Transcription

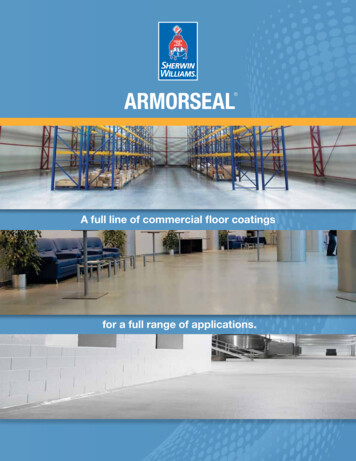

ARMORSEAL A full line of commercial floor coatingsfor a full range of applications.

A solid foundation fora dependable floor.You want your floor coating to look good, performto your requirements and last long. But each floor isdifferent, so choosing products that will work best foryour application is critical.Sherwin-Williams has the answer. Our full line ofArmorSeal Heavy Duty Floor Coatings will stand up toanything from light foot traffic in retail stores to facilitieswith heavy vehicular traffic. And like every product weoffer, ArmorSeal is backed by more than 145 years ofexperience and innovation — along with the support ofmore than 3,400 stores across North America.Consider your needs. Then explore the variety ofproducts within the ArmorSeal line using the easy-tocompare charts, performance guides and applicationrecommendations in this brochure.

Quick Reference for Common RecommendationsTo make selecting the right products easy, Sherwin-Williams has paired some common applicationswith appropriate ArmorSeal products. A standard and premium option are provided for each. If you havea more-specific project or think your floor requires even greater durability, Sherwin-Williams offers moreadvanced products. Contact your local sales representative for details.STANDARD PERFORMANCEPrimerTopcoatPREMIUM PERFORMANCEPrimerTopcoatLIGHT FOOT TRAFFICApplication areas: Offices, janitorial closets, back rooms, service corridors and areas subject to light foottraffic or hand cartsWarehouse & StorageTread-Plex PrimerTread-Plex AcrylicWater Based Coating1000HS*1000HS* orHS PolyurethaneRetail, Healthcare General,Schools GeneralTread-Plex PrimerTread-Plex AcrylicWater Based Coating1000HS*1000HS* orHS PolyurethaneLIGHT TO MODERATE TRAFFICApplication areas: Service areas, restrooms, locker rooms, aisleways, cafeteria floorsFloor-Plex 7100 PrimerWater Based Epoxy*1K Urethane33 EpoxyPrimer/Sealer650 SL/RC* orHS PolyurethaneAutomotive Service Areas,Schools, Restrooms,Locker Rooms1000HS*Rexthane I33 EpoxyPrimer/Sealer650 SL/RC* orHS PolyurethaneAuditoriums,Convention Centers1000HS*1000HS*33 EpoxyPrimer/Sealer650 SL/RC* orHS PolyurethaneFloor-Plex 7100 PrimerWater Based Epoxy*Floor-Plex 7100*1000HS*1000HS* orHS PolyurethaneAutomotive ShowroomsAmusement Parks & ZoosMODERATE TO HEAVY VEHICLE TRAFFICApplication areas: Aisleways used for heavy fork trucks with rubber and steel wheels, high-traffic wearareas, loading docksManufacturing,Warehouses, Retail Areaswith Fork Trucks, LoadingDocks (Optional nonskidadditive)1000HS*1000HS*33 EpoxyPrimer/Sealer650 SL/RC* orHS PolyurethaneAutomotive Service Bays,Airplane Hangars1000HS*Rexthane I33 EpoxyPrimer/Sealer650 SL/RC* orHS Polyurethane*These products are for interior use only.

