Transcription

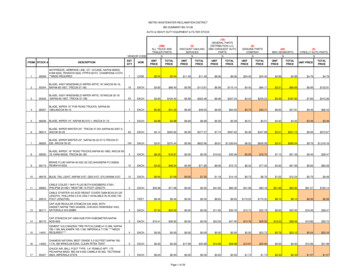

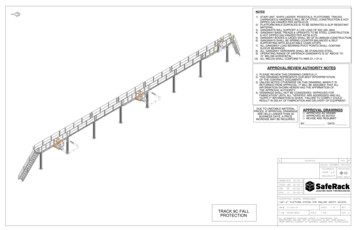

NOTESN1) STAIR UNIT, SHIPS LADDER, PEDESTALS, PLATFORMS, TRACKS,CARRIAGES & HANDRAILS WILL BE OF STEEL CONSTRUCTION & HOTDIPPED GALVANIZED PER ASTM-A123.2) PLATFORM WALK SURFACES IS TO BE SERRATED & SLIP RESISTANTMATERIAL.3) GANGWAYS WILL SUPPORT A LIVE LOAD OF 500 LBS. MAX.4) GANGWAY BASE TREADS & UPRIGHTS TO BE STEEL CONSTRUCTION& HOT DIPPED GALVANIZED PER ASTM-A123.5) GANGWAY BODIES & CAGES SHALL BE OF ALUMINUM CONSTRUCTION.6) GANGWAYS SHALL BE SPRING COUNTER BALANCED & SELFSUPPORTING WITH ADJUSTABLE CHAIN STOPS.7) ALL GANGWAY LOAD BEARING PIVOT POINTS SHALL CONTAINSLEEVE BEARINGS.8) ALL GANGWAY HARDWARE SHALL BE STAINLESS STEEL.9) OPERATING RANGE OF SAFERACK GANGWAYS IS 20 ABOVE TO15 BELOW HORIZONTAL.10) ALL WELDS SHALL CONFORM TO AWS D1.1-D1.6.APPROVAL/REVIEW AUTHORITY NOTES1) PLEASE REVIEW THIS DRAWING CAREFULLY.2) THIS DRAWING REPRESENTS OUR BEST INTERPRETATIONOF THE CONTRACT DOCUMENTS.3) UNLESS NOTED OTHERWISE ON THIS DRAWING, WHEN IT ISRETURNED FROM APPROVAL, IT WILL BE ASSUMED THAT ALLINFORMATION SHOWN HEREIN HAS THE AFFIRMATION OFTHE APPROVAL AUTHORITY.4) DRAWINGS SHALL NOT BE CONSIDERED "APPROVED FORFABRICATION" UNTIL ALL "VERIFIES" ARE ADDRESSED AND ALL"SUPPLY" INFORMATION IS GIVEN. FAILURE TO COMPLY COULDRESULT IN DELAY OF FABRICATION AND DELIVERY OF EQUIPMENT.DUE TO UNSTABLE MATERIALPRICES, IF APPROVAL DRAWINGSARE HELD LONGER THAN 30BUSINESS DAYS, A PRICEINCREASE MAY BE REQUIRED.APPROVAL DRAWINGSAPPROVED AS DRAWNAPPROVED AS NOTEDREVISE AND RESUBMITBY: DATE:#DESCRIPTIONDATEBYUNLESS OTHERWISE SPECIFIEDTOLERANCES:8"ANGULARDRAWN: BLBPROJECTION:1LINEAR12THIRD ANGLE05-20-13CHECK: N: GENERAL ARRANGEMENT140'-2" PLATFORM SYSTEM FOR RAILCAR SAFETY ACCESSTRACK 9C ALE:1:1281 OF 7REV:-SIZE: DALL INFORMATION CONTAINED HEREIN IS CONFIDENTIAL ANDPROPRIETARY AND MAY NOT BE DISCLOSED IN ANY FORM WITHOUTPRIOR WRITTEN CONSENT OF SAFERACK LOADING RACK TECHNOLOGIES

