Transcription

Food Protection Trends, Vol. 32, No. 10, Pages 574–584Copyright 2012, International Association for Food Protection6200 Aurora Ave., Suite 200W, Des Moines, IA 50322-2864Characteristics of FoodContact Surface Materials:Stainless SteelRonald H. Schmidt,1* Daniel J. Erickson,2 Steven Sims3 and Philip Wolff41Food Science and Human Nutrition Dept., University of Florida, P.O. 110370, Gainesville, FL 32611, USA;2Harold Wainness and Associates, 2460 – 1st Ave. East, North St. Paul, MN 55109, USA; 3U.S. Dept. of Healthand Human Services, Food and Drug Administration, Office of Food Safety, Center for Food Safety and AppliedNutrition, 5100 Paint Branch Pkwy., College Park, MD 20740-3835, USA; 4U.S. Dept. of Agriculture, AgriculturalMarketing Service, Dairy Grading Branch, 1400 Independence Ave., SW, Washington, D.C. 20250-2030, USAsummaryThis technical review article describes the properties and characteristics of stainless steelin sanitary design when used as a food contact surface, particularly when compliance with therequirements of standards promulgated by 3-A Sanitary Standards, Inc. is intended. It discusses thegeneral characteristics of stainless steels, including ferrite, austenite, cementite, and martensite. Itdiscusses stainless steel categories and grades used in industrial applications and their properties,including both non-magnetic types such as superaustenitic and magnetic types such as ferric andmartenistic as well as duplex stainless steel and precipitation hardened stainless steel. Specific emphasisis given to those categories and grades used in food contact applications. The article contains adiscussion on the general steps in stainless steel manufacturing, including melting/casting, forming,heat treatment/annealing, descaling, cutting, and finishing, and describes common types of acceptablesurface modification and finishing of stainless steel. In addition to the topics listed above, the articledescribes common types and causes of corrosion of stainless steel, including uniform, pitting, crevice,stress cracking, galvanic, contact, and biologically and microbiologically influenced corrosion. Finally thearticle discusses methods of preventing corrosion, including surface maintenance and cleaning and aprocess referred to as “passivation.” This article contains micrographs showing, at varying levels ofmagnification, chemical corrosion and some common surface finishes, including number 4 (150 grit),2B, and 2D finishes, as well as photographs showing unacceptable product contact surface finishesof welds in stainless steel tubing.A peer-reviewed article*Author for correspondence: Phone: 1 352.367.2877; Fax: 1 352.392.9467E-mail: schmidt2@ufl.edu574 FOOD PROTECTION TRENDS OCTOBER 2012

INTRODUCTIONFrom a sanitary design perspective,food contact surfaces should be smooth,impervious, free of cracks and crevices, non-porous, non-absorbent, noncontaminating, non-reactive, corrosionresistant, durable, and cleanable (24).Further, materials used in food contactsurfaces must be non-toxic, and materials containing heavy metals (e.g., lead,cadmium, hexivalent chromium or mercury) or other toxic materials must beavoided. Finally, these surfaces should befabricated, operated, and maintained ina manner such that these criteria are notcompromised. Stainless steel is generallythe most preferred and most commonlyused material in the design, constructionand fabrication of food processing equipment and is specified in the 3-A SanitaryStandards (1) as well as in other commonly used food processing equipmentstandards throughout the world (20).The general advantages of stainlesssteel over other materials for food contact are as follows: corrosion resistance (rangingfrom fair to outstanding); high strength, high hardness,high modulus; availability of a wide range ofproduct forms; relative ease of machining andfabrication; and relatively low cost.A wide variety of stainless steelmaterials are available with widelyvarying composition, surface finish, andfunctional properties (2, 4, 5, 6, 7, 8, 23).In addition, the functionality of stainlesssteel is impacted by surface treatmentsand coatings. Thus, an awareness of theproperties of the various stainless steelsis required by fabricators, as well as bypotential users of food equipment.General