Transcription

plantemoran.comTIA-942: Data Center StandardsSri ChalasaniMerit 2010 ConferenceMay 25, 2010

Objectives What are concerns in the datacenter? Data center standards & bestPractices

Data Center Definition Computer facility designed for continuous use byseveral users, and well equipped with hardware,software, peripherals, power conditioning andbackup, communication equipment,security systems, etc. – businessdictionary.comycnadnudeRrewg includes redundant or backupnP o .It generallyinoipowert supplies, redundant dataid&con (e.g., airrotinsconditioning,fire osuppression)and securitylorMtdevices. – wikipedia.orgnCo Notice the common terminology Levels of implementation set them apart

Why should we care? DCs house mission-critical data &equipment. In addition to protectingthis Challenges increased demand for: Applications / systems availability / SLA Complex & heterogeneous systems Service levels for uptime and responsiveness Amount of data (live and retention) Regulatory compliance and security Changing business demands Green practices & energy costs

Data Center Standards Without standards enormous variationin data center designs Three commonly known tier systems Uptime Institute(1995) Syska Hennessy Group ANSI/TIA-942 or TIA-942(2005, 2008, 2010)

Data Center Standards Uptime and TIA-942 Neither addresses the challenges Both provide a framework to alleviatechallenges TIA-942 Requirements / guidelines for the design& installation of a data center Multidisciplinary Design Considerations Intended Audience

TIA-942 Multidisciplinary Design Design Considerations1. Design Process12.Access Providers2. Space Planning13.Telecom Spaces3. Redundancy14.Cabinets & Racks Architectural Design4. Sitefloor,Selection15.Cabling Pathways(space,light, security etc.) 5. Architectural WiringStructured6. StructuralElectrical7. ElectricalCooling8. Mechanical/CoolingOperations16.Cabling Systems17.Cabling Field Testing18.Telecom Administration19.Information Technology9. Fire e11.Building Automation

TIA-942 – Discussion Topics For today’s discussion, focus on 1. Data Center Spaces.2. Data Center Cabling3. Electrical4. Cooling5. Tier System

Spaces TIA-942 – 5-key functional areas: (1) Entrance Room (ER) (2) Main Distribution Area (MDA) (3) Horizontal Distribution Area (HDA) (4) Zone Distribution Area (ZDA), opt. (5) Equipment Distribution Area (EDA) Ideally separate rooms but not practicalfor normal organizations; Can beconsolidated with defined areasSource: Corning – Distribution in the data center

Spaces(5)(3)(2)(1)(4)ZDASource: ADC’s Data Center Optical Distribution Frame: The Data Center’s Main Cross-Connect

SpacesSource: Corning – Distribution in the data center

Spaces Typical Data Center Requirements:LocationCeiling Height Avoid locations that restrictexpansion Min. 8.5’ from finished floor toany obstruction (sprinklers,lighting fixtures, or cameras) Redudnat Access Delivery of large equipment Located away from EMI sources Cooling architecture maydictate higher ceilings Min. 18” clearance from water No exterior windows (inc. heat &sprinkler headssecurity risk)Flooring / Walls Provide authorized access & Anti-static propertiesmonitored Sealed / painted to minimizeSize – no magic formuladust Sized to meet the known Light color to enhance lightingrequirements of specificequipment Min dist floor loading 150 lbf/Sq-ft, Reco. 250 lbf/Sq-ft Include projected future as wellas present requirements

SpacesDoorsOperational parameters 3’ wide x 7’ high, no /removable center obstructions Dedicated HVAC system preferred(68 – 77 F); measured every10-30 ft at 1.5ft heightLighting HVAC – min. 100 sqft/ton Min. 500 lux in the horizontalplane and 200 lux in thevertical plane Max. temp rate of change: 5 F/hr Lighting on separate circuits/panels Emergency lighting & signsOther Equipment 40% to 55% relative humidity(reduces ESD) Electrical - Signal reference grid(SRG) Sprinkler systems must be preaction system UPS, power dist. or conditionerSecurity 100kVa inside room Camera monitoring (int./ext.) 100kVa in separate room 100-yr flood plain

Spaces – Best Practices Locate ER outside of the DC for securitypurpose; if inside DC, consolidate ER & MDA MDA centrally located Both MDA & HDA require separate racks forfiber, UTP and coax cable ZDA is optional, but provides additional flexibility(pre terminated cables) EDA – contains equipment only Each space requires same power/cooling req.ER: Entrance Room, MDA: Main Distribution Area, EDA: EquipmentDistribution Area, ZDA: Zone Distribution Area, DC: Data Center

Spaces – Raised vs. Solid Floor Raised floor a very common notion, but. Older equipment vs. newerequipment air flow (bottom-upvs. front to back) Only place to go is creep intocold aisle .warmer air atcabinet tops. Hot aisle – Cold aisle air flowdynamics Typically see passivecomponents or open spacesnear top of cabinets Cold air – want to fall, but weare pushing – requirespressure through perf. tiles Both use anti-static tiles orflooring Opening / leaks in flooring hasimpact on pressure Data & electrical cablingrestrictions Equip. densities increase - higher head load - higherpressure of cold air throughrestrictive space New build – more expensive What happens to hot air? –flows up, reduces temperatureand begins to fall down again Have to look at yourenvironment to see if raisedfloor makes sense .do use thisas the rule of thumb!

