Transcription

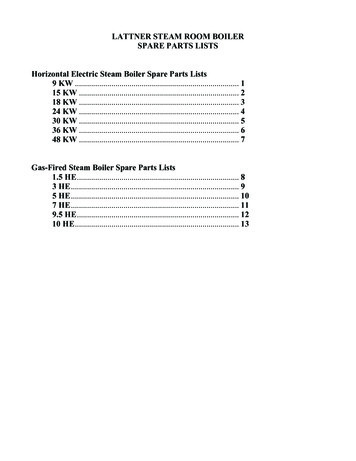

Steam Sample Conditioning - LPMTLow Pressure Medium TemperaturePressure 35 bar Temperature 250 CControl Your Steam Quality Increase lifetime of your steam applicationsPrevent corrosion in boilers and pipelinesOptimize steam chemical compositionExtract true representative samples of your steam water cycleSampleIN7H7hMechatest Steam Sample conditioning panels are available inmany configurations for as many applications in the industry.This sampling panel is used in power plants and mostly usedin combination with water analyser equipment for analysison chemical parameters like Conductivity, pH, DissolvedOxygen, Silica and Sodium. The panels are used for sampleconditioning and collection.CWR11*9s9S2233Sample to analysers44TI55TSVFISPECIFICATIONS9F9fSample pressure (recommended)Sample temperature (recommended)Flow single phase samples (water/condensate)Flow condensing samples (steam)Cooling water flowSample tube length and cooling areaStandard panel dimension 49 CMax. 4 streams outputBPR /RV7c7CCWS6688PIHotBlowdownCWDrain0.5 bargColdBlowdownTypical P&ID Steam Sample Conditioning SystemNumbers correspond to the panel configurator on thenext pageSample reliefFlush / Tap 35 barMax. 250 CMax. 72 L/hNot recommendedMax. 1100 L/h5.5 m (0.11 m2 )850 x 500 mmTYPICAL APPLICATOINSBUILT CONFORM ASME PTC 19.11-2008 ASTM D1066 ASTM D1192 / D3370 SO 5667.7Demi waterFeed waterBoiler waterCondensateMECHATESTSAMPLING SOLUTIONS

SCS Steam Panel Configurator - LPMTLow Pressure Medium TemperatureSeriesCooler TypeTube MaterialTube DesignShell MaterialShell DesignLPMTLPMTALPMTAATSR-4225TSR-42B5TSR-4BB51/4'' OD - 316 SS1/4'' OD - Inconel 6251/4'' OD - Inconel 625345 bar @ 538 C345 bar @ 593 C345 bar @ 593 C304 SS304 SSInconel 62531 bar @ 343 C31 bar @ 343 C31 bar @ 343 CDesignatorsExample Ordering No.LPMT-Ordering No.1INLET BLOCK VALVE2FILTER (1)3PRESSURE REGULATION4TEMPERATURE INDICATION (1)5-12345-67891011111-0000X--0 No inlet valve1 Needle valve 316 SS (Std. Swagelok)2 Double inlet valve6BACK PRESSURE REGULATION7SAMPLE BLOWDOWN OPTIONS8PRESSURE SAFETY OPTIONS9FLOW INDICATION0 No filter1 T-Filter 90 micron 316 SS (Std. Swagelok)2 Filter large volume 90 micron 316 SS (Std. Classic)0 No pressure regulating valve1 Regulating valve 316 SS (Std. Swagelok)0 No temperature gauge1 Temperature gauge 0 - 60 C 316 SS in flow chamber (Std.)TEMPERATURE SAFETY (1)0 No temperature shut-off valve1 Automatic Temperature shut-off valve @ 46 C (Std.)(automatic open if temperature below setpoint)2 Reset Temperature shut-off valve @ 46 C (Std. Centry)(reset to open if temperature below setpoint)3 Electronic Temperature shut-off valve @ 46 C(1)(2)100 No BPR mounting plateB Mounting plate for Swan BPR on panel0CHCHNo sample blowdown (Std.)Cold sample blowdownHot sample blowdownCold and Hot sample blowdown0 No pressure safety (Std.)1 Pressure relief valve on C.W. connection2 Pressure relief valve on Sample connection0 No flow indication (Std.)F Flow indicator in sample lineS Sight glass indicator in C.W. lineOPTIONS (2)XAELPNo optionsAcid purging connection (T-conn. valve)Extension handle (on hot inlet valve)Lab sample tablet / drain funnelPortable (system on rack with wheels)Other sizes, ranges or specifications available on requestSelect from the ''options'' designator one or more options andfill in all these letters in the same columMechatest Sampling SolutionsTel: Koperslager 32631 RK NootdorpThe NetherlandsBe part of the best solutionMECHATESTSAMPLING SOLUTIONSMechatest is a Certified Industrial Sampling Systems Company with over 26 years of experience in design and manufacturing of fluid sampling systems. We understand howa sample behaves at the sample tap and transport into the lab. We offer the best knowledge, equipment and sampling solutions in the field.