characteristicsof stainless steelFrom a metallurgical perspective,steel is an iron alloy composed of iron(Fe) and carbon (C), with ferric carbide(Fe3C) as the base component. However,depending upon formulation/alloyingand manufacturing techniques, the ironexists as a solid solution of varied levelsof iron and carbon of different crystallinetextures (e.g., ferrite, austenite, pearlite,martensite, ledenburite, spheroidite, andcementite) as well as different strengths,hardnesses, and other properties. Theseproperties are dependent upon compo-sitional distribution and chemical combinations of iron and carbon. For example, ferrite (predominately α- iron andδ- iron) is relatively soft, while austenite(predominately γ- iron) is much harder,and cementite (predominately Fe3C) isextremely hard. Martensite has intermediate Fe-C levels and mixed chemicalspecies and forms. In general, the crystalline structure of ferrite, austenite, andmartesite is usually body-centered cubic,face-centered cubic and needle-like, respectively.Stainless steel, in general, is anFe-C alloy with additional alloying elements. These alloying elements mayinclude copper (Cu), chromium (Cr),molybdenum (Mo), manganese (Mn),nickel (Ni), nitrogen (N), phosphorus(P), silicon (Si), sulfur (S), selenium (Se),tungsten (Tn), and titanium (Ti).Base stainless steels are generallyformulated from iron (minimum of 50%by weight), carbon and chromium (minimum 10.5% by weight), and their properties are dependant upon the relativeconcentrations of these elements. Properties of additional alloying elements willbe discussed.Stainless steel categoriesand grades, and their propertiesMore than 150 grades or types ofstainless steel exist. The traditional nomenclature to define stainless steel gradesis the numbering system of the AmericanIron and Steel Institute (AISI), a function now under the American Society ofTesting and Materials (ASTM) (2). Thetraditional AISI Stainless Steel ProductsManual, currently published by the Ironand Steel Society (14), provides a listingof stainless steel grades, composition,and properties. While AISI grading system has traditionally used a three-digitnumbering system, newer grades allocate1-letter 5 digit UNS numbers. Whilethe AISI grade designations define theindividual grades, they are not specifications as such. Specifications used forstainless steel are from the ASTM. Inaddition, international specifications areused to identify and distinguish specialized stainless steel products (e.g., weldingwire).The two general categories of stainless steel are non-magnetic and magnetic stainless steel. Through working,blending and manufacturing techniques,additional categories of stainless steel(e.g., duplex, precipitation hardened)are also available for specific applications.While there is considerable variationwith regard to properties within each ofthe stainless steel categories, their generalproperties are summarized in Table 1.The general classes of stainless steelalloys can be further subdivided according to composition, common AISI grade,crystal structure, specific properties, andapplications. A comparison of properties, characteristics, and applications ofselected stainless steel grades is presentedin Table 2, and the chemical alloy composition of selected stainless steel gradesis presented in Table 3.The most common stainless steelsused in food processing and handlingequipment are made from Fe-C-Cr alloysand Fe-C-Cr-Ni alloys, with other alloying elements used to varying degrees. Cr,upon exposure to air, gives stainless steelits characteristic high resistance to “stain”(or corrosion) by forming a thin “passive”layer of chromium (III) oxide (Cr2O3),iron oxide, and other oxides. The passivelayer protects the “active” material (iron),which is susceptible to rust and corrosion. Nickel (when present) providesadditional corrosion resistance as wellas greater strength and structural hardness to stainless steel. However, as willbe discussed, Ni-based stainless steels aremore susceptible to one type of corrosion, termed Stress Corrosion Cracking(SCC), than are those without Ni.In general, alloys formulated athigher carbon levels are of greater structural hardness and strength than thoseformulated at lower carbon levels. Additional carbon also provides resistance tooxidation and