Transcription

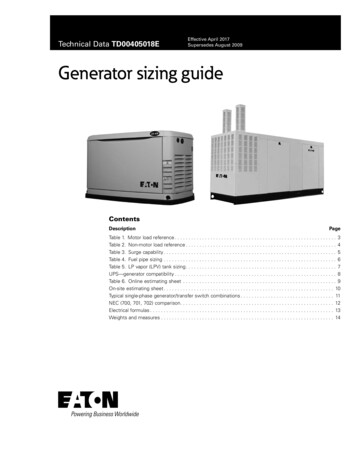

OverviewEnclosed Control1.1Enclosed Control ProductsWelcome . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Eaton Corporation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Eaton Support and Service Center Capabilities . . . . . . . . . . . . . . . . . .Technical ReferenceEnclosure Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Enclosure Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Motor Circuit Elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Power Supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Functions of Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Two- and Three-Wire Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111Volume 10—Enclosed Control CA08100012E—November 2012 www.eaton.comV10-T1-1

1.11OverviewEnclosed Control ProductsContentsEnclosed Control ProductsDescription1Enclosed Control ProductsTechnical Reference . . . . . . . . . . . . . . . . . . . . .Enclosure Types . . . . . . . . . . . . . . . . . . . . .Enclosure Ratings . . . . . . . . . . . . . . . . . . . .Motor Circuit Elements . . . . . . . . . . . . . . . .Power Supplies . . . . . . . . . . . . . . . . . . . . . .Functions of Control . . . . . . . . . . . . . . . . . .Two- and Three-Wire Control . . . . . . . . . . .111111111111WelcomeEaton CorporationWelcome to the latest editionof the Enclosed ControlCatalog from Eaton’s electricalsector. In this updated edition,you will find complete detailson our extensive line ofenclosed products.Eaton Corporation is adiversified industrialmanufacturer ranked amongthe largest Fortune 500companies. The electricalgroup is Eaton’s largestdivision and is a global leaderin electrical control, powerdistribution, power quality,automation and monitoringproducts and services.Eaton’s electrical productsinclude brands such asMGE Office ProtectionSystems , Powerware ,Holec , and MEM . Eatonprovides PowerChain solutions to serve the needsof the industrial, institutional,IT, data center, missioncritical, utility, residential andOEM markets worldwide.1111111PowerChain Managementsolutions help enterprisesachieve sustainable andcompetitive advantagesthrough proactivemanagement of the powersystem as a strategic,integrated asset throughoutits life cycle. With Eaton’sdistribution, generation andpower quality equipment; fullscale engineering services;and information managementsystems, the power systemis positioned to deliverpowerful results: greaterreliability, operating costefficiencies, effective useof capital, enhanced safetyand risk mitigation.111111111V10-T1-2Volume 10—Enclosed Control CA08100012E—November 2012 10-T1-7V10-T1-7V10-T1-8

1.1OverviewEnclosed Control ProductsEaton Support and Service Center CapabilitiesEnclosed Control ServiceCenter Product Offering Type 1, 12, 3R, 4, 4X and 7/9 enclosuresNon-combination startersCombination starters—non-fusible/fusible andcircuit breakerFull voltage non-reversing,reversing and multi-speedFreedom (NEMA Size00–5), vacuum contactors,soft starters, lightingcontactors, motor controlcenters and MCCaftermarketModifications includingcover control, CPTs,auxiliary contacts, heatersand more1Eaton Provides EnclosedControl Solutions That AreUnmatched In The Industry 11Local assembly andmanufacturing capabilitiesAssembly and wiring ofenclosed control and motorcontrol centersCustomized enclosedmotor starting and lightingpanelsModified pump panelsEngineering supportCustom AutoCAD drawing capabilitiesQuick-ship capabilitiesCustomer visits arewelcome!11111111Six regional service centers111Denver– Tel: 303-366-9949– Fax: 303-366-2084Hartford– Tel: 860-683-4221– Fax: 860-683-0764Los Angeles– Tel: 562-944-6413– Fax: 562-941-7178Chicago– Tel: 630-260-6304– Fax: 630-690-7453Houston– Tel: 713-939-9696– Fax: 713-939-0427Fayetteville– Tel: 910-677-5249– Fax: 910-677-52581111111111111111Volume 10—Enclosed Control CA08100012E—November 2012 www.eaton.comV10-T1-3

