Transcription

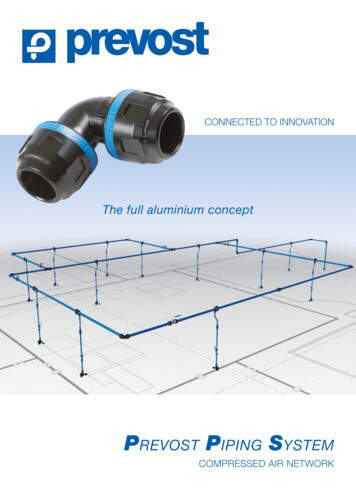

CONNECTED TO INNOVATIONThe full aluminium conceptPrevost Piping SystemCOMPRESSED AIR NETWORK

PREVOST : a manufacturer at the heart ofyour networks, connected to innovationFor more than 40 years, PREVOST has been successfully designing, manufacturing and marketing a comprehensive range ofproducts for compressed air and fluid distribution networks, including safety fittings, filtration solutions and pneumaticequipment.Prevost has become the preferred partner for companies using pneumatic and hydraulic power.Every day, our teams work to expand the horizon for our customers : through innovation and constantly seeking areas for improvement, through the quality of our products, advice and services. CONNECTED TO INNOVATIONAn R&D strategy for patented products: PREVOST offersproducts that provide increasingly optimised performanceand enhanced safety, and comply with all applicablestandards.Making the best use of our products: our solutionsenable you to optimise yield and improve your return oninvestment.European manufacture: our new Prevost Piping Systemnetworks range, made entirely from aluminium, is designedand produced in Europe. CONNECTED TO QUALITYPrevost is certified according to :CONNECTED TO YOUR BUSINESSREQUIREMENTS We comply with the requirements of all industries,specialised distributors, decision-makers, architecturefirms, design offices and installers. CONNECTED TO YOUR NEEDSPREVOST possesses a technical unit dedicated toyour designing your network.uISO 9001DIAGRAMS andQUOTATIONfor your planned facility ON REQUESTA web application is accessible viasmartphones and tablets.TÜV : certification of compliance with thePressure Equipment Directive.PED 2014/68/EUOur products comply with the requirements of:Quality of pipe coatingthe REACH standard: Registration,Evaluation, Authorisation and restriction ofChemicals Standard for fire rating of construction products andcomponents (EN 13501-1)2 Prevost Piping SystemFirst-class logistics: our team manageslogistical flows so as to ship products on the same day asyou place your order.Our training centre enables you to reinforce yourknowledge of our products and fluid mechanics.Our dynamic and responsive sales force is present inmore than 80 countries.Our after-sales department is at your service

What is a compressed air network?A compressed air network involves linking a source of compressed air, i.e. one or morecompressors, to a designated distribution points.The structure of PREVOST networks is made of aluminium pipes.These are fixed at a minimum height of 2.5 m from the floor and form the primary loop of the network.From this loop, pipe with a smaller diameter, known as “drops” feed off. Their ends are approximately 1.2 m above the floor.These are compressed air distribution points where equipment such as safety fittings, filters, hoses, etc., can be attached.* The warranty is limited to the replacement value of defective products.The products must be used as instructed in the technical manuals (temperature, ambiance, pressure, etc.) NETWORK DESIGNTo design a network, the pipe diameter must be calculated by taking the desired flow rate and the length of the mainpipe. The date below is calculated for operating pressure of 8 bar with 5% pressure loss.COMPRESSOR*POWERFLOW RATEkWCVNm3/h 250008831602151750291671030200270200033333117750 m164 ft1616202020252532323240405050636363636380100 m328 ft1620202025253232404040405050636363808080150 m492 ft2020202525323240404050505050636363808080LENGTH OF MAINLINE300 m500 m750 m984 ft1640 ft2460 801000 m3280 ft2532323240405050636363638080801300 m4265 ft25323232405050636363638080801600 m5249 ft3232324040505063636380808080* These values may vary slightly from compressor data EXPANSION OF MATERIALSAs the temperature rises and falls, aluminium issubject to expansion and contraction.To compensate for these variables, it isrecommended that the systemps be designed toallow this movement.For small diameters, a hose will play this role.For larger diameters, expansion kits will performthe function. They also make it possible to changedirection (corners) and divert around obstacles inthe workshop (pillars, beams, etc.).Expansion coefficient: 0.024 mm per metre and per degree Celsius.Expansion is calculated as follows:C Expansion coefficientL Length of the straight stretch (between two fixed points)ΔT Discrepancy between the maximum and minimum ambienttemperatures in C.DL Overall expansionI.e. DL C x L x ΔTExample: a 20 metre line using 40 mm piping, at an ambient temperature of15 C with a maximum temperature of 40 C, i.e. a difference of 25 CDL: 0.024 x 20 (m) x 25 C (40 C - 15 C) 12 mmPrevost Piping System 3

