Transcription

HDPE Fittingsand EquipmentProduct Catalogwww.IntegrityFusion.comButt Fusion Electrofusion Socket Fusion Transitions Poly Ball Valves Equipment

Integri Fuse Product Catalog Table of ContentsMolded Butt Fusion.790 Degree ElbowsCaps45 Degree ElbowsFlange AdaptersTeesSDR 11 DI Backup RingsReducing TeesSDR 7 DI Backup RingsReducersSDR 11 316SS Backup RingsLateral WyesMJ Adapters & KitsElectrofusion.33CouplersSpecialy FittingsSDR 1190 Degree ElbowSDR 1745 Degree ElbowSDR 26TeesSDR 7ReducersBranch SaddlesFlex RestraintsTapping TeesSocket Fusion.5390 Degree ElbowsCouplersTeesCapsReducersSocket x Brass TransitionsTransitions Fittings . 59Standard NPTSupertech ID ControlledMPT or FPT Epoxy CoatedThreadedMPT or FPT 304 Stainless SteelWeld EndMPT or FPT 316 Stainless SteelGroovedGrooved Epoxy CoatedIntegriFuse OD ControlledThreadedGroovedPoly Ball Valves . 69Equipment . 732www.IntegrityFusion.com

IntegriFuse PE3408 / PE4710 / PE100 HDPE Fittings SpecificationsIntegriFuse fittings are manufactured with black high density bimodal polyethylenecopolymer designed for use in, but not limited to, potable water, natural gas, industrial,landfill, oil & gas, and mining applications.Fittings meet AWWA and ASTM-D2513 & ASTM-D3261 requirements, and aremanufactured with material that is NSF Standard 14 certified, and complies with ANSI/NSF Standard 61 health effects requirements. IntegriFuse fittings are recognized by thePlastic Pipe Institute as having a material designation code ofPE 3408, PE3608, PE 4710, and PE 100.Physical PropertiesDensityEnvironmental Stress CrackResistanceCarbon Black LoadingMelt FlowMechanical PropertiesPENTHardness, Shore DTensile Strength at BreakTensile Strength YieldElongation at BreakFlexural ModulusIzod Impact, NotchedHydrostatic Design BasisThermal PropertiesVicat Softening PointBrittleness TemperatureDecomposition TemperatureDescriptive PropertiesCell ClassificationProcessMetric.959 g/cm3 5000 hourEnglish0.0346 lb/in 5000 hourCommentsBlack: ASTM D4883Condition C; ASTM D16932.30%8.00 g/10 min@Load 21.6 kg,Temperature 190 CMetric 10000 hour66.037.9 MPa24.99 MPa 600%1.03 GPa4.81 J/cm6.89 MPa11.0 MPaMetric126 C, -118 C 220 CMetric2.30%8.00 g/10 min@Load 47.6 lb,Temperature 374 FEnglish 10000 hour66.05500 PSI3625 PSI 600%150 KSI9.00 ft-lb/in1000 PSI1600 PSIEnglish259 F -180 F 428 FEnglish445574CInjection MoldingASTM D1603ASTM D1238www.IntegrityFusion.comCommentsNotched Tensile; ASTM F1473ASTM D22402 in/min; ASTM D6382 in/min; ASTM D6382 in/min; ASTM D6382% Secant-Method; ASTM D790ASTM D256At 60 C; ASTM D2837Room Temp; ASTM D2837CommentsASTM D1525ASTM D746Thermal Stability; ASTM D2513CommentsASTM D33503

Order & Price InformationPricing: Please contact Integrity Fusion Products, Inc, or your local authorized distributor forpricing inquiries. We welcome all inquiries via telephone, email, or fax.Phone: 770-632-7530Fax: 770-632-7540E-mail: Info@IntegrityFusion.comOrdering: Minimum Billing: 50.00 (orders less than 50.00 will be subject to a handlingcharge)Terms: Net 30 days from date of invoice for established accounts.Freight Charges: All orders greater than 3,000 will be shipped freight allowed via standardground transportation (excluding equipment, backup rings, MJ Adapter kits, fabricated &non-stock items). Air-freight or expedited shipments will incur appropriate freight charges.For orders less than 3,000, freight will be prepaid and added to the invoice unless otherwisespecified.Order Placement: Orders are accepted by our Customer Service department via fax or emailand require a written purchase order. Integrity Fusion Products, Inc sells only to approveddistributors.Availability of Product: Integrity Fusion Products Inc. has a large inventory of HDPE fittingsand accessories. Items that are in stock are typically shipped within 24 hours. Non-stock orout of stock items will be processed with an estimated ship date given upon receipt of order.Cancellations: Cancellation of items that have been ordered may be subject to cancellationcharges. Some non-stock items may not be returnable.Rental Policy: Rental charges begin the date that the unit ships and continues up to, andincluding, the date returned. Accrued rental costs cannot be applied to the purchase ofequipment.4www.IntegrityFusion.com

Return PolicyAll returns must be approved by Integrity Fusion Products, Inc prior to return.An approved, RGA (Return Goods Authorization) form must be obtained by contacting ourCustomer Service department. Upon approval, the RGA form, including a list of all items tobe returned, conditions concerning restocking fees and/or credit information, and shippinginstructions(if applicable) will be issued and sent via fax or email. A copy of the RGA formmust accompany the returned shipment for proper credit to be issued.Policies concerning returned materials:Products stored outside will not be accepted for return.Standard Stock Items:A restocking fee will be charged for the return of standard stock items:25% restock within 1 - 30 days35% restock within 31- 180 days50% restock within 181 – 365 daysIntegrity Fusion will not accept returns after 365 days.Material must be returned in a saleable condition. Items stored outside will not be acceptedfor return or credit.Customer will be responsible for freight charges incurred with the return of the materials.Non-stock or Custom Ordered Items:Most non-stock or custom ordered items are non-cancelable/non-returnable. Any productthat is not a standard stock item is subject to factory acceptance for return approval.Freight instructions will be issued for these items on the approved RGA form obtained byour Customer Service department.www.IntegrityFusion.com5

