Transcription

TA INSTRUMENTSRHEOMETERS

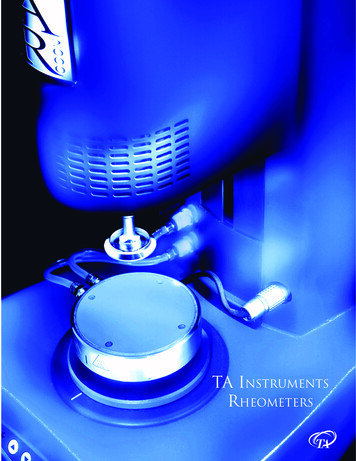

THE TA INSTRUMENTS RHEOMETERSensitive, Accurate, Rugged, and Reliable,these words describe a TA Instruments rheometer.Our exciting new rheometers are fifth generationproducts from the pioneer of controlled stress rheology.Designed with the customer in mind, and backed bythe superior customer support, which is the hallmarkof TA Instruments, these rheometers have set anew standard for performance.The AR 2000 is the world's most advanced rheometer. Itsinnovative Mobius Drive offers unprecedented controlledstrain and controlled stress performance. The AR 2000’s uniquefeatures are its broad torque range, superior strain resolution,wide frequency range, and ingenious convenience features, likethe Smart Swap interchangeable temperature control options.It is well equipped to handle the most demanding rheologicalapplications.

The AR 1000 is a research grade rheometerincorporating a unique motor design, andadvanced material air bearing. It hasexcellent torque performance, very lowinertia, and easily outperforms competitiveresearch grade systems. The AR 1000 can beequipped with multiple temperature controloptions, normal force sensor, and customgeometries.The AR 500 is a general purpose rheometerwith many of the features of our research gradesystems. The AR 500 is an upgradeablesystem that can grow as your applicationsexpand. It is the ideal rheology system forusers interested in a robust, cost-effectivesystem with outstanding basic performance.Are you ready to transfer rheological tests fromthe lab to manufacturing facilities, orquality control labs ? Based on the successfulAR 500, the QCR II is a robust rheometerthat easily automates the analysis of a broadrange of samples.

TECHNICAL SPECIFICATIONSAR 2000Minimum Torque0.1 µN.mMaximum Torque200 mN.mMotor Inertia15 µN.m.s2Angular Velocity RangeMobius Drive Frequency RangeDisplacement ResolutionAir Bearing1 E-8 - 300 rad/sStandard1.2E-7 - 100 Hz0.04 µradPorous CarbonAuto Gap SetStandardGap Resolution0.06 µmNormal Force Range0.01 to 50 NTemperature Control OptionsPeltier Plate-20 to 200 C (2)Environmental Test Chamber-150 to 600 CConcentric Cylinder-Peltier Control-10 to 150 CExtended Temperature ModuleNot AvailableConcentric Cylinder-with CirculatorNot AvailableAdvanced FeaturesSmart Swap SystemStandard

12AR 1000AR 500 / QCR0.1 µN.m1.0 µN.m100 mN.m50 mN.m14 µN.m.s226 µN.m.s21 E-8 - 100 rad/s1 E-8 - 100 rad/sNot AvailableNot Available1 E-4 - 100 Hz1 E-4 - 40 Hz0.62 µrad0.62 µradPorous CarbonJetStandardStandard0.06 µm0.06 µm0.01 to 50 N0.01 to 50 N-10 to 100 C (1,2)-10 to 100 C (1,2)-150 to 400 C-150 to 400 CNot AvailableNot Available-100 to 400 C-100 to 400 C-20 to 150 C-20 to 150 CNot AvailableNot AvailableExtended Peltier available with temperature range -20 to 180 C.Lower temperature can be reduced to -40 C by use of a suitable fluid in the external circulator.

INSTRUMENT DESIGN FEATURESANDBENEFITSA Rheometer is only as good as its ability to apply torqueand measure displacement. Our engineers use customdesigned components and proprietary materials (describedbelow) to achieve unequalled stress and strain performance.31. Drive Motor Non-contact, with an excellent torque2to inertia ratio, and no overheating problems, the MobiusDrive motor provides torque over a very wide range. Ourengineers used finite element analysis of the high efficiencyAR 1000 motor to optimize the performance, torque range,and very low inertia of the AR 2000 motor. Benefits: Awide variety of materials can be studied from very lowviscosity materials to polymer melts and solids.2. Air Bearing TA Instruments’ unique, custom-12designed, air bearings provide frictionless support for thedrive shaft and measuring geometry. Our long-life jetbearings (AR 500) and porous carbon bearings (AR 2000/1000) provide low levels of residual torque. Rotational Mapping automatically corrects for residual torque in thesystem. The ultra-stiff air bearing on the AR 2000 preventsmeasurement errors due to axial forces. Benefits: TAbearings provide excellent torque resolution, and allow theapplication of a wide range of torque (stress). The porouscarbon air bearing on the AR 2000/1000 extends the lowtorque performance of the instrument.3. Optical Encoder Measures angular deflection withhigh resolution. Benefit: Sample measurements can beconducted at low shear rates, small displacements (strain),and high velocities.

