Transcription

LIGHTER. EASIER. FASTER.AQUAPANEL Cement Board Indoor

Expectations. RedefinedAQUAPANEL CEMENT BOARD INDOORRedefining expectations for building walls and ceilings in wetroom areasRepresenting modern drylining technology,AQUAPANEL is one of the leading premiumcement boards, helping change the waypeople build, and the way buildings lookand perform. Designed for interior walls andceilings, AQUAPANEL Cement Board Indooris a key part of the range – enhancing thework of architects and installers alike.It’s the perfect board for exceptionally lightperformance, reliability and stability even inthe most challenging wet and humid conditionsfor both wall and ceiling applications –making it ideal for everything from swimming2pools and steam saunas to communal showersand kitchen areas.Manufactured from inorganic materials and highlyresistant to water and mould, AQUAPANEL Cement Board Indoor weighs only 11 kg persquare metre - making it easy to handle and fastto install. With outstanding flexibility comparedto alternative products, it is suitable for use withcurved walls and ceilings too.Created for the next generation of imaginative,sustainable buildings, AQUAPANEL CementBoard Indoor is changing the way the world builds.

ContentsCONTENTSFEATURES AND BENEFITS4 –5SYSTEM OVERVIEWAccessoriesSystem solutions6–78–9PRODUCT HANDLINGINSTALLATIONGeneral informationInstallation of interior wallsSurface finishing and quality levelsInstallation of interior ceilings1214 – 161718CONSTRUCTION OVERVIEWInterior wallsInterior ceilings20 – 2322 – 23CURVED CONSTRUCTIONSAQUAPANEL Cement Board Indoordraws on our pioneering technologyand the partnerships we build withour customers to deliver worldchanging innovation in construction.By changing the way people build,we’re redefining expectations for whatcan be achieved in wet and humidconditions – and making the wholeprocess lighter, easier and faster.25DETAILS FOR WETROOMS26 – 27LOAD FASTENINGLoad fastenings for walls and ceilingsPermitted console loads2930 – 31ACCESS DOORS32 – 33TECHNICAL PRODUCT DETAILSExpectations. Redefined.1135Only 11 kg/m² for exceptionally lightperformance, AQUAPANEL Cement BoardIndoor saves effort in transportation andhandling – while still delivering dimensionalstability, reliability and best-in-classperformance in the wet.With a bending radius of 1 m, withoutneeding to cut strips, AQUAPANEL CementBoard Indoor provides unlimited designfreedom for curved walls in everything fromswimming pools to showers. Simple to scoreand snap, it’s also easy to install.As easy to use as gypsum board, the lightcement board means faster installation,higher productivity and increased profitabilityat all stages of a construction project – evenin the most challenging wet areas.3

FEATURES AND BENEFITSAggregated Portland cement board with coated glass fibre meshembedded in back and front surfaces. Ends are square cut, and edgesreinforced and finished smoothly (EasyEdge ).Performance 100% water-resistant Mould and mildew-resistant Non-combustible (A1) – EN 13501-1 Robust and reliable with high impactresistance and sound insulation Safe to use, hygienic andmanufactured from natural materialsProcessing/Installation Only 11 kg/m² – meaning less effortin handling, including overheadinstallation Easy to cut using a simple score-andsnap technique No pre-drilling required Bending radius of 1 m at full board sizeApplication fieldsAQUAPANEL Cement Board Indoor is perfect for wall and ceiling applications in wet andhumid areas in a range of buildings, from sports halls and gymnasiums to schools, museums,hospitals and public buildings, as well as luxury hotels and apartments. The wide range ofapplications include: Communal/Public showersand bathroom areas Changing rooms Swimming pools and hot tubs4 Wellness areas and spa suites Steam saunas Operating theaters Industrial kitchensFinishing Ready keyed for tiling – only onelayer required for tile finish Supports tiling up to 50 kg/m² Surface qualities up to Q4-level canbe achievedProperties and dimensions Thickness (mm)12.5 Weight (kg/m²)Approx. 11Width (mm)90012001250Length 0/3000900/2000/2500/2600