ARMORSEAL

ARMORSEAL Product FeaturesFrom color options to cleanup methods, ArmorSeal products offercharacteristics that suit nearly any application need—including yours.PRIMERSProtective & MarineCoatingsProtective & MarineCoatingsProtective & EX 7100Armorseal Water Based Floor Epoxy Primer/SealerCLEARWater Based Acrylic FloorPRIMERB90W110Water Based EpoxyPRIMERPart A B70VQ10Part B B60VQ10Part A B70W410Part B B70V400DESCRIPTIONGeneral-purpose, 100% acrylic,interior and exterior floor primer.When topcoated, it provides a tough,alkali-resistant finish which willwithstand hard wear, abrasion,grease, oils and cleaning equipment.A 38% solids primer, compatiblewith most high-performance finishcoats and, in many cases, can beused as an effective barrier coatwhen coating previously paintedsurfaces. Can also be used asa primer for damp concrete ormasonry surfaces.A heavy-duty, low-VOC, low-odor,two-component, catalyzed,waterborne, polyamide epoxy floorprimer. Provides overall performancecomparable to that of mostsolventborne epoxy floor systems.Designed for use under ArmorSealfinish coats.Features Fast-drying Water cleanup Enhances adhesion by penetratingconcrete E xcellent surface-wettingproperties Outstanding application properties Abrasion-resistant Fast-drying Excellent adhesion Chemical-resistant Impact-resistant Solvent-resistant Dry heat-resistant P enetrates into concrete topromote adhesion W ater cleanup O utstanding application propertiesFinishLow SheenGlossLow GlossPackage Color(s)Off WhiteClearOff WhiteNoNoNo 100 g/L 250 g/L 250 g/Lcustom colorsStandardscomplianceAs of 04/30/12IM Industrial Maintenance CoatingsOTC IM 340 g/LYesOTC IM 340 g/LYesOTC IM 340 g/LYesSCAQMD IM 100 g/LYesSCAQMD IM 100 g/LNoSCAQMD IM 100 g/LNoCARB IM 250 g/LYesCARB IM 250 g/LYesCARB IM 250 g/LYesCanada IM 340 g/LYesCanada IM 340 g/LYesCanada IM 340 g/LYesLighter foot traffic

Protective & MarineCoatingsTOPCOATSProtective & MarineCoatingsProtective & l 33 Armorseal 1K Water Based Floor Epoxy PrimerLIGHT GRAYProtective & MarineCoatings Epoxy Primer/SealerLIGHT GRAY - EPOXYWater Based Urethane Floor EnamelEXTRA WHITEWater Based AcrylicWHITEPart A B70AQ11Part B B60VQ11Part A B58AQ33Part B B60VQ33B90 SeriesB65-700 SeriesAn 87% solids primer, compatible withmost high-performance finish coatsand, in many cases, can be used as aprimer for damp concrete or masonrysurfaces.Low-viscosity, 100% solids, high-build,fast-cure, epoxy primer designed foruse under ArmorSeal 650 or where ahigh-build primer is needed.A one-component general-purpose,interior and exterior waterbornefloor coating. This dries rapidly to atough, alkali-resistant finish whichwill withstand hard wear, abrasion,grease, oils and cleaning equipment.High-performance, one-componentpolyester water-based urethane,formulated specifically for industrialfloor applications. Providesoutstanding abrasion resistanceand good chemical resistance withexcellent color and gloss retention.Performance comparable to twocomponent waterbased urethane. Abrasion-resistant Fast-drying Excellent adhesion Chemical-resistant Impact-resistant Solvent-resistant Dry heat-resistant Penetrates into concrete topromote adhesion Outstanding application properties Fast-drying Water cleanup Slip-resistant properties Abrasion-resistant Fast-drying Impact-resistant Abrasion-resistant Resistant to hot tire pickupSatinGlossSemi-GlossGlossLight GrayLight Gray, ClearDeck Gray, Haze Gray, Tile Red, WhiteHaze Gray, Clear, Extra WhiteNoNoYes, EnviroToners and Blend-A-ColorYes, EnviroToners 340 g/L 50 g/L 100 g/L 250 g/LOTC IM 340 g/LYesOTC IM 340 g/LYesOTC IM 340 g/LYesOTC IM 340 g/LYesSCAQMD IM 100 g/LNoSCAQMD IM 100 g/LYesSCAQMD IM 100 g/LYesSCAQMD IM 100 g/LNoCARB IM 250 g/LNoCARB IM 250 g/LYesCARB IM 250 g/LYesCARB IM 250 g/LYesCanada IM 340 g/LYesCanada IM 340 g/LYesCanada IM 340 g/LYesCanada IM 340 g/LYesHeavier floor trafficLighter foot traffic

