Transcription

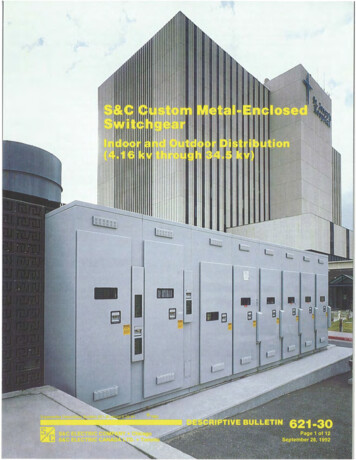

S&C Custom Metal-Enclosed SwitchgearIndoor and Outdoor Distribution (4.16 kv through 34.5 kv)IGENERALIS&C Custom Metal-Enclosed Switchgear provides you exceptionalflexibility in satisfying even extremely complex switching and protectionrequirements of medium-voltage power distribution systems.S&C Custom Metal-Enclosed Switchgear, incorporatinginterrupter switches and power fuses in ruggedmonocoque enclosures, permits you to tailor reliable,economical, medium-voltage switching and protectionpackages totally matched to your power distributionsystem requirements. Available in ratings through290 Mva at 4.16 kv, 960 Mva at 13.8 kv, 1080 Mva at25 kv and 1000 Mva at 34.5 kv, S&C Custom Switchgearis es ecially suited for those applications having uniquerequirements beyond the scope ofS&C's pre-engineeredSystem II Modular Metal-Enclosed Switchgear. Forexample, custom switchgear is often used when complex automatic source-transfer schemes are necessary,such as those involving three or more incoming powersources and utilizing multiple split-bus sections or ringbus arrangements. Custom switchgear is also appropriate where special installation requirements must besatisfied such as is often necessary for transformerprimary' unit substations, and those applicationsrequiring special-purpose components, which includegrounding switches, control power transformers,extensive metering panels, capacitors for power-factorcorrection, etc. Unordinary combinations of components such as hot-sequence metering, or particularfloor-space restrictions that require unusual switchgearlayouts-"U shaped" configurations for example-arealso applications for which S&C Custom Switchgear isideally suited.For your medium-voltage systems through 34.5 kv,S&C Custom Metal-Enclosed Switchgear utilizes highlyengineered, thoroughly tested and field-proven switching, protection, control, and insulation components.These components are effectively integrated into anS&C enclosure of unmatched security, versatility, anddurability. The components and enclosure are developed at S&C's research and development center . theNicholas J. Conrad Laboratory . especially for metalenclosed switchgear based on years of experience withsuch applications. With S&C Metal-Enclosed Switchgear, you are assured that the components andenclosure selected to match your specific requirementsare all built to exacting standards of quality by a singlemanufacturer. As a result, you receive an exceptionalcomprehensively engineered switching and protectionpackage that ensures the unparalled level of reliabilityyou should demand for your power distribution system.This superior performance is complemented by UL listing of all S&C Metal-Enclosed Switchgear rated4.16 kv and 13.8 kv with 600-ampere or 1200-ampere621-30Page 2 of 12September 28, 1992main bus . . . even including Category A enclosureswhen needed.S&C Custom Metal-Enclosed Switchgear is availablewith all types of S&C Power Fuses including S&CSM-20, SM-40, SM-4Z, SM-5S, SM-5SS, and Fault Fiter Electronic Power Fuses, which provide ratings through720E amperes continuous. This broad choice of fusesprovides a wide variety of ampere ratings and timecurrent characteristics to give you the utmost flexibilityin meeting your protection and coordination needs.For all three-phase switching duties, S&C CustomSwitchgear offers a choice of field proven, three-polegroup-operated switches-S&C Mini-Rupter Switchesand S&C Alduti-Rupter Switches. These switches coverthe range of full-load switching through 1200 ampereswith no external arc or flame and offer duty-cycle faultclosing ratings matched to the ratings of the entireswitchgear lineup. S&C Switch Operators provide poweroperation of these switches for automated switchingapplications. The switches with switch operators canbe utilized for remote supervisory control or, incombination with S&C automatic control equipment,to implement power distribution systems featuring:automat.ic source transfer using S&C Micro-ATTMSource-Transfer Controls; source-side and load-sideopen-phase detection using S&C Open-Phase Detectors;and protection from single phasing using S&C Overcurrent Relays. S&C switches, switch operators, andsource-transfer controls can also be incorporated intocustom switchgear for implementing special sophisticated automatic switching schemes such as faultclearing on resistance-grounded systems, load shedding, and high-speed source transfer for use incombination with UPS systems.The combination of interrupter switches for switching and fuses for protection eliminates the need forexpensive circuit-breaker gear (metal-clad switchgear),particularly on cable distribution systems where therare and permanent nature of the faults makes theautomatic reclosing feature of circuit-breakers anunnecessary extravagance. Unlike circuit-breaker gear,S&C Metal-Enclosed Switchgear is virtually maintenance free. The interrupter switches never needadjusting, setting, or dielectric testing. Only an occasional inspection and exercising is required. And themaintenance-proof fuses, unlike relays, never needsetting or testing. With metal-enclosed switchgear, thereare no batteries requiring special facilities and monitoring.DESCRIPTIVE BULLETINS&C ELECTRIC COMPANY ChicagoS&C ELECTRIC CANADA LTD. Toronto

