Transcription

SMRP BEST PRACTICESMETRICS WORKSHOP

Safety TopicCopyright SMRP 2018

Reliability and Safety Reliability is a stable, trouble free, operation Unreliability is unscheduled downtime A reliable site prevents upsets, equipmentfailures and Unscheduled Downtime lessexposure to injuries. Unscheduled downtime creates the potential forpeople to get hurt when the unit goes off-line,when it's being repaired and once again whenit's restarted.Copyright SMRP 2018

Best Practices Metrics Workshop AbstractHow do you know which metrics truly matter? The Society forMaintenance & Reliability Professionals (SMRP) Body of Knowledgeand Best Practices, 5th Edition, are the basis for this workshop. In thisworkshop, you’ll gain insights into the latest thinking on maintenanceand reliability (M&R) metrics. Attendees will learn how to use the metrichierarchy for linking M&R activities to an organization’s strategy. Usingthis proven process, M&R practitioners will be able to make thebusiness case for reliability to operations and leadership. M&R bestpractices will be discussed, along with how the metrics align withSMRP’s five pillars in the Body of Knowledge. This hands-on workshopreviews the standard definitions and application of common metricsdeveloped by the SMRP Best Practices Committee. Attendees willunderstand how to measure performance consistently, make validcomparisons and provide guidance to their organization on how to useSMRP metrics. The workshop is interactive; attendees will participate inactivities using specific examples to apply and calculate metrics.Copyright SMRP 2018

Learning Objectives1. Understand SMRP’s metric development practice2. Increase the understanding of M&R metrics3. Transfer knowledge about the application of metrics4. Understand standardized metric calculation5. Discuss the application of metrics6. Review leading and lagging metrics7. Identify critical data and how it impacts performanceCopyright SMRP 2018

Today’s Agenda1. Introductions and Workshop Objectives2. History of SMRP and Metric Development Process3. Sample Metric Calculations4. Why Use Maintenance and Reliability Metrics5. Group Exercise; Speedy Mac Reliability Products (SMRP)6. Selecting the Right Metrics7. Benchmarking8. Critical Information Needs9. Data Quality10. SummaryCopyright SMRP 2018

Introductions1.Your name and where do you live?2.Who do you work for?3.What’s your job?4.What is your interest in reliability management?5.What do you want to get from today’sworkshop?6.Tell us an interesting fact aboutyourself022.57.5015Copyright SMRP 2018

Introductions1.Your name and where do you live?2.Who do you work for?3.What’s your job?4.What is your interest in reliability management?5.What do you want to get from today’sworkshop?6.Tell us an interesting fact aboutyourself022.57.5015Copyright SMRP 2018

Introductions1.Your name and where do you live?2.Who do you work for?3.What’s your job?4.What is your interest in reliability management?5.What do you want to get from today’sworkshop?6.Tell us an interesting fact aboutyourself022.57.5015Copyright SMRP 2018

Introductions1.Your name and where do you live?2.Who do you work for?3.What’s your job?4.What is your interest in reliability management?5.What do you want to get from today’sworkshop?6.Tell us an interesting fact aboutyourself022.57.5015Copyright SMRP 2018

Instructor BiographyCopyright SMRP 2018

Key SMRP BOK DocumentsCopyright SMRP 2018

Today’s Workshop is InteractiveCopyright SMRP 2018

Section 2Section 2:SMRP History and the Metric DevelopmentProcessCopyright SMRP 2018

Learning Objectives1. Review History of SMRP2. Understand the Metric Development Process3. European Federation of National Maintenance Societies(ERNMS) and SMRP Harmonization ProjectCopyright SMRP 2018

History of SMRP SMRP – Society for Maintenance & ReliabilityProfessionals An organization “By Practitioners, for Practitioners” Formed and Chartered in 1992 6500 members worldwide 210 Executive Company members SMRP’s certifying organization, SMRPCO, manages thecertification program for M&R professionalsCopyright SMRP 2018

BOK DirectoratePaul CastoDirectorBoK DirectoratePaul DufresneKeith NyeBest PracticesM&RKCommittee ChairCommittee ChairCopyright SMRP 2018

Body of Knowledge MissionEstablish SMRP as a Global Authority on theMaintenance and Reliability Body of Knowledgefor Best Asset Management Practices.Copyright SMRP 2018