19'-2"19'-2"19'-2"19'-2"19'-2"17'-8 16 "19'-2"12'-0"CLPLATFORMSTAIR& LADDERSEE DETAIL "1" SHEET 72'-9 78 "19'-2"1514'-4"1'-5"3"1) PLEASE REVIEW THIS DRAWING CAREFULLY.2) THIS DRAWING REPRESENTS OUR BEST INTERPRETATIONOF THE CONTRACT DOCUMENTS.3) UNLESS NOTED OTHERWISE ON THIS DRAWING, WHEN IT ISRETURNED FROM APPROVAL, IT WILL BE ASSUMED THAT ALLINFORMATION SHOWN HEREIN HAS THE AFFIRMATION OFTHE APPROVAL AUTHORITY.4) DRAWINGS SHALL NOT BE CONSIDERED "APPROVED FORFABRICATION" UNTIL ALL "VERIFIES" ARE ADDRESSED AND ALL"SUPPLY" INFORMATION IS GIVEN. FAILURE TO COMPLY COULDRESULT IN DELAY OF FABRICATION AND DELIVERY OF EQUIPMENT.1'-4 16 "NAPPROVED AS DRAWNAPPROVED AS NOTEDREVISE AND RESUBMITBY: DATE:SEE DETAIL "7" SHEET 7SEE DETAIL "2" SHEET 7CLRAIL2'-10"APPROVAL/REVIEW AUTHORITY NOTESAPPROVAL DRAWINGSPAD LAYOUT#DESCRIPTIONDATEBYUNLESS OTHERWISE SPECIFIEDTOLERANCES:8"ANGULARDRAWN: BLBPROJECTION:1LINEAR12THIRD ANGLE05-20-13CHECK: JMG05-20-13ENG:RR05-20-13APVL:LS05-20-13HOME OFFICE: 730 ELECTRIC DRIVE, SUMTER, SC29153DESCRIPTION: GENERAL ARRANGEMENT140'-2" PLATFORM SYSTEM FOR RAILCAR SAFETY ACCESSTRACK 9C ALE:1:642 OF 7REV:-SIZE: DALL INFORMATION CONTAINED HEREIN IS CONFIDENTIAL ANDPROPRIETARY AND MAY NOT BE DISCLOSED IN ANY FORM WITHOUTPRIOR WRITTEN CONSENT OF SAFERACK LOADING RACK TECHNOLOGIES

APPROVAL/REVIEW AUTHORITY NOTESAPPROVAL DRAWINGSNAPPROVED AS DRAWNAPPROVED AS NOTEDREVISE AND RESUBMITBY: DATE:12'-0"1) PLEASE REVIEW THIS DRAWING CAREFULLY.2) THIS DRAWING REPRESENTS OUR BEST INTERPRETATIONOF THE CONTRACT DOCUMENTS.3) UNLESS NOTED OTHERWISE ON THIS DRAWING, WHEN IT ISRETURNED FROM APPROVAL, IT WILL BE ASSUMED THAT ALLINFORMATION SHOWN HEREIN HAS THE AFFIRMATION OFTHE APPROVAL AUTHORITY.4) DRAWINGS SHALL NOT BE CONSIDERED "APPROVED FORFABRICATION" UNTIL ALL "VERIFIES" ARE ADDRESSED AND ALL"SUPPLY" INFORMATION IS GIVEN. FAILURE TO COMPLY COULDRESULT IN DELAY OF FABRICATION AND DELIVERY OF EQUIPMENT.94'-10 16 '-6"2'-6"D11'-1"C3'-0"WIDEYELLOW GATE ATTOP OF LADDERCLRAIL8'-0" (TYP)8'-0" (TYP)10'-6"8'-0" X 8'-0"1 1/2" PIPE2-RAIL SAFETY CAGE(A15713)G4-FRT-24-5-A(TYP)DE15'-0" GANGWAYTRACKING RANGE (TYP)A23'-3 1316 " CAGETRACKING RANGE (TYP)ABBPLAN VIEW#DESCRIPTIONDATEBYUNLESS OTHERWISE SPECIFIEDTOLERANCES:8"ANGULARDRAWN: BLBPROJECTION:1LINEAR12THIRD ANGLE05-20-13CHECK: N: GENERAL ARRANGEMENT140'-2" PLATFORM SYSTEM FOR RAILCAR SAFETY ACCESSTRACK 9C ALE:1:643 OF 7REV:-SIZE: DALL INFORMATION CONTAINED HEREIN IS CONFIDENTIAL ANDPROPRIETARY AND MAY NOT BE DISCLOSED IN ANY FORM WITHOUTPRIOR WRITTEN CONSENT OF SAFERACK LOADING RACK TECHNOLOGIES

