Transcription

Introduction to PressureVessel Inspection:ANSI/API 510John R. RueckelPCA Engineering, Inc.PCA Engineering, Inc.111/6/2013

IntroductionPressure vessels have the potential toeffect safety and operational aspects of thefacility The goal is to provide an introduction tothe periodic inspection procedures for inhouse vessels What information can help ISP addresstheir requirements PCA Engineering, Inc.211/6/2013

AgendaInspection Scope Ultrasonic Testing Frequency of Inspection Documentation Site walk-through / Hands-On – This can be at any time, though early may bemost productive.PCA Engineering, Inc.311/6/2013

OverviewThe ANSI/API 510 standard providesguidance in the evaluation of vessels Each portion of the inspection processlinks to provide for continuous evaluation Documentation & RecordsvisualU/TPCA Engineering, Inc.Safety411/6/2013

Vocabulary Pressure Vessel: a container designed towithstand internal or external pressure, and asdefined in the ASME Boiler and Pressure VesselCodeAuthorized Inspector: a person qualified andcertified to perform inspections under theANSI/API 510 Code.Minimum Allowable Shell Thickness: thethickness required for each element of a vesselbased on calculations that consider temperature,pressure and all loadings.PCA Engineering, Inc.511/6/2013

Inspection Program Goals Periodic inspection by facility-designatedinspectorReview any issues observed in conjunction withoperationDefine inspection interval (Daily, Monthly,Annual, 5-year)Review of data and results by AuthorizedInspectorEvaluate for any changes in inspection intervalsPCA Engineering, Inc.611/6/2013

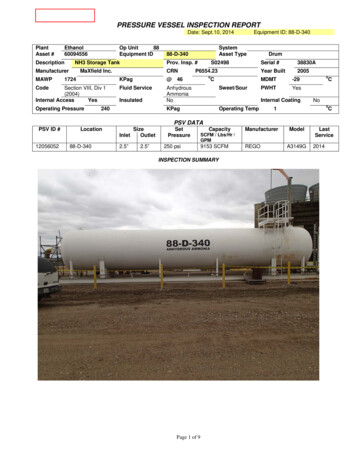

Visual Inspection A physical inspection of the vessel, either interioror exterior, evaluating for:Corrosion activityLeakageWeld conditionsAppurtenance Conditions:– Relief valves– Piping / venting– Control equipment, alarms, etc.PCA Engineering, Inc.711/6/2013

Ultrasonic Inspection Ultrasonic Thickness (UT) Gauging equipment isused to determine remaining wall thickness.Thickness data is assessed in a pattern, to obtainrepeatable data over time. The establishment ofthickness measurement locations (TMLs)Proper calibration of the UT equipment is vitalfor continued accuracy and data integrity (overtime).Data is recorded in a manner that comparisonsover time can be established.PCA Engineering, Inc.811/6/2013

Frequency of Inspection Determine Minimum allowable wall thicknessfrom design data, data plate, operationalprocedures, or engineering evaluation. Typicallyin accord with ASME B&PV Code.Gather UT data, determining average andminimum thickness, plus any pitting depths.Compare MRT with time interval to determinecorrosion rate– Use original construction date for first inspection– Use time between inspections for following intervals Using corrosion rates, calculate time untilreaching MAWT.– For safety use current, average and worst-case ratesPCA Engineering, Inc.911/6/2013

DocumentationAll inspection work has limited valuewithout proper documentation Establish a file for each vessel Develop a form for each periodicinspection to simplify documentation. Aform for short-term (monthly/quarterly)and annual inspections are typical The short-term form might be more“check-box” oriented to simplify use Keep all inspection forms and data in therespective files. PCA Engineering, Inc.1011/6/2013

SummaryA properly applied inspection program canimprove vessel safety and extendequipment availability A hands-on approach will help detecttrends before a significant event occurs The Authorized ANSI/API 510 Inspectorand/or Pressure Vessel Engineer providessupport and review. PCA Engineering, Inc.1111/6/2013

Where to Get More Information Other training sessions and certifications:– API 510, 570 & 653– ASNT-TC-1A NDT qualifications, exp Level 2: UT, VT, RVT, PT, MTResources:– ANSI/API 510 standard– API RP 572 (Inspection of PV)– ASME B&PV Code, especially sections II, V, VIII &IX PCA Engineering, Inc. (800) 666-7221PCA Engineering, Inc.1211/6/2013

Introduction to PressureVessel Inspection:ANSI/API 510 Discussion / Questions?For more information please contact:John R. RueckelPCA Engineering, Inc.PO Box 196Pompton Lakes, NJ 07442(800) 666-7221 x12jrueckel@cpbypca.comPCA Engineering, Inc.1311/6/2013

–API 510, 570 & 653 –ASNT-TC-1A NDT qualifications, exp Level 2: UT, VT, RVT, PT, MT Resources: –ANSI/API 510 standard –API RP 572 (Inspection of PV) –ASME B&PV Code, especially sections II, V, VIII & IX PCA Engineering, Inc. (800) 666-7221 . PCA Engineering, Inc. 11/6/2013 13 Introduction to Pressure Vessel Inspection: ANSI/API 510 For more information please contact: John R .