SMRP Metric nitions0Best PracticesCommitteeFormedCopyright SMRP 2018

Purpose of SMRP Metrics Initiative1. Develop maintenance and reliability metrics usingcommon terminology2. Standardize M&R terms and definitions (Glossary)3. Establish standard calculation methods for metrics4. Provide a common platform to benchmark performancebetween peers and across industry verticalsCopyright SMRP 2018

Purpose of SMRP Metrics InitiativeWhy do we need standardization and commonterminology?Copyright SMRP 2018

Define MaintenanceEveryone grab your pen and write down your definition ofmaintenance and be prepared to read it to the class.022.57.5015Copyright SMRP 2018

Defining MaintenanceThe set of actions taken to ensure that systems, equipment and componentsprovide their intended functions when required. (The primary focus of thisdefinition is on maintaining the intended function of an item rather than itsdesign performance.) Many designs provide excess performance capacity orendurance as an inherent characteristic of the design (e.g. the pumpselected for a system may be rated at 100 gpm when the system designrequirement is only 75 gpm). Maintenance that is oriented to sustainingexcess capability not needed for operations expends resources withoutbenefit. This is not good maintenance practice. This definition requires thefunction being maintained to be available when it is required. Since certainfunctions, such as weapons firing and overpressure relief, may not berequired continuously, there may be a need to verify their availability. Theterms “component, equipment and systems”, as used in this definition, applyto hardware at a particular level where the analysis is being performed. Thismay be a system, a subsystem, equipment or component, depending on thespecific task being examined.Copyright SMRP 2018

Break into GroupsTake five minutes and describe what you think a goodprocess would be to develop common, standardmetrics0:005:003:451:152:30Copyright SMRP 2018

What Did Your Group Agree On?Copyright SMRP 2018

Metrics Development ProcessCopyright SMRP 2018

Metric Definition ProcessStandard Approach to Defining tDefinitionsE. QualificationsF.G.H.I.Sample CalculationBest in Class TargetCautionsHarmonizationCommentsJ. ReferencesCopyright SMRP 2018

Metrics and the Five PillarsPillar 1 - Business and Management1.1 - Ratio of Replacement Asset Value (RAV) to Craft-Wage Head Count1.3 - Maintenance Unit Cost1.4 - Stocked Maintenance, Repair, and Operating (MRO) Inventory Value as a Percent ofReplacement Value1.5 - Total Maintenance Cost as a Percent of Replacement Asset Value (RAV)Pillar 2 - Manufacturing Process Reliability2.1.1 - Overall Equipment Effectiveness (OEE)2.1.2 - Total Effective Equipment Performance (TEEP)2.2 - Availability2.3 - Uptime2.4 - Idle Time2.5 - Utilization TimeCopyright SMRP 2018

Metrics and the Five PillarsPillar 3 - Equipment Reliability3.1 - Systems Covered by Criticality Analysis3.2 - Total Downtime3.3 - Schedule Downtime3.4 - Unscheduled Downtime3.5.1 - Mean Time Between Failures (MTBF)3.5.2 - Mean Time to Repair or Replace (MTTR)3.5.3 - Mean Time Between Maintenance (MTBM)3.5.4 - Mean Downtime (MDT)3.5.5 - Mean Time to Failure (MTTF)Pillar 4 - Organization and Leadership4.1 - Rework4.2.1 - Maintenance Training Cost4.2.2 - Maintenance Training Hours4.2.3 - Maintenance Training Return of Investment (ROI)Copyright SMRP 2018