Protective & MarineCoatingsArmorsealFLOOR-PLEX 7100Protective & MarineCoatingsArmorseal1000HS Epoxy Floor CoatingWHITE/TINT BASEWater Based EpoxyWHITEProtective & MarineCoatingsArmorsealREXTHANE IProtective & MarineCoatingsArmorseal650 SL/RCArmorseal HS Polyurethane Floor EnamelHAZE GRAYMoisture Cure UrethaneWHITE/WHITE TINT BASEProtective & MarineCoatingsEpoxy – Self LevelingWHITE TINT BASEPart A B70-400 SeriesPart B B70V400Part A B67-2000 SeriesPart B B67V2002B65-60 SeriesPart A B65-220 SeriesPart B B65V220Part A B58-650 SeriesPart B B60VQ655Heavy-duty, interior,VOC-compliant, low-odor,two-component, catalyzed,waterborne, polyamide epoxyfloor coating. Product driesrapidly to an extra-tough glossfinish which will withstandheavy industrial traffic,abrasion and generalchemical attack.A high-solids, heavy-duty,two-component, catalyzed,polyamide epoxy coatingformulated for demandingindustrial requirements. Thisdries rapidly to a tough, highgloss finish with excellentresistance to alkalis, abrasion,corrosion and chemical attack.High-solids, single-component,aliphatic, moisture-cureurethane, VOC-complying,moisture-resistant industrialfloor coating. This urethanecoating cures to a high-glossand chemical-resistant filmequivalent to two-parturethane coatings.Two-component, heavy-duty,exterior/interior, low-VOC,high-solids, polyester aliphaticurethane industrial floorcoating. Provides a high gloss,excellent chemical resistance,color retention and chalkresistance.100% solids, self-leveling,recoatable epoxy, twocomponent, heavy-dutyfloor system that provides ahigh-gloss, seamless, hygienicsurface that is extremelyhard-wearing and durable. Chemical-resistant Impact-resistant Abrasion-resistant Resists yellowing Low-odor Chemical-resistant Impact-resistant Abrasion-resistant Outstanding applicationproperties Chemical-resistant Impact-resistant Abrasion-resistant Resists yellowing Fast hardness development Fast-drying Slip-resistant Abrasion-resistant Chemical-resistant Impact-resistant Abrasion-resistantGlossGlossGlossGlossGlossDeck Gray, Haze Gray,Tile Red, WhiteDeck Gray, Haze Gray,Tile Red, Safety Yellow,Sandstone, Clear, WhiteDeck Gray, Haze Gray,Sandstone, Clear, WhiteHaze Gray, Clear,Extra WhiteDeck Gray, Tile Red,Haze Gray, Sandstone,Clear, WhiteYes, EnviroToners Yes, MaxitonersYes, MaxitonersYes, MaxitonersYes, Maxitoners 250 g/L 340 g/L* Colors only 400 Clear 300 g/L 250 g/L 100 g/LOTC IM 340 g/LYesOTC IM 340 g/LSCAQMD IM 100 g/LNoCARB IM 250 g/LCanada IM 340 g/LYes* / NoOTC IM 340 g/LYesOTC IM 340 g/LYesOTC IM 340 g/LYesSCAQMD IM 100 g/L No* / NoSCAQMD IM 100 g/LNoSCAQMD IM 100 g/LNoSCAQMD IM 100 g/LYesYesCARB IM 250 g/LCARB IM 250 g/LNoCARB IM 250 g/LYesCARB IM 250 g/LYesYesCanada IM 340 g/L Yes* / NoCanada IM 340 g/LYesCanada IM 340 g/LYesCanada IM 340 g/LYesNo* / NoHeavier floor traffic