APPROVAL/REVIEW AUTHORITY NOTESAPPROVAL DRAWINGSAPPROVED AS DRAWNAPPROVED AS NOTEDREVISE AND RESUBMITBY: DATE:SPRING HINGES MAKEGATES SELF CLOSING112" SQ. TUBEGATESTUBE HANDRAILS1) PLEASE REVIEW THIS DRAWING CAREFULLY.2) THIS DRAWING REPRESENTS OUR BEST INTERPRETATIONOF THE CONTRACT DOCUMENTS.3) UNLESS NOTED OTHERWISE ON THIS DRAWING, WHEN IT ISRETURNED FROM APPROVAL, IT WILL BE ASSUMED THAT ALLINFORMATION SHOWN HEREIN HAS THE AFFIRMATION OFTHE APPROVAL AUTHORITY.4) DRAWINGS SHALL NOT BE CONSIDERED "APPROVED FORFABRICATION" UNTIL ALL "VERIFIES" ARE ADDRESSED AND ALL"SUPPLY" INFORMATION IS GIVEN. FAILURE TO COMPLY COULDRESULT IN DELAY OF FABRICATION AND DELIVERY OF EQUIPMENT.2" SQ. TUBEUPRIGHTST.O.H.3'-6"SERRATED SLIPRESISTANTWALK SURFACET.O.W.S.18'-0" TRACKSECTION4" TOE BOARDSTOPS ATBOTH ENDSC8X11.52'-8"4 5 T.O.W.S.1" GROUT(TYP)C8X11.512'-0"T.O.H.HSS 10X10X1/4" (TYP)99T.O. RAIL T.O. GRADESECTION A-A#DESCRIPTIONDATEBYUNLESS OTHERWISE SPECIFIEDTOLERANCES:8"ANGULARDRAWN: BLBPROJECTION:1LINEAR12THIRD ANGLE05-20-13CHECK: JMG05-20-13ENG:RR05-20-13APVL:LS05-20-13HOME OFFICE: 730 ELECTRIC DRIVE, SUMTER, SC29153DESCRIPTION: GENERAL ARRANGEMENT140'-2" PLATFORM SYSTEM FOR RAILCAR SAFETY ACCESSTRACK 9C ALE:1:324 OF 7REV:-SIZE: DALL INFORMATION CONTAINED HEREIN IS CONFIDENTIAL ANDPROPRIETARY AND MAY NOT BE DISCLOSED IN ANY FORM WITHOUTPRIOR WRITTEN CONSENT OF SAFERACK LOADING RACK TECHNOLOGIES

APPROVAL/REVIEW AUTHORITY NOTESAPPROVAL DRAWINGSAPPROVED AS DRAWNAPPROVED AS NOTEDREVISE AND RESUBMIT1) PLEASE REVIEW THIS DRAWING CAREFULLY.2) THIS DRAWING REPRESENTS OUR BEST INTERPRETATIONOF THE CONTRACT DOCUMENTS.3) UNLESS NOTED OTHERWISE ON THIS DRAWING, WHEN IT ISRETURNED FROM APPROVAL, IT WILL BE ASSUMED THAT ALLINFORMATION SHOWN HEREIN HAS THE AFFIRMATION OFTHE APPROVAL AUTHORITY.4) DRAWINGS SHALL NOT BE CONSIDERED "APPROVED FORFABRICATION" UNTIL ALL "VERIFIES" ARE ADDRESSED AND ALL"SUPPLY" INFORMATION IS GIVEN. FAILURE TO COMPLY COULDRESULT IN DELAY OF FABRICATION AND DELIVERY OF EQUIPMENT.BY: DATE:SPRING HINGES MAKEGATES SELF CLOSING112" SQ. TUBEGATESTUBE HANDRAILS2" SQ. TUBEUPRIGHTSTUBE HANDRAILST.O.H.3'-6"SERRATED SLIPRESISTANTWALK SURFACET.O.W.S.18'-0" TRACKSECTION4" TOE BOARDC5 XHSS 10X10X1/4" (TYP)STOPS ATBOTH ENDS12 RISERS @ 12" 12'-0"C8X11.570 6.7T.O. RAIL T.O. GRADESECTION