Transcription

(c)2000 AmericanInstituteof Aeronautics& Astronauticsor publishedwith permissionof author(s)and/or author(s)’ sponsoringorganization.A004 6576AIAA 2000-0722HEAT RELEASE RATES OFBURNING ITEMS IN FIRESHYEONG-JIN KIMandDAVID G. LILLEYLilley & AssociatesRoute 1 Box 151Stillwater, OK 7407438th Aerospace SciencesMeeting & Exhibitlo-13 January 2000 / Reno, NVFor permission1801 Alexanderto copy or republish, contact the AmericanBell Drive, Suite 500, Reston, VA 20191Instituteof Aeronauticsand Astronautics

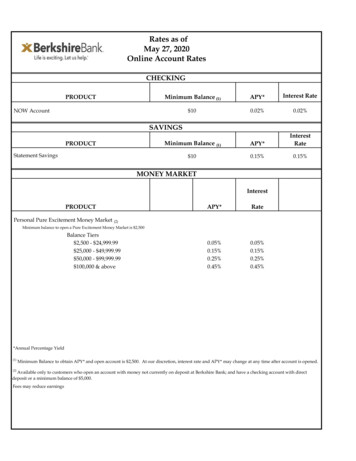

(c)2000 AmericanInstituteof Aeronautics& Astronauticsor publishedwith permissionof author(s)and/or author(s)’ sponsoringorganization.HEATRELEASERATESOFBURNING ITEMS IN FIRESHyeongJinKim* and David G. Lilley**Lilley & AssociatesRoute 1 Box 151Stillwater, OK 74074ABSTRACTHeat release rates of typical items in fires are neededas a prerequisite for estimating fire growth andtemperatures in structural fires. That is, these burningrates are required to be specified by the user as input tosingle-room and multi-room structural fire computer codeslike FPETool, FASTLite and HAZARD. Data are givenhere that permit burning items to be specified in a usefulmodeled way, taking a t*-fire for the growth and decayperiods, with a constant maximum heat release ratebetween these two periods.release rate between these two periods. A vast range ofmany items are considered. Detailed tabulation andgraphic display of the parameters (for each item duringexperimental bums) permits fire modelers to initiatecalculations. Further knowledge enables the deduction ofwhen second and subsequent items may become involved,whether flashover may occur, and when conditions maybecome untenable. Thus, it is clear that many importantphenomena that are calculated in fires depend on thequality and accuracy of the initial bum specification.FUNDAMENTALSINTRODUCTIONComputer codes are available that permit calculationsto be made of the effect of a given specified fire on thesubsequent environment in a structural fire. Things liketemperature of the smoke layer, its depth from the ceilingdownwards, its optical density, ceiling, wall and floortemperatures, floor surface heat flux rate, etc arecalculated a a function of time in all the rooms of a typicalmulti-room structural fire. However, the accuracy of thesecalculations is strongly dependent upon the correctness ofthe initial fire specifications.Heat release rates of typical items in tires are neededas a prerequisite for estimating fire growth andtemperatures in structural tires. That is, these burning ratesare required to be specified by the user as input to singleroom and multi-room structural tire computer codes likeFPETool, FASTLite and HAZARD, see Bukowski et al(1989), Peacock et al (1994), and Portier et al (1996).Data are given here that permit burning items to bespecified in a useful modeled way, taking a t2-fire for thegrowth and decay periods, with a constant maximum heat* Member AIAA** Professor, Fellow AIAACopyright 1999 by D. G. Lilley. All rights reservedPublished by AIAA with permission.Typically, the heat release rate (heat energy evolvingon a per unit time basis) of a fire 0 (kW) changes as thesize of the fire changes, as a function of time t (seconds)after fire ignition. That is, the variation of ” G ” versus “t”is extremely important in characterizing the rate of growthof a fire.Data are available for heat release rate vs. time formany items, see for example Babrauskas and Grayson(1992), SFPE (1995) and the data base in Bukowski et al.Furniture calorimeter and cone calorimeter(1989).measurements are available, with data specifically for:Pools, liquid or plasticCribs (regular array of sticks)Wood palletsUpholstered furnitureMattressesPillowsWardrobes (closets)Television setsChristmas trees

