Transcription

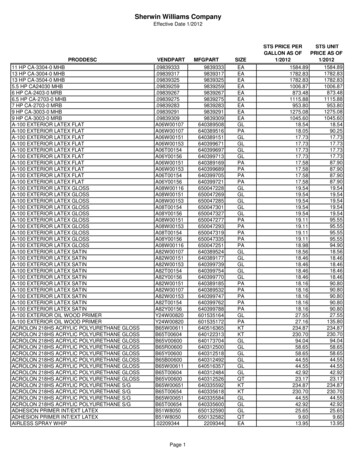

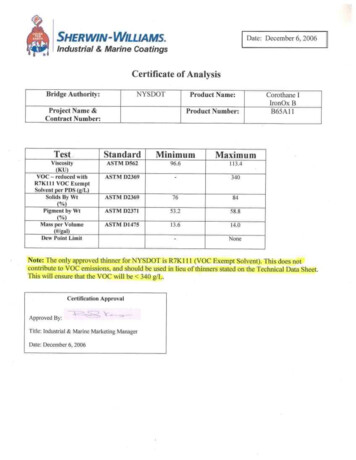

SHERWIN-WILLIAMS.Date: December 6, 2006Industrial & Marine CoatingsCertificate of AnalysisBridge Authority :NYSDOTProduct Name :Project Name &Contract Number:TestViscosity(KU)VOC - reduced withR7K 1 I I VOC ExemptSolvent per PDS (/L)Solids By Wt(%))Pigment by WtMass per Volume(#/ al)Dew Point LimitProduct Number :StandardMinimumMaximumASTM D2369-340ASTM D23697684ASTM D237153 .258 .8ASTM D147513 .614 .0ASTM D56296.6-Corothane IIronOx E3B65A 1 1113.4INoneNote: The only approved thinner for NYSDOT is R7K11 1 (VOC Exempt Solvent). This does notcontribute to VOC emissions, and should be used in lieu of thinners stated on the Technical Data Sheet.This will ensure that the VOC will be 340 g/L .Certification ApprovalApproved By :Title: Industrial & Marine Marketing ManagerDate : December 6, 2006

IndustrialandR ECFIVF71',NOV Ot MarineCoatingsINPU.STRIALA MARINEREDDISH GRAYPRODUCT DESCRIPTIONCOROTHANE I IRONOX B is a single component, VOC compliant, moisture curing urethane intermediate coat with micaceous iron oxide designed for low temperature applications,providing chemical and abrasion resistance .Low temperature application - down to 20 FOutstanding adhesion to most surfacesOutstanding abrasion and chemical resistanceSuitable for use in USDA inspected facilitiesPRODUCT CHARACTERISTICSFinish :Low GlossColor:Reddish GrayVolume Solids :61% 2%, may vary by colorWeight Solids :79 .9% 2%, may vary by colorVOC (calculated) : 340 g/L; 2.8 Ib/galRecommended Spreading Rate per coat:Wet mils :5.0-8 .0Dry mils:3.0-5 .0Coverage :195 - 326 sq ft/gal approximateDrying Schedule @ 5.0 mills wet @ 50% RH :@40 F@ 75 F@100 FTo touch:2 hours1 hour20 minutesTo handle :1-1/2 hours3 hours1 hourTo recoat :minimum: 3 hours1-1/2 hours1 hourmaximum: 12 months12 months12 monthsTo cure :4 days3 days1 dayDrying time is temperature, humidity, and film thickness dependent.Shelf Life :12 monthsStore indoors at 40 F to 100 FFlash Point:110 F, PMCCReducer/Clean Up :Reducer #15, R7K15PolyurethaneCOROTHANE@ IIRONOX@ BB65AIIRevised 11 /04PRODUCT INFORMATIONCOATINGS""""5 .075.07RECOMMENDED USES" Intermediate coat for lead overcoating system" Ideal for stripe coating over primed surfaces ." Superior coverage on edges and bridging over cracks dueto micaceous iron oxide" Must be topcoated for exterior usePERFORMANCE CHARACTERISTICSSystem Tested : (unless otherwise indicated)Substrate:SteelSurface Preparation :SSPC-SP61 ct .Corothane I GalvaPac Zinc Primer @ 3 .0 mils dft1 ct .Corothane I IronOx B @ 3.0 mils dft1 ct .Corothane I IronOx A @ 3.0 mils dftAbrasion Resistance :Method : ASTM D4060, CS 17 wheel, 1000 cycles, 1 kg loadResult :21 mg lossAdhesion :Method : ASTM D4541Result :1000 psiDirect Impact Resistance :Method : ASTM D2794Result :80 in . lbs.Dry Heat Resistance :Method : ASTM D2485Result :300 FFlexibility :Method : ASTM D522, 180 bend, 7/16 " mandrelResult :PassesMoisture Condensation Resistance :Method : ASTM D4585, 100 F, 300 hoursResult :PassesPencil Hardness :Method : ASTM D3363Result:2HSalt Fog Resistance :Method :ASTM B117, 2500 hoursResult :PassesWet Heat Resistance :Method :Non-immersionResult :180 Fcontinued on back