Limited WarrantyIntegrity Fusion Products, Inc. warrants its materials to be free of defects in workmanship undernormal use, service and when used for the purposes under the conditions for which they areintended.This warranty shall not apply to any Integrity Fusion Products, Inc. material that has been altered,repaired and/or used in any way, stored outside, or has been subject to misuse, negligence,accident and/or has not been installed in accordance with installation instructions.Installation of EF fittings requiring 42V-48V to fuse must be carried out using an IntegriFuse EF processor. The IntegriFuse processor is an 8-48-volt output multi-voltage fusion processor with temperature compensating feature operating at 110/120 VAC requiring power supplied through a portablepower generator rated at 6500 continuous watts (minimum). If pipe is more than 1.5% out of roundthe use of a ReRound Clamp is recommended to ensure proper installation.Installation instructions must be adhered to or our Limited Warranty is null and void. Installationof electrofusion fittings must be carried out by properly trained and qualified operator(s) and/orby witness of the factory representative.The obligation of Integrity Fusion Products, Inc. under this warranty shall be limited to thereplacement of any part that may prove defective under normal use.Integrity Fusion Products, Inc. shall have the right to inspect said material and purchaser shall, ifrequested, return defective product prepaid to Integrity Fusion Products, Inc. Purchaser shallassume all responsibility and expenses for removal, reinstallation and freight charges inconnection with the foregoing remedy.Integrity Fusion Products, Inc. shall not be liable for indirect, special, incidental or consequentialdamage or penalties and does not assume any liability of purchaser to others, or to anyone forinjury to persons and/or property.Integrity Fusion Products, Inc. shall not be held liable for any delays caused by shipping anymaterial or equipment by third party shipping companies. Integrity Fustion Products, Inc. shallnot be responsible for any delays caused by shipping errors of material and/or equipment.Any claim regarding shortage or damages from shipment of material must be submitted inwriting to Integrity Fusion Products, Inc within 10 days after receipt of shipment. Buyer shall noteloss or damage on shipment Bill of Lading and provide a delivery receipt stating such with driver’ssignature.Purchaser is responsible for passing on this Limited Warranty to their customer.6www.IntegrityFusion.com

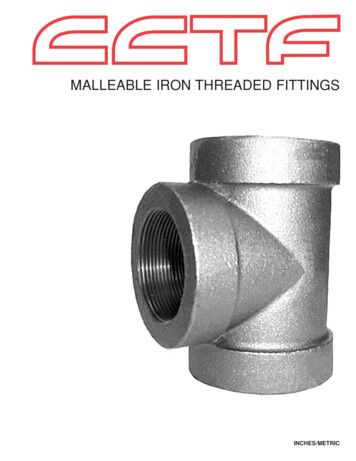

IntegriFuse Molded Butt Fusion Fittings90 Degree Elbows45 Degree ElbowsTeesReducing TeesReducersWyesCapsFlange AdaptersBackup RingsMJ Adapters & Kitswww.IntegrityFusion.com7

IntegriFuse Molded Butt Fusion 90 Degree ElbowsSDR 17 (Standard Dimension Ratio) 125 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEWeightPipe S-1790BI-8IPS-1790BI-10IPS-1790BI-12IPS-17SDR 11 (Standard Dimension Ratio) 200 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEWeightPipe 40.101.053.820.101”3.312.180.121.324.060.151 ¼”3.482.150.151.664.410.251 ion.com9

IntegriFuse Molded Butt Fusion 90 Degree Elbows10SDR 9 (Standard Dimension Ratio) 255 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEWeightPipe 990BI-3IPS-990BI-4IPS-990BI-6IPS-990BI-8IPS-9SDR 7 (Standard Dimension Ratio) 335 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEWeightPipe IntegrityFusion.com

IntegriFuse Molded Butt Fusion 45 Degree ElbowsSDR 17 (Standard Dimension Ratio) 125 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEPipe I-6IPS-1745BI-8IPS-1745BI-10IPS-1745BI-12IPS-17SDR 11 (Standard Dimension Ratio) 200 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEPipe w.IntegrityFusion.com11

IntegriFuse Molded Butt Fusion 45 Degree Elbows12SDR 9 (Standard Dimension Ratio) 255 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEPipe 9SDR 7 (Standard Dimension Ratio) 335 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEPipe -7www.IntegrityFusion.com

IntegriFuse Molded Butt Fusion TeesSDR 17 (Standard Dimension Ratio) 125 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEPipe 17TEEBI-12IPS-17SDR 11 (Standard Dimension Ratio) 200 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEPipe 01.052.141”6.623.310.121.322.181 ¼”6.973.480.151.662.151 BI-10IPS-11TEEBI-12IPS-11www.IntegrityFusion.com13

IntegriFuse Molded Butt Fusion Tees14SDR 9 (Standard Dimension Ratio) 255 PSI (Working Pressure at 73.4 F)Nominal IPSABCDEWeightPipe 3.786.890.264.503.9

Fittings meet AWWA and ASTM-D2513 & ASTM-D3261 requirements, and are manufactured with material that is NSF Standard 14 certified, and complies with ANSI/ NSF Standard 61 health effects requirements. IntegriFuse fittings are recognized by the Plastic Pipe Institute as having a material designation code of PE 3408, PE3608, PE 4710, and PE 100. PE3408 / PE4710 / PE100 HDPE