Prevost Piping SystemThe100% aluminium conceptThe Prevost Piping System compressed air network range is compact, lightweight and corrosive resistant with all aluminumfittings.The system is quick, easy to install and can be pressurised immediately.The Prevost Piping System range ensures: a clean and high quality air supply a leak free network with an optimised flow rate a max operating pressure of 16 bar.The network will provide a long service life and can easily be configured so each workstation is well supplied,accessible and organised.Advantages of the new Prevost Piping System range COMPACT AND LIGHTWEIGHTThe upgraded design of the new PPS1 aluminiumfitting is more compact, lighter and vibrationresistant. IMPACT STRENGTHAluminium is tough towithstand pressure andimpacts. HIGH-TECH MATERIALThe aluminium alloy used duringconstruction combined with epoxypaint on the outside and a treatmenton the inside, protects the pipeagainst any risks of oxidation andcorrosion.QUICK AND EASYTO ASSEMBLE Simply insert the pipe intothe fitting, and then tightenthe PPS1 fitting.COMPATIBILITYWITH COMPRESSOR LEAK FREE WITH MINIMALPRESSURE LOSS The « PPS Grip Concept » guaranteesa flawless connection and zero leaks.Flow rates are optimised thanks to aperfectly smooth internal pipe surface, alow friction coefficient and a large internaldiameter.4 Prevost Piping SystemFULLYADAPTABLE The PPS1 fitting ensuresthat facilities are modularand scalable.

Prevost Piping System100% aluminium pipes RUSTPROOF MI N I MAL P R E S S U R E L OS Sdue to a smooth internal surface C OST- E FFE CT I V EU V AN D HE AT-R E S I S TAN T MAR K I N G AN D I S O C OL OU RN O FI R E HAZ AR Dno need for fire permit EASY TO CUTand chamfer for easy installation and maintenance LIGHTWEIGHTcan be handled by one person PI PE PROPERTIES Material: extruded aluminium alloy: EN AW 6060 T6 UNI-EN 573-3 Treatment: interior and exterior (compliant with RoHS standard) Coating: electrostatic paint Extrusion quality: calibrated, seamless Compatible fluids: compressed air, vacuum, neutral gases Pipe lengths: 4 or 6 metres Density: 2.7 kg/dm³ Pipe external diameter: Ø 16, 20, 25, 32, 40, 50, 63, 80 mmPrevost offers a wide range of 100% aluminium pipes for compressed air, vacuum and nitrogen.Grey compressed airand vacuum pipes,RAL 7001Green nitrogen pipes,RAL 6029Ø 16 PPS BTU1640Ø 16 PPS GTU1640Ø 20 PPS VTU2055Ø 20 PPS BTU2040Ø 20 PPS GTU2055Ø 25 PPS VTU2555Ø 20 PPS BTU2055Ø 25 PPS GTU2555Ø 25 PPS BTU2540Ø 32 PPS GTU3255Ø 25 PPS BTU2555Ø 40 PPS GTU4055Ø 32 PPS BTU3240Ø 50 PPS GTU5055Ø 32 PPS BTU3255Ø 63 PPS GTU6355Ø 40 PPS BTU4040Ø 80 PPS GTU8055Blue compressed airpipes, RAL 5012Ø 40 PPS BTU4055Ø 50 PPS BTU5055Ø 63 PPS BTU6355Ø 80 PPS BTU8055Prevost Piping System 5