INDIJSTR1i4L& MARINECOATINGSIndustrialandMarineCoatingsV7:7 F),MATERIALS' 6UREAU REDDISHGRAYB65A11ORODUCT INFORMATIONRECOMMENDED SYSTEMSSteel:1 ct.COROTHANE@ IIRONOX@ B1 ct.1 ct.Corothane I GalvaPac Zinc Primer@ 3.0 - 4.0 mils dftCorothane I IronOx B @ 3.0 - 5.0 mils dftCorothane I IronOx A @ 2.5 - 3.5 mils dftSteel:1 ct.1 ct .1 ct .Corothane I PrePrime @ 1 .5 - 2.0 mils dftCorothane I IronOx B @ 3.0 - 5.0 mils dftCorothane I IronOx A @ 2.5 - 3.5 mils dftConcrete, smooth :1 ct .Corothane I PrePrime @ 1 .5 - 2.0 mils dft1 ct .Corothane I IronOx B @ 3.0 - 5.0 mils dft1 ct .Corothane I IronOx A @ 2.5 - 3.5 mils dftConcrete, rough :1 ct .Kern Cati-Coat HS Epoxy Filler/Sealer@ 10.0 - 30 .0 mils dft/ct, as required to fill voids andprovide a continuous substrate.1 ct .Corothane I IronOx B @ 3.0 - 5 .0 mils dft1 ct .Corothane I Aliphatic Finish Coat@ 2.0 - 3.0 mils dftPreviously painted surfaces :Spot prime all bare steel with 1 coat Corothane I GalvaPacZinc Rich Primer1 ct .Corothane I IronOx B @ 3.0 - 5.0 mils dft1 ct .Corothane I IronOx A @ 2.5 - 3.5 mils dftSURFACE PREPARATIONSurface must be clean, dry, and in sound condition. Removeall oil, dust, grease, dirt, loose rust, and other foreign materialto ensure adequate adhesion .Refer to product Application Bulletin for detailed surface preparation information .Minimum recommended surface preparation :'" Iron & Steel:SSPC-SP6"" Concrete :SSPC-SP13/NACE 6Previously Painted :SSPC-SP2 or SP3'' Primer requiredTINTINGDo not tint .APPLICATION CONDITIONSTemperature:air and surface:material :20 F minimum, 100 F maximum45 F minimumDo not apply over surface iceCan be applied at relative humidities up to 99% .Relative humidity :Refer to product Application Bulletin for detailed applicationinformation .ORDERING INFORMATIONPackaging:1 and 5 gallon containersWeight per gallon :13 .9 0.2 I bSAFETY PRECAUTIONSRefer to the MSDS sheet before use.The systems listed above are representative of the product'suse. Other systems may be appropriate .Published technical data and instructions are subject to changewithout notice. Contact your Sherwin-Williams representativefor additional technical data and instructions .The statements made herein are based on our research and/or the research of others believed to be accurate .No guarantee of their accuracy is made however, and such statements may be changed without notice .