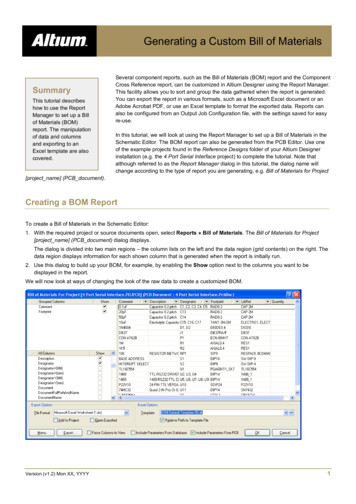

IGENERAL- ContinuedThe s implicity of m etal-e nclo sed switchgear, itsexceptional dependab ility, its low first cost, and itsminimal maintenance cost make it the best choice foryour system.S&C has developed a n inventory of engineerin gconcepts and tec hniques compiled during nearly 50years of metal-enclosed switchgear design and ma nu facture. Sophisticated CAD/ CAM computer systemsfurther enhance efficiency a nd accuracy in the drawingpreparation process a nd in the manufacturing process.All custom switchgear employs proven components andconstruction techniques. Manufacturing is done inultramodern fac ilities including a utomated productionmethods employing comp uter- numerically-controlled(CNC) machine tools, many equipped with d irectnumerical-control (DNC) capabilities, as well as roboticwelding systems, laser cutting centers, a nd electronically controlled finis hing systems. This sophisticatedequipment produces acc urately fabricated a nd finishedcomponents and matching assemblies of a classicquality not achievable with simple manual punching,Iforming, and welding equipment. Th e r es ultan tsw itc hgear is uniqu e ly profes s ional in everyaspect . it meets your mec hanical, electrical, a ndfinish specifications while providing the ultimate inoperating s impli c ity, fl ex ibility, dur ab ili ty, andreliability.S&C Custom Metal-Enclosed Switchgear can solveyo ur power distribution problems, and is especiallyvaluable for those app lication s requiring spec ia lcomponents and features not available in modularswitc hgear. The comb inations of system circuitry andswitchgear configurations that you can use to ac hievet he desired level of economy, functionality, a nd poweravailability in medium-voltage switching and protectionare virtually limitless. To see how in-plant powerdistribution systems can be implemented using custommetal-enclosed switc hgear, refer to S&C Data Bulletin620-55. For assistance in selecting S&C Custom MetalEnclosed Switchgear matched to your spec ific needs,contact your nearest S&C Sales Office.Figure 1. S&C Custom Metal-Enclosed Switchgear offers design flexibility with a choice of components tailored to eachapplication. The lineup shown here in final assembly at S&C is especially configured to match the floor space at the installation.Lineups are completely factory-assembled and tested to facilitate installation in the field.- - - - - - - - - - - · DESCRIPTIVE BULLETIN S&C ELECTRIC COMPANY ChicagoS&C ELECTRIC CANADA LTO. Toronto621·30Page 3 of 12September 28, 1992