Metrics and the Five PillarsPillar 5 - Work Management5.1.1 - Corrective Maintenance Cost5.1.3 - Preventive Maintenance Cost5.1.5 - Conditioned Based Maintenance Cost5.1.9 - Maintenance Shutdown Costs5.3.2 - Unplanned Work5.3.4 - Actual Hours to Planning Estimate5.3.6 - Planner Productivity5.4.2 - Proactive Work5.4.4 - Schedule Compliance Work Orders5.4.6 - Work Order Aging5.4.8 - Planned Backlog5.4.11 - Preventive Maintenance (PM) & PredictiveMaintenance (PdM) Work Orders Overdue5.4.14 - PM & PdM Compliance5.5.2 - Craft Worker to Planner Ratio5.5.4 - Indirect Maintenance Personnel Cost5.5.6 - Craft Workers on Shift Ratio5.5.8 - Overtime Maintenance Hours5.5.32 - Vendor Managed Inventory5.5.34 - Inactive Stocks5.5.36 - Storeroom Records5.5.71 - Contractor Cost5.6.1 - Wrench Time5.1.2 - Corrective Maintenance Hours5.1.4 - Preventive Maintenance Hours5.1.6 - Condition Based Maintenance Hours5.3.1 - Planned Work5.3.3 - Actual Cost to Planning Estimate5.3.5 - Planning Variance Index5.4.1 - Reactive Work5.4.3 - Schedule Compliance Hours5.4.5 - Standing Work Orders5.4.7 -Work Order Cycle Time5.9 - Ready Backlog5.4.12 - PM & PdM Yield5.5.1 - Craft Worker to Supervisor Ratio5.5.3 - Direct to Indirect Maintenance Personnel Ratio5.5.5 – Internal Maintenance Personnel Cost5.5.7 - Overtime Maintenance Cost5.5.31 - Store Inventory Turns5.5.33 - Stock Outs5.5.35 - Storeroom Transactions5.5.38 - Maintenance Material Cost5.5.72 - Contractor Hours5.7.1 - Continuous Improvement HoursCopyright SMRP 2018

EFNMS-SMRP Metric Harmonization European Federation of National Maintenance Societies,Developed European standard EN 15341 EFNMS and SMRP Developed List of harmonized metricsCopyright SMRP 2018

EFNMS 22 MembersCopyright SMRP 2018

EFNMSCopyright SMRP 2018

EFNMS-SMRP Harmonization ProjectSMRP BestPracticeMetricsEN15341”Maintenance KeyPerformance Indicators”HarmonizedIndicatorsThe Harmonized Indicators Bookdocuments differences and similarities forthe indicators and metricsCopyright SMRP 2018GlobalMaintenance GlobalMaintenanceAndReliabilityIndicators

The Harmonization ProcessEN 15341IndicatorSMRP BestPractice MetricCompareNoEnd ProcessCommon?YesEliminateDifferences /Qualify andExplainCopyright SMRP 2018

Harmonization ClassificationEach harmonized indicator is given a qualitativeclassificationIDENTICAL – the bases of the indicators are the same, although theremay be some differences in how they are presented. The differences aredetailed in the comments.SIMILAR – there are some differences in the differences that are detailedin the comments.SAME PERFORMANCE – the indicators measure the same performancearea, but there are significant differences in the definitions or calculationsthat are detailed in the comments.Copyright SMRP 2018

Section 3Section 3Sample Metric CalculationsCopyright SMRP 2018

Learning Objectives1. Understand how metrics are documented in the BPCompendium2. Learn the standardized process for metric calculationCopyright SMRP 2018

Sample Metric CalculationsCopyright SMRP 2018

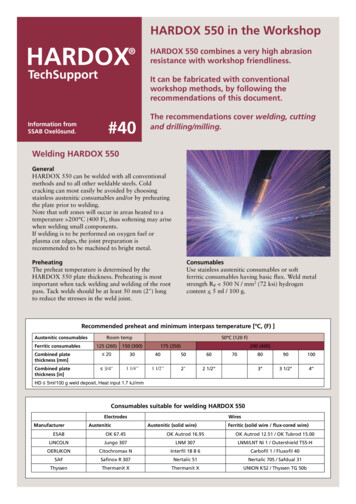

Metric 5.4.2 Proactive Work Refer to the Metric Definition 5.4.2 handout aswe walk through the document and the samplecalculation Lets calculate together Proactive Work for eachof the three sample plants A, B and C.Remember there are 10 .Component DefinitionsI.QualificationsJ.Copyright SMRP 2018Sample CalculationBest in Class TargetCautionsHarmonization CommentsReferences

Metric 5.4.2 Proactive WorkDEFINITIONThis metric is maintenance work that is completed to avoidfailures or to identify defects that could lead to failures. Includesroutine preventive and predictive maintenance activities andcorrective work tasks identified from them.OBJECTIVESThis metric is used to measure and monitor the amount of workthat is being done in order to prevent failures or to identifydefects that could lead to failures.FORMULAProactive Work (%) [Work completed on preventive maintenance work orders,predictive maintenance work orders, and corrective workidentified from preventive and predictive work orders (hours) /Total Maintenance Labor Hours] 100PW (%) (PWC / TML) 100Copyright SMRP 2018