(c)2000 AmericanInstituteof Aeronautics& Astronauticsor publishedwith permissionNotice that although data may well be available fromcareful laboratory experiments, the data may not applydirectly to real-world fire situations. The laboratory datadoes not usually take into account the enhancement ofburning rates because of radiation feedback.at 260 sat 230 sat 215 sUseful information about the rate of burning of poolfires is readily available in Tables, see SFPE (1995) forexample, via the mass consumed per unit area per unittime. From the energy per unit mass values also given,one can readily compute the heat release rate 0 in kW, orin Btu per hour since 100,000 Btuihr 29.3 1 kW. It maybe nored that for pool diameters less than 1 meter, theburning rate expression is reduced because of a reductionin radiation feedback.The F number used here corresponds to the particularexperiment performed, see Bukowski (1989). Other usefulpeak heat release rates:Mattress and boxspringCurtain, cotton, 1.87 kgWastepaper basket, 0.93 kgTelevision, 39.8 kgCooking oil, corn, cottonseed,etc. 12-inch panChristmas tree, spruce, 7 kgorganization.A systematic study of liquid hydrocarbon pool firesover the widest range of pool diameters was conducted byBlinov and Khudiakov. Gasoline, tractor kerosene, dieseloil, and solar oil (and, to a limited extent, householdkerosene and transformer oil) were burned in cylindricalpans (depth not indicated) of diameters 0.37 cm to 22.9meters. Liquid burning rates and flame heights weremeasured, and visual and photographic observations of theflames were recorded. Hottel plotted these data and theresults are shown in the Figure. The lower curve of thisfigure shows the variation of burning velocity (inmeters/second of depth burning) as a function of the pandiameter. The upper curves give the ratio of flame heightto flame diameter as a function of the pan diameter. Thediagonal lines on the lower curves represent lines ofconstant Reynolds numbers, based on pan diameter.Full-scale timiture calorimeter tests give usefulinformation on the burning rates of many typicalhousehold items. Peak heating values are particularlyuseful to know, since in some cases a triangular heatrelease rate vs. time representation can be utilized forsimplicity. Upholstered furniture - wood frame, with fireretardant polyurethane padding and olefin cover fabric show peak heat release rates as follows:2100 kW2886 kW3120 kWand/or author(s)’ sponsoringexperimental data from small- and medium-scale tests.Needless to day, such semiempirical methods are alwayssubject to uncertainties when experimental data fromsmall-scale fires are extrapolated to predict the thermalproperties of very large-scale fires.Curtains (drapes)Electric cable traysTrash bags and containersIndustrial rack-stored commoditiesF21 ChairF3 1 LoveseatF32 Sofaof author(s)660 kW240 kW15kW290 kWat 910 sat 175 sat 350 sat 670 s116kW650 kWconstantat 350 sTHE t2-FIRE GROWTHand the values help to visualize the differences betweenthe items under burning conditions.MODELEmphasis is often placed on the growth phase of thefire. Slow, medium, fast and ultra-fast fire growths may bespecified by the t2-fire growth model, where, after aninitial incubation period,Of special concern in fire investigation and computerreconstruction of building fires is the use of accelerants.Liquid fuels are often preferred.They are used toaccelerate the development of the fire, as indicated bytemperature and spreading rates.On the practicalinvestigative side, features often include: low bums, hightemperatures at low hidden locations, rapid house firedevelopment, and particular flame and smoke colors seenby witnesses. Burning rates of liquid pool fires areavailable in SFPE (1995):Q af(t - to)2where af is a fire-growth coefficient (kW/s2) and to is thelength of the incubation period (s). The coeficient afappears to lie in the range 10s3 kW/s2 for ,very slowlydeveloping tires to I kW/s2 for very fast fire growth. Theincubation period (to) will depend on the nature of theignition’source and its location, but data are now becomingaiailable (see Babrauskas) on fire growth rates on singleitems of fiuniture (upholstered chairs, beds, etc.) whichmay be quantified in these terms. Suggested values for thecoefficient gf are also given in