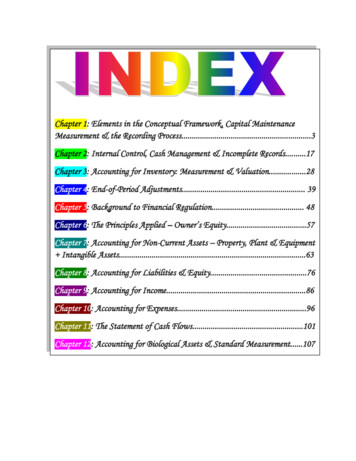

Transcription

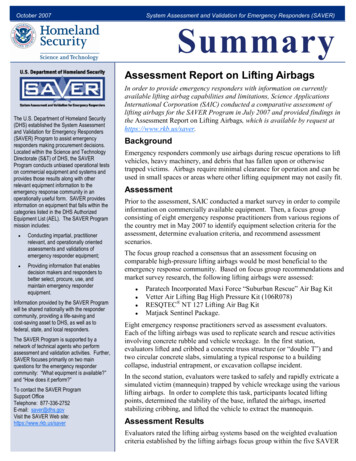

October 2007System Assessment and Validation for Emergency Responders (SAVER)SummaryAssessment Report on Lifting AirbagsThe U.S. Department of Homeland Security(DHS) established the System Assessmentand Validation for Emergency Responders(SAVER) Program to assist emergencyresponders making procurement decisions.Located within the Science and TechnologyDirectorate (S&T) of DHS, the SAVERProgram conducts unbiased operational testson commercial equipment and systems andprovides those results along with otherrelevant equipment information to theemergency response community in anoperationally useful form. SAVER providesinformation on equipment that falls within thecategories listed in the DHS AuthorizedEquipment List (AEL). The SAVER Programmission includes: Conducting impartial, practitionerrelevant, and operationally orientedassessments and validations ofemergency responder equipment;Providing information that enablesdecision makers and responders tobetter select, procure, use, andmaintain emergency responderequipment.Information provided by the SAVER Programwill be shared nationally with the respondercommunity, providing a life saving andcost saving asset to DHS, as well as tofederal, state, and local responders.The SAVER Program is supported by anetwork of technical agents who performassessment and validation activities. Further,SAVER focuses primarily on two mainquestions for the emergency respondercommunity: “What equipment is available?”and “How does it perform?”To contact the SAVER ProgramSupport OfficeTelephone: 877 336 2752E mail: saver@dhs.govVisit the SAVER Web site:https://www.rkb.us/saverIn order to provide emergency responders with information on currentlyavailable lifting airbag capabilities and limitations, Science ApplicationsInternational Corporation (SAIC) conducted a comparative assessment oflifting airbags for the SAVER Program in July 2007 and provided findings inthe Assessment Report on Lifting Airbags, which is available by request athttps://www.rkb.us/saver.BackgroundEmergency responders commonly use airbags during rescue operations to liftvehicles, heavy machinery, and debris that has fallen upon or otherwisetrapped victims. Airbags require minimal clearance for operation and can beused in small spaces or areas where other lifting equipment may not easily fit.AssessmentPrior to the assessment, SAIC conducted a market survey in order to compileinformation on commercially available equipment. Then, a focus groupconsisting of eight emergency response practitioners from various regions ofthe country met in May 2007 to identify equipment selection criteria for theassessment, determine evaluation criteria, and recommend assessmentscenarios.The focus group reached a consensus that an assessment focusing oncomparable high pressure lifting airbags would be most beneficial to theemergency response community. Based on focus group recommendations andmarket survey research, the following lifting airbags were assessed: Paratech Incorporated Maxi Force “Suburban Rescue” Air Bag KitVetter Air Lifting Bag High Pressure Kit (106R078)RESQTEC NT 127 Lifting Air Bag KitMatjack Sentinel Package.Eight emergency response practitioners served as assessment evaluators.Each of the lifting airbags was used to replicate search and rescue activitiesinvolving concrete rubble and vehicle wreckage. In the first station,evaluators lifted and cribbed a concrete truss structure (or “double T”) andtwo circular concrete slabs, simulating a typical response to a buildingcollapse, industrial entrapment, or excavation collapse incident.In the second station, evaluators were tasked to safely and rapidly extricate asimulated victim (mannequin) trapped by vehicle wreckage using the variouslifting airbags. In order to complete this task, participants located liftingpoints, determined the stability of the base, inflated the airbags, insertedstabilizing cribbing, and lifted the vehicle to extract the mannequin.Assessment ResultsEvaluators rated the lifting airbag systems based on the weighted evaluationcriteria established by the lifting airbags focus group within the five SAVER

