Transcription

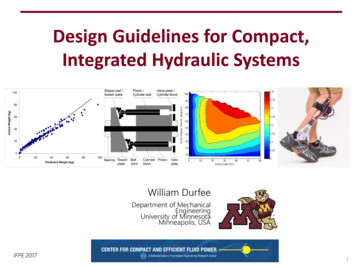

Design Guidelines for Compact,Integrated Hydraulic SystemsWilliam DurfeeDepartment of MechanicalEngineeringUniversity of MinnesotaMinneapolis, USAIFPE 20171

This PresentationOutline1.Application background2. Component-based models3. System-level case studies4. Application: an “Ironman”ankleTake-Home Messages Good opportunity forhydraulics in small-scale,high-force applications Unlike large-scale, in smallscale, friction and fluid dragdominate Mathematical models andcomputer simulations canassist the designer in makingsystem-level design choices Weight saving is at finalactuator, not whole system2

Background: Wearable Robots3

Electric-motor powered exoskeletons areflourishingReWalkEksoIndego4

Why hydraulics?5

Force increases with pressure, but not weight6

Comparing Actuator TechnologiesHigh-torque,low-velocity machineLow-torque, high-velocityPower WeightHigh-torque, low-velocityPower Pressure7

A common small-scale hydraulics application8

But!9

As size goes down, friction loss incylinder, drag loss in conduit go upCircumferenceCircumferenceAreaArea10

How much power?11

How much power?10001000Watts8006003504002001000Athlete 5 minAthlete 100 minAll Day12

ConfigurationBatteryBatteryDC MotorDC Cylinder13

EHAServovalve14

Analysis of Small-Scale Hydraulic Systems15

CreditJon NathMSME, 2017Brett NewbauerPhD, 2017Jicheng XiaPhD, 2015Supported by NSF EEC-0540834 and NIH R21 EB 019390-0216

Component-Level Models17

Modeling Cylinder WeightExample formulasCylinder wall thickness: thin-walled pressure vesselJB Johnson (thick rods)Rod diameter: buckling formulasEuler (thin rods)Xia & Durfee, ASME J Mech Des, in press, 201318

Analysis predicts the real world100Actual Weight (kg)8060Commercial cylindersweigh what they should40186 data points from Airpot, Bimba,Prince, Hercules200020406080100Predicted Weight (kg)19

O-ring Friction Model(Al-Ghathian & Tarawneh, Amer J Appl Sci, 2005)fs π µ f B d E ε 2 ε εfrict coeffboreYoung’smodulus2d1 d 2d 2ε dsqueezeratioXia & Durfee, Bath/ASME Fluid Power, 201420

Small cylinders follow model for seal friction4mm6mmXia & Durfee, Bath/ASME Fluid Power, 20149mm21

Axial Piston-Pump ModelViscous friction loss,pistons and cylinderblockViscous friction, valveplate and cylinder blockLeakage between valveplate and cylinder blockViscous friction, slippersand swash plateCoulomb friction, pistonsand cylinder blockLeakage between pistonsand cylinder blockJeong, H., Kim, H., 2007. “A novel performance model given by the physical dimensions of hydraulic axial pistonmotors: model derivation”. Journal of Mechanical Science and Technology, 21(1), pp. 83–97.22

Piston pump validation experiments23

Experiments validated the piston pump model0.4 cc/rev Takako pump @ 200 rad/secNath, FPIRC 201624

Dynamic experiments also validated thepump modelMeasuredSimulation25

Electric motor efficiency and weight can be bounded usingcatalog dataMotor maximum efficiency10.8188 data points from Maxon and MicroMo0.60.40.20050150100Motor output power (W)20025026

Real electric motors can also beapproximated by a mathematical modelPower as f(weight)Nath, FPIRC 2016Efficiency as f(power)27

Gearhead efficiency can be estimated fromcatalog data100Gearhead efficiency (%)840 data points from Maxon Motor8060402000η 55 200351 0.02 N400600Gear ratio800100028