Cabling Systems Structured vs. Unstructured Cabling Horizontal cabling Backbone cabling Cross-connect in theentrance room or maindistribution area Main cross-connect (MC)in the main distributionarea Horizontal cross-connect(HC) in thetelecommunicationsroom, horizontaldistribution area or maindistribution area Zone outlet orconsolidation point inthe zone distributionarea; and Outlet in the equipmentdistribution area

Cabling SystemsSource: Corning Cable Systems – Just the Technical Facts

Cabling Systems Reduced Data Center Topology Consolidated ER/MDA/HAD Applicable to most enterprisesSource: Orthronics – Standards-Based Data Center Structured Cabling System Design

Cabling Systems – Transmission Media 100-ohm twisted-pair copper cable Category 5e or 6, 6A 10GbE: Cat 6 – 37-55mts, Cat 6A – 100mts Multimode fiber optic cable 62.5/125 µm or 50/125 µm 50/125 µm 850 nm laser optimized mmf Singlemode optical fiber cable 75-ohm coaxial cable Type 734 & 735 cable Type T1.404 coaxial connector

Cabling Systems – Overhead / Under floor Under Floor Cabling Less expensive if raised floor than overhead Cabling in cable trays to minimize airflow blocks;consider multilevel trays for fiber/copper Provide adequate capacity for growth Separate fiber cords from copper cabling frompower Typically placed in the hot aisle Electrical – color coded PDU with lockingreceptacle. Receptacles labeled with PDU/panelID & breaker #

Cabling Systems – Overhead / Under floor Overhead Can be used in raised floor environments also Multi level cable tray system (3 Layer) Bottom layer – copper Middle layer – fiber Top layer – power Suspended from ceiling; min.12” clearanceabove each ladder Separation from fluorescent lights (5”) & power Avoid blocking cooling ducts (overhead cooling)

Racks / Cabinets Placement of racks / cabinets Hot aisle / Cold aisle - arranged in an alternatingpattern (with fronts facing each other) Cold aisles are front & Hot aisles are rear ofracks/cabinets – If there is a raised floor, PDU cables are run incold aisle. Data cable trays for telecom cablingare typically placed in hot aisle. Common bonding network (CBN) Racks / cabinets individually, cable trays, HVAC,PDU, panel boards, raised floor structure, columns Front clearance – min. 3ft, 4ft recommended Raised Flooring vs. Traditional Flooring

Racks / Cabinets Placement of racks / cabinets Front rails recessed for wire management Switch-Panel-Switch arrangement Front edge of cabinet on edge of tile Perforated tiles at front of cabinets Provide blank panels in empty spaces

Electrical Considerations Unfortunately no magic bullet! Manual process for load configuration APC ‘s “Calculating Total Power Requirements forData Centers” By Richard Sawyer – frameworkfor calculating req. Color coded PDU with locking receptacle.Receptacles labeled with PDU/panel ID &breaker # Best Practices Multiple power grid connects Intelligent PDU Sub-breakers per relay rack Generator capacity to includeor lineupfor cooling Dual A-B cording Accommodate growth UPS capacity to includecooling and lights

Cooling Considerations # 1 Mitigating Factor – heat removal No specific guidelines; basic physics Cooling reqd. Heat Generated Electrical load Design Implications Layout of racks in alternatingrows Quantity and location of vents Location of CRAC units Proper internal configuration ofracks Sizing of ductwork

Cooling Considerations Process Determine critical heat load Establish critical loads - wattsper-RLU Determine cooling deliverymethodology(s) Room, Row, Rack Determine the CFMrequirements per RLU Blank panels/short circuits If possible, divide the roominto cooling zones by RLU Special Considerations – highBTU Determine appropriate airconditioner type(s) Equip. airflow (f- b / s- s) Cold air containment Establish a floor plan Deploy a comprehensivemonitoring system Cooling is not enough – airflow required