SAVER Category DefinitionsAffordability: This category groups criteria related tolife cycle costs of a piece of equipment or system.Capability: This category groups criteria related to thepower, capacity, or features available for a piece ofequipment or system to perform or assist theresponder in performing one or moreresponder relevant tasks.Concrete liftingDeployability: This category groups criteria related tothe movement, installation, or implementation of apiece of equipment or system by responders at the siteof its intended use.categories. The scoring system was based on a100 point scale and utilized the evaluation criteriaweighting factors established by the focus group. Theevaluator category and composite scores are shown intable 1. Higher scores indicate better airbagperformance.Maintainability: This category groups criteria relatedto the maintenance and restoration of a piece ofequipment or system to operational conditions byresponders.Usability: This category groups criteria related to thequality of the responders’ experience with theoperational employment of a piece of equipment orsystem. This includes the relative ease of use,efficiency, and overall satisfaction of the responderswith the equipment or system.The following sections provide a brief summary of theevaluator comments and feedback on each liftingairbag system. The sections present the lifting airbagmodels from highest to lowest evaluator scores. Thefull report includes a breakdown of evaluatorcomments by individual criterion.ParatechThe Paratech received the highest score in thecapability, usability, and affordability categories.Evaluators commented that the Paratech airbag systemappears durable and well built, and its surface has asoft rubber coating with a raised grid pattern. Theynoted that the regulator gauge, pressure relief valve,and controller appear durable and capable ofwithstanding repetitive emergency responder use.Evaluators stated that the Paratech kit is packaged forquick deployment and can be set up and operational inless than 10 minutes. They also commented that itscomponents are clearly labeled. The Paratech airbagscan be placed in a clearance of approximately 1 inch,and the center markings enable the user to properlyposition the bags. Evaluators stated the airbags aredesigned without handles, but each of the airbags witha 10 ton rating or higher are equipped with eyelets,which allow for safe vertical placement and retrieval,as well as easy carrying. The airbags can be stackedtwo high in order to increase lift height; however,evaluators noted that stacked Paratech airbagsdemonstrate a slight tendency to roll when fullyinflated. Evaluators remarked that the airbagcontroller is easy to operate and works well with agloved hand but becomes difficult to operate afterextended use due to the stiff control buttons.Table 1. Lifting Bag Assessment yDeployabilityMaintainabilityUsability(15% Weighting)( 30% Weighting)(20% Weighting)(15% Weighting)(20% 73RESQTEC 71.76480607674Matjack71.15579806766Note:a2Scores contained in the complete assessment report may be listed in a different numerical scale. For the purposes of the SAVER Summary,SAVER category scores are normalized and rounded to the nearest whole number.

