Transcription

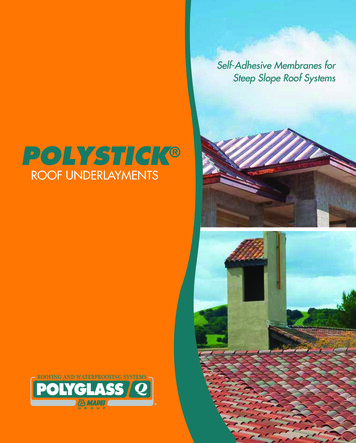

Self-Adhesive Membranes forSteep Slope Roof SystemsPOLYSTICK ROOF UNDERLAYMENTS

Provide Proven Performance withPolystick UnderlaymentsWhen deciding on what roof assembly to install,choosing a quality roof underlayment can play acritical role in the performance of the roof system.Provide your customer with the most technicallyadvanced and time tested underlayment productson the market; build your business with long-termsatisfied clients, reduced installation costs andfewer call backs.Choosing the Right UnderlaymentPolyglass produces quality roof underlayments forsteep slope roofs. Safe and easy installation Independently-tested and certified products Warranties up to 30 years

PROTECT what matters most

HIGH TEMPERATURE METAL ROOFSDesigned for high-temperature environments to 265 F

Polystick MTS Approved for environments to 265 F Designed for metal roof assemblies Advanced film surface for exceptionalskid resistance Exposure rating of up to 180 days Fiberglass reinforced for superiorthermal stabilityPolystick TU Plus Approved for environments to 265 F Fiberglass reinforced to provide longterm performance Approved exposure ratings to 180 days Skid resistant surface

CONCRETE/ CLAY TILE ROOFS

Polystick TU Plus Designed for tile roof assemblies Approved for foam and mechanically-fastenedroof tile applications Exposure rating to 180 days Non-wicking, high strength, fabric surfaceproviding superior skid resistancePolystick TU Max High performance underlayment for most steeproof coverings Approved for foam and mechanically-fastenedroof tile applications High strength reinforced polyester surfaceproviding extreme tear resistance Skid resistant surface

Polystick TU Designed for tile applications Approved for foam and mechanically-fastenedroof tile applications 100 mils thick with exposure rating up to 36 months Fiberglass reinforced for dimensional stability Granular surface engineered for superior slipresistancePolystick TU P Designed for tile applications Approved for foam and mechanically-fastenedroof tile applications 132 mils thick with exposure rating up to 36 months Polyester reinforced for advanced tear andpuncture resistance Granular surface engineered for superior skidresistance

OTHER ROOF COVERINGSSHINGLE, WOOD SHAKE

Polystick IR-Xe Ideal for full surface underlayment protection Designed for flashing details Provides exceptional ice and wind driven rainprotection Fiberglass reinforced Sand and black mineral surface for skid resistance

What makesPolystick Underlaymentsdifferent from the competition?Polystick underlayments feature ADESO Technology,a patented dual-compound self-adhered technology.Unique to the industry, products with ADESO Technology feature a polymer modified asphalt compoundapplied on the top layer and an aggressiveself-adhesive compound applied on the bottom layerresulting in long-term performance.

Polystick Family of ProductsRECOMMENDED USEPRODUCTShingleMTSXTU EXX1.5mm (60 mils)XXCODE APPROVALSMiamiDadeFBCICC2 squaresXXX2.0mm (80 mils)2 squaresXXXTU MAXX1.5mm (60 mils)2 squaresXXXTU PX3.3mm (132 mils)1 squareXXXTUX2.5mm (100 mils)1 squareXXX1.5mm (60 mils)2 squaresXXXIR-XEXTMMIAMI DADE COUNTYAPPROVEDVisit your local distributor and ask for the best in underlaymentperformance – Polystick underlayments.

POLYGLASS U.S.A., Inc.1111 West Newport Center DriveDeerfield Beach, FL 33442(888) 410-1375Fax (954) 418-4453pgmarketing@polyglass.comCustomer Service: (800) 222-9782Technical Support: (866) 802-8017PSTICK-BR - 2500 -PSG2013www.polyglass.com

Polystick IR-Xe Ideal for full surface underlayment protection Designed for flashing details Provides exceptional ice and wind driven rain . MTS X X X 1.5mm (60 mils) 2 squares X X X TU PLUS X X X X 2.0mm (80 mils) 2 squares X X X TU MAX X

![[Page 1 – front cover] [Show cover CLEAN GET- AWAY 978-1 .](/img/13/9781984892973-6648.jpg)