Transcription

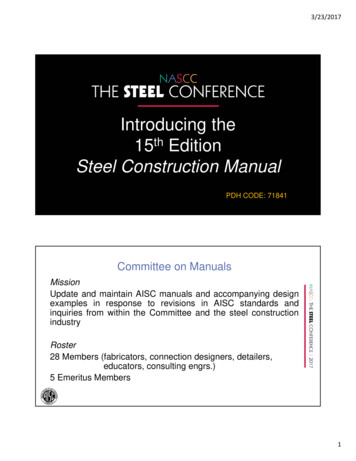

3/23/2017Introducing the15th EditionSteel Construction ManualPDH CODE: 71841Committee on ManualsMissionUpdate and maintain AISC manuals and accompanying designexamples in response to revisions in AISC standards andinquiries from within the Committee and the steel constructionindustryRoster28 Members (fabricators, connection designers, detailers,educators, consulting engrs.)5 Emeritus Members1

3/23/2017Steel Solutions Centersolutions@aisc.orgor866.ASK.AISC (866.275.2472)Table of ContentsPart 1. Dimensions and PropertiesPart 2. General Design ConsiderationsPart 3. Design of Flexural MembersPart 4. Design of Compression MembersPart 5. Design of Tension MembersPart 6. Design of Members Subject to Combined Forces2

3/23/2017Table of Contents (continued)Part 7. Design Considerations for BoltsPart 8. Design Considerations for WeldsPart 9. Design of Connecting ElementsPart 10. Design of Simple Shear ConnectionsPart 11. Design of Partially Restrained Moment ConnectionsPart 12. Design of Fully Restrained Moment ConnectionsPart 13. Design of Bracing Connections and Truss ConnectionsPart 14. Design of Beam Bearing Plates, Column Base Plates, AnchorRods and Column SplicesPart 15. Design of Hanger Connections, Bracket Plates, and CraneRail ConnectionsTable of Contents (continued)Part 16. Standards 2016 AISC Specification for Structural Steel Buildings 2014 RCSC Specification for Structural Joints UsingHigh-Strength Bolts 2016 AISC Code of Standard Practice for SteelBuildings & BridgesPart 17. Misc. Data and Mathematical Information3

3/23/2017Part 1. Dimensions and Properties New shapes:W-shapes (& corresponding WT-shapes)HP-shapeAnglesHSSPipePart 1. Dimensions and x808& corresponding 0x1L10x10x7/8L10x10x3/4& corresponding 2Ls4

3/23/2017Part 1. Dimensions and ,HSS12x12x3/4HSS10x10x3/43/43/4, 5/8, 1/23/4, 5/8, 1/23/43/43/43/4HSS24x12x3/4, 5/8, 1/2HSS20x12x3/4HSS16x12x3/4Pipe 26, 24, 20, 18, 16, 14 (std and x-strong)& Pipe 12, 10 (xx-strong)Part 1. Dimensions and Properties New shapes Updated fillet radiikdet, k1, T affected5

3/23/2017Part 1. Dimensions and Properties New shapesUpdated fillet radiiCheck material availability: See www.aisc.orgV15.0 DatabasePart 2. General Design Considerations Table 2-4: Applicable ASTM Specifications for VariousStructural Shapes Table 2-5: Applicable ASTM Specifications for Plate Table 2-7: Summary of Surface Preparation Standards6

3/23/2017Part 2. General Design ConsiderationsPart 2. General Design Considerations7

3/23/2017Part 3. Design of Flexural Members Footnote for noncompact sections:“ tabulated values have been adjusted accordingly”(also in Part 4 column tables)Part 3. Design of Flexural Members Footnote for noncompact or slender sections:“ tabulated values have been adjusted accordingly” Table 3-19, Composite beam table footnote:“ Ductility (slip capacity) of shear connection at thebeam/concrete interface may control minimum Qnvalue per AISC Spec. Sect. I3.2d.”8

3/23/2017Part 4. Design of Compression Members Eliminated K factor in tables/discussionLc Clarifies Cw 0 is used in WT column tables Chapter E revisions reflected in tables- Slender members- Double angles use more general Fcry equation Removed Tables 4-13 to 4-20: Composite Columns W-shape column tables: added 65 and 70 ksi for somePart 4. Design of Compression Members W-shape column tables: added 65 and 70 ksi for some9

