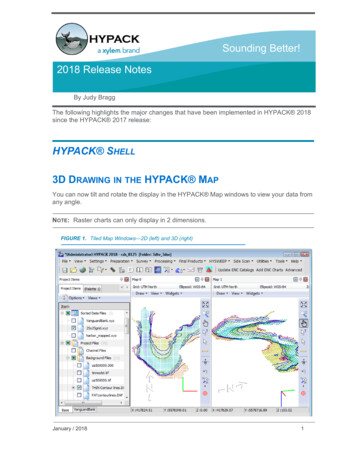

Transcription

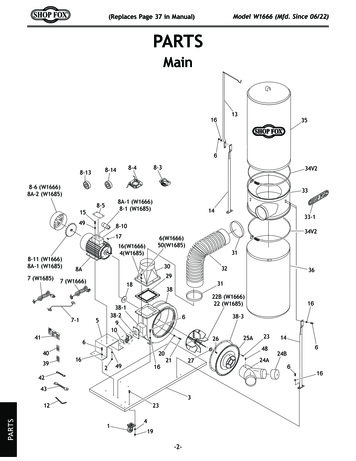

(Replaces Page 37 in Manual)Model W1666 (Mfd. Since 06/22)PARTSMain13163568-38-48-148-1334V28-6 (W1666)8A-2 (W1685)33158A-1 (W1666)8-1 (W1685)8-54914178-11 (W1666)8A-1 (W1685)7 A7-13218313822B (W1666)22 234842121638-3664036297 (W1666)4133-18-10419-2-24A14624B616

Model W1666 (Mfd. Since 06/22)(Replaces Page 38 in Manual)Main Parts ListREF PART #DESCRIPTIONREF PART 22324A24B25ASWIVEL CASTERHEX NUT M8-1.25BASE PLATEFLAT WASHER 6MMMOTOR MOUNTHEX BOLT M8-1.25 X 16POWER CORD 14G 3W 120" (W1666)POWER CORD 14G 3W 72" 5-15 (W1685)MOTOR CORD 14G 3W 24"SHOP FOX PADDLE SWITCH 110V W/KEYPADDLE SWITCH KEYHEX WRENCH 5MMUPPER BAG HANGERSEPARATOR SUPPORTHEX BOLT M8-1.25 X 25FLAT WASHER 8MMKEY 5 X 5 X 25MOTOR SHAFT SPACERHEX NUT M6-1LOCK WASHER 10MMHEX BOLT M10-1.5 X 16IMPELLER (W1666)IMPELLER (W1685)PHLP HD SCR M6-1 X 10INLET Y-CONNECTOR 6" X (2)4" V2.12.01INLET Y-CONNECTOR CAPIMPELLER COVER 6" -138-238-3394041414243484950CAP SCREW M6-1 X 20 LHARBOR WASHEROUTLET GASKET 6 HOLE (W1666)OUTLET GASKET 8 HOLE (W1685)OUTLET FLANGE 6 HOLE (W1666)OUTLET FLANGE 8 HOLE (W1685)HOSE CLAMP 5"TRANSFER HOSE 5"SEPARATORCURVED SHOP FOX NAME PLATEBAG CLAMP POLYPROPYLENE V2.07.10UPPER BAG 2.5 MICRON V2.02.15LOWER BAG (PLASTIC) V2.02.15IMPELLER HOUSING (W1666)IMPELLER HOUSING (W1685)SWITCH BOXSWITCH BOX COVERIMPELLER COVER GASKETHAND/INLET WARNING LABELREAD MANUAL LABELMACHINE ID LABEL (W1666)MACHINE ID LABEL (W1685)WRENCH 8 X 10MM OPEN-ENDSWRENCH 11 X 13MM OPEN-ENDSPHLP HD SCR M5-.8 X 10FLAT WASHER 8MMHEX BOLT M6-1 X 66024AX1666024BX1666025AW1666 2 HP, 220V, Single-Phase 66042X1666043X1666048X1666049X1685050W1685 1-1/2 HP, 110V, Single-Phase MotorREF PART #DESCRIPTIONREF PART #DESCRIPTION8AX1666008AMOTOR 2HP 220V 1-PH V2.11.028AX1685008AMOTOR 1-1/2HP 110V 1-PH 11X1666008A-1X1666008-13X1666008-14CENTRIFUGAL SWITCHCONTACT PLATEMOTOR BOX COVERMOTOR FAN COVERWIRING BOX WITHOUT COVERMOTOR FANS CAPACITOR 200M 250VBALL BEARING 6203ZZBALL BEARING 1X1685008-1X1685008-13X1685008-14CENTRIFUGAL SWITCHCONTACT PLATEMOTOR BOX COVERMOTOR FAN COVERWIRING BOX WITHOUT COVERMOTOR FANS CAPACITOR 600M 125VMOTOR FRONT BEARINGMOTOR REAR BEARINGPARTS-3-