creep. However, the riskof corrosion may be increased with highcarbon stainless steel materials.In higher grade stainless steels, Moand/or N (and to a lesser extent Cu) areadded to enhance the passivation layerthrough forming oxides of these elements, thus providing additional corrosion resistance. Mo (which forms molybdenum oxide in the passivation layer) isespecially effective at preventing the typeof corrosion termed “pitting corrosion.”Enhanced machinability is attainedthrough the addition of P, S, and/orSe. Stainless steels of excellent strength,strength, durability, heat resistance, andcorrosion resistance (especially in acidenvironment) may be attained with theaddition of Ti. Because of the relativelyhigh economic cost, Ti-based stainlesssteels are primarily used in situationswhere high acid and/or salt levels (e.g.,citrus juice, tomato products) may beencountered.OCTOBER 2012 FOOD PROTECTION TRENDS575

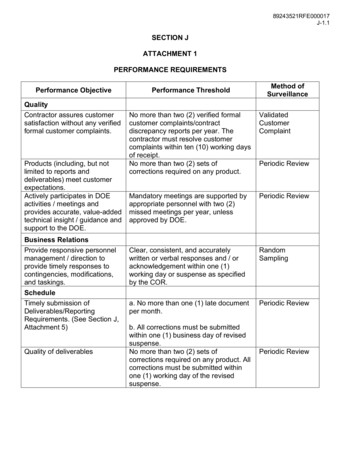

MagneticWorkCorrosion Harden able Ductility LE1. Generalpropertiesand stainless steel categoriesTemperature(2, 23)RateResistanceResistanceGroupA. Nonmagnetic(Austenitic)WeldabilityNoVery HighHighCold or workhardenedonlyVery HighVery HighVery HighVery High1. FerriticYesMediumVery HighNoMediumHighLowLow2. MartensiticYesMediumMediumYes – quench& temperLowLowLowLowC. DuplexYesMediumVery HighNoMediumLowMediumHighD. PrecipitationHardenedYesMediumMediumHardened bylow heating(aging)MediumLowLowHighB. Magnetic1Variation between grades and formulations within each group2The property of metal which permits it to show considerable elongation with increase in local stressesNon-magnetic stainless steelThe non-magnetic stainless steels,primarily austenitic alloys, are generallyFe-C alloys with Cr (ranging to 26%) andNi (usually less than 35%). As shown inTable 3, other alloying elements may beused, depending upon the grade.Most of the stainless steel used inthe fabrication of food equipment is ofthe austenitic AISI 300 series. Approximately 50% of all stainless steel produced is 304 stainless steel, formulated at18% Cr and 8% Ni. As shown in Table3, type 316, austenitic stainless steel hashigher Ni (10%) and Mo levels and isgenerally considered a higher grade material for food contact surfaces than 304stainless steel because of its enhancedcorrosion resistance. The 3-A SanitaryStandards (1) require that food product contact surfaces be of stainless steelthat conforms to the applicable composition ranges established by ASTM A 959or AIST Stainless Steels: Steel ProductsManual for 304/304L and 316/316Lor corresponding Alloy Cast Institutetypes or metal that, under conditionsof intended use, is at least as corrosionresistant as 304 stainless steel. The 3-ASanitary Standards (1) restrict the use of303 stainless steel, and expressly prohibitalloys containing lead, leachable copperor other toxic materials. Lower gradeaustenitic stainless steel alloys (e.g., AISI100 and 200 Series) are generally not recommended for use in food equipment.Higher grade alloys, termed superaustenitic (e.g., AL-6XN, 254SMO),contain higher levels of all alloying elements (especially molybdenum). Thesealloys have excellent corrosion resistanceand strength for use in harsh environments such as marine applications.Variations with regard to composition and properties are also seen withinthe stainless steel grades, depending uponthe composition. For example, alloysmay be formulated at low carbon levels(e.g., 304L, 316L) to enhance weldability. These alloys, however, would havelower strength than the base grade ( e.g.,304, 316). Conversely, higher carbonlevels may be used for enhanced strengthalloys (e.g., 304H, 316H). Thus, modified stainless steel of lower AISI grademay, through compositional modification, exhibit properties similar to thoseof a higher grade designation.Magnetic stainless steelThese alloys are less commonly usedin food equipment applications than arenon-magnetic alloys. However, they maybe used for highly specialized applications. They are formulated from Fe-CCr alloys, generally without Ni. The twobasic categories of magnetic stainless steelare ferritic and martensitic.Ferritic stainless steels are Fe-C-Cralloys formulated at higher Cr and/orlower C than the martensitic alloys. Theypossess less strength, but higher ductil-576 FOOD