Transcription

Propane Stripping MachinePE440STOperator’s Manual

Instructions For UseFailure to read and understand this manual before operating this machine or performing serviceon this machine may result in injury to the operator or nearby personnel or result in damage to themachine or nearby property. Each operator must be trained in the operation of this machine beforebeing allowed to use it. Contact Amano Pioneer Eclipse Customer Service at 1-800-367-3550 or 1-336-372-8080 or an authorized Amano Pioneer Eclipse Distributor to inquire about training or torequest a replacement manual.NOTICEProper maintenance is necessary with all propane powered floormachines. Following the scheduled maintenance procedures found inyour operation manual will provide many years of uninterrupted service.In addition to the scheduled maintenance procedures listed it isrecommended to have your machine serviced by certified service personnelevery three months. This service should include an emissions check.3

DANGER! For your safety, if you smellpropane:1. Extinguish any open flame.2. Open window.3. Do not touch electrical switches.4. Immediately call your propane supplier.DANGER! Do not store or use gasoline orother flammable vapors and liquids in thevicinity of this or any other appliance.Record This Important InformationDate of PurchasePurchased FromAddressCity State ZipPhone ContactMachine ModelMachine Serial NumberImportant Phone NumbersMedical EmergencyPoliceFire DepartmentIn this Operation Manual you will find three statements that you must read and observe to ensuresafe operation of this machine.DANGER! indicates that the possibility of severe bodily injury or death can occur if DANGER!statements are ignored. Read and observe all DANGER! statements included in the OperationManual and attached to the machine.WARNING! indicates that the possibility of bodily injury to the operator and other people can occurif WARNING! statements are ignored. Read and observe all WARNING! statements included inthe Operation Manual and attached to the machine.CAUTION! indicates that the possibility of damage to the machine or other property can occur ifCAUTION! statements are ignored. Read and observe all CAUTION! statements included in theOperation Manual and attached to the machine.4

Table of ContentsQuick Reference Specifications.6Oil Filter Replacement.24Safety Precautions.7Spark Plug Inspection and Replacement.24Refueling and Storage of Fuel Cylinders.9Hood Removal.24Operator Responsibility.9Air Filter Inspection and Replacement.24Canadian Safety Requirements.10Engine Dust Filter.25Test for Operator-Ear Sound Pressure Level.11Valve Clearance & Re-torque Heads.25Test for Hand Arm Vibration.11Valve Seating.25Machine Preparation.12Head Bolt Maintenance.25Unpacking the Machine.12Cooling Fin Maintenance.25Filling the LP Cylinder.12Inspect Fuel Hose and Connections.25Installing the LP Cylinder.12Inspect Brushes and Pad Holders.25Machine Components.13Belt Maintenance.26Controls and Instruments.13Belt Replacement.26Engine Ignition Switch.14Gearbox Maintenance.26Hour Meter/Tachometer.14Tire Maintenance.26Bail Throttle.14Battery Maintenance.27Fuse.14Machine Storage.27SafeSense Emissions Monitoring.15Repacking the Machine.27Rok-Bak & Pad Change.16Transporting the Machine.27SafeStop (optional).16Machine Specifications.28Pad / Brush Change.17Parts Manual.29Handle Adjustment.17Electrical Schematic (with SafeSense).30Transport Cart.18Electrical Schematic (without SafeSense).31How the Machine Works.18Connections (with SafeSense).32Pre-Operation Checklist.18Connections (without SafeSense).34LP Fuel Cylinder.19Engine Assembly.36Installing the LP Fuel Cylinder.19Frame Assembly.38Starting the Machine.20Bulkhead Assembly.40Idling and Stopping the Machine.20Main Assembly.42Stripping.20Main Assembly (Deck).44Machine Troubleshooting.21Regulator, Handle, & Hood Assembly.46Maintenance.22Transport Cart Assembly.48Scheduled Maintenance Chart.22Small Off Road Engine Certification Warranty.51Oil Level Inspection.23Manufacturer’s Warranty.52Oil Change.23Safety Awareness Form.535