Li-Poly batteries have constant energy density300Energy Densigy (Wh/Kg)250200150100Li-PolyAvg Wh/Kg50y 0x 1480050100150200Energy (Wh)334 data points from ThunderPower and Tenergy29

What you can learn from thecomponent models30

Below 4 mm bore, efficiency drops rapidly100Efficiency (%)90@ 10um gap seal, 35 bar, 0.1 m/s80706050123456Bore size (mm)78Xia & Durfee, 52nd Natl Conf Fluid Power, 201191031

Seal friction does not matter for highpressure or larger diameters1700 psi700 psi300 psi50 psiCampos, unpublished, 201632

Cylinders better without piston seal10.98Efficiency0.960.940.920.90.880.861234Xia & Durfee, 52nd Nat’l Conf on Fluid Power, 201178569Bore size (mm) @ 10 µ gap, 1450 psi1033

What you can learn from combiningcomponent-level into system models34

Case Study #1: Which is lighter, anelectric or a hydraulic actuator?ACTUATORElectricPOWER SUPPLYWIREHydraulicPOWER SUPPLYCONDUITELECTRICMOTORBALLSCREWCYLINDER35

Hydraulics lighter if high pressure1000750600500800Electric100 psi Hydraulic1000 psi HydraulicWeight (gms) for 100 W systemXia & Durfee, J Mech Des, 201336

When include power supply, hydraulicsystem necessarily heavier, but can locatesupply away from ITCYLINDERHydraulicBATTERYELECTRICMOTORPUMP37

Case Study #2: What should be the i.d.of the conduit?38

Steady state analysis: tube or hose weight39

Case Study #3: Gear pump or piston pump?40

Gear pumps are light but inefficient, so totalsystem weight is higherGEAR41

Case Study #4: Pump control orservovalve control?42

EHA configuration (pump control) islighter than servovalve configuration43

Case Study #5: What size electricmotor?BatteryDC MotorPump44

Larger motors are heavier, but moreefficient70W100W0.140 kgR 0.608 OhmKt 0.036 Nm/A0.05 Nm,300 rad/sec0.390 kgR 1.01 OhmKt 0.091 Nm/Avs.0.28 Nm,200 rad/sec0.39 Nm,150 rad/sec0.5 Nm,100 rad/sec45

Optimal motor size depends on run time,and whether active cooling is usedMinimum motor size as f(run time)5 Mpa, 5 cc/sSystem weight as f(motor size)5 Mpa, 5 cc/s, 0.5 hr run time36 g46

Application: Powered Ankle-Foot Orthosis47

1 KgUnder Pant Leg3,000 Steps48

HAFO ConfigurationSPECS 138 bar(2,000 psi) 90 Nm 100 deg/s 968 g at ankle(plus shoe) 2.16 kg at waistNeubauer & Durfee, EMBC 201449

HAFO Prototype50

Biomimicry configuration51

Measured system efficiencyBattery power to mechanical power at ankle52

Measured and simulated performancefor HAFO53

HAFO for children with CP, ages 8-1154

The Guidelines Run small-scale hydraulics at high pressure Use a piston pump Use EHA configuration (unless bandwidthmatters more than weight) The smallest electric motor may result in greateroverall weight Separate the power supply Analyze efficiency and weight at the system, notjust component, level55

Fundamentals ofFluid PowerAn online, free, six-week courseAbout the Course Introduction to fundamental principlesand analytical modeling of fluid powercomponents, circuits, and systems. You will learn The benefits and limitations offluid power How to formulate and analyzemodels of hydraulic componentsand circuits how to design and simulate theperformance of fluid powercircuits. Supported by the Center for Compactand Efficient Fluid Power Endorsed by the National Fluid PowerAssociationEvery student gets a freecopy ofSimscape Fluids!Enroll any time! www.coursera.org/course/fluidpower56

Integrated Hydraulic Systems IFPE 2017. This Presentation Outline 1. Application background 2. Component-based models 3. System-level case studies 4. Application: an “Ironman” ankle Take-Home Messages Good opportuni