ARMORSEAL PerformanceCharacteristicsApplication methods vary. So does the level of performance you may need. Let us helpyou determine the product type, the time and the tools necessary to get your job done.PRIMERSTread-Plex PrimerWater BasedEpoxy Primer/Sealer ClearFloor-Plex 7100Primer WaterBased EpoxyWater BasedEpoxy PrimerLight Gray33 EPOXYPRIMER/SEALER2.85-to-1 by volumeMix RatioSingle component4-to-1 by volume1-to-1 by volume4-to-1 by volumeApplicationmethodBrush or roll using anylon/polyester brushor a ¼" or 3 8" softwoven, solvent-resistantcore roller coverBrush or roll using anylon/polyester brushor a 3 8" or ½" softwoven, solvent-resistantcore roller coverBrush or roll using anylon/polyester or naturalbristle brush or a ¼" or3 8" soft woven, solventresistant core roller coverSpread with rubbersqueegee and back rollwith a 3 8" soft woven,solvent-resistant coreroller coverSpread with rubbersqueegee and back rollwith a 3 8" soft woven,solvent-resistant coreroller coverRecommendedSpread Rate341 – 458 sq. ft./gal200 – 300 sq. ft./gal368 – 490 sq. ft./gal200 sq. ft./gal200 sq. ft./gal1.5 – 2.0 mils2.0 – 3.0 mils1.5 – 2.0 mils5.0 – 7.0 mils8.0 milsNoneNone15 minutesNoneNoneNA6 – 8 hours6 hours30 minutes30 minutes30 minutes1 – 2 hours45 minutes4 – 6 hours4 – 6 hoursto Foot Traffic8 hours–48 hours––to Heavy Traffic18 hours–72 hours––Recoat window@77 F45 minutes6 – 48 hours8 hours – 30 days6 – 48 hours6 – 24 hoursOdor (slight,moderate, strong)*SlightModerateSlightModerateSlightMeets ADArequirementsNoNoNoNoNoExterior UseYes(Topcoat w/ exterior product)(Topcoat w/ exterior product)(Topcoat w/ exterior product)YesYesEASE OFAPPLICATION**HHHHHHHHHHPrep CategorySealerSealerSealerThin FilmThin FilmDry FilmthicknessSWEAT-IN TIME@77 FPot LifeDry @77 Fto TouchLighter foot traffic*NOTE: High-odor products have a longer return-to-service time.YesYes(prepackaged units)Heavier floor traffic**Ease-of-application key: Least difficult H Some difficulty HH More difficult HHH Most difficult HHHH

TOPCOATSTread-Plex ACRYLIC WATERBASED COATING1K UrethaneFloor-Plex 7100Single componentSingle component1-to-1 by volume1-to-1 by volumeSingle component2-to-1 by volumeBrush or roll usinga nylon/polyesterbrush or a ¼" or 3 8"soft woven, solventresistant core rollerBrush or roll usinga nylon/polyesterbrush or a ¼" or 3 8"soft woven, solventresistant core rollerBrush or roll usinga nylon/polyester ornatural bristle brush ora ¼" or 3 8" soft woven,solvent-resistant coreroller coverBrush or roll usinga nylon/polyester ornatural bristle brushor a 3 8" soft woven,solvent-resistant coreroller coverBrush or rollusing a naturalbristle brushor a mohairroller coverBrush or rollusing a ¼" softwoven rollercover or a naturalbristle brushRubber squeegee andcross-roll with a 3 8"soft woven roller. After20-30 minutes, spikeroll. Don't spike rollafter 40 minutes328–437 sq. ft./gal 206–350 sq. ft./gal 358–537 sq. ft./gal 380–570 sq. ft./gal50–160 sq. ft./gal345–460 sq. ft./gal 136–272 sq. ft./gal1000HSRexthane IHSPolyurethane650 SL/RC2 components(prepackaged units)1.5 – 2.0 mils1.0 – 4.0 mils1.5 – 2.0 mils3.0 – 5.0 mils2.0 – 3.0 mils2.0 – 3.0 mils10.0 – 30.0 milsNoneNone30 minutes30 minutesNoneNoneNoneNANA4 hours4 hoursNA4 hours40 minutes30 minutes45 minutes1 hour2 hours2 hours2 hours6 –12 hours8 hours8 hours24 hours24 hours24 hours12 hours24 hours18 hours18 hours72 hours48 –72 hours3 days72 hours72 hours4 hours6 hours – 30 days8 hours – 30 days8 hours –7 days9 hours –14 days12 – 48 hours8 –72 HHHHHHHHHHHHSealerThin FilmSealerThin FilmSealerSealerHigh BuildLighter foot trafficHeavier floor traffic