RECF-11117-DIndustrial;c} NE@ IIRONOX@ B2006.IKCERk .'b P3UMEAUREDDISH GRAYB65A11APPLICATION BULLETINSURFACE PREPARATIONSurface must be clean, dry, and in sound condition . Removeall oil, dust, grease, dirt, loose rust, and other foreign materialto ensure adequate adhesion .Iron & SteelRemove all oil and grease from surface by Solvent Cleaningper SSPC-SP1 . Minimum surface preparation is CommercialBlast Cleaning per SSPC-SP6 . For better performance, useNear White Metal Blast Cleaning per SSPC-SP10 . Blast cleanall surfaces using a sharp, angular abrasive for optimum surface profile (2 mils) . Prime any bare steel the same day as it iscleaned or before flash rusting occurs .Revised 11 /04APPLICATION CONDITIONSTemperature:air and surface:material :Relative humidity :20 F minimum, 100 F maximum45 F minimumDo not apply over surface iceCan be applied at relative humidities up to 99% .APPLICATION EQUIPMENTThe following is a guide. Changes in pressures and tip sizesmay be needed for proper spray characteristics . Always purgespray equipment before use with listed reducer. Any reduction must be compliant with existing VOC regulations andcompatible with the existing environmental and applicationconditions .Poured ConcreteNewFor surface preparation, refer to SSPC-SP13/NACE 6. Surfacemust be clean, dry, sound, and offer sufficient profile to achieveadequate adhesion . Minimum substrate cure is 28 days at 75 F.Remove all form release agents, curing compounds, salts, efflorescence, laitance, and other foreign matter by sandblast- Reducer/Clean Up . . . . . Reducer #15, R7K15ing, shotblasting, mechanical scarification, or suitable chemical means. Refer to ASTM D4260. Rinse thoroughly to achieve Airless SprayPump . . . . . . . . . . . . . . . . 30 :1a final pH between 6.0 and 10 .0 . Allow to dry thoroughly priorPressure . . . . . . . . . . . . 1800 - 2000 psito coating .Hose . . . . . . . . . . . . . . . . . 1/4" IDOldTip . . . . . . . . . . . . . . . . . . .013" - .017"Surface preparation is done in much the same manner as newFilter . . . . . . . . . . . . . . . 60 meshconcrete ; however, if the concrete is contaminated with oils,Reduction . . . . . . . . . . . As needed up to 10% by volumegrease, chemicals, etc., they must be removed by cleaning witha strong detergent. Refer to ASTM D4258. Form releaseagents, hardeners, etc. must be removed by sandblasting, shot- Conventional SprayUnit . . . . . . . . . . . . . . . . Grac oBinksblasting,mechanical scarification, or suitable chemical means.Gun . . . . . . . . . . . . . . . . 90095If surface deterioration presents an unacceptably rough surFluidNozzle.07066/65face, Kem Cati-Coat HS Epoxy Filler/Sealer is recommendedAirNozzle.94766PRto patch and resurface damaged concrete .Atomization Pressure . . 60-70 psi60-70 psiFill all cracks, voids and bugholes with ArmorSeal Crack Filler .FluidPressure.15-20psi15-20 psiAlways follow the ASTM methods listed below:Reduction . . . . . . . . . . . . As needed up to 10% by volumeASTM D4258 Standard Practice for Cleaning Concrete .ASTM D4259 Standard Practice for Abrading Concrete .BrushASTM D4260 Standard Practice for Etching Concrete .Brush . . . . . . . . . . . . . . Natural bristleASTM F1869 Standard Test Method for Measuring MoistureReduction . . . . . . . . . As needed up to 10% by volumeVapor Emission Rate of ConcreteSSPC-SP 13/Nice 6 Surface Preparation of ConcreteRollerCover . . . . . . . . . . . . . 1/4" natural or synthetic withPreviously Painted Surfacesphenolic coreIf in sound condition, clean the surface of all foreign material .Reduction.As needed up to 10% by volumeSmooth, hard or glossy coatings and surfaces should be dulledby abrading the surface. Apply a test area, allowing paint to dryIf specific application equipment is listed above, equivalentone week before testing adhesion . If adhesion is poor, or if thisproduct attacks the previous finish, removal of the previous equipment may be substituted .coating may be necessary. If paint is peeling or badly weathered, clean surface to sound substrate and treat as a new surface as above .Polyurethane5.07Acontinued on back

