Transcription

Best Practice Approaches to ImprovingClinical Supply Chain ManagementMatthew DoClient Development LeadAlmac Pharmaceutical Services

A variety of challenges complicate trialsupply managementMultiple languagesCountry-specificregulationsLack of historical data tocreate accurate forecastsLogistical challenges intransporting anddistributing trial drugShorter timelines for patientenrollmentComplex protocolsSupplyChallengesCross vendor alignment

A new model is needed to drive greaterquality, speed and efficiencyINITIATIONEXECUTIONCLOSEOUTSupply PlanningTrial Execution Tech Set-Up istributionStrategyIntegrated processes and tools can improve visibility and enable optimalexecution across the entire supply chain – and throughout the life of your trial

Proper supply planning is a critical firststep in the processIdentify KeyStakeholdersGather Information Randomization designDefine Roles andResponsibilities IRT Treatments Governance chart Quality Visit schedule Technical agreement Regulatory Unblinding procedures Project plans CRO Ancillary and concomitantsupplies Deliverables checklist CMO Clinical Team Drug Management Team Sample size, patient,duration Standardized and processflows

Lessons learned from prior trials set thestage for future successPlan forsuccess! Form strategic partnerships across functional teams toreduce risk, time and cost Have pre-defined working processes for outsourcingstakeholders Be actively engaged in timeline management acrosscross-functional deliverables Establish well-coordinated import/export applications Understand that IRT delays can negatively impact whensupplies can be shipped, which can impact First PatientFirst Visit (FPFV) milestones – get started on this as earlyas possible!

Establishing a baseline forecastinforms manufacturing and distributionA forecast predicts demand based on clinical events and patientactivity in the clinical trial supply chain over a period of timeReduces the Riskof Stock-OutsManages – andMinimizes – CostOptimizesInventory andMaintains Balance

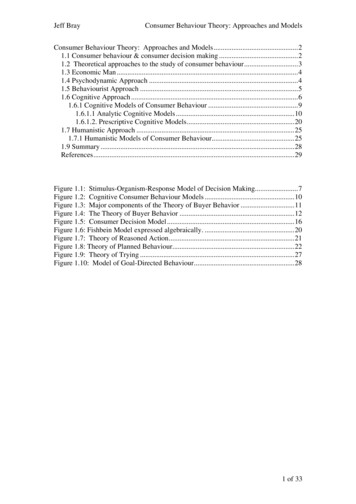

Steps to forecast generation1ESTABLISH A DATA COLLECTION PLAN Outlines which study variables will drive product demand A baseline is then established to inform manufacturing anddistribution plans2UTILIZE EXPERIENCE If assumptions are used, rely on historical data of regional clinicaltrials to ensure accurate forecasting and baseline generation.3MAKE ADJUSTMENTS Using IRT throughout the study to refresh the baseline forecast basedon real-time data Variances from the forecast can be detected and used to optimizeshipping/distribution

Packaging design is another area thatshould be addressed early-onKEY CONSIDERATIONSPRODUCT TYE: Comparator and study drug will be blistered and in walletsPATIENT COMPLIANCE: Need to reduce the possibility of over dosing as much aspossibleSITE COMPLIANCE: Ambient storage (if possible) / clean and neat kit designBLINDING: Indicating the strength of comparator will not unblind the studyCOST: Comparator is relatively expensiveCOUNTRIES: Country specific requirements. i.e., booklet labels, child resistantrequirementsVISIT SCHEDULE: Quantity and kit configurationSHELF LIFE: Potential of expiry updating

When distribution is optimized, ‘just enough’investigational product is on handFor best results, begin planning when the protocol is still under developmentIdentifystudymilestonesthat sticaldetails thatmay impactdeliveryPerform athoroughrisk analysisDesign asystem thatdeliversrequisitesupplyAdjustsupplybased onshiftingdemand andenvironmental factorsWhen the proper ordering, tracking, and information-sharing processes arein place within the IRT, every function along the way can monitor supply anddemand, working proactively to forestall potential issues

Supply distribution considerationsMeeting import/exportregulationsMinimizing transportationcostMaintaining temperaturestability across climaticzonesComplying with return anddestruction regulations

IRT plays a central role in supplymanagementMonitor Depots andSite InventoryEnrollment/RandomizationIRTVisit Schedule/Drug AssignmentResupplyRequests

Technology should link and integratekey supply management activitiesActual patient event data considered in net forecastForecasting / SimulationMRPInitial forecast› Projected patient demand› Visit schedule› Protocol variables› Scenario comparisonsCreates planned production ordersbased on:› Forecast› Safety stock› Pending production orders› Existing inventory› Site inventory› Item bill of materialsNet forecast inputs› Site inventory› Patients dispensing events› Expiry dateData Integration with IRT (IVRS/IWRS)Inventory Release FileDrug OrdersPatient Event DataManufacturing PlanDistributionDispensingDetailed component planningDepots and sitesTo patientsVendor and depot inventory considered by MRPInventory at or in transit to sites considered in net forecastEnables greater visibility and accuracy across the entire supply chain

Automate execution and reporting toimprove decision-makingGet Real-time viaReportsAdjust settingsin IRT andupstreamprocessCollect, collateand analyze dataMake decisionsto optimizedemand andreduce IPwastage

A partnership model can help sponsorswho lack internal resourcesSystem and procedures must ensure both quality and efficiencyGlobal footprintDemonstrated stability and maturity in the industry over timeProven technology to support the processResponsive service and proactive communicationsFlexible offerings that can be customized, if needed

SummaryTaking a more strategic approach to supply chain managementcan pay dividends later onKey benefits include reduced drug wastage, fastertimelines, and lower costStart with an overall supply plan and central projectmanager, then develop follow-on plans, e.g., forecastingIRT is a critical success factor in proper supplymanagementPartnering may be an option, especially for less experiencedsponsors

Questions?

Thanks for attending For more information:– Matt Do: matthew.do@almacgroup.com– www.almacgroup.com

A forecast predicts demand based on clinical events and patient activity in the clinical trial supply chain over a period of time Reduces the Risk of Stock-Outs Manages – and M