Transcription

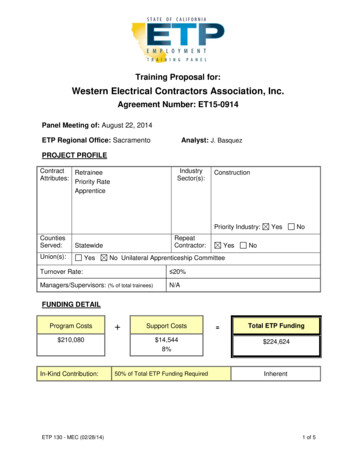

Training Proposal for:Western Electrical Contractors Association, Inc.Agreement Number: ET15-0914Panel Meeting of: August 22, 2014ETP Regional Office: SacramentoAnalyst: J. BasquezPROJECT PROFILEContractRetraineeAttributes:Priority ty tContractor:YesYesNoNoNo Unilateral Apprenticeship CommitteeTurnover Rate: 20%Managers/Supervisors: (% of total trainees)N/AFUNDING DETAILProgram Costs 210,080In-Kind Contribution:ETP 130 - MEC (02/28/14) Support Costs 14,5448%50% of Total ETP Funding Required Total ETP Funding 224,624Inherent1 of 5

WECAAugust 22, 2014ET15-0914TRAINING PLAN TABLEJobNo.1Job DescriptionType of TrainingCommercial SkillsOSHA 10RetraineeApprenticeRange ofEstimatedHoursNo. ofTrainees Class / CBTLab1018-2100AveragePostCost per RetentionTraineeWage 2,224 20.32Weighted Avg:160Minimum Wage by County: 20.32 per hour Statewide (Priority Industry)Health Benefits:Yesmedical, dental, vision.This is employer share of cost for healthcare premiums –NoUsed to meet the Post-Retention Wage?:YesNoMaybeUp to 3.58 per hour may be used to meet the Post-Retention Wage.Wage Range by OccupationOccupation TitlesApprentice Commercial ElectricianWage RangeEstimated # ofTrainees101INTRODUCTIONIn this proposal, Western Electrical Contractors Association, Inc. (WECA) seeks funding forretraining of Commercial Electrician Apprentices.Incorporated in 1937, WECA is a statewide nonprofit organization serving independent meritshop electrical contractors, their employees and the electrical industry. WECA is a UnilateralApprenticeship Committee (UAC) which is a Trust formed and funded by the membership ofemployers to provide Division of Apprenticeship Standards (DAS) approved training. WECAoffers federal and state approved commercial, residential, and voice-data-video apprenticeshipprograms as well as continuing education courses, exam prep, and a state- approved ElectricianTrainee Program. The 5-year program was created by, and is governed by, a UnilateralApprenticeship & Training Committee. Industry needs are jointly determined by the Committee,their staff and the members of the Association.Contractors need skilled workers to replace their aging workforce. WECA’s apprenticeshipprovides individuals entering the electrical industry a career path to becoming a Journeymanworker. A majority of WECA member contractors work on public works projects where thecontractors are required by California law to employ Apprentices proportionate to Journeymen.WECA dispatches Apprentices to electrical contractors throughout California.WECA’s Apprenticeship Programs provide individuals with the knowledge and skills they need tobe successful in their chosen trade. Inside Wireman, Residential Wiremen, or Sound andCommunication Technician are the occupations included within the Commercial ElectricianETP 130 - MEC (02/28/14)2 of 5