PROTECTION TRENDS OCTOBER 2012ity, than either austenitic or marstensiticalloys; however, they have superior weldability, because of high heat resistance.These stainless steels are primarily usedfor decorative purposes (e.g., appliances,automobile and architectural trim) andare not commonly used in the manufacture of food equipment. However, as willbe described, certain grades of ferriticstainless steel are used in the brewingindustry, because of their resistance toStress Corrosion Cracking (SCC).Martensitic stainless steels are FeC-Cr alloys often used for their highhardenability. In addition to varyingamounts of the base alloying elements,sulfur and/or selenium may be added toenhance machinability of certain grades.Martensitic stainless steel grades have avariety of industrial applications (e.g.,ball bearings, races, dies, screws, bolts)as well as medical/dental applications(e.g., surgical instruments, dental instruments). Higher carbon martensitic alloysare used for high-grade cutlery and razorblades because of their strength, polishability, and sharpenability. Martensiticstainless steels may also be used in avariety of food contact applications (e.g.,utensils, scoops, blades, bushings, bearings, buckets).Duplex stainless steelExcellent corrosion resistance andhigh strength can be attained by the useof duplex stainless steel alloys, which

TABLE 2. General sub-classes, characteristics, and usage applications of stainless steel alloys(2, 4, 5)General ClassificationCommon AISI GradesCharacteristics ApplicationsA. Non-magnetic Stainless Steel1. Austenitic chromiumnickel-manganese100 Series Low strength,Type 101, 102durability, and200 SeriescorrosionType 201, 201resistanceGeneral purpose;Furniture; notrecommended forfood equipment2. Austenitic chromium300 SeriesnickelType 301, 302,Relatively higher303carbon impartshardness andmachinability;low corrosionresistanceFormed products;low corrosionresistance limits foodequipment usage;303 sometimesused in lowcorrosion applicationsType 304Most commonlyused in foodequipment applicationsMore corrosionresistance, lessstrength than 303Type 308, 309 Highertemperatureresistance than304;Type 316Used as afiller metalMore corrosionSecond mostresistance thancommonly used in304, enhanced byfood equipmentinclusion ofmolybdenumType 321 Higher Weldingweldability thanapplications3043. SuperausteniticAL-6XN, High strength,Enhanced levels of all254SMOhardness,alloying elements,abrasionespecially molybdenumresistance,( 6%)resistance toSpecializedapplications; marineenvironmentspitting and othercorrosionB. Magnetic Stainless Steel1. Ferritic – chromium405, 409, 429, High heatand iron alloysresistance, good430, 439, 446formability andmachinability,poor corrosionresistance2. Marstensitic – chromium,410, 416, 420, 431, High strength,iron, carbon alloys440wear resistant;Decorativeappliances,automobile andarchitectural andappliance trimDental and surgicalinstruments; bladespolishablebushings, buckets,ball bearings, moldsand dies, utensils,cutleryOCTOBER 2012 FOOD PROTECTION TRENDS577

TABLE 2. General sub-classes, characteristics, and usage applications of stainless steel alloys (2, 4, 5)(Continued)General ClassificationCommon AISI GradesD. Precipitation Hardening –600 Seriesprimarily marstensitic(some austenitic)Characteristics ApplicationsExcellenthardness andby low heataging processSpecialtyapplicationsstrength; formedTABLE 3. General composition of selected grades of stainless steels (23)General AISICategory gradeApproximate content (% of weight)Carbon ManganeseChromiumNickel Molybdenum ss Steels3040.082.0017.5 – 20.08 – 10.5--3160.082.0016.0 – 18.010.0 – 14.02.0 – 3.03210.082.0017.0 – 19.09.0 – 12.0--5.0254SMO0.021.0018.5 – 20.517.5 – 18.56.0 – 6.51.9AL-6XN0.031.0020.0 – 22.023.5 – 25.56.0 – 7.0Ferritic Stainless Steels4050.081.011.5 – 14.5------4300.121.016.0 – 18.0------4460.201.523.0 – 27.0------Martensitic Stainless Steels410.151.011.5 – 13.0------416.151.2512.0 – 14.0--0.6--431.101.015.0 – 17.0--1.25 – 2.0--possess a mixture of ferritic and austenitic crystal structures. In addition to theiron-carbon base, the primary alloyingelements are chromium and low levelsof nickel. Typically, duplex stainless steelexhibits considerably higher strengththan austenitic stainless steel, with corrosion resistance similar to