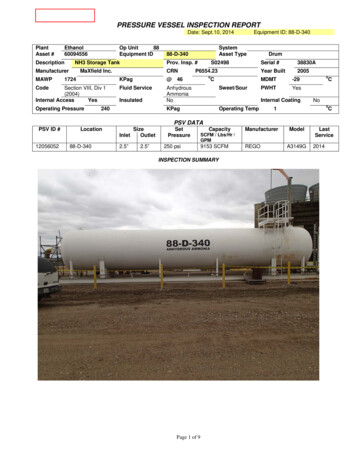

Transcription

Pressure Relief DeviceInspectionReview of NBIC Part 2, par. 2.5Prepared by: J. F. Ball, P. E.Updated November 20161

Purpose of Pressure Relief Devices Last line of defense against overpressurecondition Overpressure could lead to failure of the boileror pressure vessel (PRI) Protection for both persons and property PRDs are not designed as pressure controldevices!2

Keys to In-service Inspection Safety considerationsPressure relief device and PRI dataDevice conditionInstallation conditionTesting and Operational Inspection3

Safety Considerations High pressure discharge may have considerableenergy released High temperatures may be involved (steam) High levels of noise encountered during testing4

PRI DataFirst look at applicationand PRI nameplate Determine MAWP anddesign temperature Determine steamingcapacity or heatingsurface for boilers What is the service fluid?5

Device DataCorrect Code Stamp for application Power and heating boilers Low pressure steam heatingboilers, hot water heating boilers,hot water heaters Unfired pressure vessel service6

ASME Certification Mark withDesignatorX New ASME Certification Mark Replaced previous Codestamps after 2013 “Designator” gives service V, HV, UV, or UD for pressurerelief devices7

Device Data – Set PressureInspect pressure relief devicenameplate data Set pressure for single devicecannot exceed MAWP Set pressure of high set devicewhere multiple devices areinstalled may exceed MAWP 3% for Section I boilers 5% for heating boilers 5% for pressure vessels 10% for pressure vessel fire case Section I valves must havespread less than 10%8

Device DataRepair plate could change data on original plateVR SymbolNB Cert #SET:MODEL:CDTP:CAP.:DATE:RECORD No.:9

Device DataValve may also have “test only” nameplate Will show date of test Responsible party Gives traceability if valve reset10

Missing Nameplates2013 ASME Code, Section I, Appendix III included“CRITERIA FOR REAPPLICATION OF A CERTIFICATIONMARK” Not practically written for pressure relief valves NBIC Part 3, par. 5.12.5 includes provisions forduplicate nameplates (must be done along with VRrepair) Includes “Sec.I” instead of Code stamp11

Device Data - Capacity For boilers, combined valve capacity mustexceed maximum designed steaming capacity NBIC Part 1, Table 2.9.1.3 gives calculationmethod when heating area is used (need toknow boiler fuel)12

Device Data - capacityCompare valve capacity in BTU/Hr toburner input for heating boilers Has burner or fuel been changed?13

Device Data – Valve Seals Valve seals must havecorrect identification Valve seal identificationmust match otherinformation on the valve OEM seal Repair company seal shouldmatch repair nameplate Seal may match “test only”nameplate14

Device Condition Seals intactBolting tight and no bolts missingDeposits or material buildupDamaged or missing parts15

Device ConditionSmall valves may bepermanently sealed(what’s wrong here?)16

DeviceCondition Valve should not beleaking Drain hole notclogged or plugged17

Device Condition Bellows valve bonnetvent not plugged No leakage throughbonnet vent18

Device ConditionNo test gag!19

Installation Condition No reduced inlet oroutlet pipe sizes Drain piping open Piping should not bebinding on valve Piping should not besupported by valve Discharge hazards topersonnel20

TypicalASME Section ISafety ValveInstallation21

Installation ConditionWhat’s wrong here?22

Installation Condition23

Installation Condition Rupture diskinstallation underPRV No pressure on gage24

Installation ConditionIsolation valves Not permitted for boilers or hotwater heatersMay be permitted in some pressurevessel applications ASME Code Appendix MrequirementsJurisdiction must approve25

Installation ConditionChange-over valves26

Testing and OperationalInspection Does the valve actually work? Lift lever test At least it’s not stuck shut Test at 75% of set pressure for boiler or pressure vesselvalves Section IV valves can be checked without pressure Section VIII: Test lever required for valves for steam, air,and hot water over 140 deg. F.27

Testing and OperationalInspection Rope can be tied to lever for personnel safety Assure rope does not affect valve Allow valve to “snap” shut28

29

30

Testing and OperationalInspection Set pressure test Set pressure within Code toleranceValve should not be leaking Full pressure test on unit (not accumulation test) Remove valve and check on test stand31

Testing and OperationalInspectionLift assist devicessometimes used tocheck valve on-linewithout a full pop test32

Testing and OperationalInspection Corrective Action Remove system from service if valve is stuck shut!( 16%) Out of set pressure tolerance (NBIC Part 2,par. 2.5.7 g)) “Minor” adjustment 2x set tolerance Must be done by qualified organization “Major” adjustment indicates a repair is needed33

What is a Qualified Organization? NBIC defines a “qualified organization” as an“organization accredited by the National Board” Could be National Board VR or T/O certifiedorganization Part 3, Supplement S7.10 gives outline ofrequirements for potential Jurisdictionalacceptance34

Recommended Test Frequencies Jurisdictional Rules NBIC recommendations Boilers less than 400 psi – manual test every 6 months,annual pressure test Boilers greater than 400 psi – Pressure test every threeyears High temp. hot water boilers – annual pressure test Low pressure boilers (15 psi) – manual test quarterly,annual pressure test before heating season35

Recommended Test Frequencies Hot water heating boilers – manual testquarterly, annual pressure test beforeheating season Hot water heating boilers – manual testquarterly, annual pressure test beforeheating season Water heaters – manual test every 2 months(replace if defective)36

Recommended Test FrequenciesPressure Vessel and Piping Applications To determine inspection frequency, the vesselcontents, system operation, and previous inspectionhistory must be reviewed Steam – annually Air, clean dry gasses – every 3 years PRV with rupture disk – 5 years Propane, refrigerant – 5 years All others – Per Inspection History37

Sample Inspection Checklist38

Final Exam (outlet piping)39

Final Exam40

Final ExamWhat’s wrong with this installation?41

Conclusions Pressure relief devices are important to safesystem operation Inspections must be done to assure devicesare installed and functioning properlyTHANK YOU!42

NBIC Part 3, par. 5.12.5 includes provisions for duplicate nameplates (must be done along with VR repair) Includes “Sec.I” instead of ode stamp 11. Device Data - Capacity For boilers, combined valve capacity must exceed maximum designed steaming capacity NBIC Part 1, Table 2.9.1.3 gives calculation method when heating area is used (need to know boiler fuel) 12. Device Data .