High Quality Machines and ToolsWoodstock International, Inc. carries thousands of products designed to meet the needsof today’s woodworkers and metalworkers. Ask your dealer about these fine products: WHOLESALE ONLYPhone: (360) 734-3482Fax: (360) 671-3053Toll Free Fax: (800) 647-8801P.O. Box 2309, Bellingham, WA 98227woodstockint.com

MODEL W1666/W1685DUST COLLECTORSOWNER'S MANUAL(FOR MODELS MANUFACTURED SINCE 02/15)Phone: (360) 734-3482 Online Technical Support: tech-support@shopfox.bizCOPYRIGHT JUNE, 2000 BY WOODSTOCK INTERNATIONAL, INC., REVISED JULY, 2018 (HE)WARNING: NO PORTION OF THIS MANUAL MAY BE REPRODUCED IN ANY SHAPE OR FORM WITHOUTTHE WRITTEN APPROVAL OF WOODSTOCK INTERNATIONAL, INC.#6941CR Printed in ChinaV4.07.18

This manual provides critical safety instructions on the proper setup,operation, maintenance, and service of this machine/tool. Save thisdocument, refer to it often, and use it to instruct other operators.Failure to read, understand and follow the instructions in this manualmay result in fire or serious personal injury—including amputation,electrocution, or death.The owner of this machine/tool is solely responsible for its safe use.This responsibility includes but is not limited to proper installation ina safe environment, personnel training and usage authorization,proper inspection and maintenance, manual availability and comprehension, application of safety devices, cutting/sanding/grinding toolintegrity, and the usage of personal protective equipment.The manufacturer will not be held liable for injury or propertydamage from negligence, improper training, machine modifications ormisuse.Some dust created by power sanding, sawing, grinding, drilling, andother construction activities contains chemicals known to the State ofCalifornia to cause cancer, birth defects or other reproductive harm.Some examples of these chemicals are: Lead from lead-based paints. Crystalline silica from bricks, cement and other masonry products. Arsenic and chromium from chemically-treated lumber.Your risk from these exposures varies, depending on how often youdo this type of work. To reduce your exposure to these chemicals:Work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to filterout microscopic particles.

SAFETY.7Standard Machinery Safety Instructions. 7Additional Safety for Dust Collectors. 9SETUP. 12Unpacking. 12Inventory. 12Assembly. 13Test Run. 18MAINTENANCE. 32General. 32Lubrication. 32Bag Cleaning. 32Replacing Bags. 33SERVICE. 34Troubleshooting. 34Electrical Safety Instructions. 35Wiring Diagrams. 36PARTS. 37WARRANTY. 41OPERATIONSOPERATIONS. 29General. 29Disabling Switch. 29Machine Storage. 29SET UPDESIGNING THE SYSTEM. 19General. 19Duct Material. 19System Grounding. 22System Design. 23ELECTRICALELECTRICAL. 10Circuit Requirements. 10Grounding Requirements. 11Extension Cords. 11ACCESSORIES. 30SAFETYINTRODUCTION.2Woodstock Technical Support. 2W1666 Machine Specification . 3W1685 Machine Specification . 5INTRODUCTIONContentsMAINTENANCESERVICEPARTSUSE THE QUICK GUIDE PAGE LABELS TO SEARCH OUT INFORMATION FAST!