3/23/2017Part 6. Design of Members Subject to Combined Forces New Tables 6-1a & 6-1b: Limiting Width-to-Thickness RatiosConsistentwith Spec.Tables B4.1aand B4.1bPart 6. Design of Members Subject to Combined Forces New Tables 6-1a & 6-1b: Limiting Width-to-Thickness Ratios New Table 6-2: Available Strength for Members Subject toAxial, Shear, Flexural and Combined Forces, W-Shapes10

3/23/2017The Super TableExample—Table 6-2Given: W14x99, ASTM A992, pinned ends (K 1.0),Lcx Lcy Lb 14 ftCheck shape for combined loading using LRFD, withrequired strengths as follows:LRFDPu 400 kipsMux 250 kip-ftMuy 80.0 kip-ft11

3/23/2017Example— Table 6-2Solution: c Pn 1130 kips bMnx 642 kip-ftExample—Table 6-2Solution: bMny 311 kip-ft12

3/23/2017Example—Table 6-2Solution:Pu400 kips Pc1130 kips 0.354PBecause u 0.2, use Spec. Eq. H1-1a:PcPr 8 Mrx Mry Pc 9 Mcx Mcy 1.0 400 kips 8 250 kip-ft 80.0 kip-ft 0.928 1.0 o.k.1130 kips 9 642 kip-ft 311 kip-ft Part 6. Design of Members Subject to Combined Forces New Tables 6-1a & 6-1b: Limiting Width-to-Thickness Ratios New Table 6-2: Available Strength for Members Subject to Axial,Shear, Flexural and Combined Forces, W-Shapes Tables 6-3, 6-4 and 6-5: Cross-Section Strength Eqns &Properties for Encased W-Shapes, Filled Rectangular HSS,Filled Round HSSSee L.F. Geschwindner, Eng. Journal, 2010 &M. Denavit et al., Eng. Journal, 201513

3/23/2017Part 7. Design Considerations for Bolts Tables 7-14 includes tension-control boltsPart 8. Design Considerations for WeldsECCENTRICALLY LOADED WELD GROUPSEccentricity in the Plane of the Faying SurfaceNVPM1) Instantaneous Center of Rotation Method2) Elastic Method3) Plastic Method - new14

3/23/2017Part 8. Design Considerations for WeldsECCENTRICALLY LOADED WELD GROUPSEccentricity in the Plane of the Faying SurfacePlastic Method:VlwNfa lw4Mfb 2lwfv (8-12)(8-13)(8-14)fw fv2 fa fb 2(8-15)Part 9. Design of Connecting Elements Connecting elements subject to combined loading2010:2fe fx2 fx fy fy2 3fxy Fy22016:(9-1)4Mr Pr Vr 1.0Mc Pc Vc (9-1)Dowswell, Engineering Journal, No. 1, 2015;Neal, Journal of Applied Mechanics, 1961;Astaneh, Steel Tips, 199815

3/23/2017Part 9. Design of Connecting Elements Connecting elements subject to combined loading Coped beam strength No limits on cope length or cope depth Post-yield strength explicitly accounted for Coped flexural local buckling strength—top flange only coped ( bMn, Mn/ b)When pMn M p Fy Znetwhere(9-6)When p 2 p Mn M p (M p M y ) 1 p When 2 pMn Fcr Snet hotw p 0.475(9-7)k1 fk 1.61Fcr (9-8)k1EFy0.903Ek1 216

3/23/2017Part 9. Design of Connecting Elements Coped beam strength—top & bottom flangeUse Spec. Section F11When cb ct : ct L d Cb 3 ln b 1 ct 1.84d d When ct cb :(9-15)ct cb2 c L dCb b 3 ln b 1 ctd d ct 1.84 (9-16)Dowswell & Whyte, Engineering Journal, No. 1, 2014Part 9. Design of Connecting Elements Connecting elements subject to combined loading Coped beam strength Other Spec. requirements and design considerations- Prying action- Plate elements subjected to out-of-plane bending17