1.1OverviewEnclosed Control Products1Technical Reference11Enclosures provide mechanical and electrical protection for operator and equipment. Briefdescriptions of the various types of enclosures offered by Eaton are given below. See NEMA Standards Publication No. 250 for more comprehensive descriptions, definitions and/or test criteria.All Eaton enclosures are NEMA ICS 6 compliant.1Enclosure Type OverviewEnclosure Types11111111111Type 1 (Conforms to IP40)—for Indoor UseType 3R (Conforms to IP52)—for Outdoor UseType 4 (Conforms to IP65)—for Indoor or Outdoor UseType 4X (Conforms to IP65)—for Indoor or Outdoor UseSuitable for most applications whereunusual service conditions do not exist andwhere a measure of protection fromaccidental contact with enclosedequipment is required. Designed to meettests for rod entry and rust resistance.Enclosure is sheet steel, treated to resistcorrosion. Depending on the size, knockoutsare provided on the top, bottom andsometimes on the side.Primarily intended for applications wherefalling rain, sleet or external ice formationsare present. Gasketed cover. Designed tomeet tests for rain, rod entry, external icingand rust resistance. Enclosure is sheetsteel, treated to resist corrosion.Depending on the size, a blank cover plateis attached to the top (for a conduit hub)and knockouts are provided on the bottom.Provides a measure of protection fromsplashing water, hose-directed water andwind blown dust or rain. Constructed ofsheet steel with gasketed cover.Provides a measure of protection fromsplashing water, hose-directed water, windblown dust, rain and corrosion. Constructedof stainless steel with gasketed cover.Designed to meet same tests as Type 4except enclosure must pass a 200-hour saltspray corrosion resistance test.Cover-mounted pilot device holes areprovided and covered with hole plugs.1Designed to meet tests for hose-down,external icing and corrosion protection.When conduit connections are specified,enclosure has two watertight hubs (power)installed top and bottom or one control hubinstalled in bottom—depending on size.Cover-mounted pilot device holes areprovided and covered with hole plugs.11111111Type 7/9—for Hazardous Gas LocationsType 12 (Conforms to IP62)—for Indoor Use1For use in Class I, Group B, C or D; Class II,Groups E, F and Class III indoor locations asdefined in the National Electrical Code .Type 7/9 enclosures must withstand thepressure generated by the explosion ofinternally trapped gases and be able tocontain the explosion so that gases in thesurrounding atmosphere are not ignited.Under normal operation, the surfacetemperature of the enclosure must bebelow the point where it could igniteexplosive gases present in the surroundingatmosphere. Designed to meet explosion,temperature and hydrostatic design tests.Provides a degree of protection fromdripping liquids (non-corrosive), falling dirtand dust. Designed to meet tests for drip,dust and rust resistance. Constructed ofsheet steel. Hole plugs cover pilot deviceholes. There are no knockouts, hub coverplates or hubs installed.11111V10-T1-4Safety InterlockThe Type 12 enclosure can be ordered witha safety interlock on the door that can bepadlocked off. A vault-type door latchsystem is used. A tapered plate holds thegasketed door tight against the case edgeto provide a positive seal. The special doorinterlock consists of the door handle and ascrewdriver operated cover defeater.The cover defeater and the disconnectinterlock defeater are both recessedscrewdriver operated devices that cannotbe manipulated with other types of tools.Volume 10—Enclosed Control CA08100012E—November 2012 www.eaton.com304-grade stainless steel provided asstandard. Select 316-grade option forimproved corrosion resistance.