INTRODUCTIONModel W1666/W1685 (For Machines Mfd. Since 2/15)INTRODUCTIONWoodstock Technical SupportWoodstock International, Inc. is committed to customer satisfaction. Our intent with this manual is toinclude the basic information for safety, setup, operation, maintenance, and service of this product.In the event that questions arise about your machine, please contact Woodstock International TechnicalSupport at (360) 734-3482 or send e-mail to: tech-support@shopfox.biz. Our knowledgeable staff willhelp you troubleshoot problems or process warranty claims.If you need the latest edition of this manual, you can download it from http://www.shopfox.biz.If you have comments about this manual, please contact us at:Woodstock International, Inc.Attn: Technical Documentation ManagerP.O. Box 2309Bellingham, WA 98227Email: manuals@woodstockint.com-2-

MODEL W1666Product Dimensions2 HP DUST COLLECTORWeight. 92 lbs.Width (side‐to‐side) x Depth (front‐to‐back) x Height. 33‐1/2 x 21‐1/2 x 78 in.Footprint (Length x Width). 33‐1/2 x 21‐1/2 in.Shipping DimensionsType. Cardboard BoxContent. MachineWeight. 108 lbs.Length x Width x Height. 36 x 23 x 23 in.Must Ship Upright. YesElectricalPower Requirement. 220V, Single‐Phase, 60 HzPrewired Voltage. 220VFull‐Load Current Rating. 12AMinimum Circuit Size. 15AConnection Type. Cord & PlugPower Cord Included. YesPower Cord Length. 10 ft.Power Cord Gauge. 14 AWGPlug Included. NoRecommended Plug Type. 6‐15Switch Type. Paddle Safety Switch w/Removable KeyMotorsMainHorsepower. 2 HPPhase. Single‐PhaseAmps. 12ASpeed. 3450 RPMType. TEFC Capacitor‐Start InductionPower Transfer . Direct DriveBearings. Sealed & Permanently LubricatedCentrifugal Switch/Contacts Type. ExternalModel W1666 Machine Specifications, Page 1 of 2-3-INTRODUCTIONModel W1666/W1685 (For Machines Mfd. Since 2/15)

INTRODUCTIONModel W1666/W1685 (For Machines Mfd. Since 2/15)Main SpecificationsOperationDust Collector Type. Single‐StageApproved Dust Types. WoodFilter Type. BagAirflow Performance. 1550 CFMMax Static Pressure (at 0 CFM). 12.3 in.Main Inlet Size. 6 in.Inlet Adapter Included. YesNumber of Adapter Inlets. 2Adapter Inlet Size. 4 in.Machine Collection Capacity At One Time. 3Maximum Material Collection Capacity. 5.4 cu. ft.Filtration Rating. 2.5 MicronBag InformationNumber of Upper Bags. 1Number of Lower Bags. 1Upper Bag Diameter. 19 in.Upper Bag Length. 33 in.Lower Bag Diameter. 19 in.Lower Bag Length. 33 in.Impeller InformationImpeller Type. Radial FinImpeller Size. 12 in.Impeller Blade Thickness. 3/32 in.ConstructionUpper Bag. FabricLower Bag. PlasticBase. Steel Sheet Metal w/CastersCaster. Four PlasticImpeller. SteelPaint Type/Finish. Powder CoatedBlower Housing. Steel Sheet MetalBody. Steel Sheet MetalOtherCountry of Origin . ChinaWarranty . 2 YearsApproximate Assembly & Setup Time . 45 MinutesSerial Number Location . ID LabelISO 9001 Factory . YesCertified by a Nationally Recognized Testing Laboratory (NRTL) . NoFeaturesPowder‐Coated FinishQuick Release Band ClampIncludes Steel Base with CastersModel W1666 Machine Specifications, Page 2 of 2-4-

MODEL W1685Product Dimensions1 1/2 HP DUST COLLECTORWeight. 90 lbs.Width (side‐to‐side) x Depth (front‐to‐back) x Height. 33‐1/2 x 21‐1/4 x 78 in.Footprint (Length x Width). 33‐1/2 x 21‐1/4 in.Shipping DimensionsType. Cardboard BoxContent. MachineWeight. 107 lbs.Length x Width x Height. 36 x 23 x 23 in.Must Ship Upright. YesElectricalPower Requirement. 110V, Single‐Phase, 60 HzPrewired Voltage. 110VFull‐Load Current Rating. 16AMinimum Circuit Size. 20AConnection Type. Cord & PlugPower Cord Included. YesPower Cord Length. 6 ft.Power Cord Gauge. 14 AWGPlug Included. YesRecommended Plug Type. 5‐15Switch Type. Push ButtonMotorsMainHorsepower. 1.5 HPPhase. Single‐PhaseAmps. 16ASpeed. 3450 RPMType. TEFC Capacitor‐Start InductionPower Transfer . Direct DriveBearings. Sealed & Permanently LubricatedCentrifugal Switch/Contacts Type. ExternalModel W1685 Machine Specifications, Page 1 of 2-5-INTRODUCTIONModel W1666/W1685 (For Machines Mfd. Since 2/15)