3/23/2017Part 9. Design of Connecting Elements14th Ed: max 45 15th Ed: max 60 - Prying actionPrying forces in teeTypical bolt locationEdge bolt- Prying actionLRFDtmin 1 4Tu b pFu 1 ASD(9-19a)tmin 4Ta b pFu 1 (9-19b)d p 1.0 if 1 or lesser of 1 and1 if 1 1 1 Bc 1 Tr b a Bc available tension per bolt based ontension only or combined tension & shear rupture 18

3/23/2017Part 9. Design of Connecting Elements- Plate elements subjected to out-of-plane loadsAlso see Spec. Sect. J10.10.Transverse loadIn-plane momentOut-of-plane momentYield-Line Analysis ModelsPart 10. Design of Simple Shear Connections14th Edition ManualBolt and Angle Limit States:Minimum of: Total bolt shear on bolt group Total slip resistance for slipcritical bolts on bolt group Bolt bearing on the angles Bolt tearout on the angles Shear yielding of the angles Shear rupture of the angles Block shear rupture of theangles19

3/23/2017Part 10. Design of Simple Shear Connections15th Ed. ManualBolt and Angle Limit States:Minimum of: (Effective strengths ofindividual bolts)whereEffective strength MIN: bolt shear, slipresistance for slipcritical bolts, boltbearing, bolt tearout Shear yielding -- angles Shear rupture -- angles Block shear rupture -- anglesPart 10. Design of Simple Shear Connections14th Edition ManualBeam Web Limit States (kip/in.): Bolt bearing on the web Bolt tearout on the web Shear yielding of the web Shear rupture of the web Block shear rupture of the web20

3/23/201714th Ed.15TH Ed.Part 10. Design of Simple Shear Connections Table 10-1 revised Extended single-plate connections: Removed stabilizerplate provisionThornton and Fortney, Engineering Journal, 2011, 201621

3/23/2017Part 14. Design of Beam Bearing Plates, Column BasePlates, Anchor Rods and Column Splices14th Ed:3 1/2414th Ed:314th Ed:1 13/162 1/1614th Ed:2 5/162 3/4Part 14. Design of Beam Bearing Plates, Column BasePlates, Anchor Rods and Column SplicesNotes:1. Hole sizes provided are based on anchor rod size andcorrelate with ACI 117 (ACI, 2010). 4. ASTM F844 washer are permitted instead of plate washerswhen hole clearances are limited to 5/16 in. for rod diameters upto 1 in., 1/2 in. for rod diameters over 1 in. to 2 in., and 1 in. forrod diameters over 2 in. This exception should not be usedunless the general contractor has agreed to meet smallertolerances for anchor rod placement than those permitted in ACI117.22

3/23/2017In SummaryPart 1 New shape sizes and detailing dimensionsPart 2 ASTM A500 Grade C is preferred for HSSPart 3 New footnotesPart 4 W-Shape column tables for 65 and 70 ksiPart 6 New Super Table 6-2Part 7 Table 7-14 includes TC bolts dimensionsPart 8 New plastic method for ecc. loaded bolt grpsPart 9 Increased permitted tributary length for pryingPart 10 Removal of stabilizer plate provisionsPart 14 Updated Table 14-2 for improved anchor-rodinstallationaisc.org/manualresources23

3/23/2017Design Examples V15.0Part IV: Additional Resources Combined Flexure and Axial Force, W-shapes (Table 6-1, 14thEd. Manual) Filled HSS Column Tables, A500 Gr. C (Tables 4-13 to 4-20,14th Ed. Manual) New Super Table:W-Shapes, 65 and 70 ksiHSS, ASTM A1085HSS, A500 Gr. CPipe New Znet Table for Coped W-shapesAvailable Summer 2017SEMINARS@AISC.ORG24

3/23/2017Thank you!PDH CODE: 7184125

ASTM F844 washer are permitted instead of plate washers when hole clearances are limited to 5/16 in. for rod diameters up to 1 in., 1/2 in. for rod diameters over 1 in. to 2 in., and 1 in. for rod diameters over 2 in. This exception should not be used unless the general contractor has agreed to meet smaller tolerances for anchor rod placement than those permitted in ACI 117. 3/23/2017 23 In .