44. Smart Swap This unique magnetic device isthe location point for all AR 2000 temperaturecontrol options. Benefit: The Smart Swap base allowsrapid exchange of temperature options whilemaintaining precise location.5. Normal Force Transducer This highly sensitive, ultra-stiff transducer located below the sampleplate provides a direct measure of a wide rangeof normal forces exerted by samples, without a changein gap. The performance, fast response, and temperature isolation found in the AR 1000/500 normal forcesensors are improved in the AR 2000. Benefits: Quantitativenormal forces exhibited by materials with different viscoelastic properties are measured. Normal forces generated duringsample loading can be monitored.5 Linear Ball Slide Mounts the motor and air bearing to the casting. The high precision slide is drivenvertically by a motor in the base. A second optical encoder is located in the base to measure the movementof the slide. Benefits: Precise geometry location relative to the sample is assured. The long travel permittedby the ball slide allows for a large working space to simplify sample loading and cleaning. Auto Gap Set The software provides automatic setting of gap, and programmed gap closure via severalmethods (linear, exponential). Thermal Gap Compensation automatically corrects for any change in samplegap due to thermal expansion. Benefits: Automatic and reproducible setting of the sample gap ensuresaccuracy and reproducibility. By monitoring the normal force exerted by the sample during closure,delicate material structures are protected rather than destroyed prior to the experiment. Rigid One-Piece Aluminum Casting The key components of the rheometer are mounted in thisstiff high mass casting. Benefit: Low system compliance with high mechanical integrity.

Traditionally there are two approaches to characterizing materials usingrheometers. The controlled stress approach applies a torque (stress) to the sampleand measures the resultant strain. The controlled strain approach applies a strainto the sample and measures the resultant stress. While results from each typeof experiment are often identical, there are some material properties bestmeasured in one mode or the other. Until today, this often required twodifferent instruments, or a compromise in the materials and properties that couldbe evaluated. The new Mobius Drive solves this dilemma by providing superiorcontrolled stress and controlled rate performance in one instrument. Namedafter August Ferdinand Möbius, a 19th century German mathematician,a Möbius strip can be made by joining together two ends of a strip, aftertwisting one end. The result is a loop that, instead of having two sides, hasonly one. The Mobius Drive is so named because it takes the two classical“sides” of rheology (controlled stress and controlled strain) and combinesthem into a single seamless whole. Made possible by its low inertia motorand air bearing coupled with a 2,000,000 to 1 torque range, andhigh-speed electronics, the AR 2000 rheometer automatically engages theMobius Drive as required by experimental conditions. Rheologists no longerhave to buy two instruments, or choose one optimized for one approachor another.

FIGURE 1.STRESS RELAXATION 10,000Modulus G(t)100010010% strainmodulus G(t) (Pa)The ability to perform stress relaxation experimentshas long been synonymous with controlled strainrheometers. However, with limited torque rangetransducers the measured data can quickly disappearinto the noise. With its 2,000,000 to 1 torque rangethe AR 2000 with Mobius Drive actually improvesupon data from dedicated controlled strain rheometers by reaching the set strain in a comparable timeand extending the G(t) data well past the time wheretraditional controlled strain rheometer datawould have become too noisy for accuratemeasurements (figure 1).100101Time to set strain 60ms0.10.01.001.010.111010011000time (s)FIGURE 2.STEP SPEEDRapid step changes in shear rate (angular velocity) tomodel thixotropic behavior and to control theshear rate through a ramp are experiments alsogenerally associated with controlled strain rheometers.The AR 2000 with Mobius Drive easily performs thesetests, with the time taken to make a step change inspeed comparable to that from a dedicatedcontrolled strain rheometer (figure 2).100angular velocity (rad/s)1010.10.01Time to set speed 20ms0.0010.00010.000010.001FIGURE 3.CREEP RINGING0.010.1110100time (s)1E-3The implementation of the Mobius Drive has notcompromised the controlled stress performance of theAR 2000. Creep (step stress) data can be acquired asquickly as a point every millisecond. This can revealinteresting short timescale properties and materialssuch as gels and emulsions can show ‘ringing’behavior (figure 3) that can be modeled to deriveviscoelastic parameters from less than 1 second of data.compliance J(t) (1/Pa)1E-41E-51E-61E-70.001Gel sampleJeffrey's Model0.010.1time (s)1

