Transcription

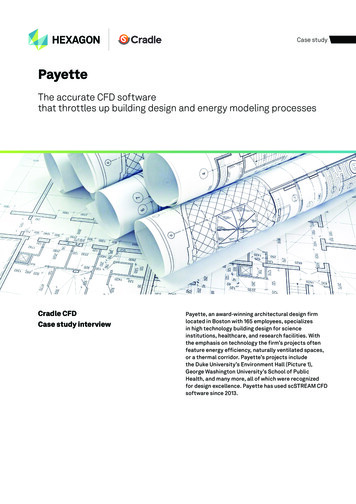

Case studyPayetteThe accurate CFD softwarethat throttles up building design and energy modeling processesCradle CFDCase study interviewPayette, an award‑winning architectural design firmlocated in Boston with 165 employees, specializesin high technology building design for scienceinstitutions, healthcare, and research facilities. Withthe emphasis on technology the firm’s projects oftenfeature energy efficiency, naturally ventilated spaces,or a thermal corridor. Payette’s projects includethe Duke University’s Environment Hall (Picture 1),George Washington University’s School of PublicHealth, and many more, all of which were recognizedfor design excellence. Payette has used scSTREAM CFDsoftware since 2013.

Picture 1: Duke University’s Environment Hall designed by Payette Warren Jagger PhotographyOne of Payette’s strengths is that, unlike typical designfirms, its designers work directly with staff scientists:Dr. Alejandra Menchaca (Picture 2) is one of the buildingscientists. As a visiting faculty at the Harvard GraduateSchool of Design and Massachusetts Institute ofTechnology (MIT) with experience serving as a buildingphysics consultant for Hulic Co., Ltd. in Japan,Dr. Menchaca took a role as a building scientist atPayette, where she provides design guidance anddirection from a sustainability and energy performancestandpoint. Her involvement begins early with schematicdesign, and continues all the way to detailing andspecifications. She uses a wide range of tools to addressspecific aspects of building design. These tools rangefrom quick back‑of‑the‑envelope calculations, to moreelaborate daylighting or energy simulations to fullCFD computations. scSTREAM, a remarkable CFD toolfor architectural hitectural designPresidentKevin Sullivan, FAIALocationBoston, MA, USASize165 employeesDr. Menchaca has extensive experience in naturalventilation. She has helped develop natural ventilationand passive cooling performance simulations, whereshe had an instrumental role in the development andimplementation of a physical model to predict the thermalstratification of air in naturally ventilated rooms.When Dr. Menchaca was looking for a CFD tool for herwork, scSTREAM caught her attention because of itsaccuracy and its full, general purpose CFD capability.Dr. Menchaca’s most critical criterion was accuracy. Sherecalls that “we did not consider any software that did notpass our validation tests. This meant that the softwarewas able to model convective and radiative heat transfer

Easier, quicker and better featuresPicture 2: Dr. Alejandra Menchaca,a building scientist at Payette.She obtained Master’s andPh.D. Degrees in Aerospace andMechanical Engineering from MIT.at room scale accurately, as well as external airflow.”For the budget Payette had available, scSTREAM wasthe most viable option after testing of the candidatetools was completed. “scSTREAM was the only softwarewithin our price range that was able to accuratelyreplicate room airflow simulations with convective andradiative heat transfer. Our validation study consisted ofcomparing scSTREAM’s output to experimental resultsof flow inside an enclosure with a hot and a cold wall(Figure 1). We compared the temperature and velocityoutput for simulations accounting for and neglectingradiation, and found that scSTREAM’s results were closerto experimental results than any other package we hadtested,” said Dr. Menchaca.She also pointed out that the ease of geometry andmesh generation was one of the strengths of scSTREAM.“The ability to easily import Rhino and SketchUpgeometries was a big advantage that we were not evenoriginally considering. This saves me a lot of time, andallows us to model exactly what architects need tobe modeled. The several meshing options offered byscSTREAM are something we had not seen in othersoftware within our price range. Meshing has neverbeen easier,” she said. Furthermore, one of the featuresDr. Menchaca really liked was the scSTREAM GUI. “Thisis where scSTREAM was probably the most superiorcompared to other CFD packages. The scSTREAMinterface is very intuitive and defining boundaryconditions – often the most painful part of setting upa simulation – is extremely simple. I tend to skip ’wizards’in most software, but scSTREAM’s external airflowsimulation wizard is a true time saver.” The external airflowsimulation wizard sets the boundary conditions for all sixcomputational boundaries with only a couple of clicks andtyped inputs.When Dr. Menchaca talks about simulation time she says“we cannot afford to run week‑long simulations, althoughwhile we are still waiting for the perfect day when CFDsimulations take one minute to complete, scSTREAMsimulation times are relatively short.” Because ofscSTREAM’s reasonable cost and efficient performanceDr. Menchaca could run a simulation on her laptop ifneeded. This enabled her to continue running jobs whenshe was away from her office.The way scSTREAM processes the data from an analysismakes it easy to visualize the results. Dr. Menchacafirst mentioned scSTREAM’s user‑friendly interface andFigure 1: Case example of air temperature validation inside a building (validation setting on left, result on right)cradle-cfd.com hexagonmi.com Manufacturing Intelligence3