Pros ConsParatech Durable, well builtLarge center markingsRaised, grid pattern surfaceDeadman featureDurable controller, color codedbuttonsDetailed setup instructionsSmooth inflation/deflationEasy transportSturdy caseInventory list1 year warrantyHoses appear to kink easilyNo inspection requirementsStiff control buttonsSlow deflation rateNo handlesNeeds an improved grip toreduce slippage when fullyinflatedComposite Assessment Score: 81.1Evaluators stated thatthe user manual doesnot specify costs forroutine maintenance orindividual componentreplacement costs, butit provides a 1 yearwarranty againstdefects in materialsInflated Paratech airbagsand workmanship.The user manual alsoincludes detailed pictures, easy to follow setupinstructions, field repair procedures, and completelisting of maintenance/service requirements.VetterThe Vetter system received the highest score in thedeployability category. Evaluators commented thatthe surface texture of the Vetter airbags preventsslippage and allows airbags to be used on concrete,wood, and metal, as well as with wet, muddy surfaces.They stated that the airbags appear durable andcapable of withstanding repetitive emergencyresponder use. Evaluators noted that the regulatorgauge, controller, and hoses appear solid and durable;however, couplings and crimps on the hose ends seemweak. The Vetter controller is capable of effectivelyoperating two airbags at the same time. The airbagscan be stacked two high, and evaluators reported thatthey remained stable when stacked together during theassessment tasks.Pros Cons VetterLarge assortment of airbag sizesRaised, grid pattern surfaceStrap handles on larger bagsand eyelets on smaller bagsLightweight airbagsDurable pressure relief valvesColor coded controller buttonsand extension hosesDurable, easy to connect hosesDetailed setup instructionsDeadman feature does notimmediately start/stop airflowWeak couplings and crimpsNo caseDifficult to featherSlow deflation rateNo warranty informationComposite Assessment Score: 76.5Evaluators reported that the Vetter manufacturer’suser manual includes easy to read setup instructions,pictures, illustrations, and troubleshootinginformation. They stated that the user manual hasnegligible procedures for making field repairs. TheVetter kit does not include a carrying case and is notpackaged for quick deployment. Evaluators stated theVetter airbag controller is difficult to operate. Theyexplained that, although the controller buttons areclearly marked and color coded for easy identification,they do not allow the operator to easily control the rateof airflow in or out of the airbags (meaning,feathering). The result is an “all or nothing” airpressure. The Vetter airbags can be placed in aclearance of approximately 1 inch, and the centermarkings enable the user to properly position the bags.Evaluators reported that one responder can easily andsafely position the airbags to perform liftingoperations, but one person cannot easily transport theairbag system. They commented that the airbags havetwo strap handles, which enhance the lifting, moving,and placing capabilities. The Vetter user manualincludes a detailed listing of replacement parts,inspection, maintenance, and service requirementsincluding a testing procedure checklist. There was nowarranty information available for the Vetter system atthe time of the assessment.RESQTECThe RESQTEC received the highest score in themaintainability category. Evaluators complimentedthe manufacturer on the system’s airbag liftingcapacity and lift height. They also noted that theRESQTEC airbags may be stacked three high. The3

Pros Cons RESQTEC Three airbag stacking capabilitySmooth, high liftColor coded components andcontroller buttonsDeadman featureEasy to operate controllerDurable hosesStep by step setup requirementsVinyl caseAirbag handlesDetailed user manualEasy transportOnly two same size airbags inkitController buttons too closetogetherNo protection on valvesRegulator not durableSlowest deflationSetup time required for stackingLarge airbag diameterInsertion height 1 1/2 to 2 inchesPressure creeps up during useComposite Assessment Score: 71.7airbags can be connected together, creating a morestabilized stacked system, and their circular shapeallows them to lift more evenly thansquare/rectangular bags. Evaluators commented thatthe RESQTEC airbag, hoses, controller, and airpressure regulator appear durable, well built, andcapable of withstanding repetitive emergencyresponder use.Evaluators stated the airbag controller is compact andeasy to operate. They commented that the controllerswitches are clearly marked and color coded for easyidentification. Evaluators noted that a 1 1/2 to 2 inchclearance is required to insert the airbags. Theyreported that the load must always be centered on theload plate for optimal stability, and they pointed outthat the large diameter of the bags makes it difficult towork the airbags into confined spaces. Theycommented that the difficulty in positioning theairbags limits the applications in which the system canbe used. Evaluators indicated the controller buttonsoperated smoothly but are positioned too closetogether, which make it difficult to control two airbagsat the same time. They expressed concerns that theoperator could inadvertently press the wrong buttonwhile wearing rescue gloves. Each airbag is packed ina soft vinyl carrying case, and a hard plastic carryingcase with foam cut outs is provided for allcomponents. Evaluators commented that this systemcan be easily repackaged for transport. They reported4Inflated RESQTEC airbagsthat the RESQTEC user manual includes detailedstep by step setup instructions, limitedtroubleshooting information, and pictures that are easyto follow. The user manual has no procedures formaking field repairs. The RESQTEC kit is configuredfor quick deployment and can be set up andoperational in less than 10 minutes. Evaluatorsexplained that the RESQTEC repositioning timeseasily exceed 10 minutes due to a slow deflation rate.They stated the RESQTEC airbags include handles,which enhance the safety of personnel duringpositioning. The RESQTEC user manual includes acomplete listing of replacement parts, maintenance,and service requirements. Inspection requirements forother system components (such as O rings andcontrollers) are also provided. Evaluators noted thatthe provided lists are detailed, clearly written, andeasy to understand. They also noted the user manualindicates a warranty is provided, but terms andconditions are not clearly described.MatjackEvaluators complimented the manufacturer on theheavy, rugged construction of the Matjack airbags.The textured surface and bag thickness create a strongsurface grip, which allowed the airbags to remainstable while lifting concrete, wood, and metalsurfaces. Evaluators stated that the controller andbuilt in pressure relief valve hoses are solidlyconstructed and sufficiently durable to withstandrepetitive first responder use. However, the regulatorgauge and hose couplings do not appear durable.Evaluators noted that the controllers are capable ofeffectively operating two airbags at the same time.The airbags can be stacked two high, and their surfacetexture allows them to be stacked with no slippage.However, stacked airbags have a tendency to rollwhen fully inflated.Evaluators reported that the Matjack airbag kit is notpackaged for quick deployment, mainly because it

