingTestTherm.ReadingAdjustments Required(yes/no)CommentsInitialsThermometers intended for measuring higher temperature items, such as cooked product, will be calibrated in hotwater, while those used for taking lower temperatures will be calibrated in ice water. All thermometers will becalibrated within or – 2 degrees F. Thermometers taken out of service , document in the “comments” column.12/02/05 version. Supersedes all previous versions.

HACCP Plan – Raw, ground; PizzaSOP for Calibration of ThermometerProcessor or designee will calibrate the thermometers prior to use by following thespecifications of the manufacturer of the equipment (this will vary) or the followingprocedures.Each thermometer will be assigned an ID number.Thermometers intended for measuring higher temperature items, such as cooked product,will be calibrated in hot water, while those used for taking lower temperatures will becalibrated in ice water. All thermometers will be calibrated within or – 2 degrees F.Thermometers in use will be checked against a certified thermometer during calibration, ifavailable. Otherwise, all thermometers will be calibrated either against each other, oragainst a thermometer that is used only during calibration. The latter methods wouldrequire at least three thermometers for accuracy. Dial thermometers will only becalibrated (and used!) on one end of the range of use, e.g. either the hot end or the coldend. This practice is followed to assure accuracy.Calibration with ice water:1. Add crushed ice and water to a clean container to form a watery slush.2. Place thermometer probe into slush for at least one minute, taking care to not letthe probe contact the container.3. If the thermometer does not read between 30 degrees and 34 degrees F., adjustto 32 degrees. Nonadjustable thermometers will be removed from use until theyhave been professionally serviced. Thermometers that have been adjusted for 3consecutive months will be replaced.4. Record the results, using actual values, on the thermometer calibration log, alongwith the date and initials of the person performing the calibration procedure.Calibration with hot water:1. Heat a clean container of water to a temperature in the range of cookedproducts. Running clean water through the coffee maker gives a watertemperature of approximately 145 degrees F. Another option is to bring a cleancontainer of water to a rolling boil.2. Place the thermometer probe into the hot water, along with the certifiedthermometer and/or reference thermometer, or at least two other12/02/05 version. Supersedes all previous versions.

HACCP Plan – Raw, ground; Pizzathermometers, for at least one minute, taking care not to let the probe contactthe container.3. If the test thermometer does not read within or – 2 degrees of the referencethermometer, adjust accordingly. If three thermometers are used and onethermometer differs from the other two by more than 2 F, that thermometershall be adjusted or removed from use. If all three thermometers differ fromeach other by more than 2 F, a reference thermometer must be used or eachthermometer must be calibrated against vigorously boiling water (212 F).Nonadjustable thermometers will be removed from use until they have beenprofessionally serviced. Thermometers that have been adjusted for 3consecutive months will be replaced.4. Record the results, using actual values, on the thermometer calibration log, alongwith the date and initials of the person performing the calibration procedure.Thermometers that cannot be easily calibrated through direct immersion in either icewater or hot water can be calibrated by comparing readings with another calibratedthermometer. Thermometers that may be calibrated in this way include smokehouseprobes and room temperature thermometers. When doing this, a recently calibratedthermometer will be used as the reference. Room temperature thermometers that areoutside the or – 2 degree F range will be replaced. Smokehouse probes that are outsidethe or – 2 degree F. range will be professionally serviced. Results will be recorded, usingactual values, on the thermometer calibration log, along with the date and initials of theperson performing the calibration procedure.Thermometers will be calibrated at a frequency dependent on production volumes, and useof monitoring CCP values or SOP values. Any thermometer that has been dropped orabused will be taken out of service until it has been recalibrated. Any “loose”thermometers, or thermometers that have been out of calibration for 3 consecutivemonths, shall be discarded.Thermometers in use will be checked against a certified thermometer during calibration, ifavailable. Otherwise, all thermometers will b

1. Make sure that every step shown on the Process Flow Diagram is entered in the Hazard Analysis Form. Make sure that each step has the same name and number in both the Process Flow Diagram and the Hazard Analysis Form. 2. Check the three categories of hazard