Steam Sample Conditioning - LPHTLow Pressure High TemperaturePressure 35 bar Temperature 538 CControl Your Steam Quality Increase lifetime of your steam applicationsPrevent corrosion in boilers and pipelinesOptimize steam chemical compositionExtract true representative samples of your steam water cycleSampleIN7H7hMechatest Steam Sample conditioning panels are available inmany configurations for as many applications in the industry.This sampling panel is used in power plants and mostly usedin combination with water analyser equipment for analysison chemical parameters like Conductivity, pH, DissolvedOxygen, Silica and Sodium. The panels are used for sampleconditioning and collection.CWR11*9s9S2233Sample to analysers44TI55TSVFISPECIFICATIONS9F9fSample pressure (recommended)Sample temperature (recommended)Flow single phase samples (water/condensate)Flow condensing samples (steam)Cooling water flowSample tube length and cooling areaStandard panel dimension 49 CMax. 4 streams outputBPR /RV7c7CCWS6688PIHotBlowdownCWDrain0.5 bargColdBlowdownTypical P&ID Steam Sample Conditioning SystemNumbers correspond to the panel configurator on thenext pageSample reliefFlush / Tap 35 barMax. 538 CMax. 108 L/hMax. 60 L/hMax. 1500 L/h11 m (0.22 m2 )850 x 500 mmTYPICAL APPLICATOINSBUILT CONFORM ASME PTC 19.11-2008 ASTM D1066 ASTM D1192 / D3370 SO 5667.7Demi waterFeed waterBoiler waterCondensateLP/HP SteamLife SteamMECHATESTSAMPLING SOLUTIONS

SCS Steam Panel Configurator - LPHTLow Pressure High TemperatureSeriesCooler TypeTube MaterialTube DesignShell MaterialShell DesignLPHTLPHTALPHTAATLR-4225TLR-42B5TLR-4BB51/4'' OD - 316 SS1/4'' OD - Inconel 6251/4'' OD - Inconel 625345 bar @ 538 C345 bar @ 593 C345 bar @ 593 C304 SS304 SSInconel 62531 bar @ 343 C31 bar @ 343 C31 bar @ 343 CDesignatorsExample Ordering No.Ordering No.LPHT---1INLET BLOCK VALVE2FILTER (1)3PRESSURE REGULATION4TEMPERATURE INDICATION (1)512345-67891011111-0000X0 No inlet valve1 Needle valve 316 SS (Std. Swagelok)2 Double inlet valve6BACK PRESSURE REGULATION7SAMPLE BLOWDOWN OPTIONS8PRESSURE SAFETY OPTIONS9FLOW INDICATION0 No filter1 T-Filter 90 micron 316 SS (Std. Swagelok)2 Filter large volume 90 micron 316 SS (Std. Classic)0 No pressure regulating valve1 Regulating valve 316 SS (Std. Swagelok)0 No temperature gauge1 Temperature gauge 0 - 60 C 316 SS in flow chamber (Std.)TEMPERATURE SAFETY (1)0 No temperature shut-off valve1 Automatic Temperature shut-off valve @ 46 C (Std.)(automatic open if temperature below setpoint)2 Reset Temperature shut-off valve @ 46 C (Std. Centry)(reset to open if temperature below setpoint)3 Electronic Temperature shut-off valve @ 46 C(1)(2)100 No BPR mounting plateB Mounting plate for Swan BPR on panel0CHCHNo sample blowdown (Std.)Cold sample blowdownHot sample blowdownCold and Hot sample blowdown0 No pressure safety (Std.)1 Pressure relief valve on C.W. connection2 Pressure relief valve on Sample connection0 No flow indication (Std.)F Flow indicator in sample lineS Sight glass indicator in C.W. lineOPTIONS (2)XAELPNo optionsAcid purging connection (T-conn. valve)Extension handle (on hot inlet valve)Lab sample tablet / drain funnelPortable (system on rack with wheels)Other sizes, ranges or specifications available on requestSelect from the ''options'' designator one or more options andfill in all these letters in the same columMechatest Sampling SolutionsTel: Koperslager 32631 RK NootdorpThe NetherlandsBe part of the best solutionMECHATESTSAMPLING SOLUTIONSMechatest is a Certified Industrial Sampling Systems Company with over 26 years of experience in design and manufacturing of fluid sampling systems. We understand howa sample behaves at the sample tap and transport into the lab. We offer the best knowledge, equipment and sampling solutions in the field.