INTRODUCTIONModel W1666/W1685 (For Machines Mfd. Since 2/15)Main SpecificationsOperationDust Collector Type. Single‐StageApproved Dust Types. WoodFilter Type. BagAirflow Performance. 1280 CFMMax Static Pressure (at 0 CFM). 10.1 in.Main Inlet Size. 6 in.Inlet Adapter Included. YesNumber of Adapter Inlets. 2Adapter Inlet Size. 4 in.Machine Collection Capacity At One Time. 2Maximum Material Collection Capacity. 5.4 cu. ft.Filtration Rating. 2.5 MicronBag InformationNumber of Upper Bags. 1Number of Lower Bags. 1Upper Bag Diameter. 19 in.Upper Bag Length. 33 in.Lower Bag Diameter. 19 in.Lower Bag Length. 33 in.Impeller InformationImpeller Type. Radial FinImpeller Size. 12 in.Impeller Blade Thickness. 1/8 in.ConstructionUpper Bag. FabricLower Bag. PlasticBase. Steel Sheet Metal w/CastersCaster. High Density PlasticImpeller. SteelPaint Type/Finish. Powder CoatedBlower Housing. Steel Sheet MetalBody. Steel Sheet MetalOtherCountry of Origin . ChinaWarranty . 2 YearsApproximate Assembly & Setup Time . 45 MinutesSerial Number Location . ID Label Above Magnetic On/Off SwitchISO 9001 Factory . YesCertified by a Nationally Recognized Testing Laboratory (NRTL) . NoFeaturesLarge CapacityPowder‐Coated FinishIncludes Steel Base with CastersModel W1685 Machine Specifications, Page 2 of 2-6-

Model W1666/W1685 (For Machines Mfd. Since 2/15)SAFETYThe. purpose. of. safety. symbols. is. to. attract. your. attention. to. possible. hazardous. conditions. hemselves. do. not. eliminate. danger. and. are. not. a. substitute. for. proper. accident. prevention. dMachinery Safety OWNER’S.MANUAL.Read and understand thisowner’s manual BEFORE using machine.ELECTRICAL.EQUIPMENT.INJURY.RISKS.You canbe shocked, burned, or killed by touching liveelectrical components or improperly groundedmachinery. To reduce this risk, only allow anelectrician or qualified service personnel todo electrical installation or repair work, andalways disconnect power before accessing orexposing electrical equipment.TRAINED.OPERATORS.ONLY.Untrained operatorshave a higher risk of being hurt or killed. Onlyallow trained/supervised people to use thismachine. When machine is not being used,disconnect power, remove switch keys, orlock-out machine to prevent unauthorizeduse—especially around children. Makeworkshop kid proof!DISCONNECT.POWER.FIRST.Always disconnectmachine from power supply BEFORE makingadjustments, changing tooling, or servicingmachine. This eliminates the risk of injuryfrom unintended startup or contact with liveelectrical components.DANGEROUS.ENVIRONMENTS.Do not usemachinery in areas that are wet, cluttered,or have poor lighting. Operating machineryin these areas greatly increases the risk ofaccidents and injury.EYE.PROTECTION.Always wear ANSI-approvedsafety glasses or a face shield when operatingor observing machinery to reduce the risk ofeye injury or blindness from flying particles.Everyday eyeglasses are not approved safetyglasses.MENTAL.ALERTNESS.REQUIRED.Full mentalalertness is required for safe operation ofmachinery. Never operate under the influenceof drugs or alcohol, when tired, or anual.Before.Operating.Machine