Prevost Piping SystemThe 100% aluminium fittingsPREVOST designs and manufactures its new PPS1 100% aluminiumfittings to ensure that they are the most compact and effective onthe market. New conceptPipes are firmly held in the fitting using a the « PPS Grip Concept ».This new concept is based on a stainless steel ring with teeth that penetrate the aluminium.The new contoured and lubricated seal design guarantees a leak free performance. IDENTIFICATIONThe Prevost logo is engraved on each fitting. PRESSUREMaximum service pressure (bar/psi). DIAMETERPipe external diameter (mm and inches). MARKERto indicate that the pipe is correctlypositioned in the fitting. TRACEABILITYclearly marked date of manufacturing code. LEAK FREEIt is comprised of two Teflon-coated lobes to create a perfectleak free seal. INTERNAL PARTSInternal parts cannot be detached from the body afterassembly.Operating pressure graph as a function oftemperature TECHNICAL SPECIFICATIONS Working pressure range: from -0.98 bar to 16 bar Temperature range: from -20 C to 80 C Body and nut: 100% aluminium, EN AB 46100 PPS Grip Concept: fastening system using teeth Tapping port flange to manage condensates6 Prevost Piping System

New range of PPS1 100% aluminium fittings:the most comprehensive on the market Diameters from 16 mm (½”) to 80 mm (3”)Ø 161/2’’Ø 203/4’’Ø 251’’Ø 321 1/4’’Ø 401 1/2’’Ø 502’’Ø 803’’Ø 632 1/2’’ Numerous configurationsStraight fittingsElbowsUnion fittingReduction90 elbowT-fittingsEqual T-fittingCapThreaded straightconnector, male90 threaded elbow, maleReduced T-fittingThreaded straightconnector, female45 elbowThreaded T-fitting, femalePrevost Piping System 7

Prevost Piping System100% aluminium fittings Tapping flangeThe body and nut are made entirely of aluminium. Thetapping flange is extremely compact, and is fitted with ananti-rotation system and removable half-shell. It can bedrilled without disassembly.The tapping flange provides a dry air supply to workstationsby drawing air from the wall of the pipe.The water remaining in the lower portion of the main pipe willdrain to a low point to automatic drain trap. ValvesMultiple options available :pipe/pipethreaded male/pipe TighteningThe nut and body can be tightened using standard tools.PREVOST wrenches are strongly recommended to ensure that the nut is tightenedcorrectly.Torque can be set using a torque wrench.8 Prevost Piping Systemthreaded female/pipe

Prevost Piping SystemGuidelines for network installationIdeally, the compressor room should be spacious, well ventilated, insulated and separated from therest of the workshops.Machines will be connected to the PPS network by hoses to eliminate problems related to vibrations and to allowf o r maintenance (refs. LEF and LEM). It is important to install bypasses between each machine, the tank(s) and filters.The main network should form a loop. For safety reasons, we advise installing the main compressed air pipes at a minimum heightof 2.50 m above floor level.The pipe must be fastened using an adeqquat number of sliding clamps so the system is securely held in place yet allowing forexpansion and contraction of the pipe (ref. PPS CI).The remaining condensates must be drained from the main line via direct drops installed lower than the bottom generating lineof the pipe and fitted with an automatic drain trap system. Mounting the networkMouting options must be selected to best suit the configuration of the workshop.The pipe in the system must be mounted in a perfectly level alignment.To do so, accurate distances are to be established between each mouting point.For correct assembly, a distance of 3 metres should be left between the two clamps.Pipe at a distance from the wallPipe parallel to the wallPipe suspendedPipe suspendedPrevost Piping System 9

Prevost Piping SystemAssembly guidelinesCUTTINGTIGHTENINGCHAMFERINGThe pipe must be cut perpendicular to itslength (ref. PPS CTU).Chamfer the external edge of the pipe to avoid damage tothe seal and the inner edge to eliminating cutting residue,improving the laminar flow of air. (For diameters 63 and 80mm, use cutting and chamfering tool ref. PPS CH).Hand tighten the nut and then use a torquewrench to the specified recommendations.(ref. PPS CLE)ASSEMBLYMARKINGLUBRICANTUnscrew the nut by several turns, and theninsert the pipe while rotating it slightly untilthe recommended depth is reached.NB: an assembly fluid (ref. PPS AL) isrecommended to facilitate the assembly.10 Prevost Piping SystemMark the tube to indicate the insertion depthin the fitting (use the reference marks on thefittings or on the wrench).