S&C Custom Metal-Enclosed SwitchgearIndoor and Outdoor Distribution (4.16 kv through 34.5 kv)IENCLOSURE- Construction and FinishIRely on S&C Custom Metal-Enclosed Switchgear to thwart theenvironment and the curious.Metal-enclosed switchgear is often located in outdoorareas and is thereby exposed to all environmentalconditions and to vandals. To keep out windblown rain,sleet, and snow and the unauthorized, S&C CustomMetal-Enclosed Switchgear for outdoor applicationsfeatures a unique system of gasketing, sealing, andformin g techniques to close off all openings, ensuringthat t he interior remains dry a nd free of contaminantsand eliminating points of purchase. All enclosuresfeature comprehensive access controls and securitymeasures to guard against un a uthorized entry. And,when spec ified , S&C Metal -E n c lo sed Switchgearprovides the industry 's highest standard of securityfor this class of equipment . Category A enclosures.Complia nce with the Category A security requirementsof ANSI/ IEEE C37.20.3 was verified by conformancetesting in accordance with ANSI C37.57 during ULcertification of 4.16 kv and 13.8 kv switchgear. Manyof the extraordinary sealing techniques and tamperresistant features employed to isolate the interna lcomponents from the environment a nd the curious areillustrated on pages 5, 6, and 7.Guarding against corrosion is S&C's UltradurTM anunparalleled outdoor finis hing system-proven toprovide lasting protection for outdoor gear. It's a highperformance comprehensive finis hing system: First, allsteel s urfaces are meticulously cleaned, phosphatized,and sealed in a fully automated multistage pretreatment process to improve the finis h-to-metal bond and .to resist rust. Next, a cohesive, impenetrable, bakedon, epoxy powder initial coating-the keystone for theexceptional durability of S&C's Ultradur finish-isapplied, followed by a superior high solids acrylictopcoat that assures lastin g prot ec tion again stdeterior ation ofthe finish by ultraviolet radiation. Then,an electronically monitored and controlled final bakeproduces the tough, beautiful finis h . a dense, hards hield that's almost ceramic in a ppearance andperforman ce. And all hardware is protected againstcorros ion, too-it's galvanized, zinc-nickel plated,stainless, or of nonferrous materials.In order to demonstrate the s uperiority of theoutdoor Ultradur finish over conventional finishes, ithas been comprehensively tested using a battery ofindustry-recognized ASTM tests designed to evaluatethe capabilities of protective coatings. All test resultsobtained for S&C's Ultradur Finishing System meet orexceed the requirements of app licable indu st rystanda rds-including ANSI C57. 12.28-as shown by thefollowing highlights of test methods used and resultsobtained.621 30Page 4 of 12September 28, 1992Salt-spray testing. The exceptional corrosionresistance of Ultradur is demonstrated by its abilityto withstand at least 4000 hours of exposure to ASTMsalt spray testing while limiting underftlm propagationof corrosion to less than 1/32 inch from the scribe, a ndloss of adhesion from bare metal to less than 1/s inchfrom the scribe.Humidity testing. Confirming the outstanding finish to-metal bond and resistance to moisture penetrationachieved with S&C's Ultradur finish is its ability towithstand at least 1000 hours of exposure to ASTMtesting with no blistering.Ultraviolet accelerated weathering testing. Ultradur's superior resistance to weathering is corroboratedby its ability to withstand at least 500 hours of exposureto ASTM weathering testing with no cha lking a nd withless t ha n 15% reduction in gloss.Adhesion testing. Verification of Ultradur's remarkable resistance to scratching and chipping is demonstrated by its ability to withstand ASTM crosshatchadhesion testing with absolutely no loss of paint, a ndby its ability to withstand ASTM impact testing usinga 160-inch-pound impact by a pointed weight with nochipping or cracking.Scab corrosion testing. Ultradur's corrosion resistance in severe environments s uch as coastal areas isvalidated in ASTM testing that shows its ability to limitcorrosion creepback to less than 1/ 16 inch from the scribewithout blistering or loss of a dhesion after 35 cyclesof exposure to various corrosive conditions.Oil resistance. Ultradur exhibits excellent resistanceto ins ulating oil (S&C Metal-Enclosed Switchgearemploys in-air insulation but oil may spill from someother equipment). Immers ion in mineral oil for72 hours produces no cha nges, such as color shift,blisters, loss of hardness, or streaking.Abrasion resistance. Ultradur's s uperlative resistance to wear (such as would be encountered duringtransit, handling, and installation) is demonstrated byits ability to be subjected to Taber Abraser t esting forat least 3,000 cycles without wearing through to thes ubstrate.As proven by the ability to withstand this severebattery of tests-and ac hieve results far s urpassingindustry standards-S&C has an outstanding finishingsystem for outdoor metal-enclosed gear. S&C's Ultradurfinish resists deterio ration to provide unequ a ledprotection from the elements, which is a key factorin assuring enclos ure integrity for enha nced security.DESCRIPTIVE BULLETINS&C ELECTRIC COMPANY ChicagoS&C ELECTRIC CANADA LTO. Torontom

