Transcription

2010-2019 DOT 195 Accidents ReviewDerek Sollberger, PETulsa, OKMay, 7 ma City, OKdsollberger@ic-solutions-llc.com

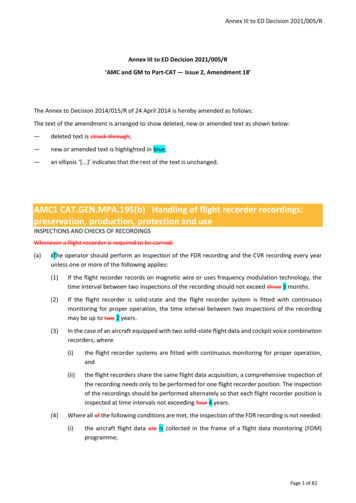

Accident Report –Hazardous Liquid PipelineSystems form updates:Pg. 1of 4 Common Geo Ref.Single unit of measure259 to 588 fieldsBiodieselSubtypesCoating selectionsValve type selectionsSCADA / CPM addersDrug and Alcohol testedUnique Int/Ext CorrosionILI: Combo & TransverseExcavator Equip TypePrevious Damage (Excav)Pg. 1of 17Form RSPA F 7000-149 CFR §195.50

TANK DATACOMMODITYEQUIPMENT FAILURENON-THREADED CONNECTTANK SUBTYPE SPILLSEQUIP BODY ( PUMP,TANK PLATE, MATERIAL)MALFUNCTION OFCONTROL/RELIEF EQUIP60,00050,000OTHER EQUIPCRUDE OILNON-HVL, LIQ @ AMB40,00030,000HVL, GAS @ AMBBIOFUEL / ALTERNATIVE FUEL10,000 20,000 30,000INCORRECT OPERATION20,00010,000VALVE LEFT OR PLACED INWRONG POSITION, NOTOVERFLOW OR OVERPRESSUREbblEQUIPMENT FAILURENATURAL FORCE DAMAGEOTHER INCIDENT CAUSEINCORRECT OPERATIONCORROSION FAILUREOTHER OUTSIDE FORCE DAMAGEMATERIAL FAILURE OF PIPE OR WELDSINGLE BOTTOMMIXERROOF/ROOF SEALOTHER INCORRECT OPERATIONROOF DRAINOTHERDOUBLE SEEQUIPMENT NOT INSTALLEDPROPERLYTANK, VESSEL, ORSUMP/SEPARATOR ALLOWED ORCAUSED TO OVERFILL-1,0002,000

Tank Damage ExpendituresTOTAL per TANK category 73,246,437AVG per incident 265,385 7-15/1,000 bll storage (0.5B-1B Part M)Inclement Weather planning / proceduredevelopment reviewMaintenance interval review, seal type andmaterial compatibility reviews,Reliability programs, rotating equipmentinspections.Mechanical Integrity program reviewsOperator Training / Vendor QualificationsControl and Safety Systems Simulations

VALVE DATACOMMODITYAUXILIARY OR OTHER VALVEOTHER INCIDENT CAUSEEXCAVATION DAMAGENATURAL FORCECORROSION FAILUREOTHER OUTSIDE FORCEINCORRECT OPERATIONEQUIPMENT FAILUREMainline Valve Type Failure1800160014001200CRUDE OILHVL, GAS @ AMB-1000800NON-HVL, LIQ @ AMBCO22,000 4,000 6,000 8,000EQUIPMENT FAILURE600400MAINLINE LEAK TYPE2000GATEBALLCHECKOTHERPLUGMANUFACTURE YEAREQUIP BODY ( PUMP, TANK PLATE, MATERIAL)400THREADED CONNECTION/COUPLING300MALFUNCTION OF CONTROL/RELIEF EQUIP200NON-THREADED CONNECTION100OTHER 198019731968196519571954PUMP OR PUMP-RELATED EQUIP1945OTHERSEAL OR PACKINGCONNECTION FAILUREPINHOLECRACKDEFECTIVE OR LOOSE TUBING OR FITTING

VALVE DATA Evaluating vandalism risk and appropriate securitymeasures.Maintenance procedure development, review, and training.Commissioning procedures and planningDesign and construct with operability in mind.Ensure OEM records are inclusive of maintenancerecommendations and easily accessible by Operations.Vendor QualificationsValve Damage ExpendituresTOTAL per VALVE category 79,267,306AVG per incident 113,40128,369 bbl on 699 events