B-B#DESCRIPTIONDATEBYUNLESS OTHERWISE SPECIFIEDTOLERANCES:8"ANGULARDRAWN: BLBPROJECTION:1LINEAR12THIRD ANGLE05-20-13CHECK: N: GENERAL ARRANGEMENT140'-2" PLATFORM SYSTEM FOR RAILCAR SAFETY ACCESSTRACK 9C ALE:1:325 OF 7REV:-SIZE: DALL INFORMATION CONTAINED HEREIN IS CONFIDENTIAL ANDPROPRIETARY AND MAY NOT BE DISCLOSED IN ANY FORM WITHOUTPRIOR WRITTEN CONSENT OF SAFERACK LOADING RACK TECHNOLOGIES

ADJUSTABLECHAIN STOPAPPROVED AS DRAWNAPPROVED AS NOTEDREVISE AND RESUBMITBY: DATE:T.O.W.S.1) PLEASE REVIEW THIS DRAWING CAREFULLY.2) THIS DRAWING REPRESENTS OUR BEST INTERPRETATIONOF THE CONTRACT DOCUMENTS.3) UNLESS NOTED OTHERWISE ON THIS DRAWING, WHEN IT ISRETURNED FROM APPROVAL, IT WILL BE ASSUMED THAT ALLINFORMATION SHOWN HEREIN HAS THE AFFIRMATION OFTHE APPROVAL AUTHORITY.4) DRAWINGS SHALL NOT BE CONSIDERED "APPROVED FORFABRICATION" UNTIL ALL "VERIFIES" ARE ADDRESSED AND ALL"SUPPLY" INFORMATION IS GIVEN. FAILURE TO COMPLY COULDRESULT IN DELAY OF FABRICATION AND DELIVERY OF EQUIPMENT.F.O.P.12'-1" TO 13'-2" HEIGHT RANGE12'-1" SHOWNCLRAIL12'-0"APPROVAL/REVIEW AUTHORITY NOTESAPPROVAL DRAWINGS6'-0" TO 8'-0" RANGE8'-0" SHOWNT.O.R.ATTENTION: CHECK WITH LOCAL RAILROADFOR CLEARANCE REQUIREMENTS10'-6"RAILROAD CLEARANCE ENVELOPESECTION C-C(STAIRS SHOWN PARTIALLY REMOVED FOR CLARITY)78'-4 16"6'-0" TO 8'-0" RANGE6'-0" "(TYP)18'-0"(TYP)19'-10 18 "F.O.P.18'-8 18 "1 16 "12'-1" TO 13'-2" HEIGHT RANGE13'-2" SHOWNF.O.P.12'-0"CLRAIL#DESCRIPTIONDATEUNLESS OTHERWISE SPECIFIEDTOLERANCES:DRAWN: BLBT.O.R.10'-6"SECTION D-D10'-6"8'-6"(TYP)SECTION E-E(GANGWAY SHOWN @ 85 ABOVE HORIZONTAL POSITION)TRACK 9C 2THIRD ANGLE05-20-13CHECK: JMG05-20-13ENG:RR05-20-13APVL:LS05-20-13HOME OFFICE: 730 ELECTRIC DRIVE, SUMTER, SC29153DESCRIPTION: GENERAL ARRANGEMENT140'-2" PLATFORM SYSTEM FOR RAILCAR SAFETY 6 OF 7REV:-SIZE: DALL INFORMATION CONTAINED HEREIN IS CONFIDENTIAL ANDPROPRIETARY AND MAY NOT BE DISCLOSED IN ANY FORM WITHOUTPRIOR WRITTEN CONSENT OF SAFERACK LOADING RACK TECHNOLOGIES