WECAAugust 22, 2014ET15-0914apprenticeship program by combining hands-on learning with Related and SupplementalInstruction (RSI).Apprenticeship PilotThe Panel is authorized to fund Apprentice training that does not displace any other source ofgovernment funds, or replace an existing apprenticeship program approved by Division ofApprenticeship Standards (DAS). The Apprenticeship Training Pilot allows funding for programssponsored by a Joint Apprenticeship Training Committee (JATC) or other program (UACsponsor registered with the DAS).The Panel provides reimbursement for the Related and Supplemental Instruction (RSI) portion ofan apprenticeship training program. RSI is delivered as class/lab training that is developed witha Local Educational Agency (LEA) and approved by DAS. In this case, there are three LEAs:San Joaquin County Office of Education, San Juan Unified School District and Central CountyOccupational Center. The Pilot reimburses up to 200 hours of RSI plus OSHA 10.For building trades where it is not customary for workers to be employed for 90 consecutive dayswith one employer, the Panel may substitute hours worked for retention. The modified retentionperiod must be no less than 500 hours within 272 days with more than one employer. WECA isrequesting this modified retention period.To ensure ETP does not displace Montoya Funds, Apprenticeship Pilot reimbursement isreduced by 5.00, reducing the priority industry rate from 18.00 to 13.00 per hour. The ETPwage for Apprentices is 20.32 per hour in FY 2014/15. This is the Special EmploymentTraining statewide wage as modified for priority industries which is being used for all Apprenticeoccupation for ease of administration.DAS Completion RatesThe completion rates for WECA apprentices in the five-year period 2008-2012 was 49.85%, ascompared to overall industry average of 66.81%, according to DAS records. The gap of some17% is explained by WECA as follows:WECA has strict compliance standards and if an apprentice does not adhere, theirapprenticeship is terminated. In addition, the downturn in the construction industry forced someapprentices to leave the program and find work in other areas. These terminations and voluntaryquits resulted in lower graduation rates. WECA works closely with DAS and has no outstandingretention issues.PROJECT DETAILSProgram participants will learn or enhance skills on how to inspect, install, troubleshoot andrepair electrical components and systems. The proposed training is entirely center-based and isscheduled to begin in September 2014.Training PlanCommercial Skills (95%) - Training will be offered to Commercial Electrician Apprentices toallow completion of 2nd semester through 5th year semester-lab training on circuits,transformers, motors, capacitors and basic principles of electricity.OSHA 10 (5%) - OSHA 10 training is a series of courses “bundled” by industry sector andoccupation. It consists of 10 hours of training for journey-level.ETP 130 - MEC (02/28/14)3 of 5

WECAAugust 22, 2014ET15-0914This training is not required as a condition of doing business in California. However, thecoursework must be approved by, and the instructors must be certified by Cal-OSHA.Completion of the training results in a certificate that expands employment opportunities. Toensure that each trainee receives certification, ETP will only consider payment earned uponcompletion of the full 10-hour. OSHA 10 is not included in the 10% limitation on safety training.Commitment to TrainingSafety training is, and will continue to be, provided by the participating employers in accordancewith all pertinent requirements under state and federal law. Training CoordinatorAll training will be center based at WECA training centers throughout the State, delivered byexperienced, in-house journeyman staff with formal instruction in training methods and subjectmatter.Electronic RecordkeepingWECA uses a recordkeeping system (“WECA Base”) to track the training. This system hasbeen in place since 2005. ETP has reviewed and approved this system for purposes of trackingthe delivery of ETP-funded training.Impact/OutcomeApprentices trained under this proposal will be certified as Journeymen Electricians once theycomplete the entire apprentice curriculum.Marketing and Support CostsEmployers participate as members of the UAC that operates WECA. All RSI training isdesigned to address their particular needs, and the general needs of the industry. WECA has acontinued relationship with EDD One-Stop offices throughout the State. WECA brochures areplaced in one-stops and WECA participates in work placement activities as invited. WECA alsoattends various job fairs targeting Veterans and females.WECA conducts assessments at the conclusion of each training session to evaluate trainingneeds and program effectiveness. Trainees and employers then provide feedback through theirrespective representatives on the UAC.WECA is requesting 8% in support costs for recruitment of new employer members andapprentices throughout the State by active membership drives, advertising and attendance atjob/career fairs and print advertising. Staff recommends the 8% support costs.RECOMMENDATIONStaff recommends approval of this proposal.ACTIVE PROJECTSThe following table summarized performance by WECA under an active ETP Agreement:ETP 130 - MEC (02/28/14)4 of 5

WECAAugust 22, 2014AgreementNo.ApprovedAmountET13-0905 sed on ETP Systems, 24,772 reimbursable hours have been tracked for potential maximum earningsof 322,036 (100% of approved amount). The Contractor is within the last 90 days of the end term dateof the Agreement. It has completed all training and will complete the remainder of retentions by the endterm date of the Agreement.DEVELOPMENT SERVICESN/AADMINISTRATIVE SERVICESN/ATRAINING VENDORSN/AETP 130 - MEC (02/28/14)5 of 5