Quick Reference Specifications:Capacities:l Engine Oil:- Filter not removed: 1.6qt. (1.5L)- Filter removed: 1.8qt. (1.7L)- Engine Oil Type: SAE30 with API Service Classification SH or SJRoutine Maintenance Parts:lEngine Dust Filter (Hood): MP373400lEngine Oil Filter: KA490657007lEngine Primary Air Filter (Paper Element): KA110130752lEngine Air Pre-Cleaner (Foam Element): KA110137046lSpark Plug: KA920702112lBattery:MP362200lDrive Belt:MP402100 (21”/38”)lFuses:SS2570 (20A)MP043000 (7.5A)lLP Cylinder: MP105900 (Steel)lBrushes / Pad Holders:16” Brush: BA013000 (30” - Qty. 2)16” Pad Holder: BA013500 (30” - Qty.2)20” Brush: BA012800 (38” - Qty. 2)20” Pad Holder: BA013700 (38” - Qty. 2)Your Authorized Amano Pioneer Eclipse Distributor:Authorized Amano Pioneer Eclipse Distributor Phone Number:Amano Pioneer Eclipse Phone Number: 1-336-372-80806

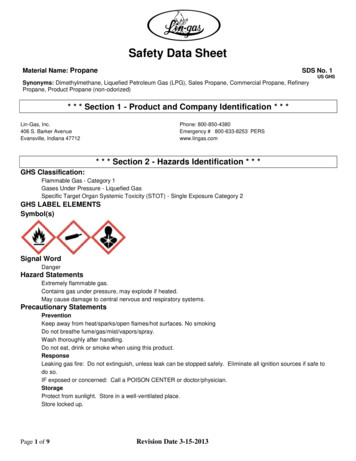

Safety PrecautionsDANGER! Federal law and California State lawprohibits the following acts or the causing thereof: (1)the removal or rendering inoperative by any personother than for purposes of maintenance, repair,or replacement, of any device or element of designincorporated into any new engine for the purposeof emission control prior to its sale or delivery to theultimate purchaser or while it is in use, or (2) the use ofthe engine after such device or element of design hasbeen removed or rendered inoperative by any person.Anyone operating the machine should read thefollowing carefully and be informed of potentiallydangerous operating conditions. Operators shouldbe familiar with the location and use of all safetydevices on the machine. Do not use the machineif it is not in proper operating condition, and reportany damage or operation faults immediately.DANGER! Operate this machine in a well-ventilatedarea. It is the responsibility of the machine operator,machine owner, and the site manager to ensure that theair exchange system where the machine is to be used isin compliance with local building codes and is operatingproperly. Failure to operate this machine in a wellventilated area could lead to sickness, injury, or deathfrom carbon monoxide (CO) exposure.Among those acts presumed to constitute tampering arethe acts listed below: DO NOT tamper with the originalemission related part.l Throttle body and internal partsl Spark plugsl Magneto or electronic ignition systeml Air cleaner elementsl Crankcasel Cylinder headsl Breather chamber and internal partsl Intake pipe and tubel Regulatorl Fuel lock-offDANGER! This machine emits CO, which is colorless,odorless, non-irritating gas. The first symptoms of COexposure include headache, drowsiness, dizziness,and nausea. If you should experience any of thesesymptoms while operating the machine, shut off themachine and go outside to get fresh air. Have themachine tested for CO emissions by a qualified servicetechnician before using it again.WARNING! Overfilled or liquid withdraw cylinders candamage the fuel system and create a fire hazard. DONOT overfill the cylinder or use a liquid withdrawcylinder on the machine. If the regulator freezes stopthe burnisher and take the cylinder outside. Inspectcylinder, if a vapor withdraw cylinder, use gloves orpliers to open bleeder valve and purge cylinder untilonly vapor is escaping. If it is a liquid withdraw cylinder,replace with a vapor withdraw cylinder. Both cylindersare shown below.DANGER! Prolonged or high exposure to CO mayresult in vomiting, confusion, and collapse in additionto loss of consciousness and muscle weakness. Ifsuch symptoms occur, call 911 for emergency medicalattention. If you have experienced these symptoms,DO NOT operate this machine or any other propanemachine again until cleared by a physician. Excessiveexposure to CO can result in death.DANGER! Propane is a highly flammable fuel. If yousmell propane, shut off the machine immediately andtake it outside the building. DO NOT use the machineagain until a qualified service technician has correctedthe propane leak. DO NOT use or allow another personto use an ignition source such as a cigarette lighternear the propane machine. DO NOT smoke near thepropane machine. DO NOT vent a propane cylinderinside a building. DO NOT store propane cylindersinside a building.DANGER! This machine has parts, including the padassemblies, that can cause severe injury if these partsare contacted while they are moving. DO NOT allowany part of the body or clothing to come in contactwith these parts while they are moving. DO NOT tryto change attachments while the machine is running.DO NOT allow other people to come near the machinewhile it is in operation. DO NOT allow the machine torun unattended. DO NOT leave the machine in a placewhere unauthorized or untrained personnel could usethe machine. DO NOT run the machine with the pad offcenter, damaged or missing. DO NOT run machine withunsecured guards and shields. DO NOT operate themachine if the machine has loose parts.7