higher gradeaustenitic alloys, and they possess better corrosion and cracking resistance.Because of a nickel level typically lessthan half of that found in austeniticstainless steel, they also have a potentialprice advantage. Higher grades of duplex stainless steel (e.g., superduplex)have high chromium and molybdenumlevels. Although type 2205 is the mostwidely used duplex stainless steel grade,other grades are available (e.g., 326, 329,A219, 2RE60, IC378, IC381). Potentialfood industry applications for duplexstainless steel are in situations where thecorrosion potential is high, such as brewing and fermentation (e.g., brine tanks,578 FOOD PROTECTION TRENDS OCTOBER 2012brewing tanks, pipelines) or for hotchemical storage and/or transport.Precipitation hardened stainlesssteelThis general class of stainless steelrefers to materials formed by hardening of stainless steel materials, usually by a low temperature aging heattreatment to develop high tensilestrength. Only certain types of stain-

TABLE 4. Stainless steel finishes (2, 8, 23)Stainless Steel Finish CategoryDescriptionMill FinishesNo. 0 Hot rolled, annealed, thicker platesNo. 1 Hot rolled, annealed, passivatedNo. 2DCold rolled, annealed, pickled, passivatedNo. 2BSame as 2D with additional roller polishingNo. 2BABright annealed 2BPolished FinishesNo. 3Coarse abrasive finishNo. 4Brushed finishNo. 5Satan finishNo. 6Matte finishNo. 7Reflective finishNo. 8Mirror finishNo. 9Bead blast finishNo. 10 Heat-colored finish (widely varied)less steel are hardenable by heatingmethods, the most common of whichare precipitation hardened martensitic(e.g., AISI 601 – 630) stainless steel. Ferritic stainless steel alloys generally cannotbe hardened by the precipitation hardening method. Although austenitic stainless steels are generally not readily hardenable by heating, certain precipitationhardened austenitic grades (e.g., AISI650 – 653, 660 – 665) are available.Although not hardenable by heating, 300 Series austenitic stainless steelcan be hardened by a process knownas “work hardening,” or “cold working” the material. This is accomplishedmechanically by cold rolling down tolighter gauges or by drawing through adie or similar device.STAINLESS STEELMANUFACTURINGGeneral manufacturing stepsThe gauge and properties, as wellas the applicability and uses of stainlesssteel, are greatly impacted by the manu-facturing steps. In addition, strict quality control must be practical to preventsurface etching or the presence of debris(e.g., tramp steel) on the surface whichcould limit the corrosion resistance quality of the material. The general steps inthe manufacture of stainless steel (29) arethe following:Melting/Casting. Raw materialsare melted together during prolongedheating at intense temperatures in anelectric furnace. The molten steel is castinto various forms (e.g., blooms, billets,slabs, tubes).Forming. This step is generallydone by a rolling process, with hot rollingbeing the most common method. Duringforming, cast materials are formed intovarious shapes ( e.g., wire, bar, sheets).Heat Treatment/Annealing. Stainless steel is heated (or annealed) to relieveinternal stresses and soften the material.The specific conditions used in this annealing step will vary with the generaltype of material (e.g., austenitic, ferritic,martensitic).Descaling. The annealing stepcauses a surface build-up, or scale, thatmust be removed. The most commondescaling method is pickling, in whicha nitric-hydrofluoric acid bath is usedto remove the scale. Electro-cleaning, aprocess by which scale is removed electrochemically, may also be used.Cutting. In this step, the material is cut into desired blank, shape,size or gauge. Cutting is usually donemechanically by use of a variety of shearing methods with specially designedknives. Flame cutting (using a flamefired torch) or plasma jet cutting (usingionized gas with an electric arc) may alsobe used.Finishing and surfacemodificationThe final surface finish of stainlesssteel is critical to its properties and applications (11). Thus, finishing is an important step in stainless steel manufacture. Generally, a dull finish is attainedthrough hot rolling, annealing, and descaling (especially if pickling is used). Anysurface debris which may have formedduring manufacture must also be removed.OCTOBER 2012 FOOD PROTECTION TRENDS579

