Transcription

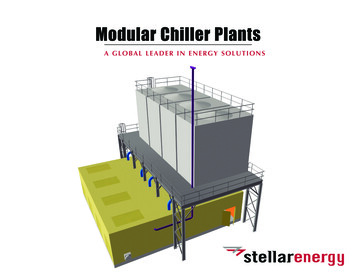

Modular Chiller PlantsA GLOBAL LEADER IN ENERGY SOLUTIONS

A B O U TStellar Energy is a global leader inthe design, construction, fabrication,installation, and servicing of a rangeof energy systems, including turbine inletair chilling (TIAC) systems, district coolingplants, modular utility plants, and fielderected utility plants. Our experience spansmore than 20 years and stretches across theglobe, with offices in the United States, theMiddle East & North Africa (MENA) region,and Asia.CustomizedWe customize our solutions to meet our clients’specific needs. By avoiding a one-size-fitsall approach, our systems more effectivelyhelp clients increase their profitability, enhancetheir power output, and cost-effectively coolS T E L L A RE N E R G Ytheir environments and industrial processes.While we often use a modular approach byprepackaging complete utility plants, weunderstand that each client and project isunique, and other methods may be moreappropriate. Through detailed feasibility studies,we can determine the most process-, cost- andenergy-efficient solution, whether it’s modular,field-erected, or hybrid—a combination ofboth.FlexibleWith an international team of direct-employedarchitects, engineers (of all disciplines,including process engineers), constructionprofessionals, refrigeration specialists andoperations and maintenance engineers, wecan supply the industry’s highest level ofin-house, self-performed work. However we’reflexible in our approach, whether it’s providingturnkey design-build services, taking fullaccountability and responsibility for theentire project, or focusing specifically on oneaspect of the project, working alongside othercontractors, sub-contractors and specialists tomeet our customers’ goals.GlobalWe are truly global in our experience, expertiseand relationships. From the United States, to theMiddle East, North Africa and Asia, we knowthat each region operates differently, requiringa tailored approach. Through our network ofsuppliers and partners across the world, we canprocure the most process and cost-efficient,high-quality solutions.stellar-energy.net

M O D U L A RSC H I L L E RP L A N TS O L U T I O Ntellar Energy offers a modular utilityStellar Energy’s MODUTILITY chiller plantplant solution called MODUTILITY .solution is based on a “Plug and Play” designThe MODUTILITY chiller plant operates like aThe MODUTILITY solution can beconcept whereby all chiller plant componentstraditional “stick built” or “field erected” plantconfigured to provide the required chilledare skid mounted, enclosed and put togetherand has the same components, however thewater, hot water, steam and electricity tolike Legos at the site to satisfy the requiredMODUTILITY chiller plant has advantages thatmeet the needs of the facility or system thatchilled water demand. The Stellar Energymake it a better choice.it is serving. Standard modular building blocksMODUTILITY chiller plant solution is the nextare utilized to supply each commodity. Ageneration chilled water plant. It integratesMODUTILITY plant may include one or moreproven chilling technology, efficient systemsof the following:design, lean manufacturing and state of the Modular Chiller Plantart controls to produce and distribute chilled Modular Boiler Plantwater in the most energy efficient and cost Modular Power Planteffective way. Modular Refrigeration Plant Delivers centralized cooling load Installed quickly to meet demandingoccupancy requirements Alleviates labor and location limitations Streamlined commissioning and start-up programMODUTILITYChiller PlantCostFlexibilityEfficiencyüüü DurabilityMaintainabilityDeliveryReliabilityRisk DeductionConstruction TimeQualityü AdvantageüüüüüTraditionalChiller Plant

E X T E R I O RArchitecturalEnhancementsThe exterior can beenhanced with anarchitectural wall orfaçade that blends withthe environment.37161Enclosure2Cooling towerstand3Cooling towers4Refrigerantevacuation system5Ventilation fan6External entrylighting7Condenser waterpiping245stellar-energy.net

S I T ER E Q U I R E M E N T S8Turnkey DeliveryOptionELECTRICALReference design requirestwo feeds for each chillermodule. Customizeddesign accommodatessingle feed supply.Stellar Energy canprovide turnkeydelivery of themodular chiller plant,including all siterequirements.9MAKEUP WATERSingle point connection atthe boundary of modularchiller plant.10DRAINSingle point connection atthe boundary of modularchiller plant.11891110FOUNDATIONConcrete slab foundationtypical, may be customized foundation designfor special site conditions.

