Transcription

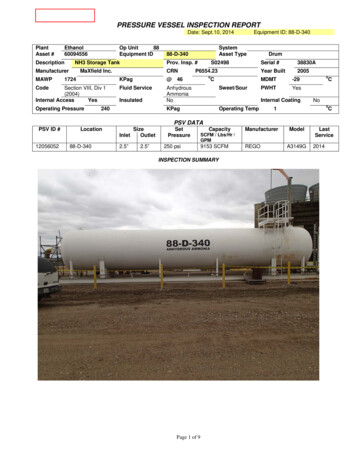

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014PlantAsset #Ethanol60094556DescriptionNH3 Storage TankManufacturerMAWPOp Unit88Equipment IDCodeSection VIII, Div 1(2004)Internal AccessYesOperating PressureSystemAsset Type88-D-340Prov. Insp. #MaXfield Inc.1724CRNEquipment ID: 88-D-340S02498Serial #P6554.230Year BuiltKPag@Fluid ServiceAnhydrousAmmoniaNoSweet/SourKPagOperating ernal Coating0C0CNo1PSV DATAPSV ID ��SetPressure250 psiCapacity9153 SCFMINSPECTION SUMMARYPage 1 of 9ManufacturerModelSCFM / Lbs/Hr /GPMREGOA3149GLastService2014