Cooling Considerations - AirflowSupply &ReturnBasedsource: apc.com

Fire Detection and Suppression Significant risk of electrical fires A comprehensive fire detection &suppression system is mission-criticalDetectionSuppression Both heat and smoke detection Follow NFPA 75 standard firewalls Interconnected with the fire suppression system, localalarms, monitoring system, etc Installed in accordance withNFPA 72E Installed below raised floorsand other areas Airflow patterns determineslocation of detection unitsSprinkler systems — both floodedand pre-actionChemical systems or Clean Agent(FM 200, Inergen, Ecaro-25(FE 25),Novec 1230) Manual systems (Manual pullstations, Portable fire extinguishers

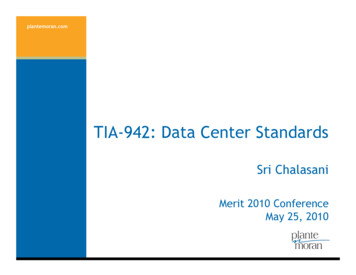

Tier System – Uptime & TIA-942 4-Tier System based on Resilience / Capacity of its MEP systems 16-pages of criteria Primary Categories Power and cooling deliverypaths Support space to raised floorratio Redundancy in components Raised floor height Initial & ultimate watts/sqft Floor loading pounds/sqft Utility voltage

Optimal Criticality – Choosing a tierCBusiness characteristicsEffect on system design1 Typically small businesses Limited online presence Low dependence on IT Perceive downtime as a tolerableInconvenience Numerous single points of failure in all aspects ofdesign No generator if UPS has 8 minutes of backup time Generally unable to sustain more than a 10 minutepower outage2 Some online revenue generationMultiple serversPhone system vital to businessDependent on emailSome tolerance to scheduled downtime Some redundancy in power and cooling systemsGenerator backupAble to sustain 24 hour power outageMinimal thought to site selectionVapor barrierFormal data room separate from other areas3 World-wide presenceMajority of revenue from online businessVoIP phone systemHigh dependence on ITHigh cost of downtimeHighly recognized brand Two utility paths (active and passive)Redundant power and cooling systemsRedundant service providersAble to sustain 72-hour power outageCareful site selection planningOne-hour fire ratingAllows for concurrent maintenance Multi-million dollar business Maj. of rev from electronic transactions Business model entirely dependent on ITsource: apc.com Extremely high cost of downtime Two independent utility paths2N power and cooling systemsAble to sustain 96 hour power outageStringent site selection criteriaMinimum two-hour fire rating; High phy. security24/7 onsite maintenance staff4 Balance cost of downtime and TCO

Tier SystemAttribute / StatisticTier ITier IITier IIITier IVPower and CoolingDelivery PathsRedundant Components1 Active1 Active2 ActiveNN 11 Active 1PassiveN 12(N 1)Support Space to RaisedFloor RatioInitial Watts / sqft20%30%80 – 90%100%20 – 3040 – 5040 – 6050 – 80Ultimate Watts / sqft20 – 3040 – 50100 – 150150 Raised Floor Height12”18”30 – 36”30 – 36”Floor Loading Pounds /sqft85100150150 208, 480208, 48012 – 15 kV12 – 15 kV33–615 – 2015 – 20Year First Deployed1965197019851995Construction / sqft 450 600 900 1,100 Annual IT Downtime Dueto Site28.8 hrs22.0 hrs1.6 hrs0.4 hrsSite Availability99.67%99.75%99.98%100.00%Utility VoltageMonths to ImplementSource: The Uptime Institute

Next / Action Steps Perform a risk assessment to determinehourly cost of downtime Determine current data center tier foreach subsystem in the data center –you might not need tier-iv across theboard Get IT and Facilities to work together onissues Work with finance to justify upgrades Understand TIA-942 (requirement &process)

Outsourced Data Center Fits business model - consideroutsourcing Affordable co-location/hosted DC and99.995% uptime are NOT mutuallyexclusive Understand levels of redundancy andthe uptime SLA in order to get the bestcombination of uptime and affordability Balance between budget and availability

Outsourced Data Center What to look for . Hardened data centerbuildings Availability of multiplecarriers Data center power &cooling redundancy Physical security Telecom entranceredundancy SAS 70 data centercompliance Claims of Uptime Tiers – III or IV; mostare not certified

Review TIA-942 Key design parameters Tier System Next Steps

Resources Useful links Excellent white papers from www.apc.com TIA - http://www.tiaonline.org/ Green data center efficiency savings /WEB A

TIA-942 – 5-key functional areas: (1) Entrance Room (ER) (2) Main Distribution Area (MDA) (3) Horizontal Distribution Area (HDA) (4) Zone Distribution Area (ZDA), opt. (5) Equipment Distribution Area (EDA) Ideally separate rooms but not practical for normal organizations; Can be consolidated with defined areas Source: Corning – Distribution in the data center . Spaces Source: ADC’s Data .