6"'-6"2'-10"4'-0"SQ.7"3"'-3"10"1"'-0"T.O. TRUCK GRADE T.O. CONCRETE(8) #5 REBAREACH WAY4'-0"2"3""3""3"" CLEAR(TYP)T.O.T.G. T.O.C.3"'-0"3""SEE DETAIL "5" FOR#5 VERTICALS SPACED 24" ON PERIMETER,OTHER VERTICALSOMITTED FOR CLARITY3""(14) #5 REBARBOTH WAYS, TOP& BOTTOM MATS6"'-6"SECTIONFDETAIL(4 REQUIRED)DETAIL31'-9"6"" PROJ.SEE DETAIL "4"741"DETAIL4'-0"SEE DETAIL "3"(TYP)6"3"'-3"F1'-7"7"3"'-3"6"'-6"3"'-3"SEE DETAIL "6"FSTRUCTURAL CONCRETE NOTES:1) THIS ITEM "CONCRETE WORK" SHALL CONSIST OF FURNISHING ALL MATERIALS INCLUDING CONCRETE ANDREINFORCING STEEL, EQUIPMENT AND LABOR, FOR THE FORMING, PLACING, FINISHING, CURING AND PROTECTING OF1'-221"CONCRETE IN THE FOUNDATIONS AND ALL NECESSARY INCIDENTALS TO COMPLETE THE WORK IN ACCORDANCE1WITH THE AMERICAN CONCRETE INSTITUTE (ACI) BUILDING CODE 318 (LATEST EDITION), PLANS AND SPECIFICATIONS.74"2) CONCRETE DESIGN:MINIMUM28 DAY COMPRESSIVE STRENGTHS OF fc' 3000 PSI AIR CONTENT OF 4 TO 6% GRADE 60 REBAR YIELD1" THK.STRENGTH OF fy 60,000 PSIPLATE3) FOUNDATION DESIGN PROVIDED BY SAFERACK BASED ON ASSUMED NET ALLOWABLE BEARING CAPACITY OF 2000PSF. IF ON SITECONDITIONS ARE FOUND TO BE LESS THAN DESIGN MINIMUM VALUES, FOUNDATION DESIGN SHOULDBE REVIEWED FOR ADEQUACY.4)FOUNDATION DESIGN BASED ON TABULATED FROST DEPTH OF 15". IF LOCAL CODES OR EXPERIENCE SPECIFY THAT3FROST DEPTH IS GREATER THAN 36", INCREASE FOUNDATION DEPTH OR LOWER PLACEMENT OF FOUNDATION TO" THK.8ACCOUNT FOR FROST DEPTH.GUSSET PLATES5)REMOVAL OR RELOCATION OF ANY EXISTING OBSTRUCTIONS ENCOUNTERED DURING EXCAVATION SHALL BE BY1OTHERS.Ø14" HOLES FOR6)THE EXISTING SUB GRADE SHALL BE CLEARED OF ALL STONES, TOP SOIL, WOOD, MUD AND OTHER DEBRIS. AØ1" ANCHOR BOLTSMINIMUM 6" OF 1" MINUS CRUSHED GRANULAR COMPACTED TO 95 SPMDD UNDER THE FOUNDATION PADS IS(BY OTHERS)REQUIRED. SOFT AREA SHALL BE OVER EXCAVATED AND REPLACED WITH GRANULAR FILL PLACED IN 6" LIFTS.7)THE DESIGN AND ENGINEERING OF THE FORMWORK, AS WELL AS IT'S CONSTRUCTION, SHALL BE THE RESPONSIBILITYOF THE CONTRACTOR.8)REINFORCING STEEL SHALL BE NEW BILLET STEEL AND SHALL CONFORM TO ASTM A615, GRADE 60. REINFORCINGSCALE: 1" 1'-0"STEEL SHALL BE HANDLED AND PLACED IN ACCORDANCE WITH ACI BUILDING CODE REQUIREMENT 318 LATESTEDITION. METAL REINFORCEMENT AT THE TIME CONCRETE IS PLACED SHALL BE FREE FROM LOOSE RUST, SCALE,OR OTHER COATINGS THAT WILL DESTROY OR REDUCE THE BOND. ALL BARS SHALL BE BENT COLD.REINFORCEMENT MAY BE SHOP FABRICATED OR FIELD-BENT. BAR LAPS SHALL BE MINIMUM OF 19".9)ALL REINFORCING SHALL BE ACCURATELY SECURED IN PLACE BY USE OF METAL OR CONCRETE SUPPORT, TIES ORSPACERS. SUCH SUPPORTS SHALL BE OF SUFFICIENT STRENGTH