the formula section ofMakefre - a subset of the FPETool Computer Program.The specification there for the fire-growth coefficient af(kW/s’) is:’POOL FIRESThe thermal radiation hazards from hydrocarbon spillfires depend on a number of parameters, including thecomposition of the hydrocarbon, the size and shape of thefire, the duration of the fire, its proximity to the object atrisk, and the thermal characteristics of the object exposedto the fire. The state of the art of predicting the thermalenvironment of hydrocarbon spill fires consists essentiallyof semiempirical methods, some of which are based onSlowMedium20.002778 kW/s’0.011111 kW/s’

(c)2000 AmericanInstituteof Aeronautics& Astronauticsor publishedwith permissionand these correspond to growth times of the tire 6om zerosize to 1 MW total heat output inBURNING1.RATES OF TYPICALtl MWt Qotd3.time to the onset of ignitiontime to reach 1 MWlevel-off timetime at which 0 decay beginstime at which Q equals zerogrowth time t, MW- t,t endGrelease rate), tp, (time to reach 0 ,,) and td (timeto start decay). Adjustments are made in order toensure that the modeled total heat release duringthe time interval of from t, to td seconds matchesthe experiment to within 0.1 percent.Then, the time to onset of ignition t,, withassociated value of fire-growth parameter as ischosen so as to match the total heat release duringthe growth phase of from t, to tao seconds. Thecorrespondence of tO, tp, and ag is automatic sincea t*-fire growth is being assumed.Finally, the end time tendwith associated value offire-decay parameter ad is chosen so as to matchthe total heat release during the decay phase offrom td to tend seconds.Again, thecorrespondence of td, tend and ad is automaticsince a t*-fire decay is being assumed.2.ITEMSExperimental data are available for a variety of items,giving heat release rate Q (kW) vs time (seconds). Eachof these graphs is in conformity with several parametersthat comnletely characterize the situation, as given inFigure 1: ’toModeled data are given for heat release rate 0 (kW)vs. tune (seconds) in Tables A, B, C and D respectively asfollows:Notice that both the ascent and decent are characterized byt*-tire activity:1.( a,t*wheret t-t,Furniture calorimeter data from FASTLite (seePot-tier et al, 1996).Furniture calorimeter data from HAZARD (seePeacock et al, 1994).Furniture calorimeter data from Building and FireResearch Laboratory (see BFRL Website, 1999).Cone calorimeter data from HAZARD (seePeacock et al, 1994).2.0 adt2 where t tend- t3.where ag and ad are the fire-growthcoefficients (kW/s*), respectively.and fire-decay4.These heat release rates G (in kW) vs time t (inseconds) are active only in the growth (to I t I t tQ,) andheatdecay (td 5 t I tend), respectively. The rfIaXimUmrelease rate o,,(kW) occurs when tp,, I t I td. Thegrowth time to reach 1 MW 1,000 kW of heat releaserate G is t, MW- t, seconds, and this is related to the firegrowth parameter ag (kW/s*) viaThe data are also given in Figures as follows:1. Table A, see Figures2. Table B, see Figures3. Table C, see Figures4. Table D, see FgiuresSimularly the tire-decay parameter ad (kW/s’) is found via Q m&end-td)*.Also note that the maximum heat release rate 0 max(kW)is related to other parameters via:Q nlax 1000[(tk, - t,)/(t,MW-A 1 throughB 1 throughCl throughDl throughA34.B2 1.ClO.D25.Careful perusal and interpretation of the figures willenable the discerning reader to deduce what the values ofthe defining parameters are. However, for completeness,the data are given directly in the extensive Tables A, B, C,and D in numerical form. Finally 0 vs. t is given byag 1000 / (tl MW - to)*.adorganization.First, one decides the values to be taken for thethree key parameters Q,,, (maximum heat600 seconds300 seconds150 seconds75 secondsSlowMediumFastUltra-fastand/or author(s)’ sponsoringIn order to characterize in the above fashion the actualexperimental data of heat release rate versus tune, oneproceeds as follows:0.044444 kW/Z0.177778 kW/s FastUltra-fastof author(s)6 oostst,Q a,(t-L)*&, 2i2t,)l*. agQ adQ o(tb(tend-to *-t)*tQ,t 2t tQ,t,,td 5 t 5 ten,,tend2 t 5 Infinitywith the parameters taken directly from the Tables for theparticular item under consideration.3