Ergonomic distribution withoptimised energy efficiencyPREVOST offers a range of compressed air network solutions. Wall brackets PrevoS1Wall fasteners are located on downpipes and provide a safe and quick single or double fitting. Air intake: G ½”or G ¾” Multiple connection profiles Material: aluminium alloy Robust four-point wall anchoring Fitted with manual drain Air outlet: two single-press safety fittings Anti-whiplash fittings compliant with the ISO 4414 standard ensuringuser protection Orientable body allowing the button position to be moved Quick and easy connection and disconnection Air treatment unitsAir treatment units help to preserve pneumatic tools and equipment. Three treatment levels are recommended :Cyclone separator: serves to effectively eliminate the largest solid particles and water particles present incompressed air (ref. SPC).Refrigerated dryer: serves to remove water from compressed air, by lowering the air temperature to the dewpoint ( 3 C) under pressure, via heat exchange (ref. ALF).25 μm standard filtration: eliminates contaminants present in compressed air (particles, water, etc.).These contaminants are evacuated via the drain valve at the base of the tank (ref. ALTO).For optimum quality, submicron filtration: eliminates various residual contaminants such as solidparticles, liquid particles and oil aerosols present in compressed air, with a filtration efficiency of morethan 99.99%. This ensures a high-quality air supply (ref. MICRO AIR). Hose reelsAutomatic hose reel: this is an essential item to ensure workshop ergonomics. Itsuse saves time and enables flexible distribution hoses to be used in safety andcomfort.All Prevost automatic hose reels comply with the Machinery Directive 2006/42/EC.The following rules are also applied : EN ISO 12100: 2010 “Safety of machinery - General principles for design - Riskassessment and risk reduction” EN 13857: 2008 “Safety of machinery - Safety distances to prevent hazard zonesbeing reached by upper and lower limbs”For more information, contact us: www.prevost.euPrevost Piping System 11

Prevost Piping SystemFinishing touches Tapping flangeA tapping port flange is used to install a downpipe to supply a workstation. It takes the place of the formergooseneck fittings and serves to limit the presence of condensates. Low pointLow points are required to ensure correct drainage of condensates. These downpipes must be positioned at strategiclocations along the network. Condensates may be drained using any conventional drainage system (electronic drain trap,automatic drain trap, valve). Cut-off valves are used to isolate certain parts of the network for maintenance purposes. Wall-mounted connectionThe angled wall-mounted connection serves to compensate fordifferent centre-to-centre spacings.Between thetapping and thewall.Between the filtrationassembly and thenetwork. Plates to mount network accessories on IPN / HEA beamsThese enable workstations to be arranged in a safe and ergonomic manner. The metal plates,used with attachment systems adapted for IPN / HEA beams, make it possible to fastenequipment in place quickly and safely, without drilling or welding, in accordance with prevailingrequirements. These plates are designed to receive the following : Open and closed reels Wall mounts ALTO air treatment assemblies Universal brackets accessories12 Prevost Piping System

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS - Aluminium blue pipe for compressed airA-B-C-D-Pipe .545.55.55.55.5Pipe 5.5Pipe OD(mm)2025Length(m)5.55.5Parts NumbersPPS BTU1640PPS BTU2040PPS BTU2055PPS BTU2540PPS BTU2555PPS BTU3240PPS BTU3255PPS BTU4040PPS BTU4055PPS BTU5055PPS BTU6355PPS BTU8055PPS - Aluminium grey pipe for vacuumA-B-C-D-Parts NumbersPPS GTU1640PPS GTU2055PPS GTU2555PPS GTU3255PPS GTU4055PPS GTU5055PPS GTU6355PPS GTU8055PPS - Aluminium green pipe for nitrogenA-B-C-D-Parts NumbersPPS VTU2055PPS VTU2555PPS - Aluminium bended link pipeABC869095480487487162025D-Pipe OD(mm)162025Parts NumbersPPS LMCB16PPS LMCB20PPS LMCB25Prevost Piping System 13