WARNING! Modifications or alterations to this machinecan lead to personal injury or damage to the machine.DO NOT make unauthorized modifications or alterationsto this machine. Amano Pioneer Eclipse assumesno liabilities for injury or damage resulting from anunauthorized modification or alteration to the machine.Any unauthorized modification or alteration to thismachine voids all warranties.CAUTION! DO NOT operate machine unless trained andauthorized. DO NOT operate machine unless you haveread and understand the operation manual. DO NOToperate machine in flammable or explosive areas.WARNING! The muffler and the engine become hotenough while the machine is in operation, and for along time after the machine is shut off, to cause severeburns. DO NOT touch these parts of the machine untilthey have cooled.CAUTION! When using machine, go slowly on inclines orslippery surfaces. Use care when operating machine inreverse.CAUTION! Before starting machine ensure all safetydevices are in place and functioning properly. Beforestarting machine check for proper operation.CAUTION! When servicing machine, stay clear of movingparts. DO NOT wear loose clothing when workingon machine. Block machine wheels before raising orjacking up machine. Use hoist stands that will supportthe weight of the machine. Wear eye and ear protectionwhen using pressurized air or water. Disconnectbattery connections before servicing machine. Use onlyreplacement parts supplied by Amano Pioneer Eclipseor a Amano Pioneer Eclipse Authorized Distributor orService Center.WARNING! Injury can occur to the eyes and body whileusing the machine. Safety goggles, safety shoes, andsafety clothing are recommended while operating themachine.WARNING! Continuous exposure to high noise levels cancause hearing loss. Hearing protection is recommendedwhile the machine is in operation.WARNING! Machine vibration may cause tinglingor numbness in the fingers or hands. Gloves arerecommended to reduce machine vibration. If tingling ornumbness persists, shut off the machine. If the vibrationis caused by loose parts, adjust or tighten these partsbefore using the machine again.CAUTION! When loading or unloading machine onto oroff a truck or trailer, turn machine OFF. Only use a truckor trailer that will support the weight of the machineto transport. DO NOT push the machine onto or off atruck or trailer unless the load height is 15 in (380mm)or less from the ground. Block machine wheels whentransporting. Tie the machine down securely to truck ortrailer when transporting.WARNING! Do not engage clutch to rotate brushes unlessthey are in contact with floor. This can damage thebrushes and/or the deck.CAUTION! Do not allow the machine to operate withoutmoving, it may damage the floor covering.WARNING! Do not operate machine on a dry floor, as thismay result in damage to the brush and/or the deck.CAUTION! A dirty engine filter can cause overheating.Check and replace following recommended maintenanceschedule.CAUTION! Overheating can be caused by insufficient orlow oil. Check oil before each use, and fill or change asneeded.CAUTION! Never over-fill engine with oil. Over-fillingcould cause irreparable damage to the engine.CAUTION! Overheating can be caused by dirty oil. Checkoil before each use and change regularly followingrecommended maintenance schedule.CAUTION! Do not engage starter for more than 5seconds. Allow a 10 second cool-down period forsecond failed start-up attempt.CAUTION! Perform all recommended scheduledmaintenance. Regular maintenance of your propanepowered floor machine is necessary to keep it in safeworking condition.8