(c)2000 AmericanInstituteof Aeronautics& Astronauticsor publishedwith permissionof author(s)and/or author(s)’ sponsoringorganization.uninvolved items. The ignition principles suggestthat, forthermally thick materials,the inverse of the squareroot oftime to ignition is expectedto be a linear function of thedifference between the external heat flux and the CHFvalueWHAT HAPPENS NEXT?During the course of the burning of the first item offurniture in a room, as specifiedfrom data such as that justpresentedin the Table, one of severalthings might occur.The abovehas provided informationabout the burning rate(heat releaserate vs. time) of a single specified item in thebum room. What happensnext? Either the item bums outwithout further damage to the surroundings, or one ormore nearby items ignite and add fuel to the fire. This canbe by direct flame contact (if the seconditem is judged tobe sufficiently close) or, more usually, by radiant heatenergy becoming sufficiently large on the surface of thesecond item. Direct flame contact requires time topyrolyze the fuel and time to heat the gasesproduced totheir ignition temperature. The radiant flux ignitionproblem is a very complicatedissue,and dependson manyfactors. The radiant energy comes from the flame abovethe first item, the upper layer and room surfaces, butsimplifying assumptions are sometimes used. As theradiant energy flux rate increasesfrom the first item to thesecond,often a simple criterion for ignition of the latter isused. A good approximationis that the radiant heat flux(arriving on the surface of the second item) necessarytoignite the seconditem is:fi(i,- CHF)TRPwhere tis is time to ignition set, qz is the externalheatflux kWlm*, and CHF is in kW/m*. Most commonlyusedmaterials behave as thermally thick materials and satisfythis equation.10 kW/m*easily ignitable items, such as thincurtainsor loosenewsprint20 kW/m*normal items, such as upholsteredfurniture40 kW/m*difficult to ignite.items, such as wood of0.5 inch or greaterthicknessThe Critical Heat Flux and the Thermal ResponseParametervalues for materials derived from the ignitiondata measured in the Flammability Apparatus and theCone Calorimeter,by Scudamoreet al (1991, are given inLilley (1998). He also shows in Tables and Figureshowthe ignition time tis may be determinedfrom the heat fluxq” and the Critical Heat Flux CHF and Thermal ResponseParameterTRP. Completedata are given in Lilley (1998)so as to enablethe ignitability question to be determinedquickly. Readersare directed to that study to see fullyhow the size and material of a pool fire determinesthetotal heat release0, the heat flux q” on a target fuel, andthe time requiredfor ignition to occur.FLASHOVERWhether or not “flashover” occurs during the courseof a fire is one of the most important outcomesof a firecalculation. Flashover is characterized by the rapidtransition in fire behavior from localized burning of fuel tothe involvementof all combustiblesin the enclosure.Highradiation heat transfer levels from the original burningitem, the flame and plume directly above it, and the hotsmoke layer spreadingacrossthe ceiling are all consideredto be responsiblefor the heating of the other items in theroom, leading to their ignition. Warning signs are heatbuild-up and “rollover” (small, sporadic flashes of flamethat appear near ceiling level or at the top of opendoorways or windows of smoke-filled rooms). Factorsaffecting flashover include room size, ceiling and wallconductivity and flammability, and heat- and smokeproducing quality of room contents. Further researchstudiesrelating to this topic include Kim and Lilley (1997and 1999),and Lilley (1995, 1997and 1998).In actuality, ignition is not immediate when theparticular level of incident radiant heat flux reaches10, 20or 40 kWlm* respectivelyfor easy,normal and difficult toignite items. These values are used