Transcription

RECOMMENDED PRACTICEDNVGL-RP-D101Edition July 2017Structural analysis of piping systemsThe electronic pdf version of this document, available free of chargefrom http://www.dnvgl.com, is the officially binding version.DNV GL AS

FOREWORDDNV GL recommended practices contain sound engineering practice and guidance. DNV GL AS July 2017Any comments may be sent by e-mail to rules@dnvgl.comThis service document has been prepared based on available knowledge, technology and/or information at the time of issuance of thisdocument. The use of this document by others than DNV GL is at the user's sole risk. DNV GL does not accept any liability or responsibilityfor loss or damages resulting from any use of this document.

GeneralThis document supersedes the October 2008 edition of DNV-RP-D101.The purpose of the revision of this service document is to comply with the new DNV GL document referencecode system and profile requirements following the merger between DNV and GL in 2013. Changes mainlyconsist of updated company name and references to other documents within the DNV GL portfolio.Some references in this service document may refer to documents in the DNV GL portfolio not yet published(planned published within 2017). In such cases please see the relevant legacy DNV or GL document.References to external documents (non-DNV GL) have not been updated.Changes Sec.3 Topside processing piping— [3.11.2.1]: The approach for estimating the blast drag pressure has been changed.Reference to DNVGL-OS-A101 Table-1 and DNVGL-OS-A101 Figure-1 have been added. Appendix J— Appendix J has been removed.Editorial correctionsIn addition to the above stated changes, editorial corrections may have been made.Recommended practice — DNVGL-RP-D101. Edition July 2017Structural analysis of piping systemsDNV GL ASPage 3Changes - currentCHANGES – CURRENT

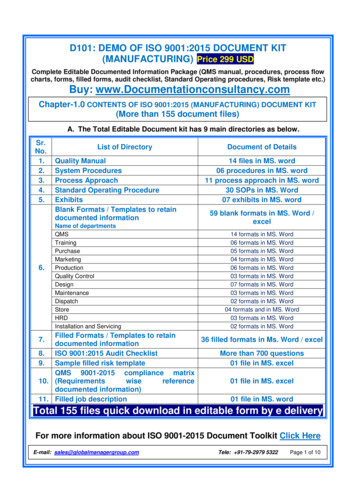

Changes – current. 3Section 1 General. 71.1 Introduction.71.2 Objective.71.3 Relationship to other codes. 71.4 References. 71.5 Definitions.101.6 Abbreviations and symbols. 11Section 2 Structural Analysis of Piping Systems. 142.1 Introduction. 142.2 Pipe stress and flexibility analysis.142.3 Analysis tools.172.4 Piping design codes. 18Section 3 Topside process piping. 213.1 General. 213.2 Commonly used design codes. 213.3 Type of calculations. 213.4 Loads to be considered in piping design. 213.5 Wall thickness calculations. 233.6 Flexibility calculations. 243.7 Equipment nozzle load calculations. 243.8 Flange calculations. 263.9 Pressure relief- and discharge force calculations.273.10 Expansion and slip-joint thrust load calculations. 283.11 Blast load calculations. 293.12 Fatigue calculations. 323.13 Non-standard component calculations. 343.14 Load case description- and combinations. 343.15 Pipe stress priority piping. 343.16 Design of pipe supports.363.17 Documentation of stress analysis. 383.18 Verification.40Section 4 Subsea piping. 414.1 General. 41Recommended practice — DNVGL-RP-D101. Edition July 2017Structural analysis of piping systemsDNV GL ASPage 4ContentsCONTENTS

4.3 DNVGL-ST-F101 Submarine pipeline systems. 424.4 Recommended design cases. 424.5 Hydrogen induced stress cracking (HISC). 434.6 Documentation of pipe stress analysis. 444.7 Verification. 44Section 5 Non standard piping components. 455.1 General. 455.2 Requirements in piping codes.455.3 FEA design and qualification of non-standard pipingcomponents. 46Section 6 Verification. 516.1 General. 516.2 Self check. 516.3 Internal verification. 516.4 Verification carried out by a 3rd part. 51Appendix A Vortex induced vibrations. 54A.1 General. 54A.2 Relevance to piping. 54A.3 Scope. 54A.4 Important parameters. 54A.5 Vortex shedding frequency. 55A.6 Lock-in. 56A.7 In-line VIV.56A.8 Cross-flow VIV.56A.9 Reduced velocity, VR. 56A.10 Stability parameter, Ks. 56A.11 Effective mass, me. 57A.12 Added mass, ma. 57A.13 Limitation to added-mass equation. 57A.14 Common error in pipe stress software. 58A.15 Wind induced vortex shedding. 58A.16 Sea current induced vortex shedding. 58A.17 Recommended VIV check-out procedure. 59A.18 Methods used to reduce VIV. 60A.19 Physical properties of air and seawater.61Recommended practice — DNVGL-RP-D101. Edition July 2017Structural analysis of piping systemsDNV GL ASPage 5Contents4.2 Commonly used design codes. 41