This machine is manufactured forcommercial use only.Refueling and Storage of Fuel CylindersThis machine uses a 20lb (9.1kg) capacity aluminum orsteel cylinder, which meets the DOT 4E240 standards.These cylinders are also listed by UL. In addition, thesteel cylinder meets European TPED specificationsand is CE compliant. Filling should be done ONLYby a qualified propane dealer. FILL THROUGH THESERVICE VALVE ONLY. A properly filled cylinder shouldnot exceed 80% of the rated capapcity.This machine is designed and manufactured forcommercial floor stripping only. Amano PioneerEclipse does not recommend use of this machine inany environment other than an indoor environment.This machine is designed to strip most modern typesof flooring including composition tile, stone, marble,terrazzo, concrete, and resilient floor covering. Eventhough NFPA 11.13.2.3 says.”the use of floormaintenance machines in buildings frequented by thepublic, including the times when such buildings areoccupied by the public, shall require the approval of theauthority having jurisdiction.” Amano Pioneer Eclipsesuggests usage when occupancy of a given work area isminimal.DO NOT attempt cylinder repair. Return the cylinder toyour propane dealer if repair is necessary. Please notethat DOT regulations prohibit shipping of cylinders afterthe cylinder has been filled with propane. When not inuse, cylinders should always be stored outside in anupright position in a secure, tamper-proof, steel meshstorage cabinet. The cabinet may be located next tothe building, but with at least five feet (1.5 m) of spacebetween the cabinet and the nearest building opening(door or window).These machines should not be usedllllllIn nursing homes, hospitals, day-care centers, etc.that are occupied.By unqualified or untrained personnel.Unless properly maintained and adjusted.On areas with obstructions such as thresholds, flooroutlet boxes, etc.In areas where loose debris or other objects arepresent.In rooms and areas without proper ventilationThe cylinder to be used on this machine is a vaporwithdraw cylinder. A liquid withdraw cylinder is notto be used with this machine. The use of a liquidwithdraw cylinder on a vapor withdraw system couldfreeze the regulator and create a fire hazard. TheNational Fire Protection Association (NFPA) Standardfor Storage and Handling of LP Gas is the appropriateauthority for safe propane use. A copy of this publicationis available through the National Fire ProtectionAssociation (1-800-344-3555) or www.NFPA.org.Operator ResponsibilityThe operator is responsible for performing therecommended daily maintenance and checkups ofthe machine to keep it in good working condition. Theoperator must inform the service mechanic or supervisorwhen recommended maintenance procedures arerequired as described in the “MAINTENANCE” sectionof this manual.l Read this manual carefully before operating thismachine.l FOR SAFETY: DO NOT operate machine beforereading and understanding the operation manual.l Check the machine for shipping damage.Keep your machine regularly maintained by followingthe maintenance information in this manual. Order partsand supplies only from an Authorized Amano PioneerEclipse Distributor. Use the parts illustration section ofyour manual when ordering parts.During and after operation, perform the recommendeddaily and hourly procedures outlined in the MaintenanceChart.9

Canadian Safety RequirementsExigences de sécurité pour le Canada1. A sign indicating “NO SMOKING” shall bepermanently displayed at the storage area. Thesign shall be in accordance with the sign required inClause 10.12.3 of CAN/CGA-B149.2-M91, PropaneInstallation Code.1. Un panneau indiquant “ INTERDICTION DE FUMER“doit être affiché en permanence dans la zone destockage. Il doit être conforme au panneau exigé parla Clause 10.12.3 du CAN/CGA-B149.2-M91, Codeinstallation propane.2. When the cylinder is attached to the floormaintenance machine for use, the operator shall notleave the unit unattended except for short periods oftime such as rest stops, washroom, or meal stops.2. Lorsque le cylindre est fixé à la machine d’entretiendes sols pour son utilisation, l’opérateur ne doit paslaisser l’unité sans surveillan

air exchange system where the machine is to be used is in compliance with local building codes and is operating properly. Failure to operate this machine in a well-ventilated area could lead to sickness, injury, or death from carbon monoxide (CO) exposure. DANGER! This machine emits CO, which is colorless, odorless, non-irritating gas.