WECAET15-0914Exhibit B: Menu CurriculumClass/Lab Hours24-210Apprentices may receive any of the following:COMMERCIAL SKILLS2nd Year 1st Semester: Day 1 - Branch Circuits & Feeders Day 2 - Conductors & Over Current Protection Day 3 -Wiring Methods, Wiring Materials, Raceways & Boxes Day 4 - Grounding Day 5 - Midterm Review Day 6 - Wiring Materials Switches Panel & Switchboards Day 7 - Dwelling Load Calculations Day 8 - Load Calculations Cont. Demand Factor Calculations Day 9 - Introduction to Motors Day 10 - Semester Review & Final Exam2nd Year 2nd Semester: Day 1 - Ohms Law Review, Parallel Circuit, Triangles Day 2 - Magnetic Induction, AC Inductance, ResistiveInductive Series Circuits/Parallel Circuits Day 3 - Capacitors, AC Circuit, Series Circuit/Parallel Day 4 - Resistive Inductive Capacitance Series/ParallelCircuits Day 5 - Midterm Exam Day 6 - Three Phase Circuits/Transformers Day 7 - Transformers, Size Primary, DC Generators/Motors Day 8 -Three Phase Alternators/Phase Motors/Single PhaseMotors, Code and Sizing the Circuit Day 9 - Motors, Wiring a Single and Three Phase Motor Day Final Exam3rd Year 1st Semester: Day 1 - Welcome and Course Overview, HarassmentPrevention, Using the NEC, Hazard Communications (readingMSDS), CPR Day 2 - The Design-Construction Process, ConstructionDocuments: Types and Functions, In-Class Assignment: UsingConstruction Documents, Construction Plans Walk-Through Day 3 - Scales, In-Class Lab: Using Architectural Scales,Plans, Elevations, and Symbols, In-Class Assignment: CivilPlans, Preparing for Electrical Underground, Optional In-ClassLab: POCO Primary Conduit Material Estimation Day 4 - Structural Sheets, Footings, Foundations, Walls,Parallel Conductors, Conduit Sizing, and EquipmentGrounding in Parallel, In-Class Assignment: Conductors inETP 100 Exhibit B Menu Curriculum (02/13/12)1 of 6

WECAET15-0914 Parallel, Grounding Electrode Systems & Main BondingJumpers, In-Class Activity: Conductors in Parallel andGroundingDay 5 - Midterm Exam, Coordinating Electrical CircuitAmpacity FactorsDay 6 - Introduction to Laguna Pointe Plans, In-Class Lab:Finding Walls for Conduit Layout, Working Clearances andServices, Sight Lighting, In-Class Lab: Site LightingDay 7 - Floor Types and Planning Conduit Runs, BuswaySystemsIn-Class Activity: Busway Systems, Mechanical SheetsDay 8 - Commercial Electrical Load Calculations and SizingElectrical Equipment, Plumbing Sheets and Basic FireProtection, Coordinating Plan Information Prior to CompletingElectrical, Rough-InDay 9 – Elevators, Coordinating Before Completing ElectricalRough-in for Lighting Circuits, In-Class Lab: CreatingInstallation Plan for Corridor Lighting for One Floor of aCommercial Structure, Preparation for Final Exam: Q & A andOpen DiscussionDay 10 - Semester Review & Final Exam3rd Year 2nd Semester: Day 1 - Welcome and Course Overview, Electrical Quantitiesand Circuits, Electrical Quantities, Ohm's Law, Series &Parallel Circuits and Calculations Review, Electrical Tools andTest Instruments, Electrical Safety, Solenoids, Shading, Coils,Sizes, and Specifications Day 2 - Coordinating Electrical Circuit Amapacity Factors,Conductor Ampacities and Derating, Sizing Single MotorSystems Using the NEC, In-Class Assignment: MotorsWorksheet, Contactors and Magnetic Motor Starters, In-ClassActivity: Lighting Contractors and Motor Starters, In-ClassActivity: Motor Starters and Overload/ “Heater” Selection Day 3 - Using the NEC for Voltage Drop, Conductors, andRaceways, Electrical Symbols & Diagrams, Control Devices,Ladder Diagrams and Wiring Diagrams, Lab Prep: Rules andOperating Procedures, Lab: Basic Control Circuits Assemble, Operate, Test, and Trouble-Shoot Day 4 - In-Class Assignment: Motors Worksheet, ControlDevices – Continued, Control Logic, Review of Control CircuitLabs, Lab Prep: Motor Control Circuits, Lab: Motor: MotorControl Circuits – Multi Start-Stop Stations - Assemble,Operate, Test, and Trouble-Shoot Day 5 - Review for Midterm Exam, Midterm Exam, OptionalLab (Time Permitting): Motor Control Circuits – HOA – E-Stop– Limit Switch - Assemble, Operate, Test, and Trouble-Shoot Day 6 - Review: Junction & Pull Boxes, Conduit Bodies &Enclosure Sizing and Fill Requirements, NEC Definitions, ACGenerators, Transformers and Motors, Reversing MotorETP 100 Exhibit B Menu Curriculum (02/13/12)2 of 6