Industrialand'NPySTRlrEL8 MARINECOATINGSMaineCoatings,LRECEIVEDNOVn n 2006MATERIALS BUREAU5.07ACOROTHANE IIRONOX@ BREDDISH GRAYB65A11APPLICATION BULLETINAPPLICATION PROCEDURESSurface preparation must be completed as indicated.Stir paint thoroughly prior to use with a power agitator . Filterslowly through a 55 mesh screen .Apply paint at the recommended film thickness and spreadingrate as indicated below:Recommended Spreading Rate per coat :Wet mils :5.0-8 .0Dry mils :3.0-5 .0Coverage :195 - 326 sq ft/gal approximateDrying Schedule @ 5.0 mils wet @ 50% RH :@40 F@ 75 F@100 FTo touch:2 hours1 hour20 minutesTo handle :3 hours1-1/2 hours1 hourTo recoat:minimum: 3 hours1-1/2 hours1 hourmaximum: 12 months12 months12 monthsTo cure :4 days3 days1 dayDrying time is temperature, humidity, and film thickness dependent.Application of coating above maximum or below minimum recommended spreading rate may adversely affect coating performance .PERFORMANCE TIPSStripe coat all crevices, welds, and sharp angles to preventearly failure in these areas .When using spray application, use a 50% overlap with eachpass of the gun to avoid holidays, bare areas, and pinholes . Ifnecessary, cross spray at a right angle.Spreading rates are calculated on volume solids and do notinclude an application loss factor due to surface profile, roughness or porosity of the surface, skill and technique of the appiicator, method of application, various surface irregularities,material lost during mixing, spillage, overthinning, climatic conditions, and excessive film build .Excessive reduction of material can affect film build, appearance, and adhesion .In order to avoid blockage of spray equipment, clean equipment before use or before periods of extended downtime withReducer #15, R7K15 .Pour a small amount of Reducer #15, R7K15 over the top ofthe paint in the can to prevent skinning or gelling.Place a temporary cover over the pail to keep excessive moisture, condensation, fog, or rain from contaminating the coating.It is recommended that partially used cans not be sealed/closedfor use at a later date .Corothane KAAccelerator is acceptable for use. See data page5.98 for details.Must be topcoated for exterior use.Refer to Product Information sheet for additional performancecharacteristics and properties .CLEAN UP INSTRUCTIONSClean spills and spatters immediately with Reducer#15, R7K15.Clean tools immediately after use with Reducer #15, R7K15 .Follow manufacturer's safety recommendations when using anysolvent.SAFETY PRECAUTIONSRefer to the MSDS sheet before use.Published technical data and instructions are subject to changewithout notice . Contact your Sherwin-Williams representativefor additional technical data and instructions .The statements made herein are based on our research and/or the research of others believed to be accurate.No guarantee of their accuracy is made however, and such statements may be changed without notice,

face, Kem Cati-Coat HS Epoxy Filler/Sealer is recommended to patch and resurface damaged concrete. Fill all cracks, voids and bugholes with ArmorSeal Crack Filler. Always follow the ASTM methods listed below: ASTM D4258 Standard Practice for Cleaning Conc