Features and benefitsA reliable, robust system for wetand humid areasDampness is the principal cause of structuraldamage. Water appears in a construction as: Standing and flowing water Capillary water Dripping water High relative air humidityIn many areas of the construction, theability to withstand damp and water iscritical for the quality and durability of abuilding unit, for example, in all domesticand commercial wet areas, in laboratories,kitchens, swimming pools and saunas.Protection from damp is also important incellars and garages because these buildingunits are often at risk from masonry dampor ground damp. Construction materialsfor these areas must meet a variety ofrequirements and display the followingcharacteristics: Water resistance and dimensional stabilityof the material Resistance to mould formation Moisture vapour permeability for optimumindoor climateAQUAPANEL Cement Board Indooris water-resistant. Under water impact,AQUAPANEL Cement Board Indoordisplays extremely slight and system-safechanges in form. The cement board changesneither its structural cohesion nor its staticcharacteristics. AQUAPANEL Cement BoardIndoor is resistant to mould growth and istherefore also suitable for use in areas wherethere is a high level of damp. Altogether,this robustness, resistance and reliability inperformance makes AQUAPANEL CementBoard Indoor perfect for both walls andceilings in wet environments.AQUAPANEL Cement Board Indoor isthe ideal building panel for such areas.CERTIFICATIONS OF AQUAPANEL CEMENT BOARD INDOORCE MarkingAQUAPANEL Cement Board Indoorcomplies with EN 12467 CategoryC, Class 2.Safety against ball throwingThe W382 wall system and the D282ceiling system (see pages 20-23) withAQUAPANEL Cement Board Indoorhave been tested for limited safetyagainst ball throwing according tostandard DIN 18032-3 [1]. Thesystems passed the handball testwithout deterioration or damagingand therefore have been officiallycertified by the Materials TestingInstitute, University of Stuttgart (MPA).Safe and hygienic solutionAQUAPANEL CementBoardIndoor is 100% water-resistant andcompletely inorganic, so there isno risk of mould or mildew. It meetsthe highest requirements for a safeand hygienic environment insidethe building – as certified by theGerman Building Biological InstituteRosenheim (IBR).5

System overviewSYSTEM OVERVIEW – ACCESSORIESLength (mm) PackagingFasteningAQUAPANEL Maxi Screw SN25›AQUAPANEL Maxi Screw SN39AQUAPANEL Maxi Screw SN55AQUAPANEL Maxi Screws have been speciallydeveloped for fixing AQUAPANEL Cement Board ontotimber and metal frameworks of differing thicknesses. Nailtip (SN) and drill tip (SB) versions with countersunk headare available. All AQUAPANEL Maxi Screws have aspecial corrosion-proof coating, which provides aguaranteed 720 hours’ corrosion resistance in a salt spraytest.Scan fordatasheetAQUAPANEL Maxi Screw SB25AQUAPANEL Maxi Screw SB39Material of substructureTimber frameworkAmount of board layersSingle layer0.6mm x 1.0 mmDouble s/carton25250pieces/carton39250pieces/cartonSteel framework-Metal thickness25Single layerDouble layer1.0mm x 2.0 mmTriple layerSingle layerDouble layerxAQUAPANEL Maxi Screw SN25 xAQUAPANEL Maxi Screw SN39xxxAQUAPANEL Maxi Screw SN55 xAQUAPANEL Maxi Screw SB25xAQUAPANEL Maxi Screw SB39xxCoveragePackagingApprox.50 ml/m²(approx. 25ml/m joint)310ml/cartridgeJointtreatment:0.7 kg/m²20kg/bag Joint treatmentAQUAPANEL Joint Adhesive (PU)››AQUAPANEL Joint Filler & SkimCoating – white›››AQUAPANEL Tape (10 cm)›AQUAPANEL Joint Adhesive (PU) is used for wallapplications to bond individual AQUAPANEL CementBoard Indoor panels.Cartridge contents sufficient for:Approx. 6.5 m² (panel size 900 x 1250 mm)Approx. 10 m² (panel size 1250 x 2000 mm;1250 x 2600 mm)AQUAPANEL Joint Filler & Skim Coating – white is acement-bound filling material for full-surface skim coatingon AQUAPANEL Cement Board, for example before theapplication of a decorative plaster or paint finish.AQUAPANEL Reinforcing Mesh must be embedded.AQUAPANEL Joint Filler & Skim Coating – white can bealso used for filling joints between panels. AQUAPANEL Tape (10 cm) must be embedded.Note: Machine processing is possible with PFT RiTMO(230 V) (A3-2L pump unit, SWiNG sprayer, LK 402 aircompressor).AQUAPANEL Tape (10 cm) is a glass fibre tape with analkali-resistant coating. It is used to reinforce joints. Mustbe embedded in AQUAPANEL Joint Filler & Skim Coating– white.Scan fordatasheetScan fordatasheet20cartridges/cartonFull-surfaceskim coating:approx.2.8 kg/m²coating depth:4 mmApprox.2.1 m/m²Scan fordatasheet10 cmwide roll,20 m long18 rolls/carton10 cmwide roll,50 m long12 rolls/carton6