Metric 5.4.2 Proactive Work % Proactive work PM PdM Corrective from PM & PdMTotal Maintenance Labor Hours Let’s look at the definitions for:PM, PdM, Corrective work, Failure, TotalMaintenance Labor HoursCopyright SMRP 2018X 100

Metric 5.4.2 Proactive Work Component DefinitionsPreventive Maintenance (PM)Actions performed on a time- or machine-run-based schedulethat detect, preclude or mitigate degradation of a component orsystem with the aim of sustaining or extending its useful lifethrough controlling degradation to an acceptable level.Predictive MaintenanceAn equipment maintenance strategy based on assessing thecondition of an asset to determine the likelihood of failure andthen taking appropriate action to avoid failure. The condition ofequipment can be measured using condition monitoringtechnologies, statistical process control, equipment performanceindicators or through the use of human senses.Copyright SMRP 2018

Metric 5.4.2 Proactive Work Component DefinitionsCorrective Work Identified from Preventive andPredictive Maintenance Work OrdersWork identified from preventive maintenance (PM) andpredictive maintenance (PdM) work orders is work that wasidentified through PM and/or PdM tasks and completedprior to failure in order to restore the function of an asset.FailureWhen an asset is unable to perform its required function.Copyright SMRP 2018

Metric 5.4.2 Proactive Work Component DefinitionsTotal Maintenance Labor HoursExpressed in hours and includes all maintenance laborhours for normal operating times as well as outages,shutdowns and turnarounds. If operator hours spent onmaintenance activities are captured, they should beincluded in the numerator and denominator of all applicablemetrics. Include labor hours for capital expendituresdirectly related to end-of-life machinery replacement sothat excessive replacement versus proper maintenance isnot masked. Does not include labor hours used for capitalexpansions or improvements. Typically, total maintenancelabor hours do not include temporary contractor laborhours.Copyright SMRP 2018

Metric 5.4.2 Proactive Work Component DefinitionsTotal Maintenance Labor Hours Expressed in hours and includes all maintenance laborhours for normal operating times as well as outages,shutdowns and turnarounds. If operator hours spent on maintenance activities arecaptured, they should be included in the numerator anddenominator of all applicable metrics. Include labor hours for capital expenditures directlyrelated to end-of-life machinery replacement so thatexcessive replacement versus proper maintenance is notmasked. Does not include labor hours used for capitalexpansions or improvements. Typically, total maintenance labor hours do not includetemporary contractor labor hours.Copyright SMRP 2018

Calculate Metric 5.4.2 Proactive Work% Proactive work PM PdM Corrective from PM & PdM X 100Total Maintenance Labor HoursNo.DataUnits2-7 Total MaintenanceHoursHrs/Year4-4 Corrective WorkIdentified4-9 PM/PdM WorkCompletedPlant APlant BPlant th2,4563,9951,765Copyright SMRP 2018

Metric 5.4.2 Proactive Work CalculationCopyright SMRP 2018

Metric 5.4.2 Proactive Work% Proactive work PM PdM Corrective from PM & PdM X 100Total Maintenance Labor Hours 2456 1939(82,799/12) 64.5% for plant A25.1% for plant B, 5.7% for plant CCopyright SMRP 2018

Metric 5.4.2 Proactive WorkPM, PdM and Corrective workID’d from PM and PDM thatwas done before the failureConcerns at each facility?What is included in Proactive work?What is Corrective work?What is the difference between Proactive andReactive Work?Corrective work is done afterthe failure or when a failureis imminent. Corrective workcan be either Proactive orreactiveCopyright SMRP 2018

Proactive WorkThis metric is maintenance work that is completed to avoid failures or toidentify defects that could lead to failures. Includes routine preventive andpredictive maintenance activities and corrective work tasks identified fromthem.Reactive workThis metric is maintenance work that interrupts the weekly schedule,calculated as a percentage of the total maintenance labor hours.Is reactive work planned or unplanned work?Is proactive work planned or unplanned work?Copyright SMRP 2018