TO MAINTAIN THE REINFORCEMENT IN PLACETHROUGHOUT THE CONCRETING OPERATION.10)CONCRETE SHALL BE DEPOSITED CONTINUOUSLY OR IN LAYERS OF SUCH THICKNESS THAT NO FRESH CONCRETESHALL BE DEPOSITED ONCONCRETE WHICH HAS HARDENED SUFFICIENTLY TO CAUSE FORMATIONS OF SEAMS ORPLANES OF WEAKNESS ACROSS THE SECTION. DUE TO POSSIBLE SEPARATION OF INGREDIENTS. FREE FALL OFCONCRETE SHALL NOT EXCEED FOUR(4) FEET UNLESS OTHERWISE APPROVED BY THE ENGINEER.Ø1" x 21" ASTM F155411)THE TEMPERATURE OF CONCRETE AT TIME OF PLACEMENT SHALL NOT BE LESS THAN 45F NOR MORE THAN 90F.GR36 GALVANIZED ANCHORANY SURFACES THAT CONCRETE SHALL CONTACT SHALL BE HEATED TO BE ABOVE 32F.BOLT W/AN A56312)ALL CONCRETE SHALL BE CONSOLIDATED BY MECHANICAL VIBRATION SO THAT THE CONCRETE IS THOROUGHLYGALVANIZED HEAVY-HEXWORKED AROUND THE REINFORCEMENT, AROUND THE EMBEDDED ITEMS AND INTO THE CORNERS OF FORMS,NUT AND A F436 WASHERELIMINATING ALL AIR OR STONE POCKETS WHICH MAY CAUSE HONEYCOMBING, PITTING OR PLANES OF WEAKNESS.EXCESSIVE VIBRATION AND USE OF VIBRATORS TO TRANSPORT CONCRETE WITHIN FORMS SHALL NOT BE ALLOWED.13)FRESHLY DEPOSITED CONCRETE SHALL BE PROTECTED FROM PREMATURE DRYING DUE TO EXCESSIVELY HOT ORCOLD TEMPERATURES, AND SHALL BE MAINTAINED WITH MINIMAL MOISTURE LOSS AT A RELATIVELY CONSTANTTACK WELD HEAVYTEMPERATURE FOR THE PERIOD OF TIME NECESSARY FOR THE HYDRATION OF THE CEMENT AND PROPERHEX NUT TO BOLTHARDENING OF THE CONCRETE. DURING THE CURING PROCESS, THE CONCRETE SHALL BE PROTECTED FROM3DAMAGE OR MECHANICAL DISTURBANCES, PARTICULARLY LOAD STRESSES, HEAVY SHOCK AND EXCESSIVE VIBRATION.5"X5"X4" 14)SAMPLING AND TESTING IF REQUIRED BY OWNER SHALL BE BASED ON SAMPLE PLAN AND SCHEDULE ASSPECIFIED BY OWNER. OWNER AND CONTRACTOR TO DETERMINE HOW COSTS OF SAMPLING AND TESTING WILL BESHARED.15)FOUNDATION BASED ON LOADS GENERATED BASED ON THE FOLLOWING:1'-7"3"'-3"1'-221"3"'-3"DETAIL14DESIGN CODES:ASCE 7D

dipped galvanized per astm-a123. 2) platform walk surfaces is to be serrated & slip resistant material. 3) gangways will support a live load of 500 lbs. max. approval/review authority notes 1) please review this drawing carefully. 2) this drawing represents our best interpretation of the contract documents. 3) unless noted otherwise on this drawing, when it is returned from approval, it will .