ARMORSEAL The Importanceof Surface PreparationProper preparation ensures adhesion and will prolongthe service life of your floor coating system.Selecting the proper preparation methods will depend on factors including the condition of the substrate,the environment and the ArmorSeal products you’ve selected. One or more of the methods listed belowmay be necessary. If you have any questions, consult your Sherwin-Williams representative.1DETERMINE THE PREP CATEGORYFOR YOUR PRODUCTARMORSEAL PRODUCTPRODUCT TYPECATEGORYPRODUCT DRY FILMTHICKNESSSEALERTread-Plex PrimerWater Based Epoxy Primer/Sealer ClearTread-Plex Acrylic Water Based CoatingFloor-Plex 7100 Primer Water Based EpoxyFloor-Plex 7100Rexthane IHS Polyurethane0 – 3 milsTHIN-FILMWater Based Epoxy Primer Gray33 Epoxy Primer/Sealer1K Urethane1000HS4 –10 milsHIGH-BUILD650 SL/RC10 – 40 milsNOTES:Order ICRI chips through a Sherwin-Williams store or representative.Always refer to the product data sheet and product application bulletin for detailed surface preparation information.

Up to 80% of all coating failures can be attributed toinadequate surface preparation. Let Sherwin-Williamshelp you achieve a sound surface.2PROPERLY CLEAN CONCRETE SURFACE andachieve appropriate concrete surface profileRemove all oil, dust, grease, dirt and other foreign materials to ensure adequate adhesion.Follow the SSPC-SP13/NACE 6 standard for concrete surface preparation.CONCRETE SURFACE PROFILE (CSP) REQUIREDICRI CHIPS AS REFERENCED BELOW (Archway #1100120)CSP #1-3CSP #3-5Archway #110 0120CSP #1-3Acceptable Methods of Preparation· scrubbing· low-pressure water· sand-blasting· diamond grind· scrubbing· low-pressure water· sand-blasting· shot-blasting· diamond grind· sand-blasting· shot-blasting· scarifying· needle-scaling· diamond grindYour Sherwin-Williams representative can review surface preparation with you using:—The SSPC (The Society of Protective Coatings) SP13/NACE 6 surface preparation standard. More information available at sspc.org.—The ICRI (The International Concrete Repair Institute) No. 03732 CSP1-5. More information available at icri.org.

Make your floor stand out with color and style.ArmorSeal delivers more than high performance; it delivers great looks. Choose from popular packagecolors, a wide range of custom colors or a clear finish to give your floor outstanding aesthetics.Haze GrayDeck GraySandstoneTile RedSafety YellowWhiteClearSandpoint989-7919Pearl Gray6403-69583ArmorQuartz A Decorative Broadcast Color Quartz SystemCharcoal6403-69567Riverstone6403-69591Gray Fox6403-69518Mt. Sage980-0764Bramble932-1340This reproduction approximates the actual color. Factors such as the type of product, degree of gloss,texture, size and shape of area, lighting, heat or method of application may cause color variance.These 50 lb. bags available through General Polymers.Flintrock932-3668Taco Red989-7927H&C Holographic and Deco-FlakesPewter Blend898-2712Beige/Ivory Blend898-2720Red Blend898-2738Green Blend6501-22864Holographic Blend6501-24951 Provides a unique decorative finish and helps hide imperfections Adds extra traction Various chip blends for a distinct look for mixing and matching Deco-Flakes available in quarts; Holographic Flakes in 1-oz. packagesH&C Holographic and Deco-Flakes available through the DSC. Additional colors available in 50 lb. bags through General Polymers at 1-800-797-8010, option 2.