Steam Sample Conditioning - HPMTHigh Pressure Medium TemperaturePressure 35 bar Temperature 250 CControl Your Steam Quality Increase lifetime of your steam applicationsPrevent corrosion in boilers and pipelinesOptimize steam chemical compositionExtract true representative samples of your steam water cycleSampleIN7H7hMechatest Steam Sample conditioning panels are available inmany configurations for as many applications in the industry.This sampling panel is used in power plants and mostly usedin combination with water analyser equipment for analysison chemical parameters like Conductivity, pH, DissolvedOxygen, Silica and Sodium. The panels are used for sampleconditioning and collection.CWR11*9s9S2233Sample to analysers44TI55TSVFISPECIFICATIONS9F9fSample pressure (recommended)Sample temperature (recommended)Flow single phase samples (water/condensate)Flow condensing samples (steam)Cooling water flowSample tube length and cooling areaStandard panel dimension 49 CMax. 4 streams outputBPR /RV7c7CCWS6688PIHotBlowdownCWDrain0.5 bargColdBlowdownTypical P&ID Steam Sample Conditioning SystemNumbers correspond to the panel configurator on thenext pageSample reliefFlush / Tap 35 bar (Max. 345 bar)Max. 250 CMax. 72 L/hNot recommendedMax. 1100 L/h5.5 m (0.11 m2 )850 x 500 mmTYPICAL APPLICATOINSBUILT CONFORM ASME PTC 19.11-2008 ASTM D1066 ASTM D1192 / D3370 SO 5667.7Demi waterFeed waterBoiler waterCondensateMECHATESTSAMPLING SOLUTIONS

SCS Steam Panel Configurator - HPMTHigh Pressure Medium TemperatureSeriesCooler TypeTube MaterialTube DesignShell MaterialShell DesignHPMTHPMTAHPMTAATSR-4225TSR-42B5TSR-4BB51/4'' OD - 316 SS1/4'' OD - Inconel 6251/4'' OD - Inconel 625345 bar @ 538 C345 bar @ 593 C345 bar @ 593 C304 SS304 SSInconel 62531 bar @ 343 C31 bar @ 343 C31 bar @ 343 CDesignatorsExample Ordering No.Ordering No.HPMT---1INLET BLOCK VALVE2FILTER (1)3PRESSURE REGULATION4TEMPERATURE INDICATION (1)512345-67891011111-0000X0 No inlet valve1 Needle valve 316 SS (Std. Swagelok)2 Double inlet valve6BACK PRESSURE REGULATION7SAMPLE BLOWDOWN OPTIONS8PRESSURE SAFETY OPTIONS9FLOW INDICATION0 No filter1 T-Filter 90 micron 316 SS (Std. Swagelok)2 Filter large volume 90 micron 316 SS (Std. Classic)0 No pressure regulating valve1 VREL pressure valve 316 SS (Std. Swagelok)0 No temperature gauge1 Temperature gauge 0 - 60 C 316 SS in flow chamber (Std.)TEMPERATURE SAFETY (1)0 No temperature shut-off valve1 Automatic Temperature shut-off valve @ 46 C (Std.)(automatic open if temperature below setpoint)2 Reset Temperature shut-off valve @ 46 C (Std. Centry)(reset to open if temperature below setpoint)3 Electronic Temperature shut-off valve @ 46 C(1)(2)100 No BPR mounting plateB Mounting plate for Swan BPR on panel0CHCHNo sample blowdown (Std.)Cold sample blowdownHot sample blowdownCold and Hot sample blowdown0 No pressure safety (Std.)1 Pressure relief valve on C.W. connection2 Pressure relief valve on Sample connection0 No flow indication (Std.)F Flow indicator in sample lineS Sight glass indicator in C.W. lineOPTIONS (2)XAELPNo optionsAcid purging connection (T-conn. valve)Extension handle (on hot inlet valve)Lab sample tablet / drain funnelPortable (system on rack with wheels)Other sizes, ranges or specifications available on requestSelect from the ''options'' designator one or more options andfill in all these letters in the same columMechatest Sampling SolutionsTel: Koperslager 32631 RK NootdorpThe NetherlandsBe part of the best solutionMECHATESTSAMPLING SOLUTIONSMechatest is a Certified Industrial Sampling Systems Company with over 26 years of experience in design and manufacturing of fluid sampling systems. We understand howa sample behaves at the sample tap and transport into the lab. We offer the best knowledge, equipment and sampling solutions in the field.