WECAET15-0914 Circuits, Optional: In-Class Reversing Motor Demonstration,Lab Prep: Motor Control Circuits, Labs: Reversing MotorControl Circuits - Assemble, Operate, Test, and Trouble-ShootDay 7 - In-Class Assignment: Grounding, Bonding, ParallelConductors and NEC Review, In-Class Actibity: Using theNEC to Size Parallel Conductors & Raceways, Sizing MainBonding Jumper, Grounding Electrode Conductor andEquipment, Grounding Conductors, etc., General-PurposeRelays and Timing & Counting Functions, Labs: Relay andTimer Function Motor Control Circuits - Assemble, Operate,Test, and Trouble-ShootDay 8 -Common Alternating Current Circuit Configurations,Adjustment & Correction Factors for Exposed RacewaysInstalled on or Above Rooftops – Review, Using the NEC:Sizing Parallel Feeder Conductors & Raceways, SizingOvercurrent Protection (for Transformers), Sizing SystemBonding Jumpers, Grounding Electrode Conductors andEquipment Grounding Conductor, etc., Labs: Additional TimerFunction Motor Control Circuits - - Assemble, Operate, Test,and Trouble-ShootDay 9 - Review of Blue Prints and Construction Documents,Lab: Motor Control Circuit Design Using Constructor Software, Optional Lab: Trouble-Shoot a Lighting ControlCircuit with SIMUTECH SoftwareDay 10 - Review for Final Exam, Final Exam, Lab (TimePermitting): Additional Motor Control Circuits or AdditionalSIMUTECH Troubleshooting4th Year 1st Semester:Day 1 – Orientation, Electrical Safety & First Aid, Arc Flash,PPE & Clothing, Power Generation, Transmission,Distribution, Types and Differences between ElectricalSystems, Single Phase/Three Phase Systems, High VoltageSystems, Wye- Delta/Open Delta Concepts Article 408,230Code Practice Service requirements and Article 100, 110Code Practice Working ClearancesDay 2 - Electromechanical and Solid State Relays: Types &Applications, Operating Characteristic and Relay Construction– Poles-Throws- Breaks, Contact Protection, and TransientVoltage Protection, Electrically Held and Mechanically HeldRelays and Contactors, Lab Exercises: Lighting AutomationControl CircuitsDay 3 - Capacito Article 300, 310 Code Practice, ConductorInsulation and Ampacity ratings, Derating applications andWorksheets, Terminal Ratings with Regards to AmpacityRatings for Conductors, Overcurrent Conditions, Article 240Code Practice, Short Circuit, Ground Fault and OverloadDefined, Differences between Fuses and Breakers, Long andShort Time Current Ratings for Conductors, DifferencesETP 100 Exhibit B Menu Curriculum (02/13/12)3 of 6