1.1OverviewEnclosed Control ProductsEnclosure Ratings1IEC IP Index of Protection tionNo protection0No protection1Protection against solid objects greater than 50 mm1Protection against vertically falling drops of water2Protection against solid objects greater than 12 mm2Protection against dripping water when tilted up to 15 degrees3Protection against solid objects greater than 2.5 mm3Protection against spraying water4Protection against solid objects greater than 1 mm4Protection against splashing water5Total protection against dust—limited ingress (dust protected)5Protection against water jets6Total protection against dust (dust-tight)6Protection against heavy seas7Protection against the effects of immersion8Protection against submersionThe UL , NEMA and IECorganizations (and otherinternational groups) definedegrees of protectionprovided by electricalenclosures with respect topersonnel, equipment withinthe housing and the ingressof water.To claim ratings to NEMAtype specifications, thetesting is performed andcertified by themanufacturers themselves.To comply to UL and IECspecifications, themanufacturers must submitproduct samples, materialsused and other data to anindependent testinglaboratory before ratings canbe claimed.Subtle differences do existbetween the test proceduresand specifications of theseorganizations.111111In addition, IEC “IP” ratingsdiffer from NEMA type in thatthey do not apply toprotection against the risk ofexplosion or conditions suchas humidity, corrosive gases,fungi or vermin. In addition,different parts of theequipment can have differentdegrees of protection and stillcomply.1The table below is acomparison of the NEMA/UL/IEC enclosure specificationsto be used as an approximatereference only. Do not usethe table to convert fromIEC to NEMA designations.111111111NEMA/UL/IEC Enclosure Type Cross-Reference—ApproximateIEC 529 does not specify equivalents to NEMA enclosure types 7, 8, 9 or P64IP65IP66IP67IP681NEMAEnclosureRating11 �———————2 �———————13 ————3R �————3S ————4 ——4X ——6 —6P 12 ———13 ———111111111Volume 10—Enclosed Control CA08100012E—November 2012 www.eaton.comV10-T1-5

1.1111111OverviewEnclosed Control ProductsIEC Environmental Enclosure Ratings—Examples of DesignationsIP44IPCharacteristic lettersfirst characteristic numeral(See previous page)Characteristic lettersfirst characteristic numeral(See previous page)Second characteristic numeral(See previous page)Second characteristic numeral(See previous page)An enclosure with this designation is protected against the penetrationof solid objects greater than 1.0 mm and against splashing water.23An enclosure with this designation is protected against the penetrationof solid objects greater than 12 mm and against splashing water.111111111111111Motor Circuit ElementsDisconnect Switch—horsepower rated—located insight of controller—arrangedfor padlocking in openposition—disconnectsmotor and controller fromungrounded ssible—115% carryingcapacity of full load motorcurrent—interrupting capacityof stalled motor current—may serve as disconnect formore than one motor ifmotors are driving parts of asingle machine or motors areall in a single room withinsight of disconnectingmeans, must equal sum ofhorsepower ratings to bedisconnected—device maybe general use switch, motorcircuit switch or circuitbreaker meeting coderequirements—disconnectingmeans should contain motorbranch-circuit short-circuitand ground fault protection.11111Motor Running OvercurrentProtection—called overloadrelay—protects motor andcontrol apparatus againstoverheating due to motoroverload—does not protectagainst short-circuits orground faults—selected totrip at not more than 125%full load motor current, 40 Crise motors—115% all othermotors—continuous dutymotor protection—intermittent duty motorsprotected by branch circuitprotection—sufficient timedelay to permit motor to startand accelerate load withouttripping—sensing devices(heater coils) in ungroundedconductor for single-phase—three sensing devices (heatercoils) required for threephase.Contactor—starting,stopping motor it controls—interrupt stalled motorcurrent—horsepower rated—not lower than horsepower ofmotor controlled—contactornot in sight of connectedmotor must have disconnectcapable of locking in openposition or manually operableswitch that will preventcontactor closing within sightof motor—interrupt allungrounded power lines—manually or magneticallyoperated.Controller or Starter—noncombination containscontactor and motor runningovercurrent protection in oneenclosure—starts, stops,protects and regulates motor—combination starters containdisconnecting means, branchshort-circuit protection insame enclosure. (See motorcontrol sections—threephase, single-phase and DC.)Typical Motor CircuitMotorDisconnectingMeansMotor 11V10-T1-6Reduced Voltage—restrictions in power supplycapacity or machine designmay require reduced voltagestarting—motor connected topower supply at voltagelower than supply voltage—requires use of primaryresistance, reactance or useof autotransformer—specialmotor designs such as partwinding and wye-deltaconsidered as reducedvoltage starting.Volume 10—Enclosed Control CA08100012E—November 2012 www.eaton.comSafety SwitchMotor CircuitSwitchCircuitBreakerMotorStarterCombination Starter withMotor Circuit Switch orCircuit Breaker

OverviewEnclosed Control Products1.1Power Supplies1All e

IEC enclosure specifications to be used as an approximate reference only. Do not use the table to convert from IEC to NEMA designations. NEMA/UL/IEC Enclosure Type Cross-Reference—Approximate IEC 529 does not specify equivalents to NEMA enclosure types 7, 8, 9 or 10. First Number Description Second Number Description 0 No protection 0 No .