System overviewPrimingAQUAPANEL Board Primer›AQUAPANEL Board Primer is a ready-to-use syntheticdispersion for priming AQUAPANEL Cement BoardIndoor panels to provide maximum adhesion of tiles andplasters.Scan fordatasheet›AQUAPANEL Reinforcing Mesh is a glass fibre fabricused to reinforce AQUAPANEL Joint Filler & Skim Coating– white.AQUAPANEL Q4 Finish›AQUAPANEL Q4 Finishis a ready-to-use andwater‑repellent skim coat for high-quality finely finishedsurfaces up to Q4 standard. For application above a tiledarea directly onto the primed boards or as an all overskim-coating onto AQUAPANEL Joint Filler & SkimCoating – white with AQUAPANEL Reinforcing Mesh.Note: If used above a tiled area, use Knauf glass fibrecover strips to reinforce the board joints.››* Not suitable forceiling application.›AQUAPANEL Traverse MH 625*›AQUAPANEL Traverses are used for fitting wall-mountedloads up to 1.5 kN/m (e.g. mounting bolts, shelving,handrails) onto drylining walls made with AQUAPANEL Cement Board Indoor panelling. They are resistant toalkalis and moisture and are available with (MH type) orwithout (M type) timber insert.M type: Without impregnated timber insertMH type: With core-impregnated MDF filler, approx.18 mm thick›AQUAPANEL Access DoorHumid RoomsAQUAPANEL Access Door HumidRooms with coatingedge 5 mm15 kg/pail2.5 kg/pailPackagingScan fordatasheetApprox.1.1 m/m²100 cmwide roll,50 m long30 rolls/palletApprox. 1.7kg/m²/mmcoating depth20 kg/pailScan fordatasheetDimensionsPackagingHeight:Approx.290 mmPlate thickness:0.75 mmwith specialcorrosion protection layeraccordingto requestHeight:Approx.290 mmPlate thickness:0.75 mmwith specialcorrosion protection layeraccordingto requestScan fordatasheetScan fordatasheet* Not suitable forceiling applicationAQUAPANEL Access Door SplashWater ProtectionApprox.40-60 g/m²CoverageAdditional accessoriesAQUAPANEL Traverse M 625*PackagingDilution:1:2(primer : water)Surface finishingAQUAPANEL Reinforcing MeshCoverageAQUAPANEL Access Doors can be installed in partitionand plumbing walls built with AQUAPANEL CementBoard Indoor. They are easy to install and safe to handle.Multi porpose model for wall and ceiling applications aswell as for single and double-layer plankingScan fordatasheetAvailable sizes: 13mx3mpiece/carton4mx4m5mx5m6mx6mThickness12.5 mm›AQUAPANEL Access Doors can be installed in partitionand plumbing walls built with AQUAPANEL CementBoard Indoor. They are easy to install and safe to handle.Scan fordatasheetAvailable sizes: 13mx3mpiece/carton4mx4m5mx5m6mx6mThickness12.5/25 mm›AQUAPANEL Access Doors can be installed in partitionand plumbing walls built with AQUAPANEL CementBoard Indoor. They are easy to install and safe to handle.Scan fordatasheetAvailable sizes: 13mx3mpiece/carton4mx4m5mx5m6mx6mThickness12.5 mm›7