ACCIDENT IDENTIFIER403226204100,00014150,000NON-HVL, LIQ @ AMB12CRUDE OIL10.5200,000HVL, GAS @ 625Pipe Body, Corrosion, MaterialFailure, Incident 00020,00010,00006PIPE DATACOMODITY50,000TYPE OF CORROSION-OTHERUNDERGROUNDGROUND PATROL BYOPS OR CONTRACTTRANSITION AREAABOVEGROUNDMANUFACTURE YEARAIR PATROLLOCAL OPERATINGSTAFF AND CONTRACT4000046% of ExternalCorrosionrecords notedPrior CoatingDamageATMOSPHERESTRAY CURRENT30000CONTROLLERSELECTIVE SEAMMICROBIOLOGICAL20000NOTIFICATION FROMPUBLICCPM LEAK DETECTIONOR SCADA 00%5%10%15%20%

PIPE DATAINTEGRITY PROGRAMSDIRECT INSPECTCLOSE INTERVALINTEGRITY HYDRO0%2018 DOT 195 Part H 20%10% 20% 30% 40%PIPE SEAM TYPE FAILURESINTERNAL CORROSION EFFORTSCORROSION COUPONS364844Off Shore403632PRIOR TOOL RUNS28On Shore248%2040%16100%-1250%18840%7% 43CORROSION INHIBITORS5%%2018 DOT 195 Part E -ERW Pipe TUDINAL ERW - HFLONGITUDINAL ERW - LFLAP WELDEDFLASH WELDEDSEAMLESSLONGITUDINAL ERW - UNKCALIPERCOMBOGEOMETRYMFL67%TOTAL ILIHIGH FREQUENCY0%10%20%30%40%LOW FREQUENCY AND DC

Pipe Damage ExpendituresTOTAL per PIPE category 1,676,554,446AVG per incident 2,250,409279,679 bbl on 745 eventsCorrosion, Material Failure, & Other Incident Integrity Management is complexDevelopment of excavation requirements, adherence, andrepresentative presence during line crossing urgentSurface owner and public relations importance to leakdetectionApplication and selection of integrity conceptsAging infrastructureVendor Qualifications

ComodityEXCAVATIONExcavator Equipment180,000160,00012140,000120,000HVL, GAS @ AMBCRUDE OILNON-HVL, LIQ @ AMB1423PROBING DEVICEBORINGAUGERDIRECTIONAL DRILLDRILLINGFARM OETRENCHER0% 20% 40% 60% 80% 100%100,00080,00057One Call Completed60,000Data includes dozer linestrike to a propanepipeline, resulting inone general publicfatality and one generalpublic injury.One Call ONAL DRILLBACKHOE/TRACKHOEFARM N PRACTICES NOT SUFFICIENTLOCATING PRACTICES NOT SUFFICIENTMedian GradeMedian DiameterAverage Install Year42,000101968OTHERONE-CALL NOTIFICATION PRACTICES NOTSUFFICIENT

Excavator Damage ExpendituresTOTAL per EXCAVATOR category 173,762,000AVG per incident 1,223,676 Equipment operator training and pipeline operatorrequirements.Farm and Road grading equipment One Call complianceLine Locator training, equipment operator fundamentalsConstruction InspectionProject planning, utility and sub-surface infrastructureidentification exercises.

2010-2019 Accident SummaryOpportunities for Improvement Risk Evaluations Procedure development,auditing, and training Mechanical Integrity Reliability Evaluations Vendor Qualifications Record KeepingData Summary 3,910 Accidents 822,129 bbl, 38% recovered 10 Fatalities, 5 public 26 Injuries, 5 public 124 Ignitions & 15 Explosions 58 Impacted Wildlife 781 Drug/Alcohol tests–2 Failed (Contractors)

IC-Solutions-LLC InspectionIC-Solutions LLC brings together 40 years of mid-continent pipeline operations, integrity, construction, and optimization experience.Our experience includes facility design and operation. We will utilize our extensive experience and background to ensure yourassets remain compliant and free of any jurisdictional interruptions; thereby leaving your schedule open for revenue generating andexpense management activities. Our years of experience inside mid-sized organizations has established a value driven approachwith all projects. We can help you unlock underutilized capacity and assist with operational challenges that appear in the form ofregulatory restrictions, inefficiencies or losses.

2010-2019 DOT 195 Accidents Review Derek Sollberger, PE Tulsa, OK May, 7 2020 IC-Solutions-LLC www.ic-solutions-l