Transcription

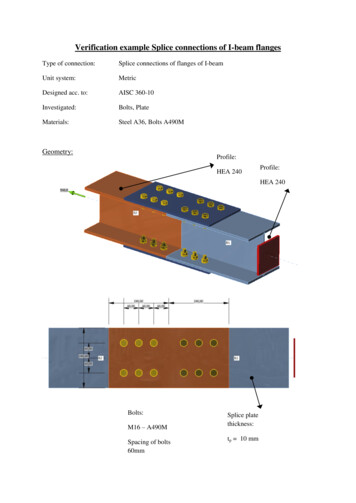

Verification example Splice connections of I-beam flangesType of connection:Splice connections of flanges of I-beamUnit system:MetricDesigned acc. to:AISC 360-10Investigated:Bolts, PlateMaterials:Steel A36, Bolts A490MGeometry:Profile:HEA 240Profile:HEA 240Bolts:M16 – A490MSpacing of bolts60mmSplice platethickness:tp 10 mm

Applied forces:V 0 kNN 540 kNM 0 kNmProcedure:Bolts are considered to be only in shear (in threaded parts). IDEA StatiCa takes into account thetension force in bolts caused by eccentricity. However, tension force does not determine the design.The check for combined tension/shear needs to be verified and is performed by IDEA StatiCa.IDEA StatiCa Connection – resultsVon Mieses stress

Plastic strain ratio Direction of resultants in boltsThe shear force in one bolt is app. Fv 45 kNThe ultimate shear strength of M16 – A490M isϕFnv 69 kNThe unit check: 45/69 0.65 65%The forcesdistributed.inboltsarealmostlinearly

AISC 360-10 and Steel construction manual – resultsSplice Plate connection (AISC) e160e1 6010mmplate width bP length of plate L pl. width at base b B 240250240mmmmmmMPa400MPamm2Φb 0,9mmCharacteristics/ 1 angle:Ag 1900radii not includedx 28,68Φbfy 225MPa328,68 mmpieces/ 1 angleΦ E 0,75200GPa60mmd0 18mme1 60mmA 201mm2e2 60mmAS 157mm2g 10mmBolts:y s 60bolt spacing s Force caused by eccentricityTotal force for design:th. 10250fu 10Fe 60Shear strength per 1 bolt:kN/ 1 angleNEd 92Fnv 135 kN/ 1 anglekNacc. Table J3.2mmin threaded part of bolts6 x M 16bP 240A36fy 100 /90 e2 Plate and beam steel:L100 /Angle: e1j60jplate thickness d1 number of bolts n 60j e1je1 60L 250Plate:s 60e1 60jkNe1 60j270s 60NEd Tension forceClassA490Mutilization of connection: 65,3% OKbB 240Bolt shear capacityn Φ Fnv acc. AISC 360-10 - J3.6413Unit Check:kNNEd / n Φ Fnv Bearing capacityOK0,65Per 1 angle (Deformation at bolt hole at service load is a consideration - J3.10 - a-i)Tension force acts in straight line, change of force direction due to eccentricity is neglected, for calculation N Ed is taken.dB0 d0 2 mm 20 mm( 2mm acc. B4.3b)minimal thickness of connected plates:t 10 mmAt edge:Between holes:Lc e1 - dB0/2 50Rn 1,2Lc fu t 240Rn 154 kNΦRn 115 kNNed mm135kN Lc s - dB0 NEd /n Block shear rupture Ubs 1,0One angle's flange:2500 mm600 mm2Anv Agv 1300 mm21800 mm2fuAnt 0,6fu Anv fuAnt 0,6fu Anv Rn 462 kNΦRn 347 kN154 kN45ΣΦRn 346 kNLongitudinal planeAnt Agt 2,4 d t fu 0,39 OKAnt 1615 mm20,85 Ag was usedRn 646 kNΦRn 485 kNUnit check0,28 OK192Rn 154 kNΦRn 115 kN(n-1)ΦRn 230 kNkN 2,4 d t fu 154 kN(in total between holes)0,39 OK0,45OK as wholeacc. AISC 360-10 - J4.3Gusset plate block shear (as shown on picture)1st bolts NEd 90 kN1st bolts NEd Ag(side) 750An(side) 6502Ant 700 mmAnt 6502Agt 900 mmAgt 750Anv 1000 mm2Anv 500Agv 1200 mm2Agv 600Rn 460 kNΦRn 345 kNUnit Check:0,26 OKLast bolts NEd 270 kNUnit Check:0,39 OKPrependicular to the force:One angle:40 mmRn 1,2Lc fu t Ant 700 mm2Agt 900 mm2Anv 2600 mm2Agv 3600 mm2Rn 820 kNΦRn 615 kNUnit Check:0,44 OKRn 45 kNmm2mm2mm2mm2mm2mm2NEd Ag(side) An(side) Ant Agt Anv Agv 7506506507501300Rn ΦRn Unit Check:0,15 OK135 kNmm2mm2mm2mm2mm21800 mm2530 kNΦRn 398 kNUnit Check:0,34 OK1st boltsAg(side) An(side) Ant Agt Anv Agv Rn 350 kNΦRn 263 kNUnit Check:0,17 OKLast boltsA area; n net; g gross; t tension; v shearNEd 7506502000240000800 kN600 kNLast boltsNEd Ag(side) An(side) Ant Agt Anv Agv 750650200024000Rn ΦRn Unit Check:0,45 OK90 kNmm2mm2mm2mm2mm2mm2270 kNmm2mm2mm2mm2mm20 mm2800 kN600 kN

The resulting shear force in one bolt is: Fnv N / 6 bolts 270/6 45 kNThe unit check: 65%Combined tension and shear:Bolt B3 is investigated (see IDEA StatiCa table with results )Fv 44.9 kNFt 9.9 kNFor M16 A490M:Fnt 157 kNFnv 92 kNA 201.1 mm2frv 44.9 kNF’nt 1.3 x 157 – 157 x 44.9/(0.75 x 92) 101.9 kNThe unit check: Ft/ϕF’nt 9.9/(0,75 x 101.9) 13%The results fully correspond to each other.Utts (unit check for combinationshear/tension):Utts 13%

Comparison:The results of both IDEA StatiCa design and manual computation according to AISC 360-10 givescomparable values:Bolt check: Both results give the same values. The check of combination of shear/tension gives thesame results as well.Plate check: Block rupture determines the plate check. Von Mises stress shows that block ruptureacross the splice plate is possible and could determine the design in manual check.However, according the IDEA StatiCa, there is still a reserve in plastic strain limit.

Bolt shear capacity acc. AISC 360-10 - J3.6 Q-) nv 413 kN Unit Check: N Ed Q-) nv 0,65 OK Bearing capacity Per 1 angle (Deformation at bolt hole at service load is a consideration - J3.10 - a-i) Tension force acts in straight line, change of force direction due to