Appendix C Third party check list, global Analysis. 64Appendix D Check list, local FE-analysis. 66Appendix E Restraint symbols.68Appendix F Pipe stress isometric. 69Appendix G Load case combinations. 70Appendix H Subsea load case matrix. 71Appendix I Subsea pipe stress model. 73Changes – historic. 74Recommended practice — DNVGL-RP-D101. Edition July 2017Structural analysis of piping systemsDNV GL ASPage 6ContentsAppendix B Analyst check list, global analysis.62

SECTION 1 GENERAL1.1 IntroductionThis recommended practice is based on, and intends to, show the best from European industrial practicefor structural analysis of piping systems intended for the offshore sector. Typical applications are oil andgas platforms, FPSOs, drilling units and subsea installations. Subsea installations are installations such astemplates, manifolds, riser-bases and subsea separation-and pump modules.There is no piping design code that fully covers these topics, and hence engineering companies havedeveloped a variety of internal design philosophies and procedures in order to meet the requirements tostructural integrity, safety, economical and functional design of piping systems.A number of references are given to below listed codes and standards from which equations for a largenumber of pipe-stress relevant calculations can be found.1.2 ObjectiveThe objective of this recommended practice is to describe a best practice for how structural analysis ofpiping systems can be performed in order to safeguard life, property and the environment. It should berduseful for piping structural engineers organising and carrying out the piping design, and any 3 partyinvolved in the design verification, such as classification societies, notified bodies etc. The proposedproject documentation should provide the operator with essential design information and be useful duringcommissioning, maintenance, future modifications, and useful in order to solve operational problems, if andwhen they occur.1.3 Relationship to other codesThis recommended practice is strongly related to the use of a large number of international design codes,standards, directives and regulations in order to succeed with a professional design.1.4 ReferencesThe below listed codes, standards, recommended practices, specifications and software are considered to bethe most important ones for analysis of piping systems and piping components to be installed in an offshoreenvironment.1.4.1 ASME codes and standardDocument codeTitleASME B16.5Pipe Flanges and Flange FittingsASME B16.9Factory Made Wrought Steel Butt welding FittingsASME B16.20Metallic Gaskets for Pipe Flanges-Ring Joint, Spiral Wound, and JacketedASME B16.28Non-metallic Flat Gaskets for Pipe FlangesASME B16.47Large Diameter Steel FlangesASME B16.49Factory Made Wrought Steel Butt welding Induction Bends for Transportation and DistributionSystemsASME B31.1Power PipingASME B31.3Process PipingRecommended practice — DNVGL-RP-D101. Edition July 2017Structural analysis of piping systemsDNV GL ASPage 7

Document codeTitleASME B31.4Pipeline Transportation Systems for Liquid Hydrocarbons and Other LiquidsASME B31.8Gas Transmission and Distribution Piping SystemsASME B36.10MWelded and Seamless Wrought Steel PipeASME B36.19MStainless Steel PipeASME BPVC Sect. IIPart D Material PropertiesASME BPVC Sect. IIIRules for Nuclear Facility Components, Division 1ASME BPVC Sect. VIIIRules for Construction of Pressure Vessels, Division 1 & 21.4.2 API codes and standardsDocument codeTitleAPI 6ASpecification for Wellhead and Christmas tree EquipmentAPI 6AFCapabilities of API Flanges under Combination of LoadAPI RP 2A-WSDRecommended Practice for Planning, Designing and Constructing Fixed Offshore Platforms Working Stress DesignAPI RP 2FBRecommended Practice for the Design of Offshore Facilities against Fire and Blast LoadingAPI RP 14ERecommended Practice for Design and Installation of Offshore Production Platform PipingSystemsAPI RP 17ADesign and Operation of Subsea Production Systems (API equivalent to ISO 13628)API RP 520Sizing, Selection and Installation of Pressure-relieving Devices in RefineriesAPI Std. 610Centrifugal Pumps for Petrochemical and Natural Gas IndustriesAPI Std. 611General-Purpose Steam Turbines for Petroleum, Chemical and Gas Industry ServicesAPI Std. 616Gas Turbines for Petroleum, Chemical, and Gas Industry ServicesAPI Std. 6171Axial and Centrifugal Compressors and Expander-compressors for Petroleum, Chemical andGas Industry Services1.4.3 Other standards and bulletinsDo

EJMA The EJMA Standards for design, installation and use of expansion bellows NEMA SM23 Steam Turbines for Mechanical Drive Service WRC 107 WRC Bulletin No. 107. Local Stresses in Spherical & Cylindrical Shells due to External Loadings