WECAET15-0914 between a Power Panel and Lighting and Appliance Panelregarding Secondary Conductor and Panel BussingProtection, Lab Exercises: Forward Reverse Motor StartingReview, Forward Reverse Motor Starting Using GeneralPurpose Relays for Electrical Interlock, Local & RemoteSwitching with Automatic Motor Restart, Electric LiftDay 4 - Photoelectric and Proximity Controls (Hall EffectSensors), Different type Detectors, Detection Applications andInstallation Techniques, Lab Exercises: Grain Silo andConveyor SystemDay 5 - Lab Exercise: Electric Gate, First Quarter Review andMidterm ExamDay 6 - Article 200, 250 Code Practice, Grounding,Applications for the Line Side of the Service, GroundingApplications for the Load Side of the Service, Article 250Terminology, The Differences Between Grounding andBonding, The Requirements for Bonding, Parallel ServiceRequirements and Adjustments Made for Voltage DropCorrections, Lab Exercise: Control for an Automatic Car WashDay 7 - Reduced Voltage Motor Starting Methods &Applications, When to apply Voltage Reduction, TheDifferences between the Starting Methods, Lab Exercises:Wye-Delta, Part Winding, Primary Resistor Reduced VoltageStarting ApplicationsDay 8 - Article 430 Code Practice, Short Circuit, Ground Faultand Overload Applications and Requirements for a SingleMotor, Service Factor Ratings, Integral Overload Protection,Supplementary Overload Protection, Fuse Ratings andBreaker Ratings for Motors, Locked Rotor CurrentCalculations, Lab Exercise Plugging, Brake Motor BrakingApplicationsDay 9 - Article 440 Code Practice, Sizing Motor Feeder CircuitConductors, Controllers, and Disconnecting Means, LabExercise Motor Braking Applications Continued DC InjectionCircuit.Day 10 - Semester Review & Final Exam4th Year 2nd Semester: Day 1 – Orientation, Designing and Installing Wiring Methods,Sizing Auxiliary Gutters, Pull Boxes, Box Fill, Branch Circuits,Feeders, & Wiring Methods, NEC Articles 210, 215, 312, 314Chapter 3 NEC, Code Practice Day 2 - Review Motors and Compressor Motors, NEC Articles430, 440, Code Practice, Accelerating/Decelerating CircuitLogic Along With Braking Application Review, Compelling,Accelerating and Decelerating Applications and Lab Exercises:Compelling, Accelerating and Decelerating Circuits Day 3 - Variable Frequency Drives, Lab Exercises: Installing& Programming a Variable Frequency DriveETP 100 Exhibit B Menu Curriculum (02/13/12)4 of 6

WECAET15-0914 Day 4 - Programmable Controllers Introduction, Theory andApplications, Lab Exercises: Computer Lab Design a PLCDiagram for a Pump House to Control General LightingCircuits and all Motor Operations for Two Motors, Apply theCircuit to a PLC Lab Board and OperateDay 5 - Review for Midterm, Midterm Exam, Code PracticeDay 6 - Solid State Devices: Types and Applications,Photovoltaic & Renewable Energy Concepts, Electronics LabExercises: Building Electronic Circuits, Half Wave, Full Wave,Full Wave Bridge Rectifiers, SCR Circuit, Triac Light DimmerCircuitDay 7 - Solid State Devices Theory & Applications (cont), LabExercises: Transistor Circuits, DC Speed Control, Photo Cell,Alternating LED Circuit, Electronic Motor Controls Circuits,Review Solid-State Relays and Solid-State Starters, RelayContact Protection Circuits, Current Sinking and CurrentSourcing Applied to Signaling Devices, Introduction toPhotovoltaic SystemsDay 8 - Working Safely and Competently with Solar Energy,Practice Worksheet Exercises on PV- Array formations, PVSystem Sizing and Installation Requirements per NEC Article690, Preventative Maintenance and Troubleshooting, MeteringEquipment, Lab Exercises: Troubleshooting Simulation andLOGO Car Wash Lab Exercise, Program the Ladder Diagramand Hard Wire Circuit in LabDay 9 - Articles 220, 404, 406, 410 and 422 Code PracticeReceptacle and Luminaire Installation Requirements, DemandFactors for Residential Ranges, Commercial Demand Factors,Determining Required Lighting and Receptacle Loads, LabExercises: Troubleshooting Circuits using ComputerSimulations for Variety of Situations, Lab Exercise Hard Wire aGarage Door Circuit, Complete any Unfinished Lab ExercisesDay 10 - Lab

In this proposal, Western Electrical Contractors Association, Inc. (WECA) seeks funding for retraining of Commercial Electrician Apprentices. Incorporated in 1937, WECA is a statewide nonprofit organization serving independent merit shop electrical contractors, their emplo