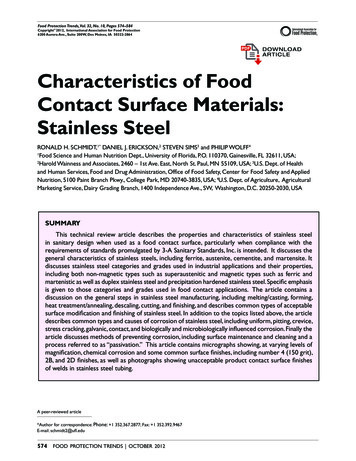

FIGURE 1. 2B Mill finish (magnifications shown at 6.3, 12, 25, and 63 X)FIGURE 2. 2D Mill finish (magnifications shown at 6.3, 12, 25 and 63 X)A wide variety of stainless steelsurface finishes are available, depending upon the desired applications. Thecosts of achieving different surface finishes are varied. In general, smoother ormore polished surfaces are more expensive than rougher surfaces. Stainless steelfinishes are given a number dependingupon their characteristics and properties,with higher numbers indicating highersmoothness (9, 26). The general stainlesssteel finishes are described in Table 4.A variety of methods of surfacemodification are used to achieve a desired surface finish (9, 26). In general,hot rolled base stainless steels are notused in food contact applications. Thehot rolled annealed (e.g., HRA or No. 0)finish, since it is neither pickled nor passivated (to be described later), does notdevelop the passive corrosion-resistantlayer and has a scaly black finish. No.1 Finish stainless steel has a rough, dullsurface and is also not recommended forfood contact surfaces, although it is usedin industrial applications.Mill finishes are attained by directapplication of rollers and mechanicalabrasives to flat rolled (wrought) stainlesssteel sheets and are the basic finishes forall flat stainless steel. Differing finishesare attained with hot or cold rolling. Forexample, cold rolling on polishing rollers is used to obtain a bright finish. A580 FOOD PROTECTION TRENDS OCTOBER 2012No. 2 finish is attained by a cold rollingprocess. The most common in this seriesis the 2B finish (shown under magnification in Fig. 1), which is smoother andbrighter than the 2D finish (Fig. 2).Bright Annealed (e.g., 2BA) is mechanically polished (or brushed). Because ofits superior release properties for higherfat products (e.g., cheese, butter, meats),the 2B mill finish has been traditionally accepted under specific 3-A SanitaryStandards (1) and U.S. Department ofAgriculture (USDA) guidelines (28) forsuch applications. Certain cold rolledstainless steels of the No. 2 series are usedin architectural applications.Polished finishes are attained byuse of a variety of techniques to “polish”stainless steel. Grinding with abrasivesand/or buffing withcloth wheels may beused to achieve a reflective finish. Further polishing with progressively finerabrasives, extensive buffing with clothrollers, or electropolishing will result ina mirror finish. Additional finishingmethods ( e.g., tumbling, dry etching/sandblasting, wet etching by use of acidsolutions, wire brushing) are used toachieve specific finishes. In some cases,a process termed “bead blasting” is usedin which the surface is bombarded withglass beads. While this is an efficientprocess, it not usually recommendedfor food contact surfaces because theglass beads tend to degrade into irregular shapes during this process, leaving anirregular surface finish. The lowersmoothness polished finish (No. 3) is aground (80 – 100 grit abrasive) finish,and is not used extensively for food contact surfaces. The No. 4 ground finish(80 – 150 grit), the most commonly usedgeneral purpose stainless steel for foodcontact surfaces, is shown under magnification in Fig. 3. Buffed finishes (No. 5,6, 7, 8) are generally more expensive andthus not used extensively in the food industry. The 3-A Sanitary Standards (1),as well as USDA guidelines specify thatall surfaces, including fabricated, weldedand soldered joints, shall be at least assmooth as a No. 4 (150 grit) finish andshall be free of pits, folds, crevices, cracks,and misalignments in the final fabricatedform. Examples of welded surfaces thatare not considered as smooth as a No. 4finish are shown in Fig. 4.The Average Roughness (Ra),measured by the profile method and