Section 3Section 4Why Use Maintenance and Reliability MetricsCopyright SMRP 2018

Learning Objectives1. Why Use Metrics?2. Linking Business Results to the Shop Floor3. Metric HierarchyCopyright SMRP 2018

Why Use Metrics“If you don’t measure it, you can’tmanage it”Dr. Joseph JuranCopyright SMRP 2018

Why Use ImprovementChallengeBest PracticesCopyright SMRP 2018

Metrics are Key for M&R Improvement1. Doing “things right” – Maintenance Execution2. Doing the “right things” – Reliability Execution3. Making sure you are doing the “right things right”How do you know if you are doing the“right things right”?By selecting the right metrics to track performanceCopyright SMRP 2018

Linking M&R to Business ResultsMetric ClassificationMetric HierarchyCORPORATEStrategicINDUSTRY VENESSCOST tical)CAPITALEFFECTIVENESSSTORESEFFECTIVENESSWORK PROCESSEFFICIENCYPROGRAMEFFECTIVENESSCopyright SMRP 2018

Comparing Apples to ApplesWhen comparing figures and evaluatingresults please take into account: LocationLaws & regulationsProcess severityPlant sizeAge of the plantOthers It is better to be consistentlyinaccurate than absolutely correct? Consider using metrics that are costindependent man-hoursCopyright SMRP 2018Example:Labor costsvary widelyacross theglobe

Linking Business and Shop FloorMETRICSMarket PositionCost of Goods SoldRevenueReturn on CapitalWork OrdersPM, PdM, CBMBolts and NutsBearingsCopyright SMRP 2018

Goals and Strategies for MaintenanceVision for companyMission for companyOrganizationMaintenance policyGoals/objectivesCompanyvalues(The way thingsare done)StrategyTechnicalMethodsActivitiesCopyright SMRP 2018

Line of Sight to Top Goals How do you pick your metrics? What are the linkages frommeasurements to goals? Need a clear line of sightto the top vision andmission, otherwise youwill be measuring thingsthat have no impact on top goalsCopyright SMRP 2018

Metrics Linked to Business GoalsMetric ClassificationMetric HierarchyCORPORATEStrategicINDUSTRY VENESSCOST tical)CAPITALEFFECTIVENESSSTORESEFFECTIVENESSWORK PROCESSEFFICIENCYPROGRAMEFFECTIVENESSCopyright SMRP 2018

Metric HierarchyMetric ClassificationMetric HierarchyCORPORATEStrategicINDUSTRY PERFORMANCE/EFFECTIVENESSOperatingOPERATING EFFECTIVENESSCOST EFFECTIVENESSRELIABILTY MANAGEMENTCAPITAL EFFECTIVENESSSTORES EFFECTIVENESSWORK PROCESS EFFICIENCYEffectiveness(Tactical)PROGRAM EFFECTIVENSSCORPORATERONA, ROCE, ROAStrategicStrategic Corporate Metrics:Return on Net Assets (RONA)Return on Capital Expended (ROCE)Return on Assets (ROA)Return on Active Capital Employed (ROACE)Return on Average Assets (ROAA)Return on Invested Capital (ROIC)True Reject Rate (TRR)Copyright SMRP 2018

Metric HierarchyMetric ClassificationMetric HierarchyStrategicCORPORATEINDUSTRY PERFORMANCE/EFFECTIVENESSOperatingOPERATING EFFECTIVENESSCOST EFFECTIVENESSRELIABILTY MANAGEMENTCAPITAL EFFECTIVENESSSTORES EFFECTIVENESSWORK PROCESS EFFICIENCYEffectiveness(Tactical)PROGRAM EFFECTIVENSSOPERATINGEFFECTIVENESSCOST EFFECTIVENESSLabor effectiveness, cost/unit , RAVTEEP, OEE, Asset Utilization, COPQOp

5.4.12 - PM & PdM Yield 5.4.14 - PM & PdM Compliance 5.5.1 - Craft Worker to Supervisor Ratio 5.5.2 - Craft Worker to Planner Ratio 5.5.3 - Direct to Indirect Maintenance Personnel Ratio 5.5.4 - Indirect Maintenance Personnel Cost 5.5.5 –Internal Maintenance Personnel Cost 5.5.6 - Craft Workers on Shift