Pros Cons MatjackThick, sturdy airbagsStable lifting capabilityTextured butyl rubber surfaceStrong gripHandles on larger bags andeyelets on smaller bagsAssortment of airbag sizesDeadman featureDurable hosesDetailed setup instructionsNo caseWeak connectionsController not ergonomicUnclear directional arrows oncontrollerDifficult feathering capabilitiesAirbag weightRegulator not durableLimited information in usermanualComposite Assessment Score: 71.1does not include carrying cases. They indicated thatrepackaging of the system for transport is difficultwithout proper carrying cases or other packagingmaterials. Evaluators stated the airbag controller iseasy to operate, but not ergonomically designed. Thecontroller’s directional arrow labeling does not clearlyindicate which buttons inflate or deflate the airbags,and evaluators experienced minor difficultiesfeathering air in or out of the system during theassessment. The Matjack airbags require a 1 to1 1/2 inch clearance. The larger Matjack bags havehandles, which enhance the lifting, moving, andplacing capabilities of the airbags; whereas, thesmaller airbags do not have handles. Evaluatorsreported that the user manual includes setupinstructions, pictures, and illustrations that are easy toread. The manual also provides service and inspectionrequirements along with procedures for making minorfield repairs. The manufacturer offers a 5 yearwarranty against defects in materials andworkmanship.An analysis of the evaluator comments and scoresrevealed these common observations concerning theassessed lifting airbags: Evaluators expressed a strong preference forkits with a wide variety of airbag sizes andlifting capacities. An assortment of airbagsizes provides added flexibility for emergencyresponse applications. For example, smallerdiameter bags are easier to place in limitedopenings to create additional lift points forlarger bags.Evaluators placed a high value on systemmobility. Features such as carrying cases andairbag handles simplify transport.Evaluators preferred airbags that can be easilypositioned for lifting operations. Airbagfeatures such as handles and eyelets enhancelifting, moving, and positioning.Evaluators placed a high value on systems withdurable airbags and rugged components.Well built, heavy duty systems allow forrepetitive emergency responder use.Evaluators expressed a strong preference forairbag systems that can be easily set up.Components such as color coded hoses andhand tightened regulators allow users to easilyset up the airbag systems.Evaluators preferred airbags that can bequickly deflated. Rapid deflation times enableresponders to reposition the bags and expeditelifting procedures during an emergencyresponse situation.Evaluators expressed a preference for airbagsystems, which included detailed user manuals.Easy to follow instructions, detailed pictures,and exploded diagrams enable users toaccurately assemble, operate, and maintain theairbag system.ConclusionThe evaluators were able to successfully complete theassessment tasks with all four of the assessed airbagsystems.5

QuickLook SnapshotaNote:aThe SAVER QuickLook, available on the SAVER Website, allows users to select the SAVER categories thatare most important to their department and view resultsaccording to their specific needs.All reports in this series, as well as reports on othertechnologies, are available on the SAVER Web site(https://www.rkb.us/saver).6

feathering). The result is an “all or nothing” air pressure. The Vetter airbags can be placed in a clearanceof approximately1 inch, and the center markings enable the user to properly position the bags. Evaluators reported that one responder can