ARMORSEAL Improve Your Results.To help you achieve the best results possible on your job, Sherwin-Williams alsooffers a full line of complementary products to help you complete the job.ArmorSeal ExpressPatchDesigned to repair and protect concrete and masonry substratesfrom thermal shock, impact, corrosion, mild chemical attackand abrasion. 100% solids Low-odor, water-based urethane slurry floor patch kit Does not support microbial growth Fast return to service — foot traffic in six hours Low temperature cure Can be applied to damp concreteArmorSeal Crack FillerDeveloped specifically for sealing, smoothing and fairingapplications on concrete, metals, plastics (FRP) wood or masonry. Two-component, fast-set epoxy paste Non-sagging — suitable for vertical and horizontal surfaces Resists salt water, oils, fuels, and many other chemicals Concrete/masonry use: fill and smooth hairline cracks,bug holes, anchor-bolt holes, gouges or divots Steel/metal use: smooth welds, pits, rough surfaces,irregularities, and seamsArmorSeal Flexible Joint Sealantswarmorseal.comA resilient filler for horizontal expansion joints that delivers excellentflexural strength and elongation while maintaining tensile strength. Two-component polymer hybrid Good adhesion and flexibility over a wide temperature range Use to fill and seal narrow masonry control joints and grooves Helps prevent damage to the joint and its edgesFor additional details, seeyour Sherwin-Williams storeor representative, or call800-524-5979 to have arepresentative contact you.ArmorSeal 5020 EpoxyFloor ResurfacerA trowelable, high-build epoxy floor resurfacer designed forconcrete, wood and steel substrates that require a high degree ofchemical and abrasion resistance. Ideal for high traffic areas Suitable for use in USDA-inspected facilities For new and old floors of concrete, wood or steel Excellent abrasion and impact resistance

ARMORSEAL Product Ordering GuideProduct/ColorRex #Sales #Size/FillHow PackagedExtra WhiteB65W775ClearB65C775Clear Tint BaseB65T775Haze 66403-659536403-659616403-659796403-659871 gal5 gal1 gal5 gal1 gal5 gal1 gal5 gal4 gal cans per box5 gal pail4 gal cans per box5 gal pail4 gal cans per box5 gal pail4 gal cans per box5 gal 46403-853081 gal5 gal1 gal5 gal1 gal5 gal1 gal5 gal1 gal5 gal4 gal cans per box5 gal pail4 gal cans per box5 gal pail4 gal cans per box5 gal pail4 gal cans per box5 gal pail4 gal cans per box5 gal pailB67C20006401-203096401-203171 gal5 gal4 gal cans per box5 gal pailB67A20006401-203331 gal4 gal cans per boxB67R20006401-203411 gal4 gal cans per boxB67A20016401-203586401-735481 gal5 gal4 gal cans per box5 gal pailB67H20006401-203661 gal4 gal cans per 31 gal5 gal1 gal5 gal4 gal cans per box5 gal pail4 gal cans per box5 gal pailB67Y20006401-203821 gal4 gal cans per boxB67V20026401-204086401-735551 gal5 gal4 gal cans per box5 gal pai

HS Polyurethane Auditoriums, Convention Centers 1000HS* 1000HS* 33 Epoxy Primer/Sealer 650 SL/RC* or HS Polyurethane Amusement Parks & Zoos Floor-Plex 7100 Primer Water Based Epoxy* Floor-Plex 7100* 1000HS* 1000HS* or HS Polyurethane LIGHT TO MODERATE TRAFFIC Application areas: Service ar