System overviewSYSTEM SOLUTIONSA technologically advanced building system that perfectly integrates with the whole range of Knaufproducts and accessories, AQUAPANEL Cement Board Indoor has been designed to be the ultimatesolution for wetrooms and other wet or humid areas.INTERIOR CEILINGSSuitable for indoor areas of high humidity including wetrooms As in wall applications, AQUAPANEL Cement Board Indoor can use single ordouble planking for ceilings, depending on fire and sound requirements. See construction overview (p.22-23) for details.EXAMPLE OF CEILING BUILD-UP1. Nonius Hanger*2. Knauf CD60/27*corrosion-resistant metal profile3. AQUAPANEL Cement Board Indoor4. AQUAPANEL Maxi Screw5. AQUAPANEL Tape (10 cm)embedded in AQUAPANEL Joint Filler & Skim Coating – white6. AQUAPANEL Board Primer7. AQUAPANEL Joint Filler &Skim Coating – white andAQUAPANEL Reinforcing Mesh8. Paint12435678* Minimum corrosion protection C3INTERIOR WALLSRobust, impact resistant and 100% water-resistant for reliable performance. For wall applications, single and double planking is possible,depending on project-specific fire protection and sound insulation requirements. See construction overview (p.20-23) for details.Interior walls with tiles218763458EXAMPLE OF WALL BUILD-UP1. Knauf CW corrosion-resistant metal profile*2. Knauf insulation materials3. AQUAPANEL Cement Board Indoor4. AQUAPANEL Maxi Screw5. AQUAPANEL Joint Adhesive (PU)**6. AQUAPANEL Board Primer7. Flexible tile adhesive8. Tiles* Minimum corrosion protection C3** The type of joint treatment is independentof the finishing method (also possible:AQUAPANEL Tape (10 cm) embedded inAQUAPANEL Joint Filler & Skim Coating – white).

System overviewInterior walls with render and paint finish21876345EXAMPLE OF WALL BUILD-UP1. Knauf CW corrosion-resistant metal profile*2. Knauf insulation materials3. AQUAPANEL Cement Board Indoor4. AQUAPANEL Maxi Screw5. AQUAPANEL Tape (10 cm)embedded in AQUAPANEL Joint Filler & Skim Coating – white**6. AQUAPANEL Board Primer7. AQUAPANEL Joint Filler &Skim Coating – white andAQUAPANEL Reinforcing Mesh8. Paint* Minimum corrosion protection C3** The type of joint treatment is independentof the finishing method (also possible:AQUAPANEL Joint Adhesive PU).Interior walls with tiles & Q4 Finish2918763EXAMPLE OF WALL BUILD-UP1. Knauf CW corrosion-resistant metal profile*2. Knauf insulation materials3. AQUAPANEL Cement Board Indoor4. AQUAPANEL Maxi Screw5. AQUAPANEL Joint Adhesive (PU)**6. AQUAPANEL Board Primer7. Flexible tile adhesive8. Tiles9. AQUAPANEL Q4 Finish* Minimum corrosion protection C3** The type of joint treatment is independentof the finishing method (also possible:AQUAPANEL Tape (10 cm) embedded inAQUAPANEL Joint Filler & Skim Coating – white).45Interior walls with Q4 Finish21876345EXAMPLE OF WALL BUILD-UP1. Knauf CW corrosion-resistant metal profile*2. Knauf insulation materials3. AQUAPANEL Cement Board Indoor4. AQUAPANEL Maxi Screw5. AQUAPANEL Joint Adhesive (PU)**6. AQUAPANEL Board Primer7. AQUAPANEL Joint Filler &Skim Coating – white andAQUAPANEL Reinforcing Mesh8. AQUAPANEL Q4 Finish* Minimum corrosion protection C3** The type of joint treatment is independentof the finishing method (also possible:AQUAPANEL Tape (10 cm) embedded inAQUAPANEL Joint Filler & Skim Coating – white).9

100%WATERRESISTANTSuperb for swimming pools Effortlessly handles splash, sprayand even the highest humidity withno expansion or warping. Eliminates humidity and thermalrelated expansion, which couldotherwise cause tiles to crack orloosen. Compatible with acoustic ceilingplaster to absorb noise – perfectfor swimming pools.10