Steam Sample Conditioning - HPHTHigh Pressure High TemperaturePressure 35 bar Temperature 538 CControl Your Steam Quality Increase lifetime of your steam applicationsPrevent corrosion in boilers and pipelinesOptimize steam chemical compositionExtract true representative samples of your steam water cycleSampleIN7H7hMechatest Steam Sample conditioning panels are available inmany configurations for as many applications in the industry.This sampling panel is used in power plants and mostly usedin combination with water analyser equipment for analysison chemical parameters like Conductivity, pH, DissolvedOxygen, Silica and Sodium. The panels are used for sampleconditioning and collection.CWR11*9s9S2233Sample to analysers44TI55TSVFISPECIFICATIONS9F9fSample pressure (recommended)Sample temperature (recommended)Flow single phase samples (water/condensate)Flow condensing samples (steam)Cooling water flowSample tube length and cooling areaStandard panel dimension 49 CMax. 4 streams outputBPR /RV7c7CCWS6688PIHotBlowdownCWDrain0.5 bargColdBlowdownTypical P&ID Steam Sample Conditioning SystemNumbers correspond to the panel configurator on thenext pageSample reliefFlush / Tap 35 bar (Max. 345 bar)Max. 538 CMax. 108 L/hMax. 60 L/hMax. 1500 L/h11 m (0.22 m2 )850 x 500 mmTYPICAL APPLICATOINSBUILT CONFORM ASME PTC 19.11-2008 ASTM D1066 ASTM D1192 / D3370 SO 5667.7Demi waterFeed waterBoiler waterCondensateLP/HP SteamLife SteamMECHATESTSAMPLING SOLUTIONS

SCS Steam Panel Configurator - HPHTHigh Pressure High TemperatureSeriesCooler TypeTube MaterialTube DesignShell MaterialShell DesignHPHTHPHTAHPHTAATLR-4225TLR-42B5TLR-4BB51/4'' OD - 316 SS1/4'' OD - Inconel 6251/4'' OD - Inconel 625345 bar @ 538 C345 bar @ 593 C345 bar @ 593 C304 SS304 SSInconel 62531 bar @ 343 C31 bar @ 343 C31 bar @ 343 CDesignatorsExample Ordering No.Ordering No.HPHT---1INLET BLOCK VALVE2FILTER (1)3PRESSURE REGULATION4TEMPERATURE INDICATION (1)512345-67891011111-0000X0 No inlet valve1 Needle valve 316 SS (Std. Swagelok)2 Double inlet valve6BACK PRESSURE REGULATION7SAMPLE BLOWDOWN OPTIONS8PRESSURE SAFETY OPTIONS9FLOW INDICATION0 No filter1 T-Filter 90 micron 316 SS (Std. Swagelok)2 Filter large volume 90 micron 316 SS (Std. Classic)0 No pressure regulating valve1 VREL pressure valve 316 SS (Std. Swagelok)0 No temperature gauge1 Temperature gauge 0 - 60 C 316

ASME PTC 19.11-2008 ASTM D1066 ASTM D1192 / D3370 SO 5667.7 Control Your Steam Quality Increase lifetime of your steam applications Prevent corrosion in boilers and pipelines Optimize steam chemical composition Extract true representative samples of your steam water cycle TYPICAL APPLICATOINS Demi water Feed water Boiler water Condensate .