as simple rules ofthumb in applied calculations, see Lilley (1995).Fundamentalignition principles, outlined for example inSFPE (1995),. suggestthat, for tire initiation, a materialhas to be heated above its critical heat flux CHF value(CHF value is relatedto the fire point). It was found that,as the surface is exposedto heat flux, initially most of theheat is transferred to the interior of the material. Theignition principles suggestthat the rate with which heat istransferred depends on the ignition temperature Tip,ambient temperatureT,, material thermal conductivity k,material specific heat c,,, and the material density p. Thecombinedeffects are expressedby a parameterdefined atthe Thermal ResponseParameter(TRP) of the materialTRP ATi, d kpcr,CLOSUREThe ability to determinefire growth in terms of whenthe second and subsequentobjects may ignite (and theirburning rates) and whether or not “flashover” occursdepends strongly on the initial fire specification. Thefocus of this entire documentwas to characterizethe initialwhere ATi& Tis - T,) is the ignition temperatureaboveambient in degreesK, k is in kW/m-K, p is in. kg/m3,cp isin kJ/kg-K, and TRP is in kW-s”*/m*. The TRP is a veryuseful parameterfor the engineering.calculations,toassessresistance of ignition and fire propagation in as-yet4

(c)2000 AmericanInstituteof Aeronautics& Astronauticsor publishedwith permissionand/or author(s)’ sponsoringorganization.Conf./Design Conf. Paper DETC 97/CIE-4428,Sacramento, CA, Sept. 14- 17, 1997.item on fire (in terms of burning rate versus time) so as tomore accurately be able to calculate fire growth and thepossible occurrence of flashover.Lilley, D. G. (1998), “Radiant Ignition of FlammableMaterials.” Proc. of Int. Joint Power GenerationConf., Baltimore, MD, Aug. 23-26, 1998.Heat release rates of typical items in fires were neededas a prerequisite for estimating fire growth andtemperatures in structural tires. That is, these burningrates were required to be specified by the user as input tosingle-room and multi-room structural fire computer codeslike FPETool, FASTLife and HAZARD. Data was givenhere that permit burning items to be specified in a permitburning items to be specified in a useful modeled way,taking a t*-fire for the growth and decay periods, with aconstant maximum heat release rate between these twoperiods.NFPA (1997). “Fire Protection Handbook.” 18thEdition (Cote, A. E. and Linville, J. L. eds.),NFPA, Quincy, MA, 1997.Peacock, R. D. et al (1994). “An Update Guide forHAZARD 1 Version 1.2.” NIST Report NISTIR5410, May 1994.Portier, R. W., Peacock, R. D. and Reneke, P. A.Engineering Tools for(1996). “FASTLite:Estimating Fire Growth and Smopke Transport.”NIST Special Publication 899, Gaithersburg,MD, April 1996. See also: Update to Version1.Ob, Feb., 1997.REFERENCESBabrauskas, V. and Grayson, S. J. eds. (1992). “HeatRelease in Fires.” Elsevier Applied Science,1992.“Handbook of Fire ProtectionSFPE (1995).Engineering.” NFPA, Quincy and SFPE, Boston,MA, 1995.“The HAZARD- 1Bukowski, R., et al (1989).Computer Code Package for Fire HazardAssessment.” NBS(NIST), Gaithersburg, MD.Scudamore, M.J., Briggs, P.J. and Prager, F.H.(1991). “Cone Calorimetry - A Review of TestsCarried Out on Plastics for the Association ofPlastics Manufacturers in Europe.” Fire andMaterials, Vol. 15, 199 1, pp. 65-84.Cooper, L. Y. (1984). “Smoke Movement in Roomsof Fire Involvement and Adjacent Spaces.” FireSafety Journal, Vol. 7, 1984, pp. 33-46.Drysdale, D. (1985)“An Introduction to FireDynamics.” Wiley, Chichester, England, 1985.Thomas, P. H. (1974). “Fires in Enclosures.” Paperin Heat Transfer in Fires (P. L. Blackshear, ed.),Halsted-Wiley, New York, 1974, pp. 73-94.Emmons, H. W. (1985). “The Needed

Heat release rates of typical items in fires are needed as a prerequisite for estimating fire growth and temperatures in structural fires. That is, these burning rates are required to be specified by the user as input to single-room and multi-room structural fire computer codes like FPETool, FASTLite and HAZARD.File Size: 1MB