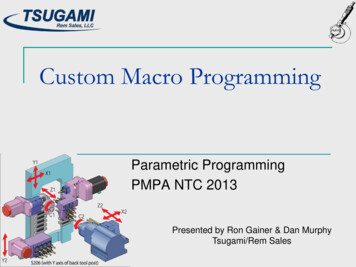

ENCLOS URE- Con stru ction and Fini sh -ContinuedGasket seals at the top andside edges of adjoining bayskeep water from enteringbetween baysClosed-cell gasketingweather-seals the roofin placeInsulating "no-drip" compound on the inner undersideof the roof checks con densationMolded con tinuous gasketingseals handle and windowopenings, protects shearededgesChannel gasketing at interbay bus openings providesadded protection again stwater entry "Lasting ly resilient compression gasketing around dooropenings keeps the water outI I"I"Rainproof vent constructionkeeps water out but lets air circulate as an aid to moisture con trol. Baffles and screens .in side the enclosures . coverall vents - discourage w irepoking by the curiousSpace heaters (not visible) maintainair circulation inside the enc losure- they keep the air moving,help keep the interior dryS&C's exceptional Ultradu r'" Fin ishingSystem protects the steel with: (a)multistage pretreatment process ofhigh- pressure sprayed cleaning,rinsing, phosphati zing, and sea lin g;(b) durable, baked on, epoxy powderinitial finish coat, ar.d (c) for outdoorsw itchg ear a tough, stab le, high solidsacry lic topcoat I " I Gasketed covers withsealants at window edgesguard again st water entry toelectronic control s andswitch operatorsFigure 2. Outdoor S&C Custom Metal-Enclosed Switchgear has enclosures with the environmental checks to assure servicecontinuity in all atmospheric and weathering conditions. Some of the features that thwart the environment are describedabove; features providing structural integrity and access control are described on pages 6 and 7.mS&C ELECTRIC COMPANY ChicagoS&C ELECTRIC CANADA LTO. TorontoDESCRIPTIVE BULLETIN621 30Page 5 of 12September 28, 1992