FIGURE 3. Number 4 (150 grit) finish (magnifications shown are 6.3, 12, 25and 63 X)assurance of the acceptability of a 2B finish on stainless steel sheets that have notbeen inspected and found free of theseserious flaws.CORROSION OF STAINLESSSTEELTypes of corrosion and theircausesFIGURE 4. Examples of surface texture or finish on the interior surface of weldsin metal tubing that are not as smooth as a No. 4 (150 grit) finish. These flaws arethe result of improper welding techniques: (A) Inadequate inert gas purge duringwelding; (B) Over pressure of inert gas during welding; (C) Uneven distribution ofheat during weldingexpressed in µm, is the roughness parameter most widely used and is accepted byvarious international bodies, includingthe International Organization for Standards (ISO standards) and the EuropeanHygienic Engineering Design Group(EHEDG) (13, 15, 16, 20, 21). An Raof less than 0.8 µm is specified for foodcontact surfaces by the EHEDG andby the American Meat Institute (AMI)Equipment Design Task Force (10) recommendations. Under 3-A SanitaryStandards(1) criteria, an Ra of less than32 µin. (0.8 µm) is specified and is considered equivalent to a No. 4 finish.Surface roughness has been generally related to cleanability of stainless steelsurfaces (25), with smoother surfaces often considered more cleanable. However,the relationships between surface roughness and cleanability, as well as the relationship between surface roughness andbiofilm formation, are not clearly established and need further research (20, 21,24), and many other factors may be important. According to the study by Steiner et. al. (24), a 2B mill finish on stainless steel sheets may, in performance, beas cleanable as a No. 4 (150 grit) finish.Under the 3A Sanitary Standards (1), a2B finish may be now be accepted forcertain surfaces, provided that the stainless steel sheets have been inspected andselected to be free of pits, folds, cracks,inclusions, and similar defects. It shouldbe noted, however, that, because mean Rais not sensitive to individual extreme surface flaws, it is not accepted by 3A as anBeing composed of an iron-basedalloy, nearly all common grades of stainless steel are prone to corrosion by removal of the passive film through continued exposure to incompatible cleaners,abrasive cleaners, abrasive cleaning pads,or chlorine and oxidizing sanitizers. Ingeneral, stainless steel does not “rust,” aprocess in which the characteristic flaking red oxide forms on regular steel.If red discoloration occurs, it is due tocontamination by iron particles on thesurface (or imbedded in the surface) ofstainless steel that have rusted. The 3-ASanitary Standards (1) require that anystainless steel or other metal materialused be at least as corrosion resistant as304 stainless steel under the conditions ofintended use of the stainless steel, metal,or alloy to be used. Corrosion of stainlesssteel is shown in Fig. 5.The general types of stainless steelcorrosion (11, 27) are as follows: Uniform Corrosion. This typeof corrosion is usually associated with continued exposureto dilute acid or alkaline solutions, or by acute exposure tomore concentrated acid or hotalkali. General resistance tothis type of corrosion is betterin stainless steels formulatedwith higher levels of Cr. Sulfuraddition, which enhances machinability, reduces the resistance to uniform corrosion. Pitting Corrosion. This typeof corrosion results from morelocalized destruction of thepassive layer and subsequentcorrosion of the steel alloy below. Pitting corrosion generally is the result of exposure tochlorides, bromides, and otherhalides and is accelerated byhigh temperature and lowerpH level. Once formed, pitting corrosion has a tendencyto continue to grow and is difficult to remove. Stainless steelgrades formulated at high CrOCTOBER 2012 FOOD PROTECTION TRENDS581

FIGURE 5. Examples of chemical corrosion and the resulting pitting of polishedstainless steel surfaces (two upper photos) and on interior surfaces of unpolishedtubing (lower left) and unpolished metal tubing at a welded joint (lower right).Magnification shown at 6.3 X) and Mo and/or N have higherresistance to pitting corrosion.The Pitting Resistance Equivalent (PRE) number, used as anindicator of pitting resistanceof stainless steel, is calculatedas: PRE %Cr 3.3 %Mo 16 x %NCrevice Corrosion. There is apotential for this type of corrosion when crevices are formedduring equipment fabri

impervious, free of cracks and crev-ices, non-porous, non-absorbent, non-contaminating, non-reactive, corrosion resistant, durable, and cleanable (24). Further, materials used in food contact surfaces must be non-toxic, and materi-als containing heavy metals (e.g., lead, cadmium, hexivalent chromium or mer -