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 UN - Aluminium female union for or pipe OD(mm)1620253240506380Parts NumbersPPS1 UN16PPS1 UN20PPS1 UN25PPS1 UN32PPS1 UN40PPS1 UN50PPS1 UN63PPS1 UN80PPS1 UNS - Aluminium female sliding union for 00121851021221421701943846576884100-D-For pipe OD(mm)253240506380Parts NumbersPPS1 UNS25PPS1 UNS32PPS1 UNS40PPS1 UNS50PPS1 UNS63PPS1 UNS80PPS1 MR - Aluminium pipe reducing fitting14 Prevost Piping SystemD-For pipe OD(mm)253240506380For pipe OD(mm)202532405063Parts NumbersPPS1 MR2520PPS1 MR3225PPS1 MR4032PPS1 MR5040PPS1 MR6350PPS1 MR8063

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 9C - 90 Aluminium equal female elbow fitting for or pipe OD(mm)1620253240506380Parts NumbersPPS1 9C16PPS1 9C20PPS1 9C25PPS1 9C32PPS1 9C40PPS1 9C50PPS1 9C63PPS1 9C80PPS1 9CM - 90 aluminium tapered male threaded elbow fitting for 7188106106D2626323838465757For pipe OD(mm)1616202525324040BSPT male threadParts NumbersR 3/8R 1/2R 1/2R 1/2R 3/4R1R 1 1/4R 1 1/2PPS1 9CM1617PPS1 9CM1612PPS1 9CM2012PPS1 9CM2512PPS1 9CM2527PPS1 9CM3234PPS1 9CM4042PPS1 9CM4049PPS1 4C - 45 aluminium equal female elbow fitting for 768841001214553617085101124146D-For pipe OD(mm)1620253240Parts NumbersPPS1 4C16PPS1 4C20PPS1 4C25PPS1 4C32PPS1 4C40PPS1 BO - Aluminium female cap for pipe-D-For pipe OD(mm)1620253240506380Parts NumbersPPS1 BO16PPS1 BO20PPS1 BO25PPS1 BO32PPS1 BO40PPS1 BO50PPS1 BO63PPS1 BO80Prevost Piping System 15

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 TE - Aluminium equal female tee fitting for 839196102D-For pipe OD(mm)20253240506380Parts NumbersPPS1 TE20PPS1 TE25PPS1 TE32PPS1 TE40PPS1 TE50PPS1 TE63PPS1 TE80PPS1 TR - Aluminium reducing tee fittingD323238323846For pipe OD(mm)202525323232For pipe OD(mm)161620162025Parts NumbersPPS1 TR2016PPS1 TR2516PPS1 TR2520PPS1 TR3216PPS1 TR3220PPS1 TR3225PPS1 TT - Aluminium parallel female threaded tee fitting for pipe16 Prevost Piping 110110110110For pipe OD(mm)1620252532324040405050506363636380808080BSPP female threadParts NumbersG 3/8G 1/2G 1/2G 3/4G 3/4G1G 3/4G1G 1 1/4G1G 1 1/4G 1 1/2G1G 1 1/4G 1 1/2G2G1G 1 1/2G2G 2 1/2PPS1 TT1617PPS1 TT2012PPS1 TT2512PPS1 TT2527PPS1 TT3227PPS1 TT3234PPS1 TT4027PPS1 TT4034PPS1 TT4042PPS1 TT5034PPS1 TT5042PPS1 TT5049PPS1 TT6334PPS1 TT6342PPS1 TT6349PPS1 TT6360PPS1 TT8034PPS1 TT8049PPS1 TT8060PPS1 TT8076