AR 2000 TEMPERATURECONTROL OPTIONSSMART SWAP Our new “Smart Swap” technology allows an AR 2000user to interchange temperature control systems and beoperational much quicker than ever before. Theintelligent firmware automatically senses the type oftemperature system present, configures the softwareaccordingly, and loads all relevant calibration data.Disconnecting an existing system is a simple pushbutton release on the rheometer front panel. Smart Swaptechnology ensures an error-free installation every time.This feature is available only for the new AR 2000Advanced Rheometer.PELTIER PLATEThe Peltier Plate, with Smart Swap technology, is the commontemperature control system for the AR 2000. Operational from–20 to 200 C, it provides a temperature accuracy of /- 0.1 Cand a typical heating rate of 20 C per minute.The Peltier Plate is the rheologist’s choice for most fluidapplications. It is ideally configured for parallel plate or coneand plate use, since the narrow gaps used permit rapidconduction of heat to the sample. The open design of the PeltierPlate also facilitates easy sample loading and cleaning of thedurable hard chrome surface. A Pt 100 sensor positioned at thecenter of the sample plate ensures accurate measurement andcontrol of sample temperature. With Smart Swap technology theAR 2000 Peltier Plate is user replaceable.

ENVIRONMENTAL TEST CHAMBERThe ETC connects easily to the AR 2000 and providescontrolled convection / radiant heating and cooling (LN2)over the extended temperature range of –150 to 600 C, withheating rates up to 15 C per minute. The ETC is ideal forthe analysis of polymer melts using cone and plate andparallel plate measuring geometries, and for curing studiesof thermosetting resins using disposable plates. It is alsocommonly used to analyze solids in torsion and canaccommodate standard samples specified in ASTM D4065Test Method. Smart Swap technology allows rapidinterchange between parallel plates for polymer melts andtorsional clamps for solids. The ETC is thus a very flexibleand easily-used accessory that covers a wide temperaturerange and allows the rheologist to measure diverse samplesover their complete viscoelastic spectrum.CONCENTRIC CYLINDERSThe AR 2000 Concentric Cylinder System is based on efficientPeltier temperature control, and brings a whole newdimension in operational and economic efficiency to viscositymeasurements using concentric cylinder systems. ThePeltier system provides much more rapid heating and cooling ofthe sample than is available from systems involvingcirculating external fluids. In particular, it results in significanttime savings, especially when large changes in temperature arenecessary. Also, since the new system does not require anexpensive controlled-temperature fluid circulator, significant costsavings can be realized.The AR 2000 Concentric Cylinder System can be operated overthe temperature range –10 to 150 C, and incorporatesSmart Swap technology for rapid interconversion oftemperature control systems – available only with the AR 2000Advanced Rheometer.

AR 1000 & 500 TEMPERATURECONTROL OPTIONSPELTIER PLATEThe Peltier Plate is the standard temperature control device for the TA Instruments AR1000 / 500 Rheometers and is available in two temperature ranges. The Standard PeltierPlate has a temperature range of -10 to 100 C while the Extended Peltier Plate operatesfrom -20 C to 180 C. Over these ranges they will provide an accuracy of 0.1 C and atypical heating rate of 20 C per minute. A Pt100 sensor is positioned at the center of thesample plate to ensure accurate measurement and control of sample temperature.CONCENTRIC CYLINDERSThe Fluid Jacket Temperature System for the AR 1000/500 Rheometers isdesigned to provide precise temperature control for concentric and doubleconcentric cylinder geometries over a wide range of temperatures. Concentriccylinders are best used for low viscosity samples, and those with large particles and/orlimited stability. A range of systems (conical, recessed, vaned, and double concentric) areavailable. The system is self-aligning, and is quick and easy to change from cone & plateto concentric cylinder use.ENVIRONMENTAL TEST CHAMBERThe ETC provides controlled convection/radiant heating and cooling (LN2)over the temperature range -150 to 400 C with heating rates up to 15 C perminute. Its main use is in the analysis of polymer melts using cone and plateand parallel plate geometries. Disposable plates are available for thermosetstudies. It is also commonly used to analyze solids in torsion.EXTENDED TEMPERATURE MODULEThe E

The Peltier Plate is the rheologist’s choice for most fluid applications. It is ideally configured for parallel plate or cone and plate use, since the narrow gaps used permit rapid conduction of heat to the sample. The open design of the Peltier Plate also facilitates easy sample loading and cleaning of the durable hard chrome surface. A Pt 100 sensor positioned at theFile Size: 1MBPage Count: 20