Figure 2: Results of an external wind flow study post‑processed in scSTREAM ‑ perspective view (left) and top view (right)explained that user‑friendly, high quality post‑processingcapabilities are critical for architectural firms like Payette.scSTREAM’s post‑processor enables users to instantlycreate surfaces, planes, volumes, streamlines, animations,dynamic views and much more. “Post‑processing optionsseem to be endless,” she said. “I often use streamlineswith semi‑transparent arrows, overlaid on contourplots (Figure 2). I also like the particle animations andall animations in general, which make it easy to conveyresults to people in the office. My students discoveredthe ability to record videos of their animations, which wasmind‑blowing.” She continued, “another priceless featureis that I can visualize several outputs and compare them,side by side or as an animation.” Of all the scSTREAMpost‑processing features, Dr. Menchaca thoughtone of the most helpful was Status File, which savespost‑processing settings including viewpoint, geometrymodification, image plots and graphs. It can then retrievethem into any post‑files.One last thing Dr. Menchaca liked about scSTREAM wasCradle’s dedicated technical support, which ultimatelyconvinced her to select scSTREAM. “The quality, and mostimportantly, quick response offered by Cradle’s technicalsupport has allowed us to overcome problems and bugsin a matter of hours, compared to the several days thatone needs to wait with other firms.”CFD analysis at a design firm andthe future of CFD for architectureCFD analysis is known to help designers and engineersunderstand and improve their architectural designs.However, practitioners in the architectural field oftensay they are hesitant to commit to CFD. Dr. Menchacaprovided her thoughts on this matter. “I think the currentusage of CFD in the architecture industry has not reachedits full potential. Because of cost, time and expertiserequired, running a CFD simulation means waiting for atleast a month to get an answer to any questions.” The timerequired to perform a CFD analysis is certainly an issuethat affect the role of CFD in the design processes.4According to Dr. Menchaca, time is an even greaterconstraint when the architectural firm outsourcesthe CFD work to a supplier. “By the time the CFD resultsare received, the building is likely to have changeddramatically. This means that, in general, we will onlyoutsource CFD studies for building elements that are lesscritical.” In contrast, the situation is entirely differentat Payette where building scientists conduct energymodeling and CFD analysis alongside their design team.Dr. Menchaca described the benefit of having CFDcapabilities in‑house. “Having CFD capabilities in‑houseallows us to speed up the simulation process to a week orso, and also allows us to tweak and explore more optionsas the design evolves.”She also explained some of the differences betweenthe current design process and the past. “Our office usedto hire outside consultants to evaluate indoor thermalcomfort conditions or to conduct wind studies, studieswhich usually require about one month to get results. Nowwe do most of the early design simulations in‑house, whichhas allowed us to use the results to modify the buildingdesign. This saves us both money and valuable time.”CFD will make greater contributions to the architecturalindustry as technology continues to improve “the easierand quicker it becomes to run accurate CFD simulations,the more CFD will be used as a tool that impacts buildingdesign, rather than an afterthought.” Dr. Menchacacompared this to the way energy modeling has slowlybecome more common in the early design stages and nowimpacts the design process.Lastly, Dr. Menchaca was asked about one featureshe would like to test with scSTREAM. “I have not hadthe chance to really test particle dispersion, which isextremely relevant for us, particularly in the healthcarepractice. Also, I would like to run parametric tests withscSTREAM, to evaluate several design options withouthaving to set each case up, just like the Wind Tool doeswhen it tests several wind directions.”Dr. Menchaca’s application example of scSTREAMindicates that scSTREAM will play even more significantrole in building design in future.Manufacturing Intelligence hexagonmi.com cradle-cfd.com

Hexagon is a global leader in sensor, software and autonomous solutions.We are putting data to work to boost efficiency, productivity,and quality across industrial, manufacturing, infrastructure, safety,and mobility applications.Our technologies are shaping urban and production ecosystemsto become increasingly connected and autonomous – ensuring a scalable,sustainable future.Software Cradle, part of Hexagon’s Manufacturing Intelligence division,provides highly reliable, multiphysics-focused computational fluiddynamics (CFD), thermal dynamics software and integrated simulation toolsthat enhance customers’ product quality and creativity. Learn more atcradle‑cfd.com. Hexagon’s Manufacturing Intelligence division providessolutions that utilise data from design and engineering, production andmetrology to make manufacturing smarter.Learn more about Hexagon (Nasdaq Stockholm: HEXA B) at hexagon.comand follow us @HexagonAB. 2020 Hexagon AB and/or its subsidiaries and affiliates. All rights reserved.Contents and specifications of products are as of October 31, 2014 and subject to change without notice.We shall not be held liable for any errors in figures and pictures, or any typographical errors in this brochure.

dynamics (CFD), thermal dynamics software and integrated simulation tools that enhance customers’ product quality and creativity. Learn more at cradle‑cfd.com. Hexagon’s Manufacturing Intelligence division provides solutions that utilise data from design and engineering, production and metrology to make manufacturing smarter.