Product handlingPRODUCT HANDLINGBoards› Always carry the boards upright, oruse board rollers. Handle with fork liftor crane as palletted goods. Take carenot to damage corners and edgeswhen setting the boards down. Placeboards down on their long edge beforelaying them flat.Profiles› Ensure that the base is strong enough tosupport the boards.› Protect boards from moistureand weathering before they areinstalled. Boards which have becomedamp must be dried on both sides ona flat surface prior to fitting. Beforeinstalling, condition the boards to theambient temperature and humidity.Powder materials› Protect profiles from moistureand weathering before theyare installed. Products shouldnot be left permanently exposedto the elements.› Store bags in a dry place andin original packaging.Health and safety› Avoid unnecessary dust on job site when using electrical saw.›››››Keep sanding and other dust generation to a minimum.Maintain adequate ventilation and/or wear suitable protection. Exercise care when using power tools and take all necessary precautions. Follow instructions on packaging when applying system accessories. When using powdered products, mix with water in well-ventilated conditions.Avoid contact with eyes and skin. In the event of contact with the eyes, irrigatewith plenty of clean water immediately. When handling insulation or cutting boards which contain glassfibre,wear suitable protection including face mask and gloves.Wear protective glasses when working overhead. Follow national health and safety regulations at all times.Product data sheets and material safety data sheets are available on our websitewww.AQUAPANEL.com/downloads.› Do not apply joint fillers, basecoator finishing materials in temperaturesless than 5 C.Insulation› Insulation materials are suppliedenclosed in packaging which isdesigned for short term protection only.For longer term protection on site, theproduct should be stored eitherindoors, or under cover and off theground. Products should not be leftpermanently exposed to the elements.11

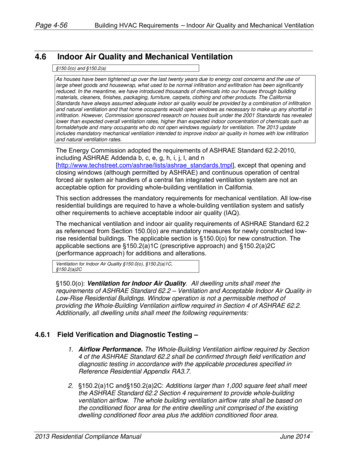

InstallationGENERAL INFORMATIONfor creating substructuresTo guarantee straight walls, display the course of the walls on the floors,ceilings and collumns before installing the profiles. It is recommended touse a chalk line, a cross-line laser or a rotating laser for these tasks.Cut profiles up to 0.7 mm thicknessto appropriate length using manualor electrical steel cutter or use anelectrical circular saw with specialmetal blade.To prevent thermal and acousticbridges and to compensateuneven surfaces, adhere selfadhesive decoupling tape to theweb of the UW runner.Use an appropriate drillingmachine to drill holes into thereinforced concrete for the anchors.coating system. This is especiallyimportant for lacquers and otherorganic coatings, which are damaged by the influence of temperature and flying sparks. The use ofband saws, low speed chop saws( 1500 rpm) or special circularsaws for cold cuts without flyingsparks is highly recommended.Cut edges of corrosion-protectedprofiles with a nominal thicknessbigger than 1.5 mm have to betreated with corrosion protectioncoating (e.g. Drystar-Korrosionsschutzlack C3/C5M).The use of seperation methodscausing sparks (e.g. anglegrinders) destroy the corrosionprotection of the profiles.Metal thicknesses bigger than0.7 mm cannot be cut by manualsteel cutters. Electric separatingtools need to be used. The toolhas to be selected according to theFor sharp-edged cuts, for example,exterior edges, use a hand-heldcircular saw with a dust extractoror a pendulum jigsaw. Use of acarbide or diamond-tipped sawblade is recommended.To make cut-outs for wiring and pipes, use a jigsaw or hole saw. Thediameter of the opening should be approximately 10 mm greater than thediameter of the pipe. The remaining gap can be closed with a cuff, suitablesealant or sealing strip.for formatting boardsMark the desired shape oropening on the board with penciland ruler. Use a knife to score thecement or gypsum boards on oneside along the line so that the meshresp. thick paper is cut. Snap thescored edge and cut the mesh/paper on the rear side.12

CLEANAND SAFEThe perfect recipe in foodprocessing 100% water-resistant – making itperfect for walls that need intensivecleaning and high-pressure jetspraying. Even with intense cleaning withchemical agents, AQUAPANEL Cement Board Indoor will not soften, swell, crumble or disintegrate. Inorganic, and so will never harbourmicrobes, mould or mildew. Offers superior fi

Ready keyed for tiling – only one layer required for tile finish Supports tiling up to 50 kg/m² Surface qualities up to Q4-level can be achieved 4 Application fields AQUAPANEL Cement Board Indoor is perfect for wall and ceiling app