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 MM - Aluminium tapered male threaded straight fitting for 84646575772729090110110D-For pipe OD(mm)1616202025252532324040505063638080BSPT male threadParts NumbersR 3/8R 1/2R 1/2R 3/4R 1/2R 3/4R1R1R 1 1/4R 1 1/4R 1 1/2R 1 1/2R2R2R 2 1/2R 2 1/2R3PPS1 MM1617PPS1 MM1612PPS1 MM2012PPS1 MM2027PPS1 MM2512PPS1 MM2527PPS1 MM2534PPS1 MM3234PPS1 MM3242PPS1 MM4042PPS1 MM4049PPS1 MM5049PPS1 MM5060PPS1 MM6360PPS1 MM6376PPS1 MM8076PPS1 MM8090BSPP female threadParts NumbersG 3/8G 1/2G 1/2G 3/4G 1/2G 3/4G1G1G 1 1/4G 1 1/4G 1 1/2G 1 1/2G2G2G 2 1/2G 2 1/2G3PPS1 MF1617PPS1 MF1612PPS1 MF2012PPS1 MF2027PPS1 MF2512PPS1 MF2527PPS1 MF2534PPS1 MF3234PPS1 MF3242PPS1 MF4042PPS1 MF4049PPS1 MF5049PPS1 MF5060PPS1 MF6360PPS1 MF6376PPS1 MF8076PPS1 MF8090PPS1 MF - Aluminium female threaded straight fitting for 4646575772729090110110D-For pipe OD(mm)1616202025252532324040505063638080Prevost Piping System 17

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 BP - Aluminium tapping flange for 102102103147147147147147147D-For pipe OD(mm)25253232404040505050636363808080For pipe OD(mm)16201620162025162025202532202532Parts NumbersPPS1 BP2516PPS1 BP2520PPS1 BP3216PPS1 BP3220PPS1 BP4016PPS1 BP4020PPS1 BP4025PPS1 BP5016PPS1 BP5020PPS1 BP5025PPS1 BP6320PPS1 BP6325PPS1 BP6332PPS1 BP8020PPS1 BP8025PPS1 BP8032PPS1 BT - Aluminium threaded tapping flange for pipe18 Prevost Piping 102147147147147147147D-For pipe OD(mm)252532324040405050636363808080BSPP female threadParts NumbersG 1/2G 3/8G 1/2G 3/4G 1/2G 3/4G1G 3/4G1G 1/2G 3/4G1G 1/2G 3/4G1PPS1 BT2512PPS1 BT2517PPS1 BT3212PPS1 BT3227PPS1 BT4012PPS1 BT4027PPS1 BT4034PPS1 BT5027PPS1 BT5034PPS1 BT6312PPS1 BT6327PPS1 BT6334PPS1 BT8012PPS1 BT8027PPS1 BT8034

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 RSIF - Parallel female threaded valves with fittings for pipeAB321213812146125571516815784204,5100 235121 300Brass bodyC6466758599,10122,5285250D252531404955-For pipe OD(mm)1620253240506380BSPP female threadParts NumbersG 1/2G 1/2G 3/4G1G 1 1/4G 1 1/2G2G 2 1/2PPS1 RSIF1612PPS1 RSIF2012PPS1 RSIF2527PPS1 RSIF3234PPS1 RSIF4042PPS1 RSIF5049PPS1 RSIF6360PPS1 RSIF8076BSPT male threadParts NumbersR 1/2R 1/2R 3/4R1R 1 1/4R 1 1/2PPS1 RSIM1612PPS1 RSIM2012PPS1 RSIM2527PPS1 RSIM3234PPS1 RSIM4042PPS1 RSIM5049PPS1 RSIM - Parallel male threaded valves with fittings for pipeAB3213038130461335716068168,584215Brass bodyC6466758599,1122,5D242427364750For pipe OD(mm)162025324050PPS1 RSI - Piping valveAB321403814746157571896820284234100 320121 394Brass bodyC6466758599,1122,5275250D-For pipe OD(mm)1620253240506380Parts NumbersPPS1 RSI16PPS1 RSI20PPS1 RSI25PPS1 RSI32PPS1 RSI40PPS1 RSI50PPS1 RSI63PPS1 RSI80Prevost Piping System 19