M A I N T E N A N C EA C C E S S I B I L I T YMaintainabilityThe Stellar Energydesign promotesease of maintenanceto ensure a safe andproductive operationsenvironment.16151213181412Access for chillermotor/compressorremoval13Monorail with hoistfor pump/motorremoval14Chiller tubecleaning/accessarea15Cooling toweraccess platform16Cooling tower fandeck access/safetyrails17Double doorentry system forcomponent removal18Maintenance aisleways for easyaccess tocomponents17stellar-energy.net

M E C H A N I C A LFlexible DesignStellar Energy’s systemcan be designed for: Primary secondary Variable primary Fixed primaryoperation and can becustomized to specialrequirements forcompo-nent type,manufacturer and model.2325272122202419262819Chiller20Primary chilledwater pump21Secondary chilledwater pump22Condenser waterpump23Chilled waterpiping24Condenser waterpiping25A/C unit26ASHRAE 15ventilation27Refrigerantevacuation28Floor drain(multiple)

E L E C T R I C A L&C O N T R O L SControlsOptimization29 Motor controlcenterStellar Energy’s controlsystem providesoptimum systemperformance and can becustomized to projectspecial requirementsand components.323030Central controlsystem31Electrical conduit32Chiller controlpanel (each chiller)33Variable speeddrive (multiple)333129stellar-energy.net

M O D U L A RSeries V1403S1404F1404V1404SC H I L L E RP L A N TC O N F I G U R A T I O NG U I D ENominal Capacity Dimensions (ft/m)Plot Size CHW In/OutRange (TR/KW)L1L2 L3 L4 LDesignW1 W2 W3 W4 WDesignH1 H2 H3 HDesign (sq ft/m2) Size (in/m)200 - 500700 - 175045 10 22 28 5513.7 3.0 6.6 8.4 16.88 12 122.4 3.7 3.6123.6185.4106 113.0 1.8 3.3278.299091100.3400 - 10001400 - 350045 10 22 28 5513.7 3.0 6.6 8.4 16.88 20 122.4 6.1 3.6247.2309.0106 103.0 1.8 3.2278.21650151100.3600 - 15002100 - 525045 10 22 28 5513.7 3.0 6.6 8.4 16.88 32 12 35 412.4 9.8 3.6 10.8 12.6106 113.0 1.8 3.3278.22255212140.4800 - 20002800 - 700045 10 22 28 5513.7 3.0 6.6 8.4 16.88 44 12 47 532.4 13.4 3.6 14.4 16.2106 113.0 1.8 3.3278.22915272160.4500 - 12501750 - 440050 12 24 30 6215.2 3.7 7.3 9.2 18.910 14 143.0 4.3 4.2144.2206.1126 22403.7 1.8 6.7 12.21240115140.41000 - 25003500 - 880050 12 24 30 6215.2 3.7 7.3 9.1 18.910 24 143.0 7.3 4.228 348.5 10.3126 22403.7 1.8 6.7 12.22108195160.41500 - 37505250 - 1320050 12 24 30 6215.2 3.7 7.3 9.1 18.910 38 14 42 483.0 11.6 4.2 12.7 14.6126 22403.7 1.8 6.7 12.22976276200.52000 - 50007000 - 1760050 12 24 30 6215.2 3.7 7.3 9.1 18.910 52 14 56 623.0 15.9 4.2 17.0 18.8126 22403.7 1.8 6.7 12.23844355240.61250 - 20004400 - 700050 14 22 28 6415.2 4.3 6.6 8.4 19.512 16 123.7 4.9 3.6309.0148 22434.1 2.4 6.6 13.21920176160.42500 - 40008800 - 1400050 14 22 28 6415.2 4.3 6.6 9.1 19.512 36 12 47 533.7 11.0 3.6 14.4 16.2148 22434.1 2.4 6.6 13.23392316200.53750 - 600013200 - 2100050 14 24 30 6415.2 4.3 7.3 9.1 19.512 52 14 70 763.7 15.9 4.2 21.2 23.1148 22444.1 2.4 6.8 13.44864450240.65000 - 800017600 - 2800050 14 24 30 6415.2 4.3 7.3 9.1 19.512 72 14 98 1043.7 22.0 4.2 29.7 31.6148 22444.1 2.4 6.8 13.46656616300.82000 - 35007000 - 1230050 18 24 30 6815.2 5.5 7.3 9.1 20.714 18 14 42 484.3 5.5 4.2 12.7 14.6148 22444.3 2.4 6.8 13.53264302200.54000 - 700014000 - 2460050 18 24 30 6815.2 5.5 7.3 9.1 20.714 32 14 84 903.7 9.8 4.2 25.6 27.4148 22444.3 2.4 6.7 13.46120567240.66000 - 1050021000 - 3690050 18 24 30 6815.2 5.5 7.3 9.1 20.714 50 14 111 1173.7 15.2 4.2 33.8 35.7148 22444.3 2.4 6.7 13.47956739300.88000 - 1400028000 - 4920050 18 24 30 6815.2 5.5 7.3 9.1 20.714 68 14 138 1443.7 20.7 4.2 42.1 43.9148 22444.3 2.4 6.7 13.49792909360.9247.2Note: To be used as a guide only. Actual dimensions may vary depending on project special requirements.Note: Last number in model designates quantity of chillersin systemSystem Chilled Water Pumping ConfigurationF Fixed primaryV Variable-primaryS Primary-secondary