SAFETYModel W1666/W1685 (For Machines Mfd. Since 2/15)WEARING.PROPER.APPAREL.Do not wearclothing, apparel, or jewelry that can becomeentangled in moving parts. Always tie backor cover long hair. Wear non-slip footwear toavoid accidental slips, which could cause lossof workpiece control.FORCING.MACHINERY.Do not force machine. Itwill do the job safer and better at the rate forwhich it was designed.NEVER.STAND.ON.MACHINE.Serious injury mayoccur if machine is tipped or if the cuttingtool is unintentionally contacted.HAZARDOUS.DUST.Dust created while usingmachinery may cause cancer, birth defects,or long-term respiratory damage. Be aware ofdust hazards associated with each workpiecematerial, and always wear a NIOSH-approvedrespirator to reduce your risk.STABLE.MACHINE.Unexpected movement duringoperation greatly increases risk of injury orloss of control. Before starting, verify machineis stable and mobile base (if used) is locked.USE.RECOMMENDED.ACCESSORIES.Consultthis owner’s manual or the manufacturer forrecommended accessories. Using improperaccessories will increase risk of serious injury.HEARING.PROTECTION.Always wear hearingprotection when operating or observingloud machinery. Extended exposure to thisnoise without hearing protection can causepermanent hearing loss.UNATTENDED.OPERATION.To reduce the riskof accidental injury, turn machine OFF andensure all moving parts completely stopbefore walking away. Never leave machinerunning while unattended.REMOVE.ADJUSTING.TOOLS.Tools left onmachinery can become dangerous projectilesupon startup. Never leave chuck keys,wrenches, or any other tools on machine.Always verify removal before starting!MAINTAIN.WITH.CARE.Follow all maintenanceinstructions and lubrication schedules tokeep machine in good working condition. Amachine that is improperly maintained couldmalfunction, leading to serious personal injuryor death.INTENDED.USAGE.Only use machine for itsintended purpose—never make modificationswithout prior approval from WoodstockInternational. Modifying machine or usingit differently than intended will void thewarranty and may result in malfunction ormechanical failure that leads to seriouspersonal injury or death!CHECK.DAMAGED.PARTS.Regularly inspectmachine for any condition that may affectsafe operation. Immediately repair or replacedamaged or mis-adjusted parts beforeoperating machine.AWKWARD.POSITIONS.Keep proper footing andbalance at all times when operating machine.Do not overreach! Avoid awkward handpositions that make workpiece control difficultor increase the risk of accidental injury.CHILDREN.&.BYSTANDERS.Keep children andbystanders at a safe distance from the workarea. Stop using machine if they become adistraction.MAINTAIN.POWER.CORDS.When disconnectingcord-connected machines from power, graband pull the plug—NOT the cord. Pulling thecord may damage the wires inside, resultingin a short. Do not handle cord/plug with wethands. Avoid cord damage by keeping it awayfrom heated surfaces, high traffic areas, harshchemicals, and wet/damp locations.GUARDS.&.COVERS.Guards and covers reduceaccidental contact with moving parts or flyingdebris—make sure they are properly installed,undamaged, and working correctly.EXPERIENCING.DIFFICULTIES.If at any timeyou experience difficulties performing theintended operation, stop using the machine!Contact Technical Support at (360) 734-3482.-8-

Model W1666/W1685 (For Machines Mfd. Since 2/15)Additional Safety for Dust CollectorsSUSPENDED DUST PARTICLES AND IGNITIONSOURCES. DO NOT operate the dust collectorin areas where explosion risks are high. Areasof high risk include, but are not limited to,areas near pilot lights, open flames, or otherignition sources.FIRE SUPPRESSION. Only operate dust collectorin locations that contain a fire suppressionsystem or have a fire extinguisher nearby.HAZARDOUS DUST. Dust created while usingmachinery may cause cancer, birth defects,or long-term respiratory damage. Be aware ofdust hazards associated with each workpiecematerial, and always wear a NIOSH-approvedrespirator to reduce your risk.IMPELLER HAZARDS. DO NOT place your handsor tools near the open inlet during oper

-2-We madthfffdoWl wdingcmdsfuppr (Replaces Page 37 in Manual) PARTS Main 1 19 4 5 6(W1666) 16(W1666) 50(W1685) 4(W1685) 2 49 24B 18 38-1