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 UF - FlangesA-B-C-D-For pipe OD(mm)6380Parts NumbersPPS1 UF63PPS1 UF80PPS1 LK - Lock kit for valveA-B-C-D-For valve Ø(mm)16 to 2532 to 405063 to 80Parts NumbersPPS1 LK1625PPS1 LK3240PPS1 LK50PPS1 LK6380PPS1 DK - Dilatation kitFor tube OD(mm)6380Attach expansion kits to the wall using clamps :PPS1 CIRSI63 for Ø63PPS1 CIRSI80 for Ø80ABCDParts NumbersPPS1 DK63PPS1 DK80PPS1 NUT - Aluminium nutA-20 Prevost Piping SystemB-C-D-For fitting Ø(mm)1620253240506380Parts NumbersPPS1 NUT16PPS1 NUT20PPS1 NUT25PPS1 NUT32PPS1 NUT40PPS1 NUT50PPS1 NUT63PPS1 NUT80

PPS SYSTEM ALL ALUMINIUM NETWORKSPPS1 SEAL - Internal sealA-B-C-D-For fitting Ø(mm)1620253240506380QuantityParts Numbers101010105522PPS1 SEAL16PPS1 SEAL20PPS1 SEAL25PPS1 SEAL32PPS1 SEAL40PPS1 SEAL50PPS1 SEAL63PPS1 SEAL80PPS1 IP - Internal parts kitA-B-C-D-For fitting Ø(mm)1620253240506380Parts NumbersPPS1 IP16PPS1 IP20PPS1 IP25PPS1 IP32PPS1 IP40PPS1 IP50PPS1 IP63PPS1 IP80PPS1 BA - 10 Band KitABCD(unit of sales 10 band)For fitting Ø(mm)1620253240506380Parts NumbersPPS1 BA16PPS1 BA20PPS1 BA25PPS1 BA32PPS1 BA40PPS1 BA50PPS1 BA63PPS1 BA80A3T - 3-pieces female equal socketA48.55963.575.5B53657389C-D-BSPP female threadG1G 1 1/4G 1 1/2G2Parts NumbersA3T 01A3T 42A3T 49A3T 60Prevost Piping System 21

ONE PORTS WALL BRACKETSFemale thread one port wall bracket - 1 coupler and drain - British Profile - ID passage 6 mmABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersBSI 06BSI 061103WKFemale thread one port wall bracket - 1 coupler and drain - British Profile - ID passage 6 mmA-B-C-D-E-Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersBRM 06BRM 061103WKFemale thread one port wall bracket - 1 coupler and drain - European Profile - ID passage 7.4 mmABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersESI 07ESI 071103WKFemale thread one port wall bracket - 1 coupler and drain - European Profile - ID passage 10.4 mmABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersESI 11ESI 111103WKFemale thread single wall bracket - 1 coupler and drain - ISO 6150 B Profile - ID passage 6 mm22 Prevost Piping SystemABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersISI 06ISI 061103WK

ONE PORTS WALL BRACKETSFemale thread one port wall bracket - 1 coupler and drain - ISO 6150 B Profile - ID passage 8 mmABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersISI 08ISI 081103WKFemale thread one port wall bracket - 1 coupler and drain - ISO 6150 B Profile - ID passage 11 mmABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersISI 11ISI 111103WKFemale thread one port wall bracket - 1 coupler and drain - ISO 6150 C Profile - ID passage 6 mmABC515038D63E6,5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersCSI 06CSI 061103WKFemale thread one port wall bracket - 1 coupler and drain - ISO 6150 C Profile - ID passage 8 mmABC515038D63E6.5Inlet BSPP femalethreadG 1/2Outlet : 1 couplingParts NumbersCSI 08CSI 081103WKPrevost Piping System 23