S T E L L A RE N E R G Y Guaranteed performance Fully supported by Stellar Energy(warranty, remote monitoring, operationand maintenance)ManufactureProductPrepare SiteShip ProductReceive ProductSet ProductC Y C L E Scope flexible (equipment supply toturnkey delivery)For more information, visit our website atstellar-energy.netL I F E Proven chilling technology, efficientsystems design, state of the art controls(“Smart Plant”)Design SolutionDELIVERY Standard product offering with ability tocustomizeConfigure SystemP R O J E C TThe Stellar Energy DifferenceDefine ProjectRequirementsPLANNINGStellar Energy utilizes a dedicated teamof internal resources includingengineering, manufacturing, productmanagement, and project management. Ourexperienced service personnel delivers acost effective quality product, on time. StellarEnergy is uniquely equipped to provide thebroad range of scope from equipment onlysupply to turnkey installation.D E L I V E R YConnect SystemComponentsConnect FieldPiping and WiringCommission andTest SystemPreventiveMaintenanceO&MRemote Monitoringstellar-energy.net

stellar-energy.netAMERICAS3015 Hartley RoadJacksonville, FL 32257 1 904 260 2044Fax: 1 904-260-9433Business Central TowersTower B, 3802Dubai Media CityP.O. Box 49434Dubai, UAE 971 4 454 8530Fax: 971 4 454 8531MENAASIALevel 15Commercial Bank PlazaWest BayP.O. Box 27111Doha, Qatar 974 4 452 8918Fax: 974 4 452 81812/F, No. 2 Nongzhanguan BeiliChaoyang DistrictBeijing 100125, PR China 86 10 6462 0909Fax: 86 10 6462 7001

modular chiller plant, including all site requirements. 8 9 11 10 8 ELECTRICAL Reference design requires two feeds for each chiller module. Customized design accommodates single feed supply. 9 MAKEUP WATER Single point connection at the boundary of modular chiller plant. 10 DRAIN Single point connection at t