S&C Custom Metal-Enclosed SwitchgearIndoo r and Outdoor Distribution (4.16 kv through 34.5 kv)ENCLOSUR E- Construction and Finish- ContinuedWhatever your system . you'll have greater service continuity andoperating flexibility by ensuring that your switchgear has all thesefeatures.S&C Custom Metal-Enclosed Switchgear featuresmonocoque construction. Each bay is fabricated from11 -gauge steel sheet and is a free-standing unit withan integral steel-channel base around the four sides.The accurately formed, matching enclosures assureperfect alignment in mu ltibay assemblies. And becauseof the cellu lar design, there are always double wallsbetween the adjoining bays. There are no externallybolted -on side sheets, rear sheets, or roofs to attractthe vandal to S&C outdoor gear. Even future busextensions are secured internally. By design, the geardiscourages the inquisitive. To guard against poking andprying, corners of doors and door openings are welded,latching mechanisms employ a cam action to pull doorstight ly c losed, and handles are flush mounted.1. Wide bu lkhead-type doo rs providefo r easy access to a ll bays.2 . Deep 90-degree fl a nges on t heext ra-rugged doo rs assure rigid ityand d isco urage tampe ri ng. Shearededges are fo ld ed back toward t heinside of t he doo r to limit ex posure,help preve nt co rrosion.3. Th ree co ncealed, h igh-strengthlatc hes seal the doo rs shut.4. 11-gauge steel fo r roof, side andEnclosures specified with Category A constructioninclude additional features - such as window covers,handle covers, and the S&C Penta-Lock-to provide theindustry's highest standard of security for this classof equipment.Enclosures are designed for complete front accessibility, except where unordinary combinations of components require an extra-deep bay, so that S&C gear maybe p laced back-to-back or against a wall. It fits in aminimum of floor space. And because it's unquestion ably rugged yet light by comparison to circuit-breakergear, only a level floor or pad is required forinstallation . never a foundation or support chan nels. It installs anywhere-even on balconies or outdoors on rooftops.8 . Padlockable window cove rsinclu ded on Category Aenclos ures.9 . Nameplate provides rat in gs of t heswitc hgear asse mbly.10. Exte rio r hazard -a lerting signswa r n t he un qualilied.11. Flush-mo unted key-operated snaplocks- plus inte rlocks and padlocks-help cont rol access tomedium -vo ltage co mpartments.14. In terio r hazard-a lert in g signs a reunmistakab ly bold a nd clear.15. Protective screen doo rs boltclosed - act as a seco nd barr ie rgua rd in g aga inst in adve rtententry to bays contain in g med ium vo ltage co mpo nents.16. Self-latch in g doo r holderssec ure ly hold t he doors openagainst acc idental o r wind blownclosing . . unl atc h wit h a touc hof the toe for closing.rear sheets, front, and door.5. Full-lengt h doo rs have t hree con cealed, extra- heavy-d uty hi ngeswit h stainless-steel pins t hat won'tco rrode . . t he doors pivot withease.6 . Fu ll s ide sheets for eac h bay res ultin do uble-wall co nstructio nbetwee n bays.7. Wide-view wind ows t hat are bot himpact a nd ma r resistant fac ili tatechecking of switch posit ions, blownfuse indicato rs, a nd stat us of co nt rols wit ho ut openin g th e doo rs.621·30Page 6 of 12September 28, 199212. Padlockable hand les on doo rs andcovers shield t he padlock shac klea nd thwart tampe ri ng by vandals.Enclos ures specilied wit h Catego ry A co nstructio n util ize S&C'sPenta- Lock, provid ing coo rd inated latc hing a nd padlocki ng o ndoo r ha ndles.13. Integr al steel base a rou nd a ll fo ursides of each bay keeps enclosu rerigidly posit io ned, helps blockin te rb ay open ings at bottom orbay.17. Low-vo ltage wirin g is in gro undedcable t r ays isolated fro m med iu mvo ltage.18. There's an exceptio na l amo un t ofroom fo r pulling cable a nd mak in gtermi natio ns.19. Storage racks keep re place mentfuse components in a co nve nientlocation.DESCRIPTIVE BULLETINS&C ELECTR IC COMPANY ChicagoS&C ELECTR IC CANADA LTO. Toronto

ENCLOSUR E- Const ruction and Fini sh -ContinuedFigure 3. Highlighted above are the many features of S&C Custom Metal-Enclosed Switchgear, including those that providestructural integrity, resistance to the environment, and access control necessary to assure enclosure security. Testing byUL of 4.16-kv and 13.8-kv switchgear has confirmed conformance with ANSI standards on enclosure security, includingthe requirements for Category A enclosures when specified. And this is all in addition to the environmental checks describedon pages 4 and 5.mS&C ELECTRIC COMPANY ChicagoS&C ELECTRIC CANADA LTD. TorontoDESCRIPTIVE BULLETIN621 30Page 7 of 12September 28, 1992

S&C Custom Met a l-Enclosed SwitchgearIndoor and Outdoor Distribution (4.16 kv through 34.5 kv)ICOMPONENTSS&C Custom Metal-Enclosed Switchgear offers an extensive selection ofstandard S&C components, allowing you to tailor a switchgear package toyour switching and protection need

Manufacturing is done in . S&C Custom Metal-Enclosed Switchgear offers design flexibility with a choice of components tailored to each application. The lineup shown here in final assembly at S&C is especially configured to match the floor space at the installation. . on, epoxy powder initial coat