TWO PORTS WALL BRACKETSFemale thread two port wall bracket - 2 couplers and drain - British Profile - ID passage 6 mmABC717157573838D7070E6.56.5Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersBSI 06BSI 06BSI 068103WKBSI 068104WKFemale thread two port wall bracket - 2 couplers and drain - British Profile - ID passage 6 mmA-B-C-D-E-Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersBRM 06BRM 06BRM 068103WKBRM 068104WKFemale thread two port wall bracket - 2 couplers and drain - European Profile - ID passage 7.4 mm and British profile - ID passage 6 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersESI 07BSI 06ESI 078104WKB6Female thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID 11 mm and British Profile - ID 6 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersISG 11BSI 06ISG 118104WKB6Female thread two ports wall bracket - 2 couplers and drain - European Profile - ID passage 7.4 mm24 Prevost Piping SystemABC717157573838D7070E6.56.5Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersESI 07ESI 07ESI 078103WKESI 078104WK

TWO PORTS WALL BRACKETSFemale thread two port wall bracket - 2 couplers and drain - European Profile - ID passage 10.4 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersESI 11ESI 118104WKFemale thread two port wall bracket - 2 couplings and drain - European Profile - ID passage 10.4 mm and 7.4 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersESI 11ESI 07ESI 118104WKE7Female thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID passage 6 mm and European Profile - ID passage 7.4 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersISI 06ESI 07ISI 068104WKE7Female thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID passage 6 mmABC717157573838D7070E6.56.5Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersISI 06ISI 06ISI 068103WKISI 068104WKPrevost Piping System 25

TWO PORTS WALL BRACKETSFemale thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID passage 8 mmABC717157573838D7070E6.56.5Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersISI 08ISI 08ISI 088103WKISI 088104WKFemale thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID passage 8 mm and 6 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersISI 08ISI 06ISI 088104WKI6Female thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID passage 11 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersISI 11ISI 118104WKFemale thread two port wall bracket - 2 couplers and drain - ISO 6150 B Profile - ID passage 11 mm and 6 mm26 Prevost Piping SystemABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersISI 11ISI 06ISI 118104WKI6

TWO PORTS WALL BRACKETSFemale thread two port wall bracket - 2 couplers and drain - ISO 6150 B and ISO 6150 C Profile - ID passage 6 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersISI 06CSI 06ISI 068104WKC6Female thread two port wall bracket - 2 couplers and drain - ISO 6150 C Profile - ID passage 6 mmABC717157573838D7070E6.56.5Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersCSI 06CSI 06CSI 068103WKCSI 068104WKFemale thread two port wall bracket - 2 couplers and drain - ISO 6150 C Profile - ID passage 8 mmABC717157573838D7070E6.56.5Inlet BSPP femalethreadG 1/2G 3/4Outlet : 2 couplingsParts NumbersCSI 08CSI 08CSI 088103WKCSI 088104WKFemale thread two port wall bracket - 2 couplings and drain - ISO 6150 C Profile - ID passage 8 mm and 6 mmABC715738D70E6.5Inlet BSPP femalethreadG 3/4Outlet : 2 couplingsParts NumbersCSI 06CSI 08CSI 088104WKC6Prevost Piping System 27

MULTI PORT WALL BRACKETSFemale thread wall bracket - Couplers and drain profile - British profile - ID passage 6 mmInlet BSPP female threadG 3/4G 3/4G 3/4G 3/4Outlet4 x BSI 066 x BSI 068 x BSI 0610 x BSI 06Parts NumbersMF 104S4BSMF 104S6BSMF 104S8BSMF 104S10BSFemale thread wall bracket - Couplers and drain - European profile - ID passage 7.4 mmInlet BSPP female threadG 3/4G 3/4G 3/4G 3/4Outlet4 x ESI 076

4 Prevost Piping System prevost piping system The Prevost Piping System compressed air network range is compact, lightweight and corrosive resistant with all aluminum fittings. The system is quick, easy to install and can be pressurised immediately. The Prevost Piping System range ensures: a clean and high quality air supply a leak free network with an optimised flow rate