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340An internal and external inspection was performed on 88-D-340 Ammonia Storage Tank during a planned maintenance schedule. Original shell thickness 0.6854” (17.41 mm)Original head(s) thickness 0.6848” (17.39 mm)Corrosion allowance 0 (both shell and heads)Shell and Heads Material SA 516-70This vessel is for Non-Corrosive Service.The inspection findings were as follows:External: Vessel shell and head condition was acceptable for continued service. Vessel Manufacturer name plate was intact and secure. The TSASK sticker was attached and legible. Surface corrosion exists where paint has failed at the south-west end of vessel. All tank legs and saddles showed no weld defects. All mounting nuts and bolts were intact. Fixed liquid level gauge was replaced by MaXfield. The pressure gauge is broken/non-functioning on the west head. Code CSA B149.2-10 7.5.1 states that a pressure gauge needs to beoperational whenever the vessel is in service. The temperature gauge was intact and operational. This vessel has two ground wires and both were intact (located at South-West & South-East ends). All piping ground clearance was acceptable. All flange connections had no missing, loose or short bolts. The Bulk Head was intact with all piping tight and no loose bolts. The Emergency Shutoff Valve (ESV) appeared to be operational. A Snappy Joe (Safety Equipment) was installed with its cable control in place. The intent of this equipment is to prevent NH3 frombeing released to the atmosphere in case an unloading truck drives away with its hose still attached to the bulk head piping. TheSnappy Joe spring assisted valve would close if the piping broke off. The liquid valve, vapor excess flow valve, two back check valves and the bottom level gauge valve showed no defects underneath thewest end of the vessel. No defects were observed on the manway with no scoring present on the gasket face. The old gasket was replaced by MaXfield duringthe outage. The standpipe level gauge replacement was completed by MaXfield. MaXfield confirmed the rain caps on the PSV stacks would come off if the pressure goes above the 250 psi set pressure. They weren’tloose fitting at the time of this inspection, but apparently are on tighter to prevent them from being blown off by the wind.Internal: A visual inspection found no corrosion; pitting or mechanical deficiencies were present.NDE: PRV: Note: MaXfield performed an internal Wet Fluorescent Magnetic Particle Inspection (WFMPI) on all six circumferential welds and all nozzlewelds. No relevant indications were found on any welds (MaXfield Inc. NDE report number 054356).Four new pressure relief valves were installed on the PRV manifold during this outage. One PRV is always mechanically plugged off.The manifold can rotate while in service, thus allowing any PRV to be replaced during normal operation if required.After all the inspections and repairs were complete, it was Process Operations intent to leave this vessel out of service with a nitrogenblanket inside. Applying nitrogen gas displaces the presence of oxygen thereby preventing the development of corrosion within thevessel.RECOMMENDATIONS1.2.3.Paint exterior of vessel where it has failed and surface corrosion exists.Replace non-functioning pressure gauge on north head (completed by MaXfield).Replace manway gasket (completed by MaXfield). No NCR’s were issued.NONCONFORMANCES / INSPECTION DEFICIENCIESPage 2 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340INSPECTION PLANNINGInspection StrategyInspection DateAvailabilitySeptember 10,2014Date of Last InternalInspectionN/AInspection Interval10 YearsDate of Next InspectionSeptember 10,2024REPORT CERTIFICATIONThe signatures below certify that inspections/tests have been completed in accordance with the identified inspection strategy and thatthe specified equipment is considered fit for service until the date of next inspection.Inspected by / Certification #DateTerry SchulzePEI Class 1 #109, API 510 # 31739January 7, 2015Reviewed and Approved byDateKeenan FowlerCriticality Assessment RerunJanuary 7, 2015Inspection Planning RerunAssessed Next Inspection DateDETAILED INSPECTIONVISUAL EXTERNALNCR l Other (PleaseExplain)General CorrosionGeneral LeaksVibrationDissimilar Flange RatingLadder/StairwayHeadsGuy WiresElectrical GroundPainted Inactive CorrosionCoating/PaintingExpansion Joint or BellowsGauge/Site GlassShellJacketSupport Other (PleaseExplain)FoundationAnchor BoltsSaddle/Skirt/LegsDavitFireproofingConnections Other (PleaseExplain)Small BranchesNozzlesManwaysReinforcing PadsInadequate ThreadEngagementBoltingFlangesLeak ClampsInsulation Other (PleaseExplain)DamagePenetrationsInsulation JacketBandingSeals/JointsRelief Devices Other(Please Explain)GoodThis equipment was found to be acceptable for continued rGoodN/AN/ANo corrosion was evidentNo leaks were presentGoodGoodGoodN/AN/AGoodSteel skid on concrete with no spalling on foundationAll bolts were tightAll saddles and legs were in serviceable conditionGoodGoodN/AN/AGoodInstrumentation tubing was acceptableNo defects were observedGoodGoodN/AN/AAll bolting was tightAll flanges were V46V51No dissimilar flange ratings notedNo defects presentVessel has 2 grounds on skid packageSurface corrosion was present where paint was peelingPaint was peeling in some areasPressure gauge was brokenNo defects presentAll piping connections were secureNo short boltingN/AN/AN/AN/AN/AGoodPRV’s replaced during this outagePage 3 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, ksRestricted Inlet/OutletManual Operation LeverGoodGoodGoodN/AIDDescriptionV1General Other (PleaseExplain)Corrosion(depth, length, ozzlesShellGasket SurfacesInternals mowellsMetallic LiningsNonmetallic LiningsTraysTray RingsOther cationNCR /IDREquipment ID: 88-D-340CommentsNo corrosion presentNo leaks were evidentInlet and Outlet were clearDETAILED INSPECTIONVISUAL INTERNALNCR /LocationIDRCommentsGoodNo internal defects were observedGoodNo corrosion was evidentGoodGoodGoodGoodGoodGoodGoodGoodGoodGoodNo erosion was presentNo distortion was visibleNo over heating or blisters were observed.No deposits were notedNo dents or gougesNo cracking, undercut, overlap or lack of fusionAll clear with no defectsNo erosion, corrosionNo scoring, dents or gougesNo relevant indications foundN/AN/AN/AN/AN/AN/AN/AN/AN/AN/AN/APHOTOSVessel Name PlateTSASK Regulatory StickerPage 4 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340PHOTOS(L) Standpipe Level Gauge and (R) Paint Failing on West HeadBroken Pressure GaugeOperational Temperature GaugeWest End OverviewWest End Bulk HeadWest End Snappy JoePage 5 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340West End ESVWest End Valves: (L-R) Liquid Excess Flow Valve, Back Check Valve,Vapor Excess Flow Valve, Level Gauge Valve, Back Check ValveNew PRV StickerOld PRV Name Plate DataNew PRV’sNew PRV Top InternalPage 6 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340Old PRV Bottom InternalExisting PSV Manifold on top West End of Vessel where PRV’s areInstalled (Note: bottom left opening is plugged off)PRV Manual Remover/Installer when used with a pipe wrenchPRV Stacks with Rain Caps (laying on catwalk un-installed)PRV on discharge line to Ethanol PlantPRV Name PlatePage 7 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340South-West Ground WirePaint Failing at South-West End of VesselSouth-East Ground WireEast End Manway Opening with Portable Venting EquipmentOld Manway GasketMaXfield (Blake Fifield) performing internal WFMPIPage 8 of 9

PRESSURE VESSEL INSPECTION REPORTDate: Sept.10, 2014Equipment ID: 88-D-340Lower Shell Circumferential WeldsTop West End Internal Nozzle OpeningBottom West End Internal Nozzle OpeningsWest End Head InternalPage 9 of 9

10.09.2014 · PRESSURE VESSEL INSPECTION REPORT Date: Sept.10, 2014 Equipment ID: 88-D-340 . Plant Ethanol Op Unit 88 System Asset # 60094556 Equipment ID 88-D-340 Asset Type Drum Description NH3 Storage Tank Prov. Insp. # S02498 Serial # 38830A Manufacturer MaXfield Inc. CRN P6554.23 Year Built 2005 MAWP 1724 KPag @ 46 . 0. C MDMT -29 . 0. C Code . Section VIII, Div 1